L. J. WANG ET AL. 95

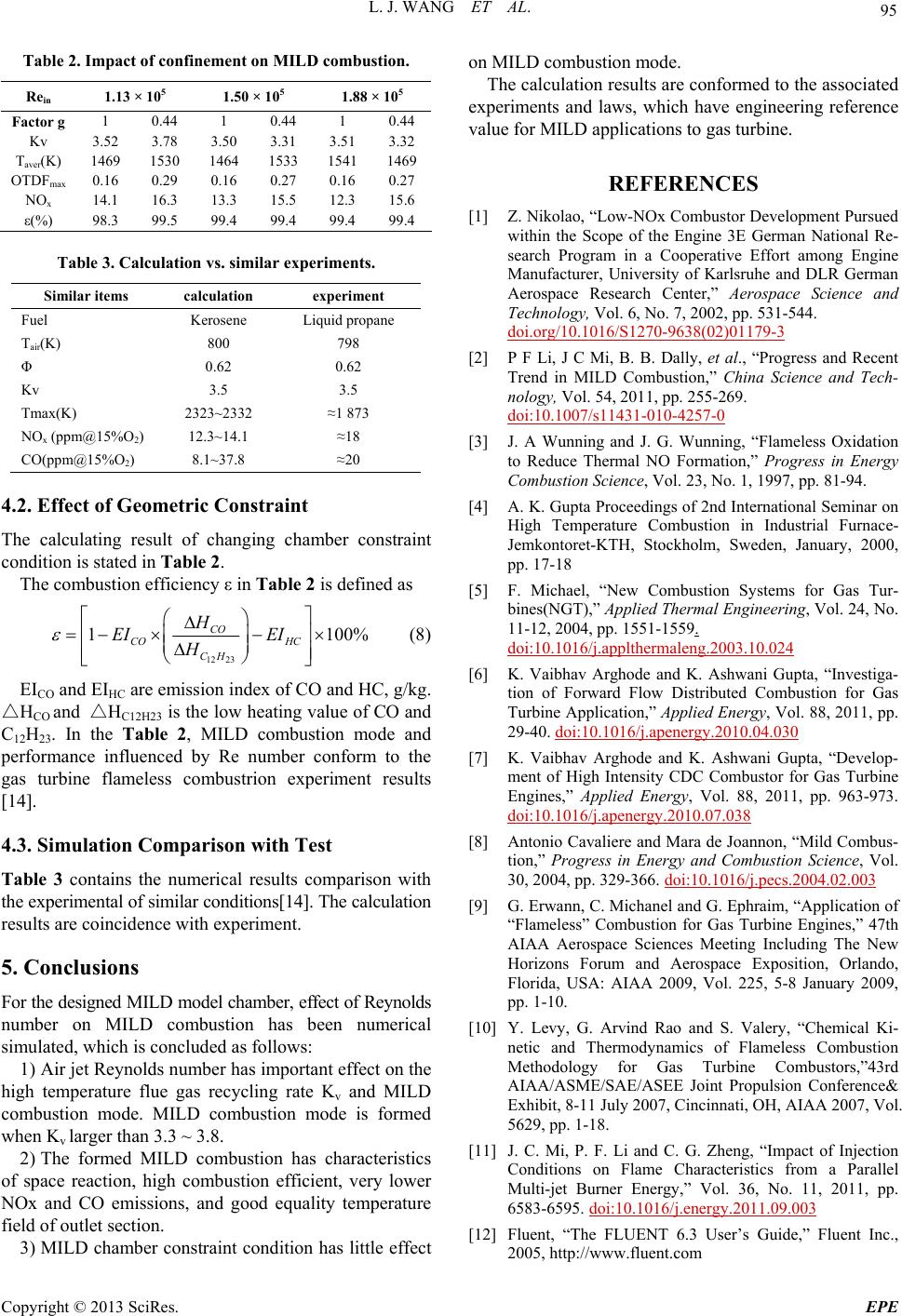

Table stion. 2. Impact of confinement on MILD combu

Rein 1.13 × 10

51.50 × 10

5 5

1.88 × 10

Fg actor 1 0.44 1 0.44 1 0.44

Kv 3. 523.78 3. 503.31 3. 513.32

T)

aver(K 1469 1530 1464 1533 1541 1469

OTDFmax 0.16 0.29 0.16 0.27 0.16 0.27

NOx 14.1 16.3 13.3 15.5 12.3 15.6

ε(%) 98.3 99.5 99.4 99.4 99.4 99.4

Table 3. Calculation vs. similar experiments.

Similar items calculation experiment

FueL l Kerosene iquid propane

Tair(K)

23232 ≈

15%O2)

800 798

Φ 0.62 0.62

Kv 3.5 3.5

Tmax(K)3~23 1 873

NOx (ppm@12.3~14.1 ≈18

CO(ppm@15%O2) 8.1~37.8 ≈20

4.2. Effect of Geometric Constraint

ber const

Table 2 is defined as

The calculating result of changing chamraint

condition is stated in Table 2.

The combustion efficiency ε in

12 23

1 100%

CO

CO HC

CH

H

EI EI

H

(8)

EICO and EIHC are emission index of CO and HC,

△

4.3. Simulation Comparison with Test

arison with

5. Conclusions

LD model chamber, effect of Reynolds

effect on the

tion has characteri

onstraint condition has little effect

conformed to the associated

ex

REFERENCES

[1] Z. Nikolao, “Lvelopment Pursued

g/kg.

HCO and △HC12H23 is the low heating value of CO and

C12H23. In the Table 2, MILD combustion mode and

performance influenced by Re number conform to the

gas turbine flameless combustrion experiment results

[14].

Table 3 contains the numerical results comp

the experimental of similar conditions[14]. The calculation

results are coincidence with experiment.

For the designed MI

number on MILD combustion has been numerical

simulated, which is concluded as follows:

1) Air jet Reynolds number has important

high temperature flue gas recycling rate Kv and MILD

combustion mode. MILD combustion mode is formed

when Kv larger than 3.3 ~ 3.8.

2) The formed MILD combusstics

of space reaction, high combustion efficient, very lower

NOx and CO emissions, and good equality temperature

field of outlet section.

3) MILD chamber c

on MILD combustion mode.

The calculation results are

periments and laws, which have engineering reference

value for MILD applications to gas turbine.

ow-NOx Combustor De

within the Scope of the Engine 3E German National Re-

search Program in a Cooperative Effort among Engine

Manufacturer, University of Karlsruhe and DLR German

Aerospace Research Center,” Aerospace Science and

Technology, Vol. 6, No. 7, 2002, pp. 531-544.

doi.org/10.1016/S1270-9638(02)01179-3

[2] P F Li, J C Mi, B. B. Dally, et al., “Progress and Recent

Trend in MILD Combustion,” China Science and Tech-

nology, Vol. 54, 2011, pp. 255-269.

doi:10.1007/s11431-010-4257-0

[3] J. A Wunning and J. G. Wunning, “Flameless Oxidation

on

l, “New Combustion Systems for Gas Tur-

to Reduce Thermal NO Formation,” Progress in Energy

Combustion Science, Vol. 23, No. 1, 1997, pp. 81-94.

[4] A. K. Gupta Proceedings of 2nd International Seminar

High Temperature Combustion in Industrial Furnace-

Jemkontoret-KTH, Stockholm, Sweden, January, 2000,

pp. 17-18

[5] F. Michae

bines(NGT),” Applied Thermal Engineering, Vol. 24, No.

11-12, 2004, pp. 1551-1559.

doi:10.1016/j.applthermaleng.2003.10.024

[6] K. Vaibhav Arghode and K. Ashwani Gupta, “Investiga-

tion of Forward Flow Distributed Combustion for Gas

Turbine Application,” Applied Energy, Vol. 88, 2011, pp.

29-40. doi:10.1016/j.apenergy.2010.04.030

[7] K. Vaibhav Arghode and K. Ashwani Gupta, “Develop-

ment of High Intensity CDC Combustor for Gas Turbine

Engines,” Applied Energy, Vol. 88, 2011, pp. 963-973.

doi:10.1016/j.apenergy.2010.07.038

[8] Antonio Cavaliere and Mara de Joannon, “Mild Combus-

tion,” Progress in Energy and Combustion Science, Vol.

30, 2004, pp. 329-366. doi:10.1016/j.pecs.2004.02.003

[9] G. Erwann, C. Michanel and G. Ephraim, “Application of

G. Arvind Rao and S. Valery, “Chemical Ki-

and C. G. Zheng, “Impact of Injection

“Flameless” Combustion for Gas Turbine Engines,” 47th

AIAA Aerospace Sciences Meeting Including The New

Horizons Forum and Aerospace Exposition, Orlando,

Florida, USA: AIAA 2009, Vol. 225, 5-8 January 2009,

pp. 1-10.

[10] Y. Levy,

netic and Thermodynamics of Flameless Combustion

Methodology for Gas Turbine Combustors,”43rd

AIAA/ASME/SAE/ASEE Joint Propulsion Conference&

Exhibit, 8-11 July 2007, Cincinnati, OH, AIAA 2007, Vol.

5629, pp. 1-18.

[11] J. C. Mi, P. F. Li

Conditions on Flame Characteristics from a Parallel

Multi-jet Burner Energy,” Vol. 36, No. 11, 2011, pp.

6583-6595. doi:10.1016/j.energy.2011.09.003

[12] Fluent, “The FLUENT 6.3 User’s Guide,” Fluent Inc.,

2005, http://www.fluent.com

Copyright © 2013 SciRes. EPE