W. H. WANG ET AL.

Copyright © 2013 SciRes. OJCE

00.5 11.5 22.5 3

0

0.5

1

1.5

2

x/H

Cs

Tsuchiya-1

Tsuchiya-2

Tsuchiya-3

t

= 300s,

U

= 4.60m/s,

β

= 0

o

t

= 300s,

U

= 4.99m/s,

β

= 0

o

t

= 300s,

U

= 5.36m/s,

β

= 0

o

t

= 300s,

U

= 4.99m/s,

β

= 15

o

t

= 900s,

U

= 4.99m/s,

β

= 15

o

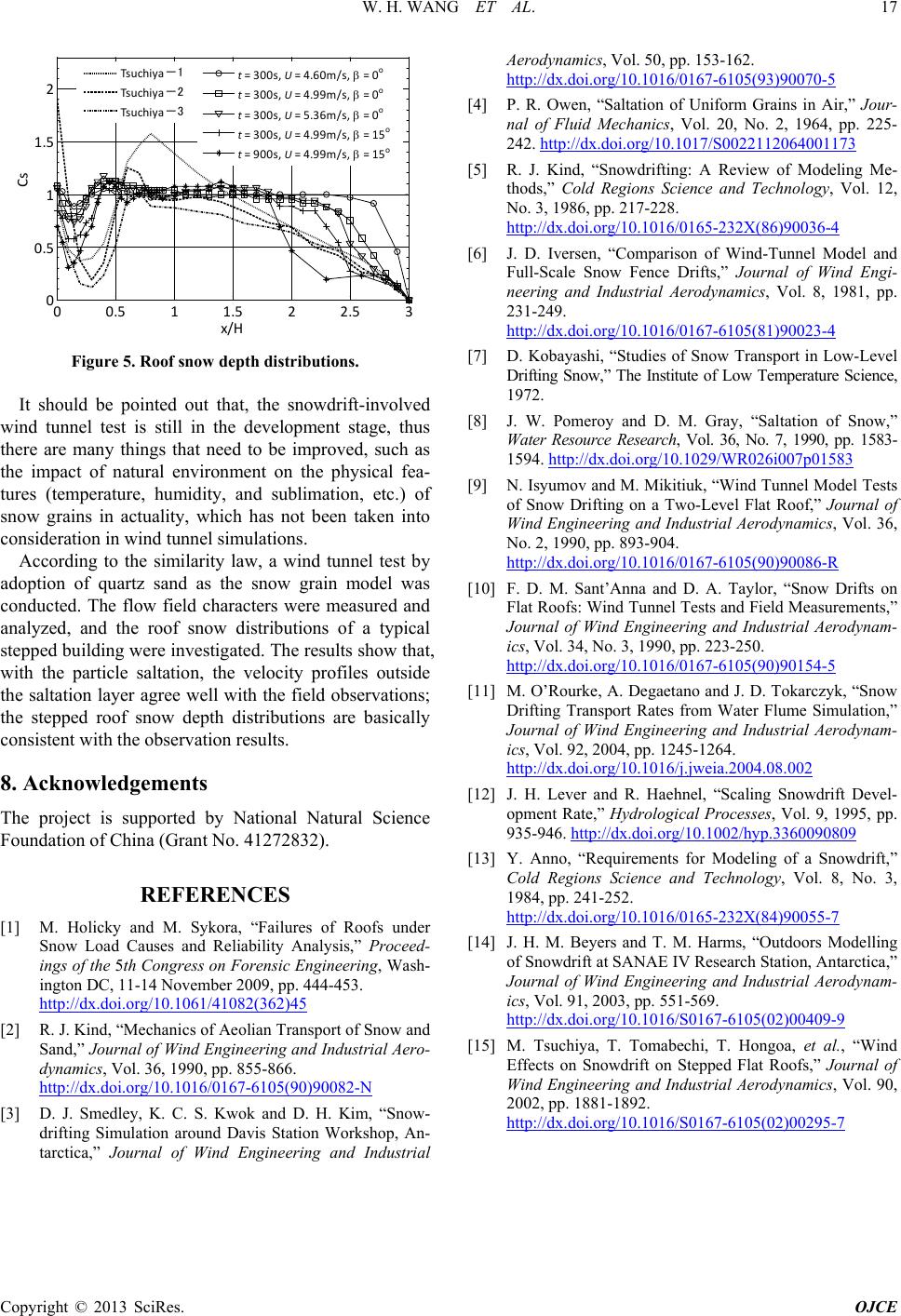

Figure 5. Roof snow depth distr i but ions.

It should be pointed out that, the snowdrift-involved

wind tunnel test is still in the development stage, thus

there are many things that need to be improved, such as

the impact of natural environment on the physical fea-

tures (temperature, humidity, and sublimation, etc.) of

snow grains in actuality, which has not been taken into

consideration in wind tunnel simulations.

According to the similarity law, a wind tunnel test by

adoption of quartz sand as the snow grain model was

conducted. The flow field characters were measured and

analyzed, and the roof snow distributions of a typical

stepped building were investigated. The results show that,

with the particle saltation, the velocity profiles outside

the saltation layer agree well with the field observations;

the stepped roof snow depth distributions are basically

consistent with the observation results.

8. Acknowledgements

The project is supported by National Natural Science

Foundation of Chi na ( G rant No. 41 272832) .

REFERENCES

[1] M. Holicky and M. Sykora, “Failures of Roofs under

Snow Load Causes and Reliability Analysis,” Proceed-

ings of the 5th Congress on Forensic Engineering, Wash-

ington DC, 11-14 November 2009, pp. 444-453.

http://dx.doi.org/10.1061/41082(362)45

[2] R. J. Kind, “Mechanics of Aeolian Transport of Snow and

Sand,” Journal of Wind Engineering and Industrial Aero-

dynamics, Vol. 36, 1990, pp. 855-866.

http://dx.doi.org/10.1016/0167-6105(90)90082-N

[3] D. J. Smedley, K. C. S. Kwok and D. H. Kim, “Snow-

drifting Simulation around Davis Station Workshop, An-

tarctica,” Journal of Wind Engineering and Industrial

Aerodynamics, Vol. 50, pp. 153-162.

http://dx.doi.org/10.1016/0167-6105(93)90070-5

[4] P. R. Owen, “Saltation of Uniform Grains in Air,” Jour-

nal of Fluid Mechanics, Vol. 20, No. 2, 1964, pp. 225-

242. http://dx.doi.org/10.1017/S0022112064001173

[5] R. J. Kind, “Snowdrifting: A Review of Modeling Me-

thods,” Cold Regions Science and Technology, Vol. 12,

No. 3, 1986, pp. 217-228.

http://dx.doi.org/10.1016/0165-232X(86)90036-4

[6] J. D. Iversen, “Comparison of Wind-Tunnel Model and

Full-Scale Snow Fence Drifts,” Journal of Wind Engi-

neering and Industrial Aerodynamics, Vol. 8, 1981, pp.

231-249.

http://dx.doi.org/10.1016/0167-6105(81)90023-4

[7] D. Kobayashi, “Studies of Snow Transport in Low-Level

Drifting Snow,” The Institute of Low Temperature Science,

1972.

[8] J. W. Pomeroy and D. M. Gray, “Saltation of Snow,”

Water Resource Research, Vol. 36, No. 7, 19 90, pp. 1583-

1594. http://dx.doi.org/10.1029/WR026i007p01583

[9] N. Isyumov and M. Mikitiuk, “Wind Tunnel Model Tests

of Snow Drifting on a Two-Level Flat Roof,” Journal of

Wind Engineering and Industrial Aerodynamics, Vol. 36,

No. 2, 1990, pp. 893-904.

http://dx.doi.org/10.1016/0167-6105(90)90086-R

[10] F. D. M. Sant’Anna and D. A. Taylor, “Snow Drifts on

Flat Roofs: Wind Tunnel Tests and Field Measurements,”

Journal of Wind Engineering and Industrial Aerodynam-

ics, Vol. 34, No. 3, 1990, pp. 223-250.

http://dx.doi.org/10.1016/0167-6105(90)90154-5

[11] M. O’Rourke, A. Degaetano and J. D. Tokarczyk, “Snow

Drifting Transport Rates from Water Flume Simulation,”

Journal of Wind Engineering and Industrial Aerodynam-

ics, Vol. 92, 2004, pp. 1245-1264.

http://dx.doi.org/10.1016/j.jweia.2004.08.002

[12] J. H. Lever and R. Haehnel, “Scaling Snowdrift Devel-

opment Rate,” Hydrological Processes, Vol. 9, 1995, pp.

935-946. http://dx.doi.org/10.1002/hyp.3360090809

[13] Y. Anno, “Requirements for Modeling of a Snowdrift,”

Cold Regions Science and Technology, Vol. 8, No. 3,

1984, pp. 241-252.

http://dx.doi.org/10.1016/0165-232X(84)90055-7

[14] J. H. M. Beyers and T. M. Harms, “Outdoors Modelling

of Snowdrift at SANAE IV Research Station, Antarctica,”

Journal of Wind Engineering and Industrial Aerodynam-

ics, Vol. 91, 2003, pp. 551-569.

http://dx.doi.org/10.1016/S0167-6105(02)00409-9

[15] M. Tsuchiya, T. Tomabechi, T. Hongoa, et al., “Wind

Effects on Snowdrift on Stepped Flat Roofs,” Journal of

Wind Engineering and Industrial Aerodynamics, Vol. 90,

2002, pp. 1881-1892.

http://dx.doi.org/10.1016/S0167-6105(02)00295-7