Applied Mathematics, 2013, 4, 17-25 http://dx.doi.org/10.4236/am.2013.410A1004 Published Online October 2013 (http://www.scirp.org/journal/am) High-Precision Numerical Scheme for Vortical Flow Kei Ito1*, Tomoaki Kunugi2, Hiroyuki Ohshima1 1Advanced Nuclear System Research and Development Directorate, Japan Atomic Energy Agency, Ibaraki, Japan 2Department of Nuclear Engineering, Kyoto University, Kyoto, Japan Email: *ito.kei@jaea.go.jp Received June 10, 2013; revised July 10, 2013; accepted July 17, 2013 Copyright © 2013 Kei Ito et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. ABSTRACT In this study, a new high-precision numerical simulation scheme for vortical flows (vortex-based scheme) is proposed. This scheme identifies a vortical flow in each computational cell, and then, reconstructs a vortical velocity distribution based on the Burgers vortex model. In addition, a pressure distribution in the vicinity of the vortex center is also re- constructed. The momentum transfer is calculated with the reconstructed velocity and pressure distributions, and there- fore, the vortex-based scheme can simulate vortical flows more accurately than the conventional schemes. In fact, as the simulation result of inviscid vortex attenuation problem, the vortex-based scheme shows lower simulation error com- pared to the conventional discretization schemes. Moreover, also in the numerical simulation of the quasi-steady vorti- cal flow, the simulation accuracy of the vortex-based scheme is superior to those of the conventional schemes. Keywords: Computational Fluid Dynamics; Numerical Scheme; Vortex Cavitation; Burgers Vortex Theory 1. Introduction Vortex cavitation can be observed in various engineering scenes, e.g. pump sump. However, in usual, the occur- rence of the vortex cavitation is not favorable because the vibration of structural components and/or the noise can be induced by the vortex cavitation. Moreover, the cavi- tation bubbles generated at the vortex core may damage a structural surface when they collapse. Also in sodium- cooled fast reactors [1], the sub-surface vortex cavitation might be induced by high-speed suction flow into an out- let pipe in the reactor vessel. However, the onset condi- tion of the vortex cavitation cannot be clarified easily be- cause the vortex cavitation shows highly complicated be- haviors associated with phase change. Therefore, the au- thors have conducted experimental and numerical studies to evaluate the onset condition of the vortex cavitation. As the experimental study, a fundamental experiment is conducted to investigate the influence of the dynamic vi- scosity on the onset condition [2], and some scale model tests are also conducted to check the dependency on the local structural geometry and the effect of countermea- sure obstacles [3]. On the other hand, in the numerical study, a high-precision simulation algorithm for sub-sur- face vortex flows is under development, in which a un- structured mesh scheme is employed to model accurately the local structural geometry near a sub-surface vortex. The high-precision numerical simulation algorithm is developed originally for the evaluation of gas entrain- ment phenomena in sodium-cooled fast reactors [4-6]. Currently, it is confirmed this algorithm can simulate the gas entrainment phenomena caused by free surface vor- tices, that is, dynamic vortex behaviors, i.e. vortex deve- lopment, movement and attenuation, can be simulated. Therefore, the algorithm is considered to be applicable to numerical simulations of the vortex cavitation. However, the numerical simulation of the vortex cavitation is not easy because the sub-surface vortex has highly thin vor- tex core compared to the free surface vortex. In other words, it is very difficult to reproduce the velocity distri- bution at the vicinity of the core of the sub-surface vortex. In this case, a very fine mesh at the vicinity of the vortex core and/or a high-precision numerical simulation scheme should be employed to simulate the sub-surface vortex accurately. A very fine mesh is easy to be constructed but requires high computational cost which may exceeds the limit of usable computational resource. Therefore, a high- precision numerical simulation scheme is necessary to si- mulate the sub-surface vortex accurately. Here, it should be noted the implementation of well-known high order (more than 2nd order) schemes, e.g. K-K scheme [7] are difficult on unstructured meshes because of irregular com- putational cell arrangement. *Corresponding author. C opyright © 2013 SciRes. AM  K. ITO ET AL. 18 In this paper, a high-precision simulation scheme for vortical flows on unstructured meshes is presented. In conventional schemes, the velocity distribution between computational cells is interpolated with the constant, li- near or higher order functions based on the discrete val- ues defined at the cells, and therefore, the existence of a vortical flow is considered indirectly through the veloc- ity distribution around the vortex. On the other hand, in our new high-precision scheme, a vortical flow is identi- fied in each cell and the vortical velocity distribution at the vicinity of the vortex center is reconstructed locally based on the Burgers vortex theory [8]. Namely, the ex- istence of a vortical flow is considered directly in the new high-precision scheme. In this sense, this new scheme is called “the vortex-based scheme” in this paper. In ad- dition to the velocity distribution, the pressure distribu- tion at the vicinity of the vortex center is also considered based on the Burgers vortex theory to simulate accurately the mechanical balance between pressure gradient and centrifugal force. Then, the calculations of momentum transport through cell faces are performed in considera- tion of the reconstructed velocity and pressure distribu- tions. The superiority of the vortex-based scheme to the conventional schemes is confirmed by the fundamental verifications, such as the numerical simulation of vortex attenuation. 2. Formulation of High-Precision Numerical Scheme for Vortical Flow (Vortex-Based Scheme) 2.1. The Identification of a Vortical Flow in Each Computational Cell In the vortex-based scheme, the existence of a vortical flow is considered directly. Therefore, in the first place of the calculation, vortical flows are identified by apply- ing the discriminant [9,10] to each computational cell. Namely, a vortex center exists in a cell when the follow- ing discriminant is satisfied in the cell. 32 427DQ R 0, (1) where Q and R are the second and third invariants of the velocity gradient tensor ,iji j Au defined in each cell. 3 ,1 ij ji ij QA A, (2) detRA, (3) In the cell with a vortex center, the direction of the vortex, i.e. the direction of the rotational axis, is obtained as the eigen vector of the eigenvalue equation of the ve- locity gradient tensor. Then, a plane is defined, which is normal to the direction of the vortex center and passes through the cell center. On this plane, the point with zero in-plane velocity is determined as the vortex center. 2.2. The Supplement of the Vortical Velocity Distribution A strong vortical flow has very large velocity gradient in the immediate vicinity of the vortex center. Therefore, it is highly difficult to simulate such a velocity distribution accurately with limited computer resources (lack of suf- ficient number of cells). In the vortex-based scheme, the vortical velocity distribution is supplemented in the vi- cinity of the vortex center by utilizing the Burgers vortex model which is known as an excellent model of the vor- tices in nature, e.g. free surface vortices, sub-surface vor- tices or turbulent vortices. The circumferential velocity u distribution of the Burgers vortex model is written as 2 0 1exp r ur rr , (4) where r is the radial coordinate with the origin at the vortex center. Equation (4) has two parameters, i.e. the circulation Γ and the specific radius r0. In the vortex- based scheme, these parameters are determined to make the circumferential velocity distribution consistent with the local velocity distribution. Namely, upon a given (si- mulated) velocity field, two parameters are adjusted to minimize the difference in the circumferential velocity distributions of Equation (4) and the given field at the cells in the vicinity of a vortex center. The calculation pro- cedure is shown in Figure 1 as follows: 1) a cell with a vortex center (called “vortex cell” in this paper) is selected; 2) vertices on the vortex cell and the cells around the vortex cell is selected; 3) when the velocity is given at the cell centers, the circumferential velocities at the vertices v u are inter- polated from the cell center velocities c u as follows: surround surround cc v c wu uw , (5) where the summations are operated on all cells surroun- ding each selected vertex, and wc is the weighting factor for the summation; 4) the differences between the Burgers model (Equa- tion (4)) and the circumferential velocities at the selected vertices v u are calculated and averaged as the form of the weighted root mean square (shown by an overbar) as follows: 2 vertices vv uwu v , (6) Copyright © 2013 SciRes. AM  K. ITO ET AL. Copyright © 2013 SciRes. AM 19 Vortex center Vortex cell (a) (b) (c) v u Burgers (d) (e) Figure 1. Procedure to determine vortex parameters: (a) selection of a vortex cell; (b) listing up of vertices; (c) interpolation of circumferential velocity at each vertex (red vectors); (d) calculation of differences at each vertex (Burgers vortex velocity in horizontal is shown by blue curve) and (e) adjustments of parameters. where the summation is operated on all selected vertices, and wv is the weighting factor for the summation; 5) the circulation and the specific radius are adjusted iteratively to minimize the averaged differences v u . The weighting factor in Equation (5) is determined by minimizing the cost-function (Co in Equation (7)) under the constraint formulated as Equation (8) [11], and the weighting factor in Equation (6) is determined in a si- milar manner. 2 surround 1 c cv Co w r in the numerical simulations on unstructured meshes. In he cell based FVM is employed on an unstruc- tu , (7) surround 0 ccv w r (8) where cv is the vector joining a cell center to a vertex. In Figure 1, the calculation procedure on a two-dimen- sional structured mesh is shown for simplification. How- ever, the calculation on a three-dimensional unstructured mesh can be conducted in the same procedure. r 2.3. The Momentum Transport Calculation The finite volume method (FVM) is employed frequently that case, each cell is generally selected as the control vo- lumes for discretization. Also in our high-precision nu- merical simulation algorithm, such simulation method (cell based FVM) is employed, and therefore, the fol- lowing description is given based on the cell based FVM. However, the concept of the vortex-based scheme is ap- plicable also to other methods, e.g. the finite difference method. When t red mesh, it is difficult to formulate high order momen- tum transport schemes, i.e. third or higher order schemes, due to the irregular cell arrangement. Therefore, the first and second order upwind schemes are used frequently for the momentum transport calculation. In the first order up- wind scheme, the momentum on a cell face is determined to be same as that in the upwind cell of the cell face. On the other hand, in the second order upwind scheme, the momentum on a cell face m is calculated in consideration of the momentum ( and momentum c m) gradient c m in the upwincell of the cell d (9) face: c fc cf mm mr,  K. ITO ET AL. 20 where is the vector joining the upwi cf r fac nd cell center to the celle center. In Equation (9), the momentum gra- dient can be calculated by the Gauss-Green method [11] or Least-square method [12]. The first or second order upwind scheme works well in the numerical simulations of smooth flows without discontinuity (shock) and strong vortices. However, as mentioned briefly in Section 2.2, the velocity distribution in the vicinity of a vortex center is very sharp and a very high resolution mesh is neces- sary to simulate the vortical velocity distribution accu- rately by the first or second order upwind scheme. Instead of such a very high resolution mesh, which is not appli- cable to practical simulations, the vortex-based scheme supplements the vortical velocity distribution in the vi- cinity of a vortex center by the Burgers vortex model (Equation (4)) and calculates the momentum transport based on the supplemented velocity distribution. Namely, when the velocity distribution in the vicinity of a vortex center is given by Equation (4), the momentum in the cir- cumferential direction m is calculated on a cell face as ff mu , (10) where is the fluid density on the cell face and u is the cmferential velocity at the cell face center c culated by Equation (4). Then, the momentum transport is calculated based on Equation (10). 2.4. The Pressure Calculation ircu al- In the vicinity of a vortex center, not only the velocity gradient but also the pressure gradient is large due to the mechanical balance between the circumferential velocity and the pressure gradient (see Equation (11)). Therefore, the pressure should be supplemented to simulate vortical flows accurately. In the vortex-based scheme, the pres- sure distribution in the vicinity of a vortex center is cal- culated in consideration of the mechanical balance equa- tion of the circumferential velocity and the pressure gra- dient, written as 2 up rr , (11) where p is the pressure. Substituting the circumferential velocity distribution of the Burges model (Equation (4)) into Equation (11) leads the pressure distribution. 2 2 2 3 0 1exp d R R pRR R rR , (12) where 0 Rrr . The pressure calculated by Equation (12) is applied to the faces on a vortex cell and the faces on the cells around the vortex cell. Then, the pressure gradient term in the momentum transport equation (Na- vier-Stokes equation) is calculated at each cell based on the applied pressure values. 3. Verification 3.1. The Reproducibility of a Vortical Flow As the first verification, the reproducibility of a vortex by the vortex-based scheme is addressed. In this calculation, the Burgers vortex is set on two-dimensional structured meshes, and then, the identification and the velocity sup- plement calculations are conducted to check the repro- ducibility of the vortex. As shown in Figure 2, the simu- lation domain is 1.00 × 1.00 and subdivided into 8 × 8 square cells. The velocity distribution of the Burgers vor- tex is applied to all cells with various vortex center posi- tions, specific radii and/or circulation values. Table 1 shows the calculation results. It is evident that the vortex center position and the circulation are well re- Table 1. Reproducibility of Burgers vortex. Original (given) valuesvalues Calculated Vortex center coordinSpecific radiusVortex center coordinate Specific radius ate Circulation Circulation (0.00, 0.00) 0.100 0.050 (0.00, 0.00) 0.106 0.107 0.100 0.102 0.138 0.125 0.102 0.158 0.200 0.101 0.221 0.250 0.100 0.267 (0.01,.00) (0.0094,.0005) 0. 1.00 (0.00, 0.00) 1.00 0.267 0 00.100 0.267 (0.01, 0.01) (0.0103, 0.0098) 0.100 0.267 (0.05, 0.05) (0.0503, 0.0488) 0.100 0.266 (0.00, 0.00) 010 (0.00, 0.00) 0.010 0.267 Copyright © 2013 SciRes. AM  K. ITO ET AL. 21 -0.5 0.0 0.5 0.5 0.0 -0.5 Figure 2. Simulation mesh and original Burgers vortex with Γ = 0.100 and r0 = 0.100. r position, circulation and/or spe- ific radius of the original Burgers vortex. As for the cal- produced in all calculation cases regardless of the varia- tions of the vortex cente c culated specific radius, almost the same values are evalu- ated regardless of the variations of the vortex center po- sition and/or circulation. However, the calculation accu- racy (reproducibility) is affected significantly by the spe- cific radius of the original Burgers vortex. In other words, the calculation error is about 25% when the original spe- cific radius is the same as the cell size (0.125), and the error is reduced to about 6.8% when the original specific radius is twice the cell size. In practical simulations, this kind of local (only in the vicinity of a vortex) calculation error may be negligible even if it reaches about 25%, because much larger error sources can exist in such simu- lations. However, the calculation results show that the mesh resolution should be at least half of the specific ra- dius of a vortex to perform accurate simulations. This constrain may seem very difficult to be satisfied. How- ever, the authors’ previous research shows that the cell size has to be about 120 of the specific radius to re- produce the vortical velocity distribution when the sec- ond order upwind scheme is employed [4]. Therefore, the necessary number of cells for accurate simulations can be reduced significantly by employing the vortex-based scheme. 3.2. The Simulation of Attenuation Behaviors of an Inviscid Vortex , viscosity deation errors of each scheme. tex ted with foures, i.e. the first order upwd order upwiird order M and vortex-bschemes, and thulation the pe It is well known that the momentum transport schemes e.g. the first order upwind scheme, have the numerical pendent on trunc Therefore, even in the numerical simulations of an invi- scid vortex, the vortical velocity distribution decays tem- porally and the total kinetic energy in the simulation do- main is not conserved. In this sense, the conservativeness of the total kinetic energy can be an indicator of the in- fluence of the numerical viscosity, that is, the simulation accuracy. Here, attenuation behaviors of an inviscid vor- compared in terms of the conservativeness of the total kinetic energy. The numerical simulations are conducted on 1.00 × 1.00 two-dimensional domain subdivided into square cells (shown in Figure 3). As for the mesh resolu- tion, four structured meshes, i.e. 8 × 8, 16 × 16, 32 × 32 and 64 × 64 square cells, are employed. At the initial state, the velocity distribution of the Burgers vortex with the circulation of 0.100 and the specific radius of 0.050 is applied to the meshes, and then, the simulations of 100 time-marching with the time increment of 0.01 are con- ducted. The temporal variations of the velocity distribu- tions and the total kinetic energies are investigated in each simulation for the comparison of four schemes. In Figure 4, the temporal variations of the velocity distributions on the 32 × 32 mesh are shown. The simu- lation result with the first order upwind scheme (Figure 4(a)) shows rapid decay of the initial vortical velocity distribution. When the second order upwind schemes is employed, such a decay behavior is suppressed and are simula schem ind, secon ased nd, th e sim USCL results are ak of the circumferential velocity in the vicinity of the vortex center is maintained appreciably even at t = 0.40. The simulation result with the third order MUSCL scheme is almost the same as the result with the second order upwind scheme. The vortex-based scheme shows superior simulation accuracy to these three schemes. The decay of the circumferential velocity distribution in the vicinity of the vortex center is apparently small com- pared to the simulation result with the second order up- wind scheme. The temporal variations of the total kinetic energies on the 32 × 32 mesh are shown in Figure 5. In the simulation with the first order upwind scheme, the total kinetic energy decreases very rapidly along with the rapid decay of the vortical velocity distribution as shown in Figure 4(a). The second order upwind scheme highly improves the total energy conservation compared to the Figure 3. Simulation mesh and initial velocity distribution on 32 × 32 mesh. Copyright © 2013 SciRes. AM  K. ITO ET AL. 22 = 0.10 t = 0.20 t = 0.30 t = 0.40 (a) = 0.10 t = 0.20 t = 0.30 t = 0.40 (b) t = 0.10 t = 0.20 t = 0.30 t = 0.40 (c) Figure 4. Temporal variations of velocity distributions on 32 × 32 mesh: (a) first order upwind scheme; (b) second order up- wind scheme and (c) vortex-based scheme. first order upwind scheme. The loss of the total kinetic energy at t = 1.0 is about 30% of its original value (t = 0.0), which is about 48% in the simulation with the first order upwind scheme. The third order MUSCL scheme shows slightly higher total kinetic energy conservation than the second order upwind scheme, and the loss of the total kinetic energy at t = 1.0 is about 26%. However, the temporal variation of the total kinetic energy is similar to that in the simulation results with the second order up- wind scheme. Compared to the other three schemes, the l kinetic energy t t = 1.0 is about 17%. Therefore, the vortex-based mentation (Section 2.4) is important as well as the velo- city supplementation (Section 2.3), because the loss of the total kinetic energy at t = 1.0 increases to about 23% when the pressure supplementation is not employed. In the vortex-based scheme, two parameters, i.e. circu- lation and specific radius, dominate the vortical velocity distribution. Here, the temporal behaviors of these two parameters are investigated as shown in Figure 6. When a relatively coarse mesh (16 × 16 mesh) is employed, th specific radius at the initial state is evaluated as a consi- tex and the specific radius becomes larger with time. On the other hand, the circulation is evaluated accurately at vortex-based scheme shows much better total energy conservation. In fact, the loss of the tota derably larger value than that of the original Burgers vor- a scheme has a superior ability to simulate vortical flows accurately. It should be noted that the pressure supple- the initial state and does not decrease significantly with time. When a finer mesh (32 × 32 mesh) is employed, the e Copyright © 2013 SciRes. AM  K. ITO ET AL. 23 50 60 70 80 0.0 0.5 1.0 Vortex-based 1st-order upwind 2nd-order upwind 3rd-order MUSCL Total kinetic energy Time Figure 5. Simulation mesh and initial velocity distribution on 32 × 32 mesh. 0.00 0.05 0.10 0.0 0.5 1.0 16 x 16 mesh 32 x 32 mesh Specific radius Time Initial value (a) 0.05 0.10 0.15 0.0 0.5 1.0 16 x 16 mesh 32 x 32 mesh Circulation Time Initial value (b) ) circulation. evaluation results of these two parameters changes com- pletely. In the finer mesh case, the specific radius is eva- luated accurately throughout the simulation because the enhanced mesh resolution improves the reproducibility of the vortical flow (as shown in the previous section). Therefore, the loss of the kinetic energy is induced main- ly by the change in the circulation. In fact, the circulation decreases temporally with the decay of the peak circum- ferential velocity. These evaluation results of the specific radius and the circulation show the characteristics of the vortex-based scheme can banged by mesh resolution. In general, the mesh resolution has a significant effect on the simulation accuracy. Figure 7 shows the loss of the total kinetic energy (ratio from its original value as the functions of the cell size Δ) in the simulations results on 8 × 8, 16 × 16, 32 × 32 and 64 × 64 meshes. The simulation accuracy is highly enhanced with the mesh re- solution when the first order upwind, second order up- wind or third order MUSCL schemes is employed. On the other hand, the vortex-based scheme gives a superior simulation accuracy of vortical flows on both the coarse and refined meshes. In other words, the vortex-based scheme shows roughly the same simulation accuracy both on the coarse and fineshes. Thereforhe vor- tex-based scheme is especi useful in the simulations s. Figure 6. Temporal behaviors of vortex parameters: (a) spe- cific radius and (b e ch e m ally e, t on rather coarse meshes, on which other schemes fails to ive accurate simulation resultg 4. Numerical Simulation of Quasi-Steady Vortex To check the applicability of the vortex-based scheme to the numerical simulation on a three-dimensional unstruc- tured mesh, the quasi-steady vortex is simulated in ref- erence to the experiment by Moriya [13]. Figure 8 shows the simulation mesh, which consists of a cylindrical tank with the diameter of 0.40 m, an inlet slit with the width of the 0.04 m and an outlet nozzle with the diameter of 0.05 m. The inlet slit is installed tangentially to the cy- 0.0 0.5 1.0 10-1 100101 Vortex-bas ed 1st-order upwind 2nd-order upwind 3rd-order MUSCL Ratio r0/ Figure 7. Loss of total kinetic energy. Inlet slit Outlet nozzle tank (a) (b) Figure 8. Simulation mesh of the quasi-steady vortex ex- Cylindrical eriment by Moriya: (a) top view and (b) bird’s eye view. p Copyright © 2013 SciRes. AM  K. ITO ET AL. 24 lindrical tank and the outlet nozzle is installed on the bottom of the cylindrical tank. The uniform flow through the inlet slit generates a vortical flow in the cylindrical tank and the strength of this vortex is enhanced by the downward flow towards the outlet nozzle. The working fluid is water at room temperature. Two cases of un- steady numerical simulations are conducted with the se- cond order upwind scheme and with the vortex-based scheme until quasi-steady states are obtained. As shown in Figure 8, the mesh resolution is rather low, that is, the horizontal cell size at the center of the cylindrical tank is about 5.0 mm, which is not small enough to the meas- ured specifi gas- quid inteental ap- aratus is not considered, and only the comparison of the simulation results is conducted. All structural walls are modeled as non-slip walls. As the other boundary condi- tions, a uniform inlet velocity with8.33 × 10−4 m 3/s is applied to the inlet a pressure condition is applied to the outlet. Figure 9 shows the horizontal velocity distributt the height of 0.15 m from the bottom of the cylindrical tank. It is evident that the vor scheme gives lar- ger velocity in the vicinity ofcenter compared to the seconfference in th simulation can be observ- c radius (about 6.0 mm). In this study rface located in the Moriya’s experim , a li p the flow rate of nd a constant ions a tex-based the vortex d order upwindcheme. The di results with these two schemes se ed clearly in the comparison of the circumferential veloc- ity distributions (shown in Figure 10). The vortex-based scheme gives larger peak of the circumferential velocity and smaller specific radius. Namely, the peak of the vor- tical velocity in the vicinity of the vortex center is simu- lated more sharply by employing the vortex-based scheme instead of the second order upwind scheme. Therefore, it is confirmed that the vortex-based scheme can simulate vortical flows accurately even on three-dimensional un- structured meshes. 5. Conclusion In this paper, the vortex-based scheme is developed to achieve high-precision numerical simulations of strong vortical flows which may cause the vortex cavitation. In (a) (b) Figure 9. Horizontal velocity distributions: (a) second order upwind scheme and (b) vortex-based scheme. -0.30 -0.20 -0.10 0.00 0.10 0.20 0.30 -0.10 2nd order upwind Vortex-based Circumferential velocity -0.050.00 0.05 0.10 Radial coordinate flow is identified in each computational cell, and then, the Burgers vortex model is applied to supplement a vor- tical velocity distribution in the vicinity of the vortex center. The pressure distribution in the vicinity of the vortex center is also supplemented. The momentum tran- sfer is calculated with those supplemented velocity and pressure distributions. The simulation result of the inviscid vortex attenuation problem shows the vortex-based scheme leads lower si mulation errd order sche- the vortex- based scheme can simulate vortical flows more accu- rately than the conventional schemes. The higher simula- tion accuracy of the vortex-based scheme than the con- ventional scheme is shown also in the numerical simula- tion of the quasi-steady vortex experiment. The vortex- based scheme succeeds in simulating the vortical flow on a three-dimensional unstructured mesh more accurately than the second order upwind scheme. This result implies that the vortex-based scheme is applicable to practical si- mulations. REFERENCES y and R&D Progress on Japan Sodium- Figure 10. Comparison of circumferential velocity distribu- tions. the vortex-based scheme, at the first place, a vortical - or compared to the first to thir mes. In addition, such a low simulation error is obtained regardless of the mesh resolution. Therefore, [1] K. Aoto, N. Uto, Y. Sakamoto, T. Ito, M. Toda and S. Ko- take, “Design Stud Cooled Fast Reactor,” Journal of Nuclear Science and Technology, Vol. 48, No. 4, 2011, pp. 463-471. http://dx.doi.org/10.1080/18811248.2011.9711720 [2] T. Ezure, N. Kimura, A. Tobita and H. Kamide, “Influ- ences of Fluid Viscosity on the Occurrences of Cavitation Due to Sub-Surface Vortex,” Proceedings of the Seventh Korea-Japan Symposium on Nuclear Thermal Hydraulics and Safety, Chuncheon, 14-17 November 2010, N7P0072. [3] T. Ezure, K. Ito, T. Onojima, N. Kimura and H. Kamide, “Fundamental Behavior of Vortex Cavitation in a 1/22 Scaled Upper Plenum Model of Sodium Cooled Fast Re- actor,” Proceedings of the 8th Korea-Japan Symposium Copyright © 2013 SciRes. AM  K. ITO ET AL. Copyright © 2013 SciRes. AM 25 on Nuclear Thermal Hydraulics and Safety, Beppu, 9-12 December 2012, N8P1068. [4] K. Ito, T. Kunugi, H. Ohshima and T. Kawamura, “Formu- lations and Validations of a High-Precision Volume-of- Fluid Algorithm on Non-Orthogonal Meshes for Nume- rical Simulations of Gas Entrainment Phenomena,” Jour- nal of Nuclear Science and Technology, Vol. 46, No. 4, 2009, pp. 366-373. http://dx.doi.org/10.1080/18811248.2007.9711542 [5] K. Ito, T. Kunugi and H. Ohshima, “High-Precision Re- construction of Gas-Liquid Interface in PLIC-VOF Framework on Unstructured Mesh,” In: A. Kuzumin, Ed., Computational Fluid Dynamics 2010, Springer, Berlin, 2011, pp. 563-567. http://dx.doi.org/10.1007/978-3-642-17884-9_71 [6] K. Ito, T. Kunugi and H. Ohshima, “A High-Precision Unstructured ue for Gas-Liquid Adaptive Mesh Techniq Two-Phase Flows,” International Journal for Numerical Methods in Fluids, Vol. 67, No. 11, 2011, pp. 1571-1589. http://dx.doi.org/10.1002/fld.2432 [7] T. Kawamura, H. Takami and K. Kuwahara, “Computa- tion of High Reynolds Number Flow around a C Cylinder with Surface Roughness,” Fluid Dynamiircular cs Re- search, Vol. 1, No. 2, 1986, pp. 145-162. http://dx.doi.org/10.1016/0169-5983(86)90014-6 [8] J. M. Burgers, “A Mathematical Model Illustrating the Theory of Turbulence,” In: R. Mises and T. Karman, Eds., Advance in Applied Mechanics, Academic Press ING., New York, 1982, pp. 171-199 [9] K. Sawada, “A Convenient Visualization Method f . or Iden- eport AIAA-95-1715, tifying Vortex Center,” Transaction of the Japan Society for Aeronautical and Space Sciences, Vol. 38, No. 120, 1995, pp. 102-116. [10] D. Sujudi and R. Haimes, “Identification of Swirling Flow in 3-D Vector Fields,” Technical R American Institute of Aeronautics and Astronautics, 1995. [11] D. Kim and H. Choi, “A Second-Order Time-Accurate Finite Volume Method for Unsteady Incompressible Flow on Hybrid Unstructured Grids,” Journal of Computatio- nal Physics, Vol. 162, No. 2, 2000, pp. 411-428. http://dx.doi.org/10.1006/jcph.2000.6546 [12] T. J. Barth and D. C. Jespersen, “The Design and Appli- cation of Upwind Schemes on Unstructured Meshes,” Technical Report AIAA-89-0366, AIAA 27th Aerospace odel Test Measurements,” Technical Sciences Meeting, Reno, 9-12 January 1989. [13] S. Moriya, “Estimation of Hydraulic Characteristics of Free Surface Vortices on the Basis on Extension Vortex Theory and Fine M Reports of Central Research Institute of Electric Power Industry U97072, 1998.

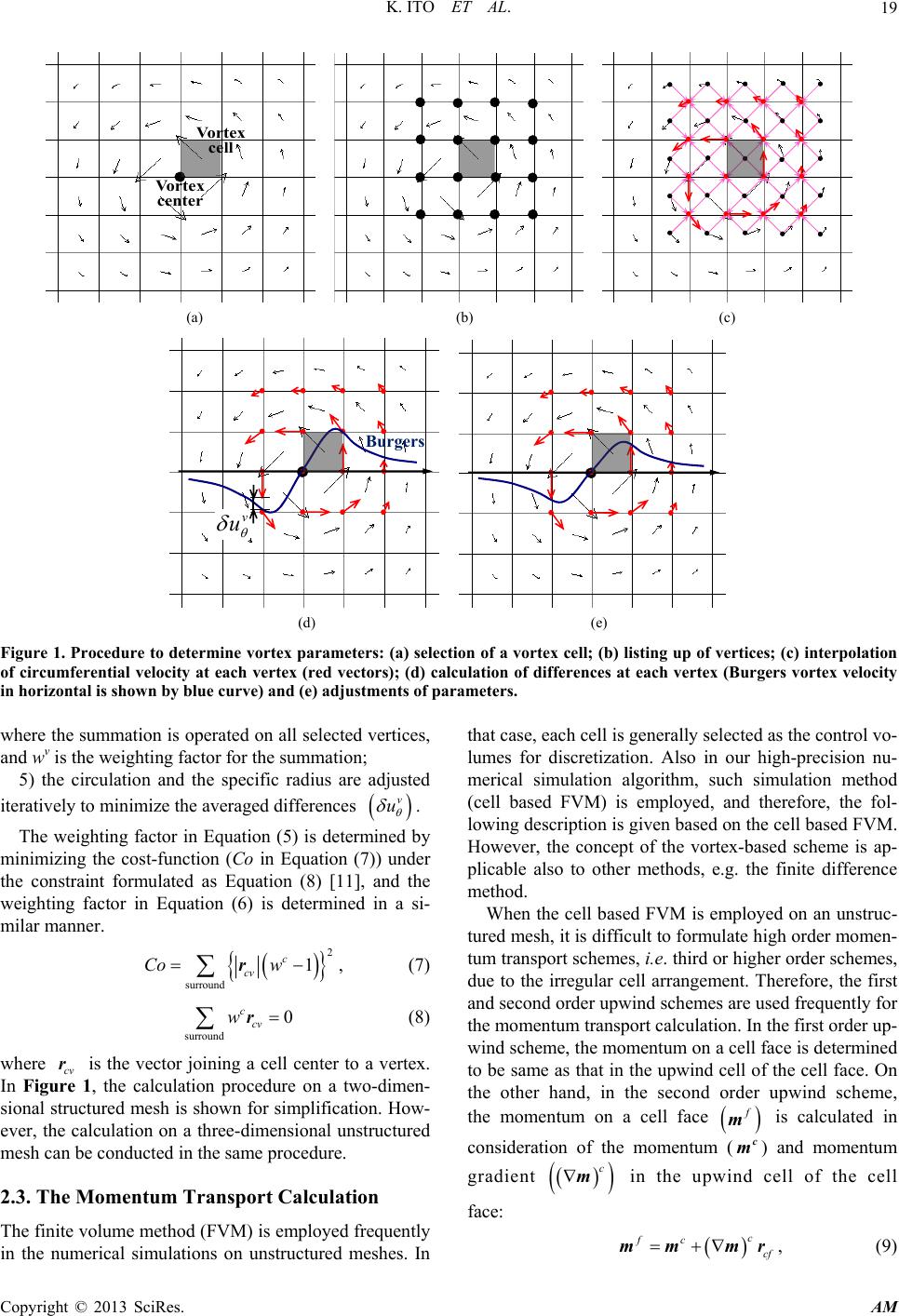

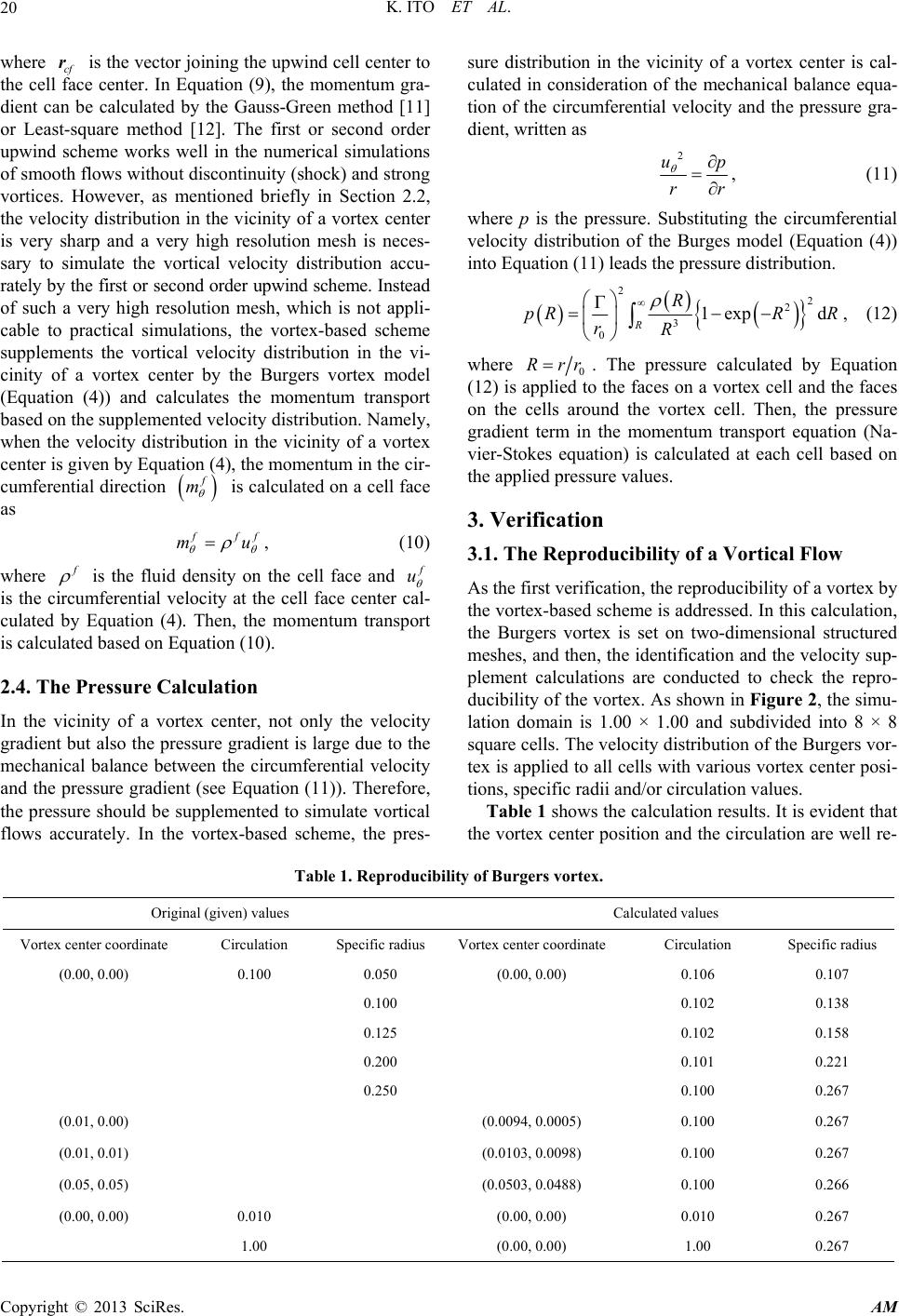

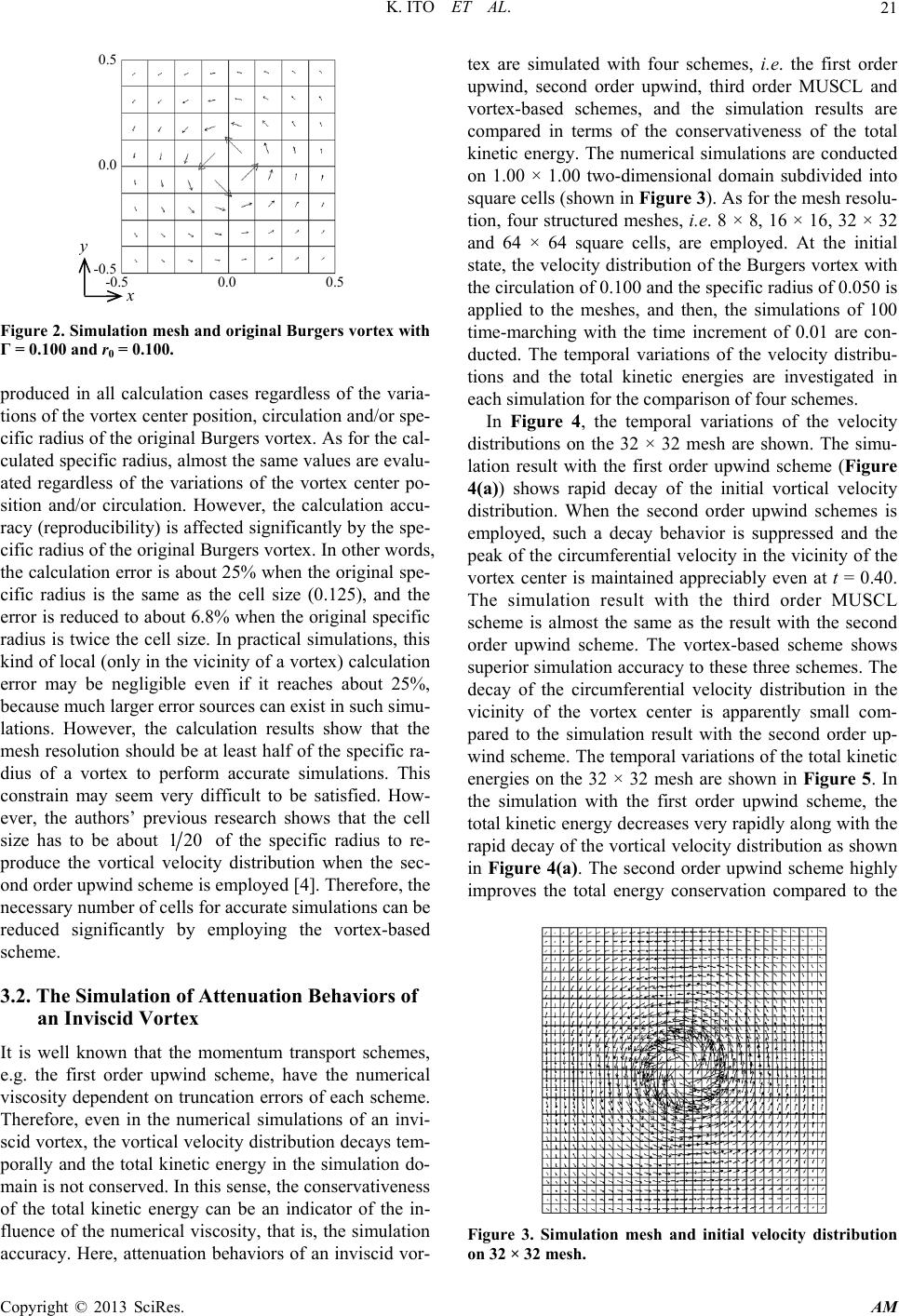

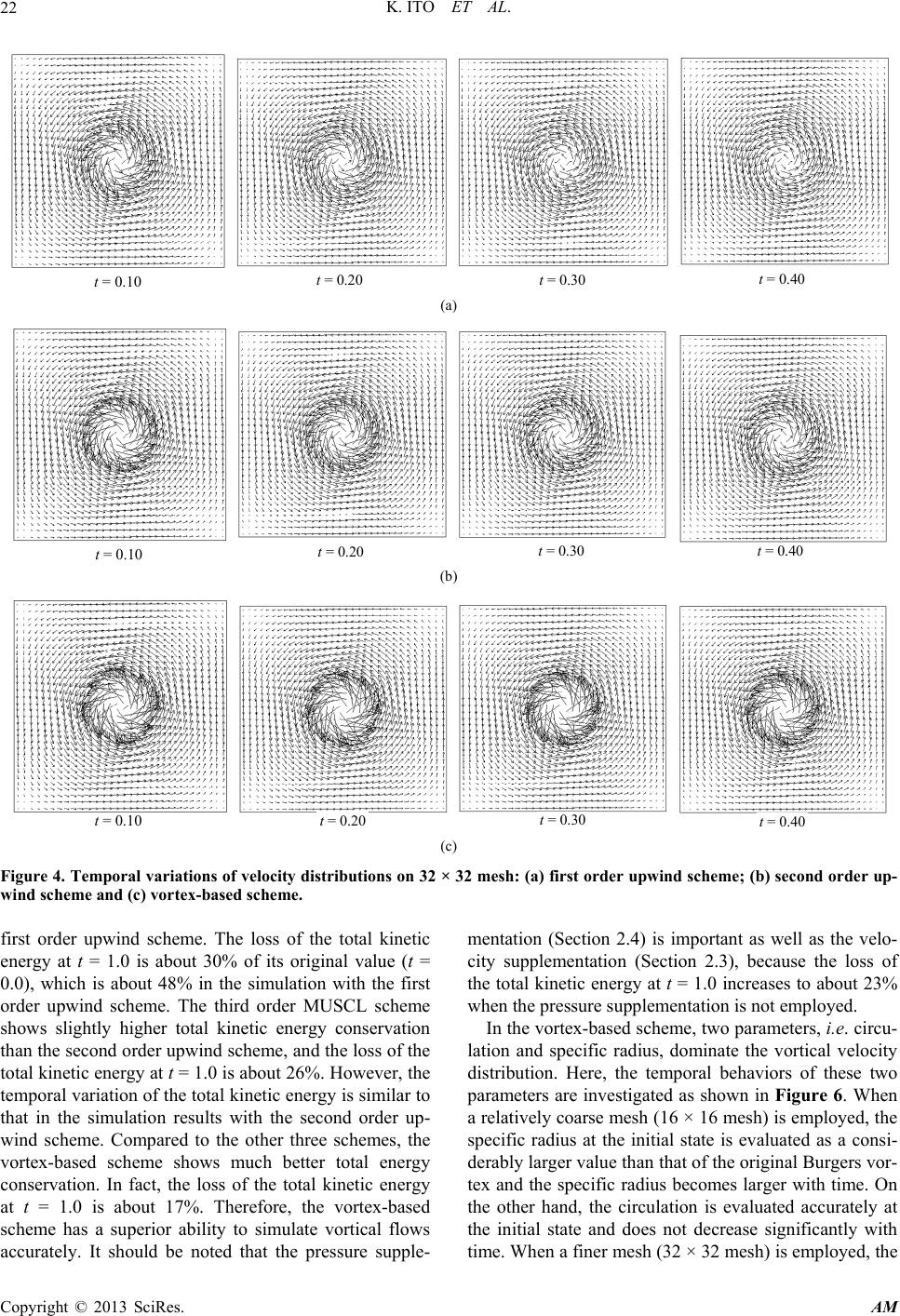

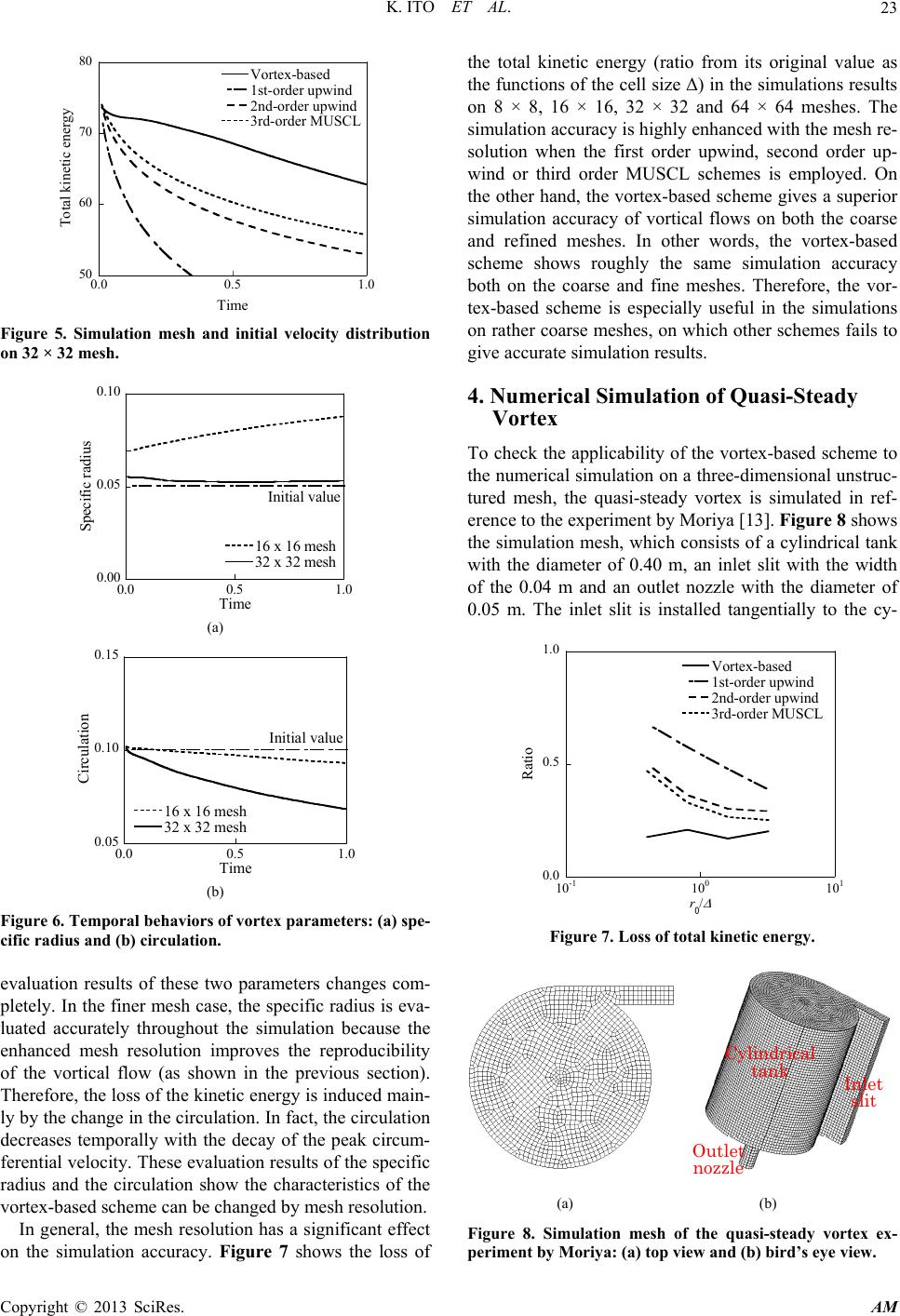

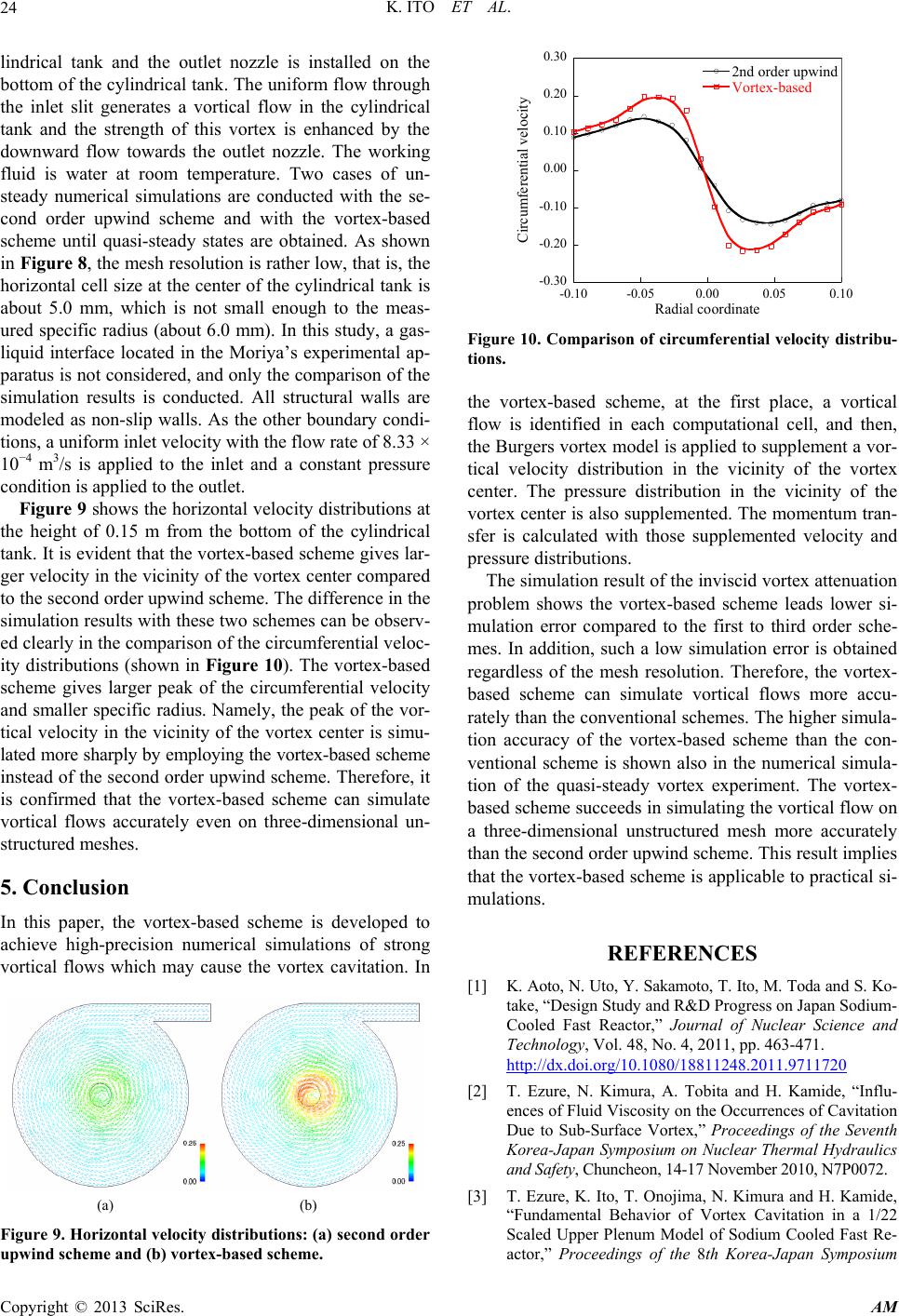

|