A. J. G. Gibe, J. G. Kim / Agricultural Sciences 4 (2013) 477-482 481

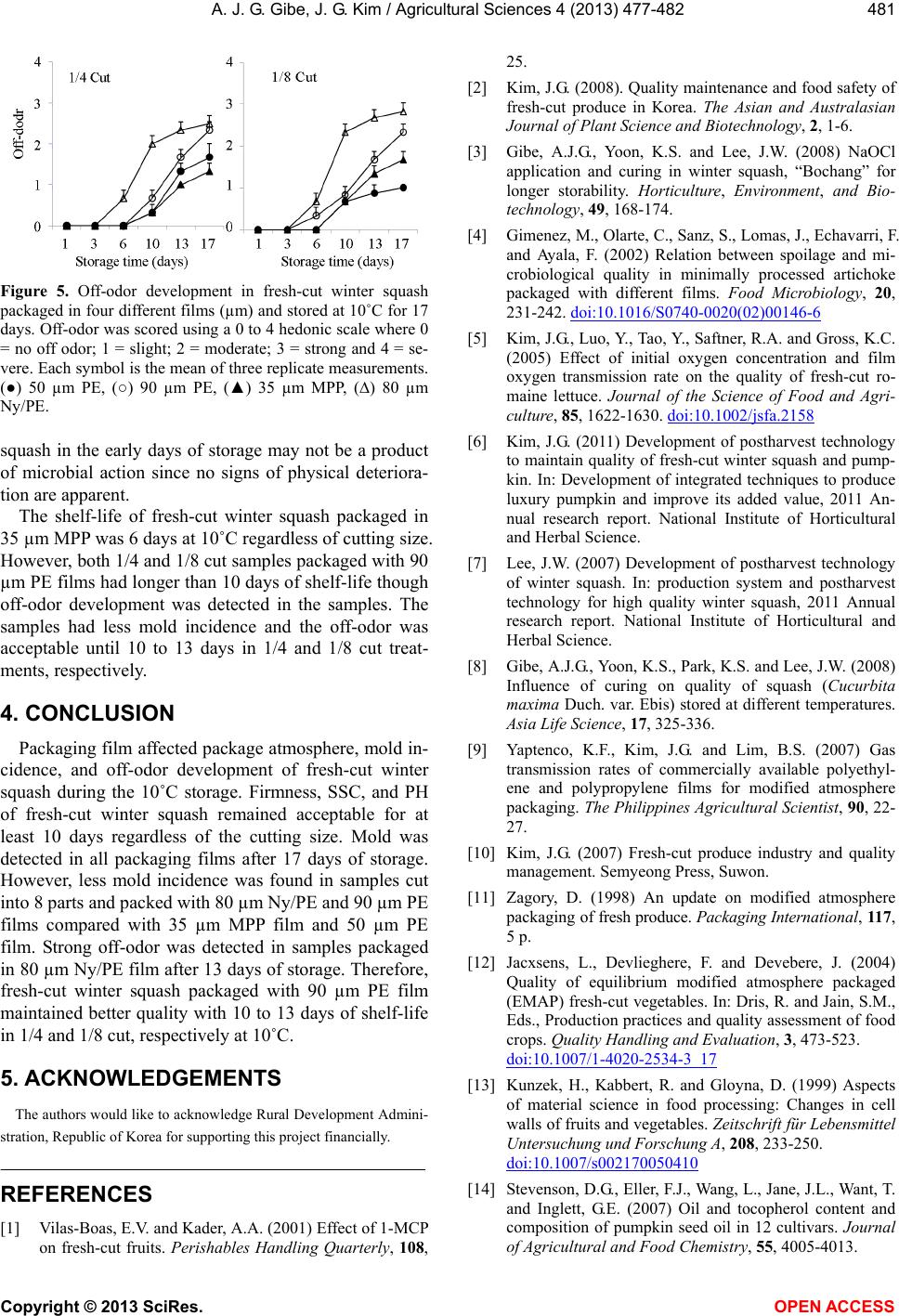

Figure 5. Off-odor development in fresh-cut winter squash

packaged in four different films (µm) and stored at 10˚C for 17

days. Off-odor was scored using a 0 to 4 hedonic scale where 0

= no off odor; 1 = slight; 2 = moderate; 3 = strong and 4 = se-

vere. Each symbol is the mean of three replicate measurements.

(●) 50 µm PE, (○) 90 µm PE, (▲) 35 µm MPP, (∆) 80 µm

Ny/PE.

squash in the early days of storage may not be a product

of microbial action since no signs of physical deteriora-

tion are apparent.

The shelf-life of fresh-cut winter squash packaged in

35 µm MPP was 6 days at 10˚C regardless of cutting size.

However, both 1/4 and 1/8 cut samples packaged with 90

µm PE films had longer than 10 days of shelf-life though

off-odor development was detected in the samples. The

samples had less mold incidence and the off-odor was

acceptable until 10 to 13 days in 1/4 and 1/8 cut treat-

ments, respectively.

4. CONCLUSION

Packaging film affected package atmosphere, mold in-

cidence, and off-odor development of fresh-cut winter

squash during the 10˚C storage. Firmness, SSC, and PH

of fresh-cut winter squash remained acceptable for at

least 10 days regardless of the cutting size. Mold was

detected in all packaging films after 17 days of storage.

However, less mold incidence was found in samples cut

into 8 parts and packed with 80 µm Ny/PE and 90 µm PE

films compared with 35 µm MPP film and 50 µm PE

film. Strong off-odor was detected in samples packaged

in 80 µm Ny/PE film after 13 days of storage. Therefore,

fresh-cut winter squash packaged with 90 µm PE film

maintained better quality with 10 to 13 days of shelf-life

in 1/4 and 1/8 cut, respectively at 10˚C.

5. ACKNOWLEDGEMENTS

The authors would like to acknowledge Rural Development Admini-

stration, Republic of Korea for supporting this project financially.

REFERENCES

[1] Vilas-Boas, E.V. and Kader, A.A. (2001) Effect of 1-MCP

on fresh-cut fruits. Perishables Handling Quarterly, 108,

25.

[2] Kim, J.G. (2008). Quality maintenance and food safety of

fresh-cut produce in Korea. The Asian and Australasian

Journal of Plant Science and Biotechnology, 2, 1-6.

[3] Gibe, A.J.G., Yoon, K.S. and Lee, J.W. (2008) NaOCl

application and curing in winter squash, “Bochang” for

longer storability. Horticulture, Environment, and Bio-

technology, 49, 168-174.

[4] Gimenez, M., Olarte, C., Sanz, S., Lomas, J., Echavarri, F.

and Ayala, F. (2002) Relation between spoilage and mi-

crobiological quality in minimally processed artichoke

packaged with different films. Food Microbiology, 20,

231-242. doi:10.1016/S0740-0020(02)00146-6

[5] Kim, J.G., Luo, Y., Tao, Y., Saftner, R.A. and Gross, K.C.

(2005) Effect of initial oxygen concentration and film

oxygen transmission rate on the quality of fresh-cut ro-

maine lettuce. Journal of the Science of Food and Agri-

culture, 85, 1622-1630. doi:10.1002/jsfa.2158

[6] Kim, J.G. (2011) Development of postharvest technology

to maintain quality of fresh-cut winter squash and pump-

kin. In: Development of integrated techniques to produce

luxury pumpkin and improve its added value, 2011 An-

nual research report. National Institute of Horticultural

and Herbal Science.

[7] Lee, J.W. (2007) Development of postharvest technology

of winter squash. In: production system and postharvest

technology for high quality winter squash, 2011 Annual

research report. National Institute of Horticultural and

Herbal Science.

[8] Gibe, A.J.G., Yoon, K.S., Park, K.S. and Lee, J.W. (2008)

Influence of curing on quality of squash (Cucurbita

maxima Duch. var. Ebis) stored at different temperatures.

Asia Life Science, 17, 325-336.

[9] Yaptenco, K.F., Kim, J.G. and Lim, B.S. (2007) Gas

transmission rates of commercially available polyethyl-

ene and polypropylene films for modified atmosphere

packaging. The Philippines Agricultural Scientist, 90, 22-

27.

[10] Kim, J.G. (2007) Fresh-cut produce industry and quality

management. Semyeong Press, Suwon.

[11] Zagory, D. (1998) An update on modified atmosphere

packaging of fresh produce. Packaging International, 117,

5 p.

[12] Jacxsens, L., Devlieghere, F. and Devebere, J. (2004)

Quality of equilibrium modified atmosphere packaged

(EMAP) fresh-cut vegetables. In: Dris, R. and Jain, S.M.,

Eds., Production practices and quality assessment of food

crops. Quality Handling and Evaluation, 3, 473-523.

doi:10.1007/1-4020-2534-3_17

[13] Kunzek, H., Kabbert, R. and Gloyna, D. (1999) Aspects

of material science in food processing: Changes in cell

walls of fruits and vegetables. Zeitschrift für Lebensmittel

Untersuchung und Forschung A, 208, 233-250.

doi:10.1007/s002170050410

[14] Stevenson, D.G., Eller, F.J., Wang, L., Jane, J.L., Want, T.

and Inglett, G.E. (2007) Oil and tocopherol content and

composition of pumpkin seed oil in 12 cultivars. Journal

of Agricultural and Food Chemistry, 55, 4005-4013.

Copyright © 2013 SciRes. OPEN ACCESS