J. J. LI ET AL.

286

of 8.5% by substituting m0 = 2 and refractive index value

from [18] into Equation. (2) and (3). So the large differ-

ence of the external quantum efficiency between sample

A and sample B is due to the different internal quantum

efficiency

int. That is to say, the cavity structure of sam-

ple B with cladding layer benefits a higher

int by con-

fining carriers effectively and reducing the AlGaInP/

AlAs interface recombination simultaneo-ussly. If we

have considered the opaque top electrode, which amounts

to 10% of the total top emitting surface, a

int of nearly

100% can be obtained for sample B.

For both samples, the optical power increases first

with increasing current before it rolls-over and decreas-

ing again due to the thermal effect. For sample B, the

light power reaches its maximum point, 7.72 mW at a

current of 90 mA. As author’s knowledge, that is the

highest output power for 650 nm RCLEDs with the same

structure. But for sample A, the maximum light power is

only 1.77 mW, meanwhile, because of the sample A’s

lower photoelectric efficiency and severer thermal effect,

it reaches its maximum power at a lower current of 70

mA. So we can say, because of the lower conduction

band offset for AlGaInP materials and the thinner active

region defined by the cavity thickness, a deliberate de-

sign of the cavity is very important for 650 nm RCLEDs.

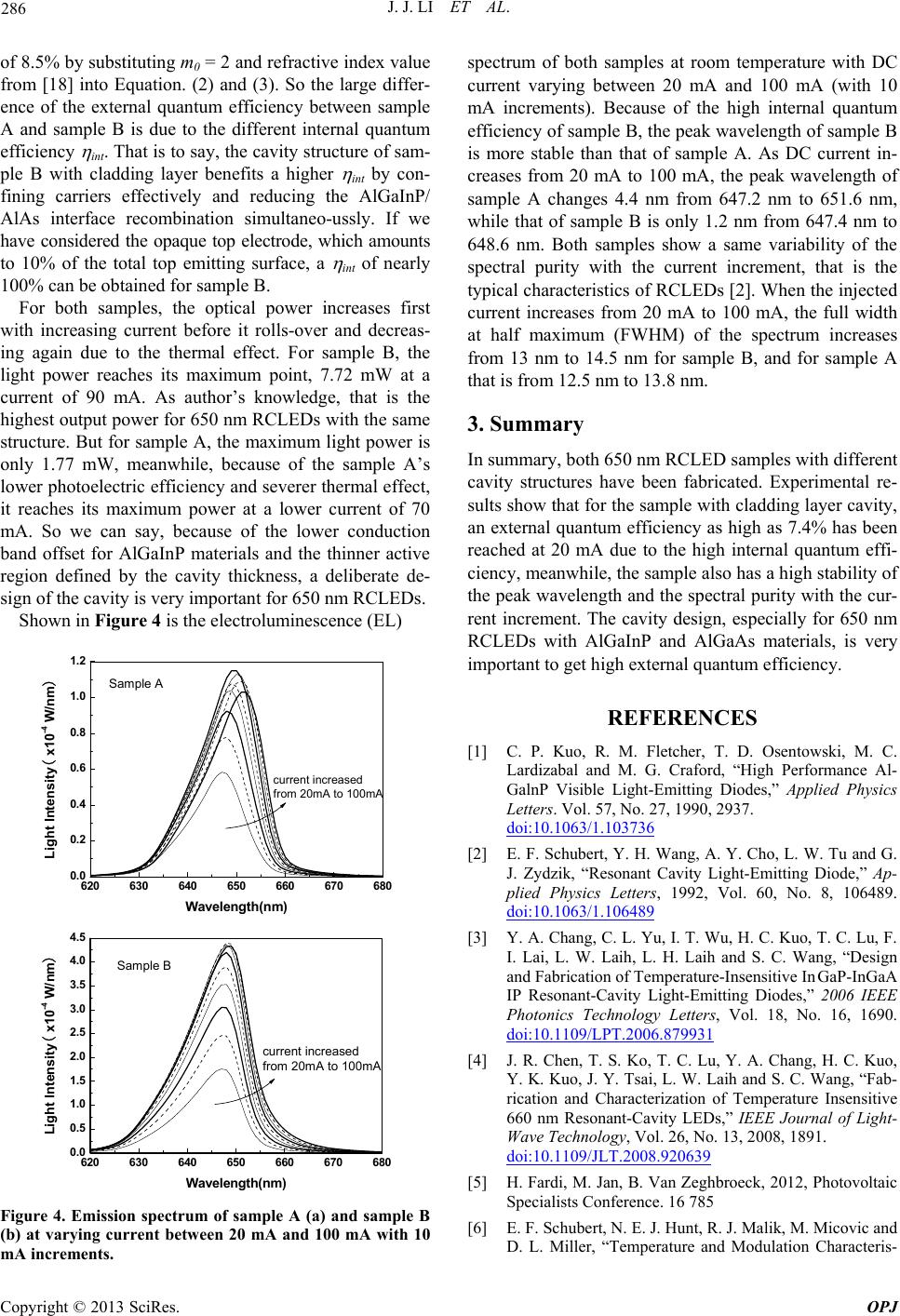

Shown in Figure 4 is the electroluminescence (EL)

620 630 640650 660 670 680

0.0

0.2

0.4

0.6

0.8

1.0

1.2

Sample A

Light Intensity( x10-4 W/nm)

Wavelength(nm)

current increased

from 20mA to 100mA

620 630 640 650 660 670 680

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

Light Intensity( x10-4 W/nm)

Wavelength(nm)

Sample B

current increased

from 20mA to 100mA

Figure 4. Emission spectrum of sample A (a) and sample B

(b) at varying current between 20 mA and 100 mA with 10

mA increments.

spectrum of both samples at room temperature with DC

current varying between 20 mA and 100 mA (with 10

mA increments). Because of the high internal quantum

efficiency of sample B, the peak wavelength of sample B

is more stable than that of sample A. As DC current in-

creases from 20 mA to 100 mA, the peak wavelength of

sample A changes 4.4 nm from 647.2 nm to 651.6 nm,

while that of sample B is only 1.2 nm from 647.4 nm to

648.6 nm. Both samples show a same variability of the

spectral purity with the current increment, that is the

typical characteristics of RCLEDs [2]. When the injected

current increases from 20 mA to 100 mA, the full width

at half maximum (FWHM) of the spectrum increases

from 13 nm to 14.5 nm for sample B, and for sample A

that is from 12.5 nm to 13.8 nm.

3. Summary

In summary, both 650 nm RCLED samples with different

cavity structures have been fabricated. Experimental re-

sults show that for the sample with cladding layer cavity,

an external quantum efficiency as high as 7.4% has been

reached at 20 mA due to the high internal quantum effi-

ciency, meanwhile, the sample also has a high stability of

the peak wavelength and the spectral purity with the cur-

rent increment. The cavity design, especially for 650 nm

RCLEDs with AlGaInP and AlGaAs materials, is very

important to get high external quantum efficiency.

REFERENCES

[1] C. P. Kuo, R. M. Fletcher, T. D. Osentowski, M. C.

Lardizabal and M. G. Craford, “High Performance Al-

GalnP Visible Light-Emitting Diodes,” Applied Physics

Letters. Vol. 57, No. 27, 1990, 2937.

doi:10.1063/1.103736

[2] E. F. Schubert, Y. H. Wang, A. Y. Cho, L. W. Tu and G.

J. Zydzik, “Resonant Cavity Light-Emitting Diode,” Ap-

plied Physics Letters, 1992, Vol. 60, No. 8, 106489.

doi:10.1063/1.106489

[3] Y. A. Chang, C. L. Yu, I. T. Wu, H. C. Kuo, T. C. Lu, F.

I. Lai, L. W. Laih, L. H. Laih and S. C. Wang, “Design

and Fabrication of Temperature-Insensitive InGaP-InGaA

IP Resonant-Cavity Light-Emitting Diodes,” 2006 IEEE

Photonics Technology Letters, Vol. 18, No. 16, 1690.

doi:10.1109/LPT.2006.879931

[4] J. R. Chen, T. S. Ko, T. C. Lu, Y. A. Chang, H. C. Kuo,

Y. K. Kuo, J. Y. Tsai, L. W. Laih and S. C. Wang, “Fab-

rication and Characterization of Temperature Insensitive

660 nm Resonant-Cavity LEDs,” IEEE Journal of Light-

Wave Technology, Vol. 26, No. 13, 2008, 1891.

doi:10.1109/JLT.2008.920639

[5] H. Fardi, M. Jan, B. Van Zeghbroeck, 2012, Photovoltaic

Specialists Conference. 16 785

[6] E. F. Schubert, N. E. J. Hunt, R. J. Malik, M. Micovic and

D. L. Miller, “Temperature and Modulation Characteris-

Copyright © 2013 SciRes. OPJ