Detection, 2013, 1, 7-12 http://dx.doi.org/10.4236/detction.2013.11002 Published Online July 2013 (http://www.scirp.org/journal/detection) 7 Preparation of Reference Material for Proficiency Test for Enumeration of Coliforms in Cheese Matrix Marcelo Luiz Lima Brandão1*, Carla de Oliveira Rosas1, Silvia Maria Lopes Bricio1, Valéria de Mello Medeiros1, Juliana de Castro Beltrão da Costa1, Rodrigo Rollin Pinheiro1, Paola Cardarelli-Leite1, Marcus Henrique Campino de La Cruz2, Armi Wanderley da Nóbrega2 1Laboratory of Products, Department of Microbiology, National Institute of Quality Control in Health, Oswaldo Cruz Foundation, Rio de Janeiro, Brazil; 2Proficiency Testing Program of Products Subject to Health Surveillance, National Institute of Quality Control in Health, Oswaldo Cruz Foundation, Rio de Janeiro, Brazil. Email: *marcelo.brandao@incqs.fiocruz.br Received June 6th, 2013; revised July 10th, 2013; accepted July 17th, 2013 Copyright © 2013 Marcelo Luiz Lima Brandão et al. This is an open access article distributed under the Creative Commons Attribu- tion License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. ABSTRACT It is widely accepted that quantitative reference materials (RM), are indispensable tools for verification of the precision and accuracy of analytical measurements. The RM can be used by food microbiology laboratories, as part of their qual- ity assurance programmes, to achieve their quality control. In Brazil, Anvisa RDC No. 12/01 specifies the enumeration of coliforms as one of the parameters for evaluating cheese quality. The aim of this study was to produce a quantitative RM for proficiency testing (PT) for use in the testing of enumeration of coliforms in cheese matrixes. A sample of an ultra-filtered cheese with a coliforms count of <3.0 MPN/g and a total n˚ of viable aerobes of 1.2 × 103 CFU/g was used as the matrix to produce the RM. The ultra-filtered cheese matrix was distributed in flasks, contaminated with a specific concentration of an Escherichia coli strain and submitted to freeze-drying. Sucrose was used as the cryo-protector. The RM produced was considered sufficiently homogeneous and stable at ≤ −70˚C during the entire study period (348 days). The material was also considered sufficiently stable at 4˚C for six days, but instable at 30˚C and 35˚C for the same pe- riod. At −20˚C the RM was sufficiently stable for 161 days. It was concluded that the material showed all the necessary requirements for a quality RM to be used as PT items and could be transported to the laboratories taking part in a PT at up to 4˚C for up to 6 days, since the results indicated maintenance of the cell concentrations during this period. This is the first study to describe a methodology for producing RM containing coliforms in a cheese matrix. Keywords: Coliforms; Cheese; Reference Material; Proficiency Test 1. Introduction Food safety and quality are two of the most important factors determining the consumer acceptance and pur- chase dynamics of a product. Laboratories of food mi- crobiology are extremely important in the performance of productive sector and for the control of the sanitary-hy- gienic quality. Official food control laboratories are re- quired to use validated methods wherever possible. For this reason, analytical methods must be subjected to in- ternal and/or external validation studies [1]. It is widely accepted that quantitative reference mate- rials (RM), are indispensable tools for verification of the precision and accuracy of analytical measurements [2]. The RM can be used by food microbiology laboratories, as part of their quality assurance programmes, to achieve their quality control, method validation, staff training control and evaluation of the laboratory’s performance [3]. Furthermore, they are employed in laboratory ac- creditation, as well as in the establishment of traceability in the framework of internationally agreed standards [1]. The formal recognition of the technical competence of assay laboratories, including food microbiology labora- tories, is done by accreditation to the ISO/IEC 17025 standard [4]. The use and traceability of RM, as well as the laboratory participation in proficiency testing (PT) schemes by interlaboratory comparisons are requirements of the aforementioned standard [4]. According to ISO guide 35, a RM is a “material, suffi- *Corresponding author. Copyright © 2013 SciRes. Detection  Preparation of Reference Material for Proficiency Test for Enumeration of Coliforms in Cheese Matrix 8 ciently homogeneous and stable with respect to one or more specific properties, which has been established to be fit for its intended use in a measurement process” [5]. To be considerate RM for food microbiology exams, the number of organisms present must be distributed homo- geneously over the units of the batch and must remain stable over a determinate period of time [2]. A great variety of techniques and matrix supports have been used to produce homogenous and stable micro- biological RM. Spray-dried is a common technique used to prepare large batch of contaminated milk powder cap- sules [6,7]. The freeze-drying by lyophilization has also been used in the production of RM in the field of food microbiology [8-11]. The main challenge in RM produc- tion destined to microbiological assays is the natural in- stability of micro-organisms, which difficult the devel- opment and maintenance of these RM [2]. The principal advantage of the lyophilized material is to allow storage for long periods with low risk of contamination. How- ever, these methods cause damage to the microbial cells and the survival rate of many micro-organisms is low after the rehydration [12]. To circumvent these problems, some authors emphasize the importance of the use of cryo-protector, such as carbohydrates, during the pro- cesses of freezing and desiccation, with the goal of increasing the viability of bacterial cells [13]. Sucrose has been one of the most commonly carbohydrate used and presented satisfactory results in the production of food RM containing micro-organisms [11]. In Brazil, the Anvisa RDC No. 12/01 specifies the enumeration of coliforms as one of parameters for evalu- ating cheese quality [14]. Soon, food microbiology laboratories in Brazil must be able to perform this testing and provide reliable results.This study aimed to present and discuss the preparation of a quantitative RM for PT for use in enumeration assays of coliforms in cheese ma- trixes. 2. Materials and Methods The RM was prepared following ISO guide 34 “General requirements for the competence of reference materials producers” [15]. 2.1. Strain The E. coli type I strain No. 03 was used to produce the RM. This strain was isolated from a sample of whole fresh lettuce and his identity was determinate with Vitek®2 Compact (bioMérieux), API 20E (bioMérieux) and classic method IMViC (++--), where I = indole production, M = methyl red reaction, V = Voges- Proskauer reaction (production of acetoin), and C = citrate utilization [16]. This strain was deposited in the Collection of Reference Micro-organisms in Health Surveillance in INCQS/Fiocruz. 2.2. Selection of the Matrix An ultra-filtered cheese sample previously analyzed and confirmed free of coliforms (<3.0 MPN/g) was used as matrix to produce the RM. The total viable aerobic microbial load in this matrix was also evaluated by pour-plate technique described by Maturin and Peeler [17]. Two grams of the ultra-filtered cheese matrix were weighed into sterile glass vials of 10 mL capacity (Schott, Brazil) until a total of 216 vials. The vials were frozen at freezer ≤−70˚C (Thermo, USA) for 24 h and lyophilized for 24 h below −105˚C under pressure lower than 13 Pa (0.1 mmHg; Liotop, São Carlos, SP, Brazil). 2.3. Preparation of the Reference Material The E. coli strain (item 2.1) was streaked for purity on sheep blood agar (Merck, Germany) and incubated for 24 h at 35˚C ± 2˚C. After incubation, a single colony was suspended in 10 mL brain heart infusion broth (Merck, Germany) and incubated for 24 h at 35˚C ± 2˚C. Then, 0.5 mL of the culture were transferred to 15 mL of Luria Bertani broth (Difco, USA) with 10% of NaCl and incubated for 28 h at 35˚C ± 2˚C. After, the culture was centrifuged, and the pellet washed, three times, with 0.1% peptone saline solution (PSS) and suspended with 2 mL of PSS. The concentration of the suspension was adjusted using a colorimeter (Libra S2, Biochrom, England) at 520 nm until a transmission value of 2% (approximately 5 × 109 cells/mL) and diluted in PSS to achieve a concentration of 5 × 105 cells/mL. Two milli- liters of the cell suspension were added to 198 mL of PSS containing 100 mM sucrose (used as cryo-protector) and homogenized in a magnetic stirrer (PC-410, Corning, USA) for 30 min in an ice bath. Portions (0.5 mL) were distributed into sterile glass vials containing the lyo- philized cheese (item 2.2), frozen at ≤−70˚C for 24 h and lyophilized for 24 h below −105˚C under pressure lower than 13 Pa (0.1 mmHg; Liotop, São Carlos, SP, Brazil). The vials were numbered and sealed with aluminum caps under vacuum and stored at ≤−70˚C. 2.4. Microbiological Examinations The cell quantification of vials was realized using the solid medium method described in the Bacteriological Analytical Manual—FDA [16]. The freeze-dried material was reconstituted with 2.0 mL of 0.1% PSS and incubated at room temperature. After 15 min, the matrix was transferred to a sterile plastic bag filter (Nasco, USA) followed by addition of 16 mL of 0.1% SSP to reach the proportion 1:10. The bag was homogenized in stomacher apparatus (Seward, Fisher Scientific, Canada) for 1 min. Copyright © 2013 SciRes. Detection  Preparation of Reference Material for Proficiency Test for Enumeration of Coliforms in Cheese Matrix Copyright © 2013 SciRes. Detection 9 Aliquots of 1.0 mL were plated, in duplicate, by pour- plate technique, in 10 mL of Violet red bile agar (VRBA) (Difco, USA) until solidification. After this time, a 10 mL VRBA overlay was added, and the plates were incubated at 35˚C ± 2˚C for 24 h. Later, the purple-red colonies on plates were enumerated and the counts were converted to log10/g. 2.5. Homogeneity Assessment For the homogeneity study, 24 vials taken randomly were enumerated under repeatability conditions, using the methodology described previously (item 2.4). The data were subjected to statistical analysis described in the International Harmonized Protocol for the Proficiency Testing of Analytical Chemistry Laboratories [18] as- signing a standard deviation for proficiency assessment (σp) of 0.35. The material was considered homogeneous if: 2 sam c; where 2 am is the between-sample variance of the batch, and c is the critical value. 2.6. Stability Assessment Two types of stability tests were done: a long-term stability test at reference temperature (≤−70˚C) and at storage temperature (−20˚C); and a short-term stability test at higher temperatures simulating transport con- ditions (4˚C, 30˚C and 35˚C). The enumeration assays were realized using the methodology described pre- viously (item 2.4). For testing the stability of the material stored at ≤−70˚C, 26 vials were examined, two per assay, at regular times intervals until a total of 348 days (classic approach) [5]. For testing the stability at −20˚C, 22 vials were stored at −20˚C and two vials stored at ≤−70˚C (0 day) were examined, two per assay, at regular times intervals until a total of 161 days (classic approach) [5]. The stability of the material stored at high temperatures was determined at 4˚C, 30˚C and 35˚C. Once a day, over a period of three days and in the sixth day, two vials were stared at each storage temperature. All vials and two vials stored at ≤−70˚C (0 day) were examined at the end of the study period (isochronous stability study) [19]. The counts obtained for each storage temperature were log10 transformed and analyzed using linear regression [5]. 3. Results and Discussion 3.1. Preparation of the Reference Material A bath of 216 units of RM containing E. coli was manufactured and tested for their quality. Although it is known that PT samples should resemble as closely as possible to routine samples analyzed by participant laboratories, it is a common practice to produce lyophi- lized samples in order to improve analyte stability [9- 11,20]. All vials presented vacuum and satisfactory appearance after freeze-drying. The freeze-drying pro- cess was considered satisfactory, since the integrity of the product was not compromised over time as demon- strated by the stability profile shown by the reference material. The ultra-filtered cheese sample presented a number of total viable aerobic micro-organisms of 1.2 × 103 CFU/g. The presence of natural competing micro-organisms in the RM is important to demonstrate the real ability of the laboratory to enumerate the target(s) micro-organism(s) in a food sample [6]. 3.2. Homogeneity of the Reference Material The results of the analyses of the homogeneity study are presented in Table 1. The Cochran test did not identified outliers counts. The results of the homogeneity studies were obtained using one-factorial analysis of variances (1-way ANOVA). As the criteria 2 sam c is met, the bath was considered sufficiently homogenous, with a confidence level of 95%. The freeze-drying process has already been success- fully used in the production of homogeneous RM in skim milk matrix [9,10]. A homogeneous RM produced in this same ultra-filtered cheese matrix containing coagulase- positive staphylococcus (CPS) was also been described [11]. The publication of others studies about production of RM in other types of food matrix is rare due to the difficulties in obtaining homogeneous and stable materi- als and because the some producers do not have interest in disclosing their production techniques. In this study, the procedure developed has succeeded in producing a sufficiently homogeneous RM containing E. coli in ul- tra-filtered cheese matrix. 3.3. Stability of the Reference Material The results of the long-term stability analyses from May 2012 to March 2013 at ≤−70˚C and from June 2012 to November 2012 at −20˚C are present in Figure 1. Figure 2 presents the results of the stability test at higher temperatures, simulating transport conditions, over a period of 6 days. The material was considered stable at ≤−70˚C, −20˚C Table 1. Summary of the statistical results from homogeneity studies of test materials containing coliforms. Analyte Average (log10 CFU/g) σp (log10 CFU/g) 2 all 2 am 2 am c Result Coliforms 2.65 0.35 0.011 0,0040 0.017 0.019 Sufficiently homogenous  Preparation of Reference Material for Proficiency Test for Enumeration of Coliforms in Cheese Matrix 10 Figure 1. Results of stability tests at reference and storage temperatures: (), ≤−70˚C; (), −20˚C. Each point corresponds to the mean count of two RM units (in log10 CFU/g per unit). Figure 2. Results of stability tests at various temperatures: (), 4˚C; (), 25˚C; (), 35˚C over a period of 6 days. Each point corresponds to the mean count of two RM units (in log10 CFU/g per unit). and 4˚C according to ISO guide 35 [5], since no signifi- cant change in number of CFU over the period tested when using linear regression. As zero value is within the confidential interval, the slope is not statistically signi- ficant, and there were no detectable changes in coliforms concentration in the course of the study times. However, the RM was not stable at the high temperatures of 30˚C and 35˚C (Table 2). Bacterial counts of the long-term stability test at ref- erence and storage temperature were stable for almost 1 year and half a year, respectively. The variability in number of CFU observed is regarded as of no, or minor, importance because the values of the slope for both tem- peratures are very small (Table 2). Literature data show that RM produced in lyophilized skim milk matrix are stable for periods up to 237 days stored at ≤−70˚C [9,10]. In cheese matrix, Brandao et al. [11] obtained a RM containing CPS stable for 10 mouths at ≤−70˚C. Similar results were obtained in this study, where the RM batch produced was stable for 348 days (12 mouths). The RM also remained stable at −20˚C throughout the study period, with a value of slope similar to the reference temperature (Table 2). This result indicates that the RM likely to remain stable in this condition for a longer period of time. Rosas et al. [9] observed that the storage for long periods at −20˚C can compromise the stability of freeze-dried skim milk RM. These authors have produced two batches containing Salmonella spp. stable for three months, but with a tendency to decrease in cell concentration, and one year after the RM did have insufficiently stability. This result indicates that the material containing E. coli produced in this study has a more lasting stability than those produced by Rosas et al. [9]. This observation may be related to the fact that the use of sucrose as a cryo-protector may have provided greater stability of micro-organisms in the matrix, since in the study realized by Rosas et al. (2010) no cryo-pro- tector additive was added to the matrix. This observation was also reported by Brandao et al. [11], that used this cryo-protector to produce a RM containing CPS stable at −20˚C for 48 days with a value of the slope of 0.00075 CFU/g per day. Sucrose was selected as cryo-protector in this study because is the most frequently carbohydrate used to preserve micro-organisms by freeze-drying [13]. Copyright © 2013 SciRes. Detection  Preparation of Reference Material for Proficiency Test for Enumeration of Coliforms in Cheese Matrix 11 Table 2. Linear regression of the stability studies. 95% Confidence interval Storage temperature Time of storage (days) Slope per day (CFU/g) Lower Higher Result −70˚C 348 0.00034 −0.00027 0.00095 Sufficiently stable −20˚C 161 −0.00067 −0.0021 0.00072 Sufficiently stable 4˚C 4 −0.019 −0.12 0.080 Sufficiently stable 30˚C 4 −0.025 −0.046 −0.0044 Insufficiently stable 35˚C 4 −0.13 −0.22 −0.046 Insufficiently stable The production of stable RM for longer extended to higher temperatures is important because not all labora- tories have equipment to store the samples at ≤−70˚C. Thus, the laboratories that acquire these RM could store them in more usual equipment such as common freezers and use them on a higher shelf life. A short-term stability was performed in order to assess the possible effect of transport at different temperatures on the stability of the material. The stability data at 4˚C indicate that normal (air) mail with cooling of the RM is possible for shipment to other laboratories if the transport time is limited to six days. At high temperatures (30˚C and 35˚C) the RM was not stable in the period of six days. These results were different from those obtained by Brandao et al. [11] who observed stability at 35˚C for up to 4 days. This observation may be related to the fact that Gram-negative bacteria, as in the case the strain E. coli, usually showed a greater rate of decline than Gram- positive bacteria [8,21], like the strain of Staphylococcus aureus subsp. aureus used by Brandao et al. [11]. The instability of the RM at temperatures ≥30˚C limits the transportation of PT items at room temperature. Further studies are needed to increase the resistance of micro- organisms to higher temperatures, since the transport under refrigeration enhances the final cost of PT. According to the databases consulted in the literature, the present study was the first to describe a methodology for the production of RM containing E. coli in cheese matrix. The development of methodologies for the pro- duction of RM in different matrices and containing the various classes of micro-organisms of interest in public health is important to increase the scope of the PT programs and consequently improving the quality of the analytical laboratories of food microbiology. 4. Conclusion This paper describes the development of the first quan- titative RM containing E. coli in cheese matrix produced by freeze-drying. The spiked material showed adequate homogeneity and stability and it is applicable for a PT. As proved stable under the used stored conditions, re- maining PT items can be provided as internal quality control materials. As long as this batch of RM is avail- able for use, the monitoring of its stability will continue. 5. Acknowledgements Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), Inovatec/Fiocruz and INCQS/Fio- cruz for financial support. REFERENCES [1] M. Koch, W. Bremser, R. Köppen, R. Krüger, T. Rasenko, D. Siegel and I. Nehls, “Certification of Reference Mate- rials for Ochratoxin A Analysis in Coffee and Wine,” Ac- creditation Quality Assurance, Vol. 16, No. 8-9, 2011, pp. 429-437. doi: 10.1007/s00769-011-0783-0 [2] W. J. Philipp, P. van Iwaarden, H. Schimmel, N. Meeus and N. Kollmorgen, “Development of Reference Materi- als for Microbiological Analysis,” Accreditation Quality Assurance, Vol. 12, No. 3-4, 2007, pp. 134-138. doi: 10.1007/s00769-006-0244-3 [3] M. Abdelmassih, V. Planchon, C. Anceau and J. Mahillon, “Development and Validation of Stable Reference Mate- rials for Food Microbiology Using Bacillus cereus and Clostridium perfringens Spores,” Journal of Applied Mi- crobiology, Vol. 110, No. 6, 2011, pp. 1524-1530. doi:10.1111/j.1365-2672.2011.05007.x [4] ISO/IEC 17025, “General Requirements for the Compe- tence of Testing and Calibration Laboratories,” ISO, Ge- neva, 2005. [5] ISO Guide 35, “Reference Materials—General and Statis- tical Principles for Certification,” ISO, Geneva, 2006. [6] P. H. in’t Veld, S. H. W. Notermans and M. van de Berg, “Potential Use of Microbiological Reference Materials for the Evaluation of Detection Methods for Listeria mono- cytogenes and the Effect of Competitors: A Collaborative Study,” Food Microbiology, Vol. 12, No. 2, 1995, pp. 125-134. [7] P. H. in’t Veld, A. H. Havelaar and N. G. W. M. van Strijp-Lockefeer, “The Certification of a Reference Mate- rial for the Evaluation of Methods for the Enumeration of Bacillus cereus,” Journal of Applied Microbiology, Vol. 86, No. 2, 1999, pp. 266-274. doi:10.1046/j.1365-2672.1999.00661.x Copyright © 2013 SciRes. Detection  Preparation of Reference Material for Proficiency Test for Enumeration of Coliforms in Cheese Matrix 12 [8] M. Peterz and A. C. Steneryd, “Freeze-Dried Mixed Cul- tures as Reference Samples in Quantitative and Qualita- tive Microbiological Examinations of Food,” Journal of Applied Bacteriology, Vol. 74, No. 2, 1993, pp. 143-148. doi:10.1111/j.1365-2672.1993.tb03007.x [9] C. O. Rosas, M. L. L. Brandao, S. M. L. Bricio, V. M. Medeiros, S. P. C. Bernardo, M. H. C. De La Cruz and P. Cardarelli-Leite, “Desenvolvimento de Material de Ref- erência para Ensaio de Proficiência em Microbiologia de Alimentos,” Revista do Instituto Adolfo Lutz, Vol. 69, No. 1, 2010, pp. 15-22. [10] M. L. L. Brandao, C. O. Rosas, S. M. L. Bricio, J. C. B. Costa, V. M. Medeiros and M. B. Warnken, “Produção de Materiais de Referência para Avaliação de Métodos Microbiológicos em Alimentos: Estafilococos Coagulase Positiva e Listeria spp. em leite em pó,” Revista Analytica, Vol. 63, 2013, pp. 60-71. [11] M. L. L. Brandao, J. C. B. Costa, F. M. Farias, C. O. Rosas, S. M. L. Bricio, J. S. Nascimento and P. Card- arelli-Leite, “Development of Reference Material for the Microbiology of Foods Containing Coagulase-Positive Staphylococcus in a Cheese Matrix,” Brazilian Journal of Food Technology, Vol. 16, No. 1, 2013, pp. 73-79. doi:10.1590/S1981-67232013005000006 [12] C. A. Morgan, N. Herman, P. A. White and G. Vesey, “Preservation of Micro-Organisms by Drying: A Review,” Journal of Microbiology Methods, Vol. 66, No. 2, 2006, pp. 183-193. doi:10.1016/j.mimet.2006.02.017 [13] Z. Hubálek, “Protectants Used in the Cryopreservation of Microorganisms,” Cryobiology Methods, Vol. 46, No. 3, 2003, pp. 205-229. doi:10.1016/S0011-2240(03)00046-4 [14] Brasil, “Ministério da Saúde, Agência Nacional de Vigi- lância Sanitária,” RDC No. 12, 26 January 2001. [15] ISO Guide 34, “General Requirements for the Compe- tence of Reference Materials Producers,” ISO, Geneva, 2009. [16] P. Feng, S. D. Weagant, M. A. Grant and W. Burkhardt, “2002, Chapter 4. Enumeration of Escherichia coli and the Coliform Bacteria,” In: Food and Drug Administra- tion (FDA), Bacteriological Analytical Manual Online, 8th Edition, Silver Spring, Berlin, 1998. [17] L. Maturin and J. T. Peeler, “2001, Chapter 3. Aerobic Plate Count,” In: Food and Drug Administration (FDA), Bacteriological Analytical Manual Online, 8th Edition, Silver Spring, Berlin, 1998. [18] M. Thompson, S. L. R. Ellison and R. Wood, “Interna- tional Harmonized Protocol for Proficiency Testing of (Chemical) Analytical Chemistry Laboratories,” Pure and Applied Chemistry, Vol. 78, No. 1, 2006, pp. 145-196. doi:10.1351/pac200678010145 [19] A. Lamberty, H. Schimmel and J. Pauwels, “The Study of the Stability of Reference Materials by Isochronous Meas- urements,” Fresenius Journal Analytical Chemistry, Vol. 360, No. 3-4, 1998, pp. 359-361. doi:10.1007/s002160050711 [20] B. F. Spisso, M. A. Monteiro, M. U. Pereira, R. G. Fer- reira, R. P. da Costa, B. S. Carlos, S. T. C. Negris, M. H. C. De La Cruz and A. W. da Nóbrega, “Preparation of In-House Reference Material of Benzylpenicillin in Milk and Results of a Brazilian Proficiency Testing Scheme,” Accreditation Quality Assurance, 2013. (in Press) doi:10.1007/s00769-013-0982-y [21] P. Wessman, D. Mahlin, S. Akhtar, S. Rubino, K. Leifer, V. Kessler and S. Hákansson, “Impact of Matrix Proper- ties on the Survival of Freeze-Dried Bacteria,” Journal of Scientific and Food Agriculture, Vol. 91, No. 14, 2011, pp. 2518-2528. doi:10.1002/jsfa.4343 Copyright © 2013 SciRes. Detection

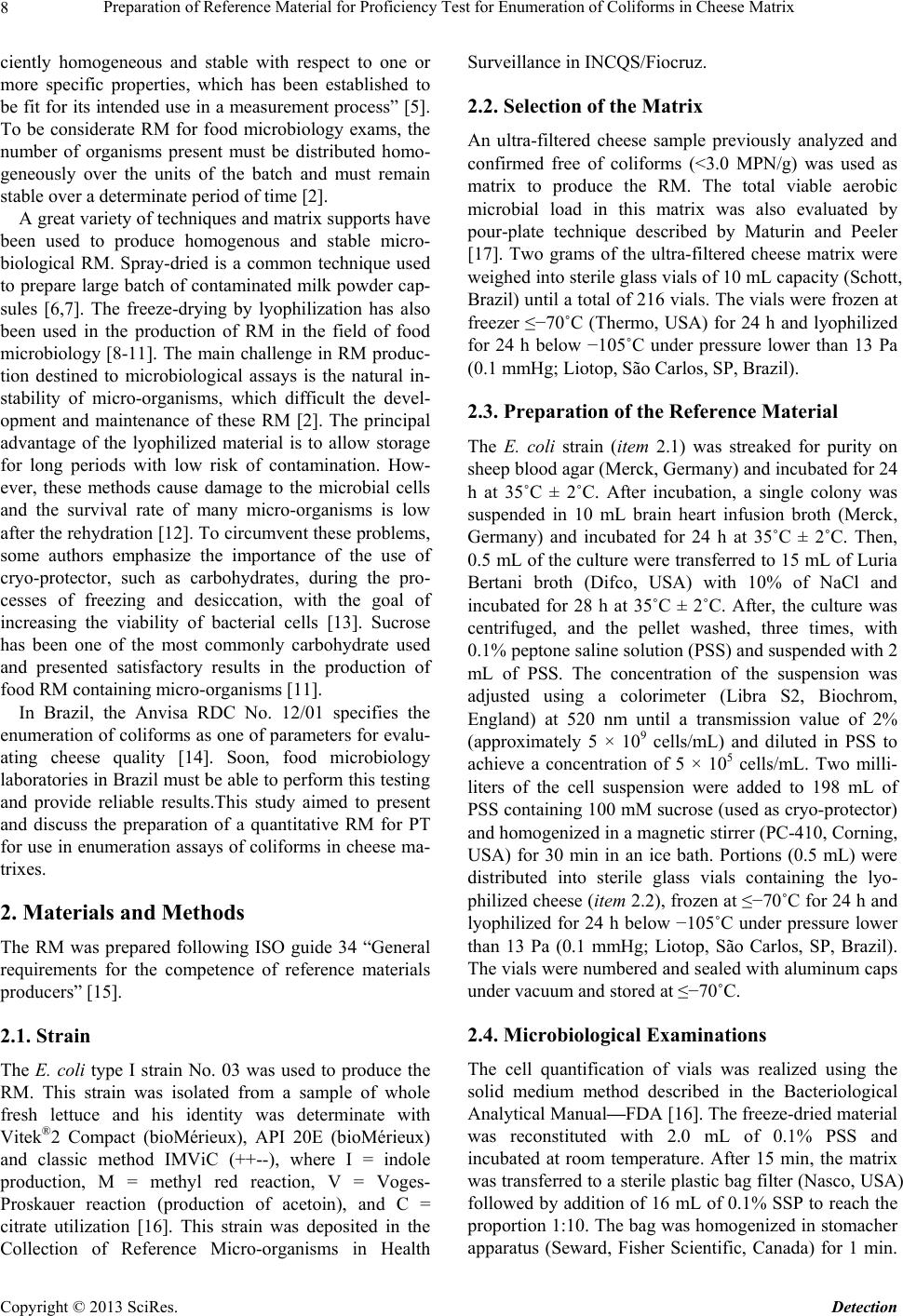

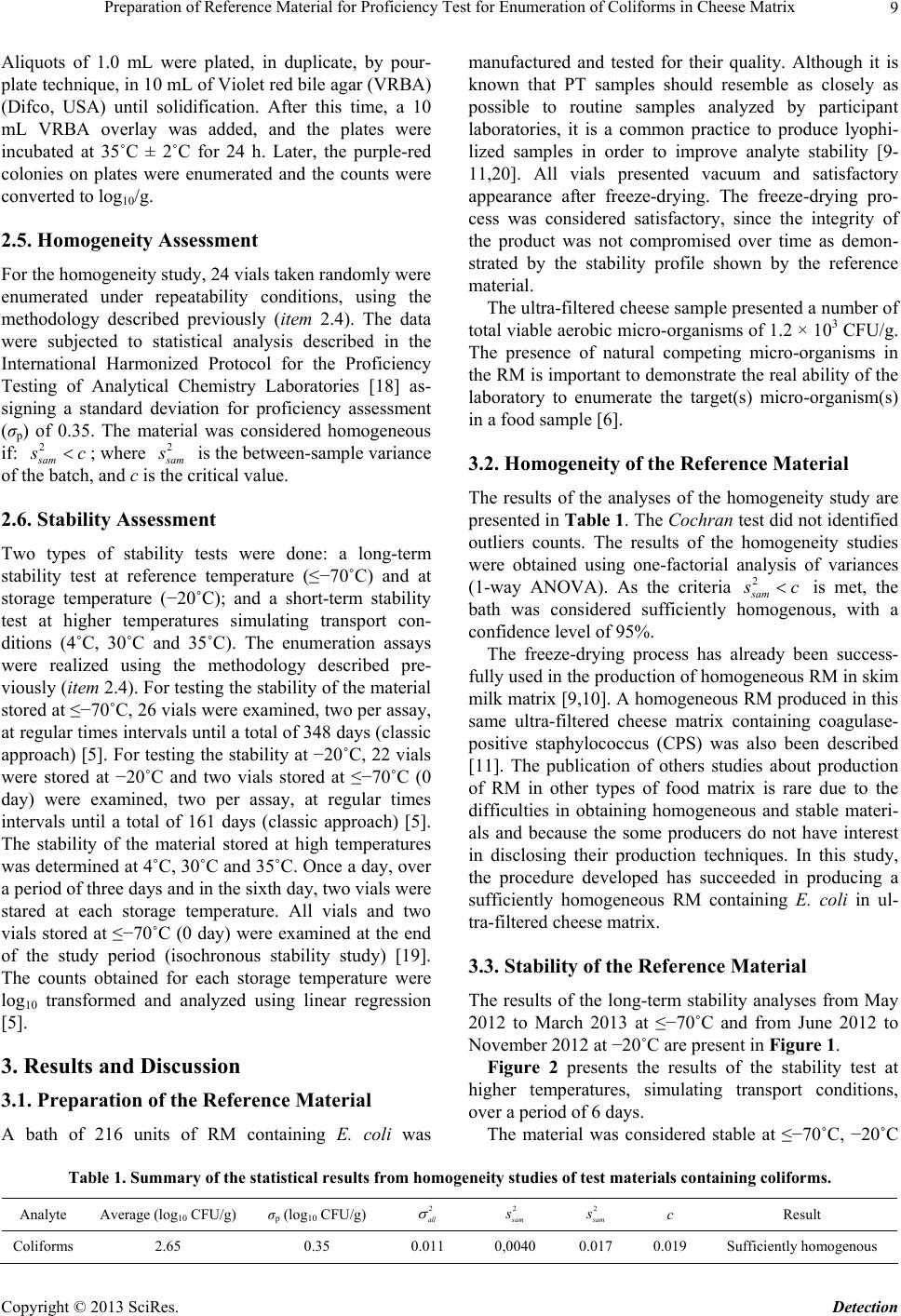

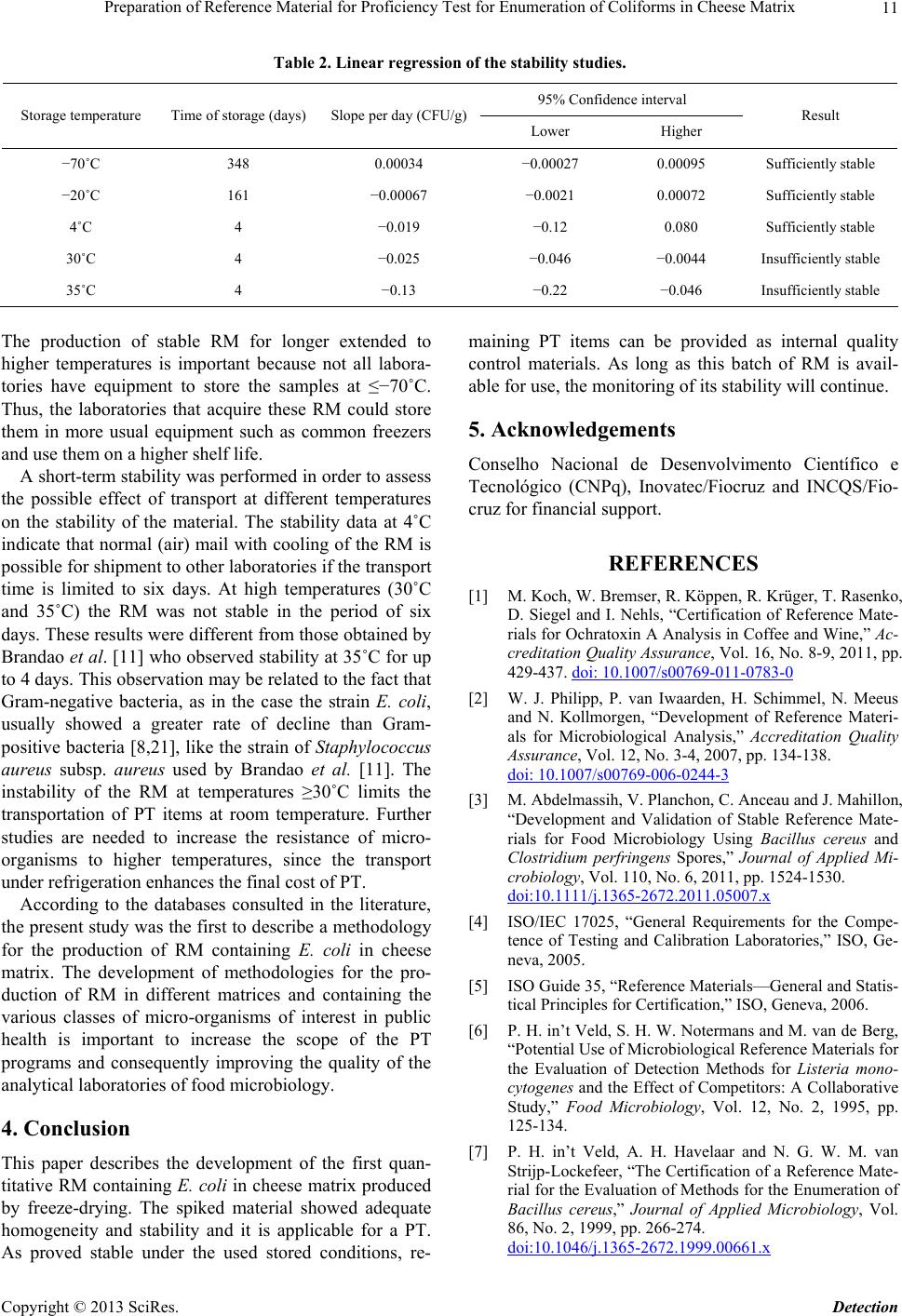

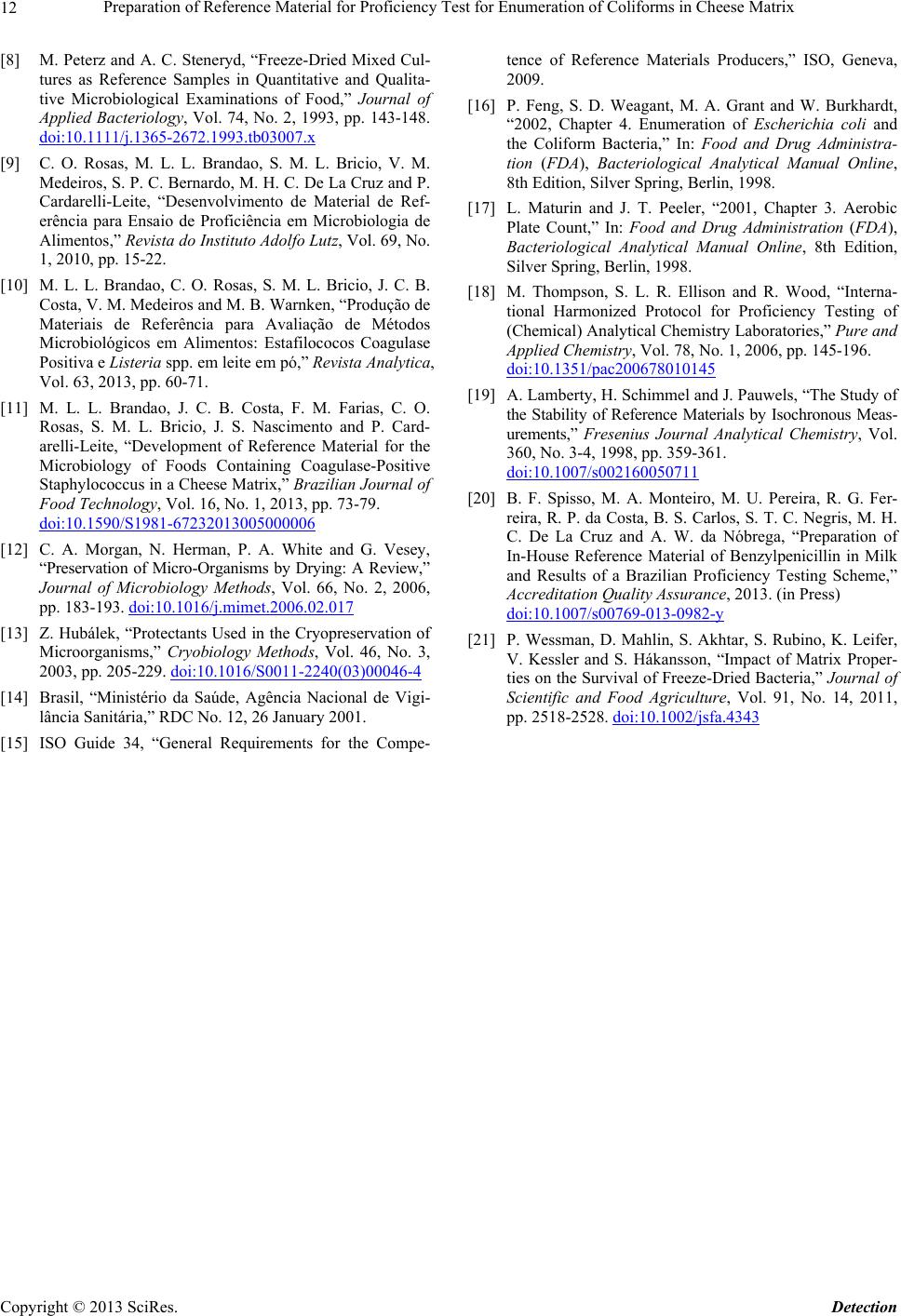

|