Food and Nutrition Sciences, 2013, 4, 721-726 http://dx.doi.org/10.4236/fns.2013.47092 Published Online July 2013 (http://www.scirp.org/journal/fns) Use of Starter Cultures in Olives: A Not-Correct Use Could Cause a Delay of Performances Marianne Perricone, Maria Rosaria Corbo, Milena Sinigaglia, Antonio Bevilacqua* Department of Agriculture, Food and Environmental Science, University of Foggia, Foggia, Italy. Email: *a.bevilacqua@unifg.it, *abevi@libero.it Received December 10th, 2012; revised January 13th, 2013; accepted January 21st, 2013 Copyright © 2013 Marianne Perricone et al. This is an open access article distributed under the Creative Commons Attribution Li- cense, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. ABSTRACT The role of lactic acid bacteria for a correct course of fermentation of table olives has been extensively reviewed and it is a common idea that the inoculum of selected strains could exert a strong benefit for product quality; however, the basic assumption of this research is that a not-correct preparation of starter could affect its performances in brines and delay the benefit of a starter inoculum. Thus, some selected strains of LAB (lactic acid bacteria) and yeasts were inocu- lated into brines of Bella di Cerignola olives (Spanish style), as a single starter (LAB or yeasts) or a combined prepara- tion (LAB + yeasts) and compared to a natural fermentation, focusing on the performances of the process (acidification, production of lactic acid) and trying to verify the basic assumption. LAB and yeasts were grown in the opportune lab media and then directly inoculated in brine after the lye treatment. LAB exerts a kind of benefit (increased content of lactic acid) only for 2 - 3 weeks; then, the inoculated samples behave in the same way as not-inoculated ones. Thus, this research underlined that a starter culture, not prepared in the correct way, could not be useful to guide the fermenta- tion. Keywords: Olives; Lactic Acid Bacteria; Yeasts; Delay in Fermentation; Starter 1. Introduction Fermentation of table olives starts spontaneously and is strongly influenced by olive cultivar, indigenous micro- biota and methodological factors, such as temperature and salt concentration in the brine [1]. Moreover, olive fermentation relies on a complex mi- crobiota, including Enterobacteriaceae, lactic acid bacte- ria and other genera of Gram positive microorganisms and yeasts; the traditional fermentations are usually based on the maintenance of this association [2]. In a natural olive fermentation after an initial stage, characterised by the growth of Gram negative bacteria, lactic acid bacteria and yeasts coexist until the end of fermentation; in particular, in Bella di Cerignola olives, yeasts were found at concentrations of approximately 5 - 6 log·cfu/g on olives and 6 log·cfu/ml in the brines [3,4]. On the other hand, Hernandèz, Martin, Aranda, Pèrez- Nevado and Còrdoba [5] recovered a yeast number of about 3.0 log·cfu·g/l and 4.9 log·cfu/ml in Spanish green olives and their brines, respectively. The role of lactic acid bacteria for a correct course of fermentation of table olives has been extensively reviewed and it is a common idea that the inoculum of selected strains could exert a strong benefit for product quality [2]. For a better course of the process and to control natu- rally occurring microflora, many authors recommended the inoculation of brine with commercial strains; the use of suitable Lactobacillus plantarum starter cultures has the potential to improve the microbiological control of the process, increase the lactic acid yield and, accord- ingly, provide the production of Spanish-style fermented green olives of consistently high quality [6]. Recently, some authors proposed a mixed starter, containing a com- bination of LAB and yeasts [4]. During the fermentation, weak acidification rates are often registered, because most of the sugars and nutrients are lost by the effect of lye treatment and strong washing, thus pH is often unsuitable for a safe storage of product [7]. However, many times a delay or a lack of fermentation of olives, especially those of the Manzanilla variety, oc- curs and there is no explanation for this phenomenon; many variables can affect the progress of lactic acid fer- mentation such as salt concentration, temperature, nutria- *Corresponding author. Copyright © 2013 SciRes. FNS  Use of Starter Cultures in Olives: A Not-Correct Use Could Cause a Delay of Performances 722 nutrient content, inhibitors and others. Earlier investiga- tions related the difficulties of LAB growth in olive brines with the presence of polyphenols [8]. However, many times the incomplete acidification can- not be related to phenols (Bevilacqua, unpublished re- sults); the basic assumption of this research is that a not- correct preparation of starter could affect its perform- ances in brines and delay the benefit of a starter inocu- lum. Thus, some selected strains of LAB and yeasts were inoculated into brines of Bella di Cerignola olives, as a single starter (LAB or yeasts) or a combined preparation (LAB + yeasts) and compared to a natural fermentation, focusing on the performances of the process (acidifica- tion, production of lactic acid) and trying to verify the basic assumption. 2. Materials and Methods 2.1. Strains 4 strains of Lactobacillus plantarum were used in this study: the strains c1, c16 and c19 isolated from a natural fermentation of Bella di Cerignola olives [9], whereas the isolate DSMZ 2601 was purchased from a Public Collection (Deutsche Sammlung von Mikroorganismen und Zellkulturen, Braunschweig, Germany). Moreover, 3 strains of Candida spp. (labelled as 22- 51-66 and isolated from a natural fermentation of Bella di Cerignola olives) were used as selected yeasts; in par- ticular the strains 22 and 51 were identified as C. famata, while the strain 66 as C. guilliermondii [2]. The strains of Lb. plantarum, stored at −20˚C in MRS broth (Oxoid, Milan, Italy) added with 33% of sterile glycerol (J.T. Baker, Milan, Italy), were grown over 2 passages in MRS broth, incubated at 30˚C for 48 h. The strains of Candida spp. were maintained on Sabouraud Dextrose Agar slants (Oxoid), stored at 4˚C and trans- ferred monthly; before each assay, the strains were grown in Sabouraud broth (Oxoid), incubated at 25˚C for 48 h. 2.2. Inocula Preparation LAB cocktail was prepared as follows: 50 ml of the cul- ture of each strain were centrifuged at 4000 rpm for 10 min. then, the supernatant was discarded and 50 ml of saline solution (9% of NaCl) was added to the pellet (cell suspension). The cocktail was prepared by mixing 50 ml of cell suspension for each LAB strain to obtain a final volume of 200 ml; this volume was used for the inoculation of 10 l of brine (the level of each strain was about 8 log·cfu/ ml). Concerning yeast cocktail, 70 ml of the culture of each strain were centrifuged at 4000 rpm for 10 min; then, the pellet was suspended in 70 ml of brine. Yeast cocktail was prepared by mixing cell suspension of each strain (ca. 6 - 7 log·cfu/ml), thus attaining a final volume of 210 ml. This suspension was used for the inoculation of 10 l of brine (high inoculum); for the batches inoculated with a low level of yeasts (low inoculum), the suspension was diluted at 5 log·cfu/ml and then used for brine inocula- tion. 2.3. Olive Preparation and Fermentation The fermentation was performed on Bella di Cerignola olives, size GGG (i.e. 70 to 80 olives/kg). After har- vesting, olives were subjected to grading, to remove fruits with visible damages, washed with tap water and treated with lye (1.3%) for 12 to 15 h. After 2 washings (2 to 3 h and 12 to 13 h), olives were brined (9% of NaCl) and inoculated with LAB and/or yeasts. The fermentation took place in vessels of 25 l, con- taining 10 kg of olives and 10 l of brine; olives were maintained dipped in the brines through a grid. The ves- sels were stored at room temperature for the entire fer- mentation and mixed periodically to avoid the formation of a mould layer on the top of the brine. NaCl was checked periodically and maintained for the entire fer- mentation at 8% - 9%. Table 1 shows the different batches prepared for the analysis. Although performed at laboratory level, the conditions used for the fermentation (ratio olive/brine 1:1, use of a grid, mixing periodically the brines, fermentation at room temperature) mimic the conditions encountered through- out olive production in Apulian region. 2.4. Microbiological Analyses Microbiological analyses were performed both on olives and brines throughout the entire fermentation; 20 g of olives were diluted with sterile saline solution (0.9% NaCl) and homogenized through a Sterilmixer (Pbi In- ternational, Milan, Italy) at 16,500 rpm for 2 min. Serial dilutions of olive homogenates and brines were per- formed and plated onto selective media. All the media and the supplements were purchased from Oxoid. Table 1. Batches prepared for the fermentation assays (T, olives; S, brines). T1/S1Control T2/S2 Batch inoculated with LAB (6 - 7 log·cfu/ml) T3/S3 Batch inoculated with yeasts (high inoculum, 5 log·cfu/ml) T4/S4Batch inoculated with LAB and yeasts (high inoculum) T5/S5 Batch inoculated with LAB and yeasts (low inoculum, ca. 3 log·cfu/ml) Copyright © 2013 SciRes. FNS  Use of Starter Cultures in Olives: A Not-Correct Use Could Cause a Delay of Performances 723 The media and the conditions were the following: 1) Mesophilic bacteria: Plate Count Agar (PCA), in- cubated at 30˚C for 24 - 48 h. 2) Spore-former bacteria: PCA, incubated at 30˚C for 24 - 48 h. The evaluation of spore-former bacteria was carried out after heat-shocking olive homogenates and brines at 80˚C for 10 min. 3) LAB: MRS Agar, added with 0.17 g/l of cyclo- heximide (Sigma-Aldrich, Milan, Italy), incubated at 30˚C under anaerobic conditions for 48 - 72 h. 4) Yeasts: Sabouraud Dextrose Agar, added of 0.1 g/l of chloramphenicol (C. Erba, Milan, Italy), incubated at 25˚C for 2 - 4 days. 5) Pseudomonadaceae: Pseudomonas Agar Base, added with CFC selective supplement (containing cetrimide, a selective antibiotic for pseudomonas), incubated at 25˚C for 48 - 72 h. 6) Staphylococci: Baird Parker Agar Base, added with egg yolk tellurite emulsion and incubated at 37˚C for 24 - 48 h. 7) Enterobacteriaceae: Violet Red Bile Glucose Agar (VRBGA), incubated at 37˚C for 18 - 24 h. 2.5. pH Evaluation pH measurements were performed on olive homogenates and brines through a pH-meter Crison 2001 (Crison In- struments, Barcelona, Spain). 2.6. Determination of Organic Acids The content of D- and L-lactic acids, as well as the con- centration of acetic, citric, D- and L-malic acids, D-glu- cose and D-fructose in the brines was determined through enzymatic kits (Megazyme, Bray, Ireland) just after the brining (beginning of the fermentation) and after 7, 21, 28, 35 and 42 days of fermentation. The analyses were performed as suggested by the producer. 2.7. Statistical Analyses All the analyses were performed in duplicate over 2 in- dependent batches, labelled A and B. Data were submit- ted to one-way analysis of variance (one-way ANOVA) and Tukey’s test (P < 0.05) through the software Statis- tica for Windows version 10.0 (Statsoft, Tulsa, Okla., USA). 3. Results 3.1. Microbiology Figure 1(a) reports the growth of lactic acid bacteria (LAB) in olives. In particular, in the batches inoculated with the starter (T2-T4 and T5), cell counts were 4 log·cfu/g higher than in the control after 7 days, whereas the difference was not significant after 21 days, as the population attained 5 to 5.75 log·cfu/g in all the samples, except for the batch inoculated with yeasts (T3) showing a LAB count 1 log·cfu/ml lower. Concerning brines (Figure 1(b)), LAB were ca. 6 log·cfu/ml just after inoculum in the batches T2, T4 and T5. Moreover, after 7 days inoculated samples showed a LAB count higher than un-inoculated ones, while the differences were not significant after 14 days. Figure 2 shows yeast evolution in brine. As expected, after 7 days the highest cell number was observed in the inoculated batches (T3, T4 and T5), with a cell load ranging from 5.6 to 6.6 log·cfu/ml; otherwise, in the un-inoculated samples (T1 and T2) yeast number was approximately 4.3 to 5.3 log·cfu/ml. As reported for LAB, the difference between inoculated and inoculated batches was not significant after 14 days. A similar trend was recovered in olives (data not shown). Enterobacteriaceae were at 3 log·cfu/g in olives and 4 log·cfu/ml in brines, whereas pseudomonads, staphylo- cocci and spore-former bacteria were at low levels (1 - 2 log·cfu/ml) or below the detection limit for the entire running time (data not shown). 3.2. pH Figure 3 shows pH values of olives. After 7 days, olives showed a pH of about 7 in the batches T2, T5 as well as in the control, whereas the pH was ca. 8 in the samples T3 and T4. After 2 week pH was ca 6 - 6.5 and decreased until 5 at the end of fermentation, without significant differences amongst the different samples. A similar trend was recovered in brines (data not shown). 3.3. Organic Acid Content Figures 4(a) and (b) show the concentration of D- and L-lactic acids in the brine; both L- and D-lactic acids increased significantly after 21 days of fermentation, then they decreased by 2 - 3 g/l; namely, in the sample T2 (sample inoculated with LAB) the concentration of L and D-lactic acids was the highest one (9.15 and 4.70 g/l), whereas the acids were at the lowest levels in the sample inoculated with a high level of yeasts. Regarding acetic acid, its concentration increased throughout the entire fermentation, without any differ- ence amongst the various batches (Figure 5). Finally, D-glucose and D-fructose decreased during the fermenta- tion until to about 0.5 g/l or below the detection limit (data not shown). 4. Discussion 4.1. Why This Research? The use of a starter culture could shorten the processing Copyright © 2013 SciRes. FNS  Use of Starter Cultures in Olives: A Not-Correct Use Could Cause a Delay of Performances Copyright © 2013 SciRes. FNS 724 (a) (b) Figure 1. LAB microflora in olives (a) and brines (b). Mean values ± standard deviation. Figure 2. Yeast microflora in brines. Mean values ± standard deviation. time for the preparation of naturally green olives and affects positively fermentation, acidification rate and flavour of the product [7]. Many food producers select promising strains jointly with Universities and Research Centres; the main result of these collaboration is the selection of “the best strains”. In the past a joint venture of the section of Applied Mi- crobiology (University of Foggia) and some food produc- ers of table olives of Apulian region resulted in the selec- tion of some promising strains of lactic acid bacteria with interesting functional traits [2] and the evaluation of the technological and spoiling impact of yeast strains of Bella di Cerignola table olives [2]. Following these results, Many authors recommended the inoculation of brine with starter colture; in particular, the use of suitable strains of Lb. plantarum could assure a correct course of fermentation [6-9]. Some benefits could be obtained also by a controlled inoculum of yeasts [10]. However, the focus of this study is different, as this research presents a new perspective on the use of starter cultures.  Use of Starter Cultures in Olives: A Not-Correct Use Could Cause a Delay of Performances 725 Figure 3. pH of olives. Mean values ± standard deviation. (a) (b) Figure 4. Content of D- and L-lactic acids (g/l) in the brine. (a) D-lactic acid; (b) L-lactic acid. Mean values ± standard deviation. Figure 5. Content of acetic acid (g/l) in the brine. Mean values ± standard deviation. lactic acid bacteria and yeasts were suggested to produc- ers for a controlled fermentation; however, what hap- pened was that producers reported a decrease of the technological impact of these strains under in vivo condi- tions. After a brief evaluation of the problem in our lab, we supposed that the same strains, showing optimal per- formances in a lab fermentation, could be affected in a real fermentation by the way of the preparation of inocu- lum; thus, we prepared the starters in the same way re- ported by producers (strain cultivation in lab media, fol- lowed by harvesting and cell suspension in brine). The initial planning included also some batches in- oculated with starters, grown in media containing in- creasing concentration of salt; then, we decided to delete these samples, as the main aim of the research was to verify if also under lab conditions the strains behave in the same way than in factories. What we found was that, as suggested by many pro- ducers, the differences between inoculated and inocu- lated samples were significant only for 2 - 3 weeks of fermentation (cell number, pH, content of lactic acid); after this time, the samples inoculated with the starter showed the same trend than the uninoculated ones. A practical implication of this result is that a preliminary adaptation could be useful to assure the success of the starter for the entire process. A particular kind of adapta- tion is the back-slopping, i.e. inoculation often carried out with brines from previous fermentations [11]. How- ever, such lactic cultures exhibit a diversity of metabolic activities, even among strains of the same species, in- cluding differences in growth rate, adaptation to a par- ticular substrate, antimicrobial properties, flavour and quality attributes as well as competitive growth behav- iour in mixed cultures, resulting in non-consistent and low quality final products. This kind of protocol was used in the past by Italian producer of table olives; al- though the process run faster, the quality was not con- stant. Another element confirming the strong implications of a not-correct use of the starter was the pH; the pH in a safe table olive must be about 4.5. In our fermentation, pH decreased until to about 5 after 28 days, then it re- mained constant during the entire fermentation. 5. Conclusion In conclusion, why this research? A possible answer: underline the risk associated with a not-correct use of the starter and the importance of a good step of starter preparation. Using the starter only after a growth phase in a laboratory medium could result a delay in this per- formances in brines. REFERENCES [1] A. Hurtado, C. Reguant, A. Bordons and N. Rozès, “Evaluation of a Single and Combined Inoculation of a Lactobacillus pentosus Starter for Processing cv. Arbe- quina Natural Green Olives,” Food Microbiology, Vol. 27, No. 6, 2010, pp. 731-740. doi:10.1016/j.fm.2010.03.006 [2] A. Bevilacqua, M. Perricone, M. Cannarsi, M. R. Corbo and M. Sinigaglia, “Technological and Spoiling Charac- teristics of the Yeast Microflora Isolated from Bella Di Cerignola Table Olives,” International Journal of Food Science and Technology, Vol. 44, No. 11, 2009, pp. 2198- 2207. doi:10.1111/j.1365-2621.2009.02060.x [3] D. Campaniello, A. Bevilacqua, D. D’Amato, M. R. Corbo, C. Altieri and M. Sinigaglia, “Microbial Charac- Copyright © 2013 SciRes. FNS  Use of Starter Cultures in Olives: A Not-Correct Use Could Cause a Delay of Performances Copyright © 2013 SciRes. FNS 726 terization of Table Olives Processed According to Span- ish and Natural Styles,” Food Technology and Biotech- nology, Vol. 43, No. 3, 2005, pp. 289-294. [4] M. Perricone, A. Bevilacqua, M. R. Corbo and M. Sini- gaglia, “Use of Lactobacillus plantarum and Glucose to Control the Fermentation of ‘Bella di Cerignola’ Table Olives, a Traditional Variety of Apulian Region (South- ern Italy),” Journal of Food Science, Vol. 75, No. 5, 2010, pp. M430-M436. doi:10.1111/j.1750-3841.2010.01742.x [5] A. Hernandèz, A. Martin, E. Aranda, F. Pèrez-Nevado and M. G. Còrdoba, “Identification and Characterization of Yeast Isolated from the Elaboration of Seasoned Green Table Olives,” Food Microbiology, Vol. 24, No. 4, 2007, pp. 346-351. doi:10.1016/j.fm.2006.07.022 [6] M. Vega Leal-Sánchez, J. L. Ruiz-Barba, A. H. Sánchez, L. Rejano, R. Jiménez-Díaz and A. Garrido, “Fermenta- tion Profile and Optimization of Green Olive Fermenta- tion Using Lactobacillus pentosus LCPO10 as a Starter Culture,” Food Microbiology, Vol. 20, 2003, pp. 421- 430. [7] V. Marsilio, L. Seghetti, E. Iannucci, F. Russi, B. Lanza and M. Felicioni, “Use of Lactic Acid Bacteria Starter Culture during Green Olive (Olea europaea cv L. cv Ascolana tenera) Processing,” Journal of the Science of Food and Agriculture, Vol. 85, No. 7, 2005, pp. 1084- 1090. doi:10.1002/jsfa.2066 [8] E. Medina, C. Romero, A. de Castro, M. Brenes and A. García, “Inhibitors of Lactic Acid Fermentation in Span- ish-Style Green Olive Brines of the Manzanilla Variety,” Food Chemistry, Vol. 110, No. 4, 2008, pp. 932-937. doi:10.1016/j.foodchem.2008.02.084 [9] A. Bevilacqua, C. Altieri, M. R. Corbo, M. Sinigaglia and L. I. I. Ouoba, “Characterization of Lactic Acid Bacteria Isolated from Italian Bella di Cerignola Table Olives: Se- lection of Potential Multifunctional Starter Cultures,” Journal of Food Science, Vol. 75, No. 8, 2010, pp. M536- M544. doi:10.1111/j.1750-3841.2010.01793.x [10] F. N. Arroyo-López, J. Bautista-Gallego, M. C. Durán- Quintana and A. Garrido-Fernández, “Modelling the In- hibition of Sorbic and Benzoic Acids on a Native Yeast Cocktail,” Food Microbiology, Vol. 25, No. 4, 2008, pp. 566-574. doi:10.1016/j.fm.2008.02.007 [11] A. Aponte, G. Blaiotta, F. L. Croce, A. Mazzaglia, V. Farina, L. Settanni and G. Moschetti, “Use of Selected Autochthonous Lactic Acid Bacteria for Spanish-Style Table Olive Fermentation,” Food Microbiology, Vol. 30, No. 1, 2012, pp. 8-16. doi:10.1016/j.fm.2011.10.005

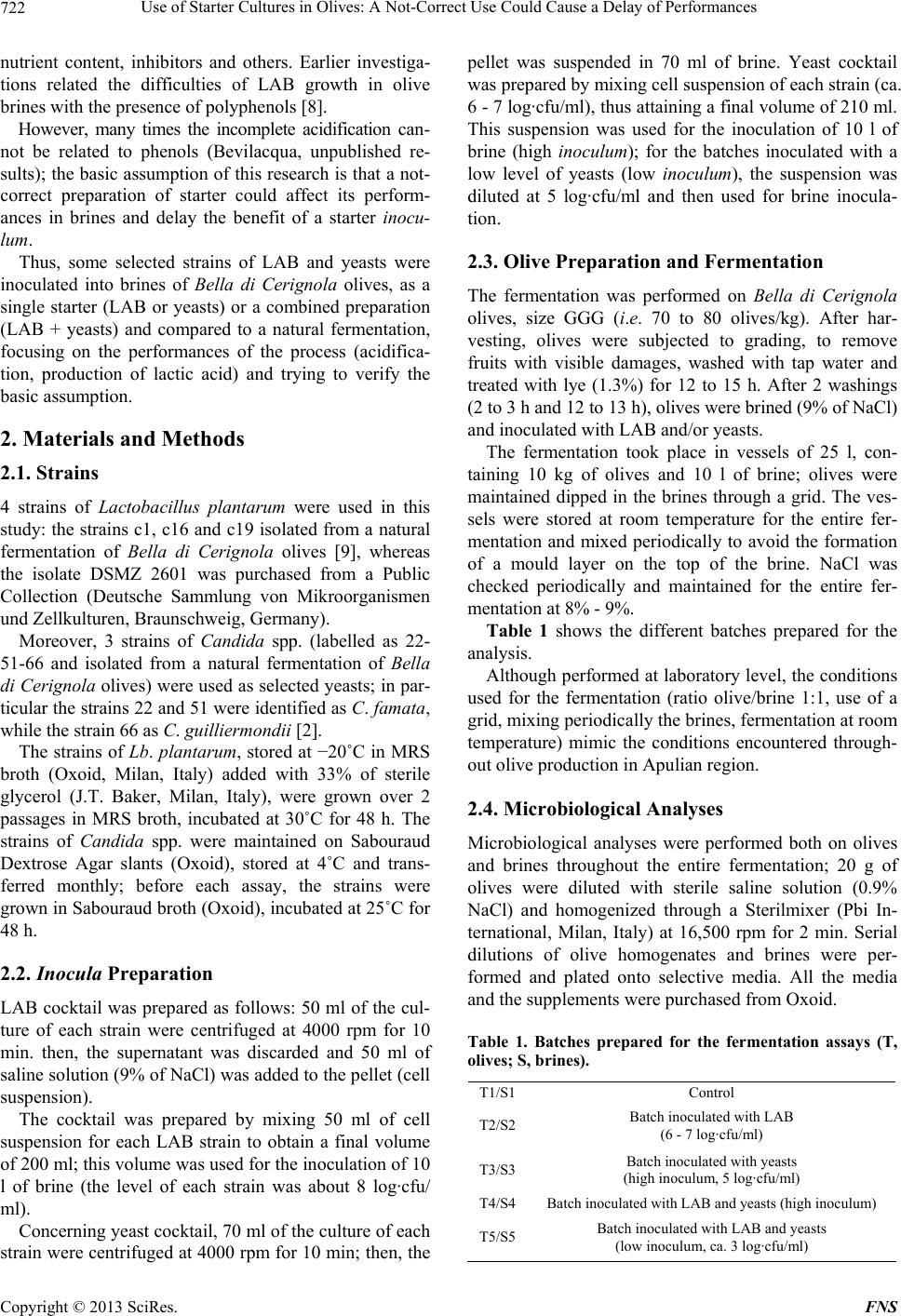

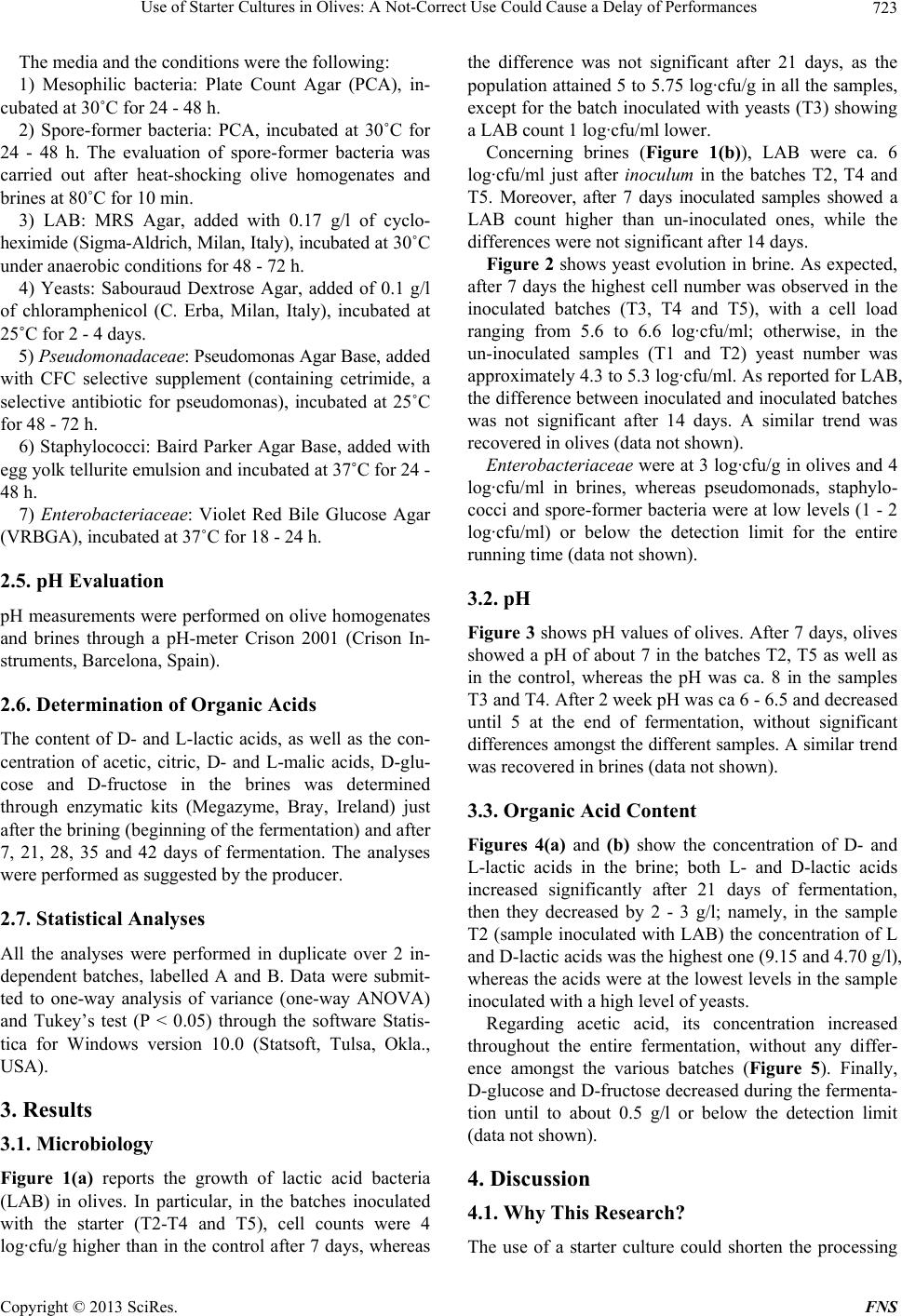

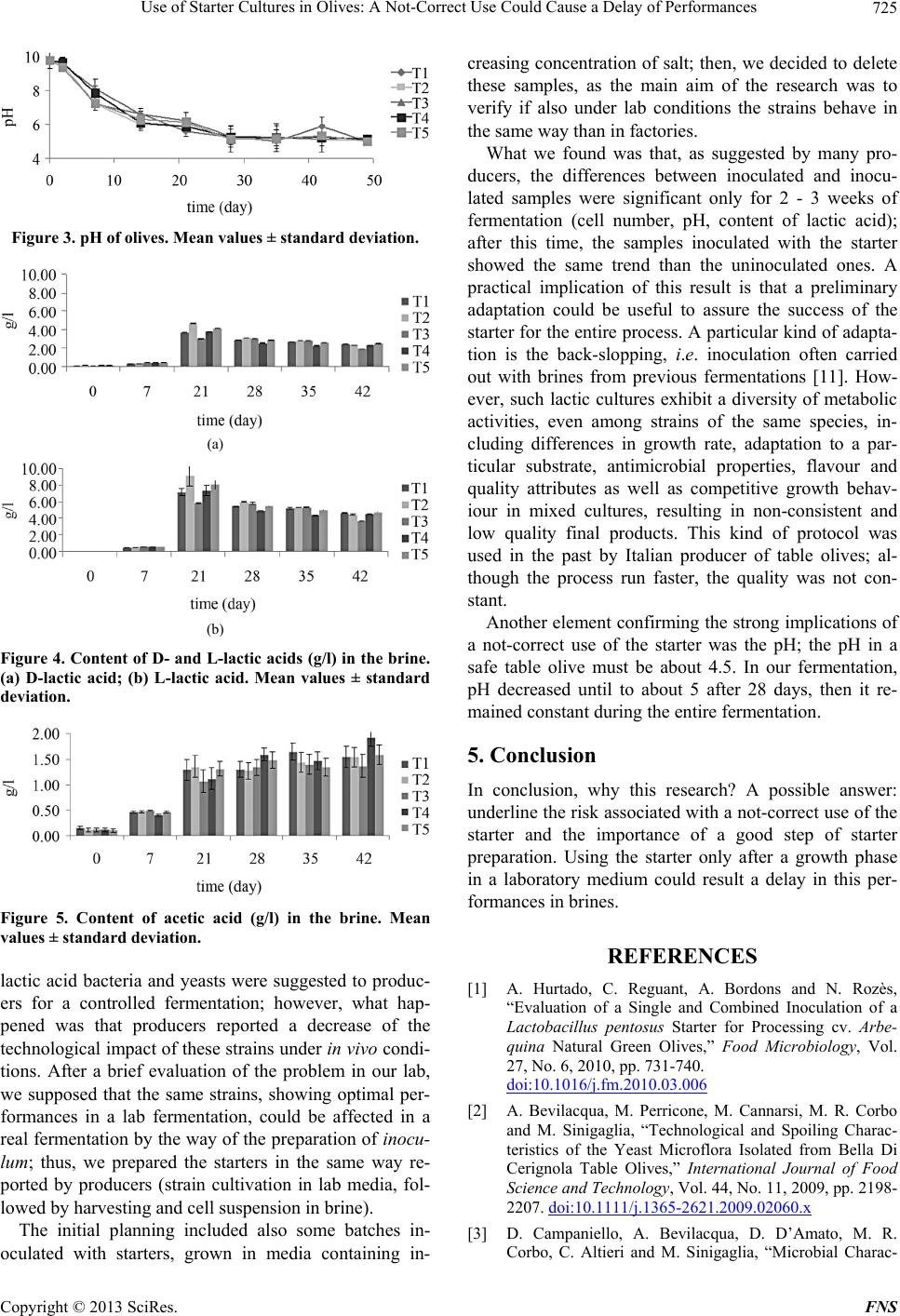

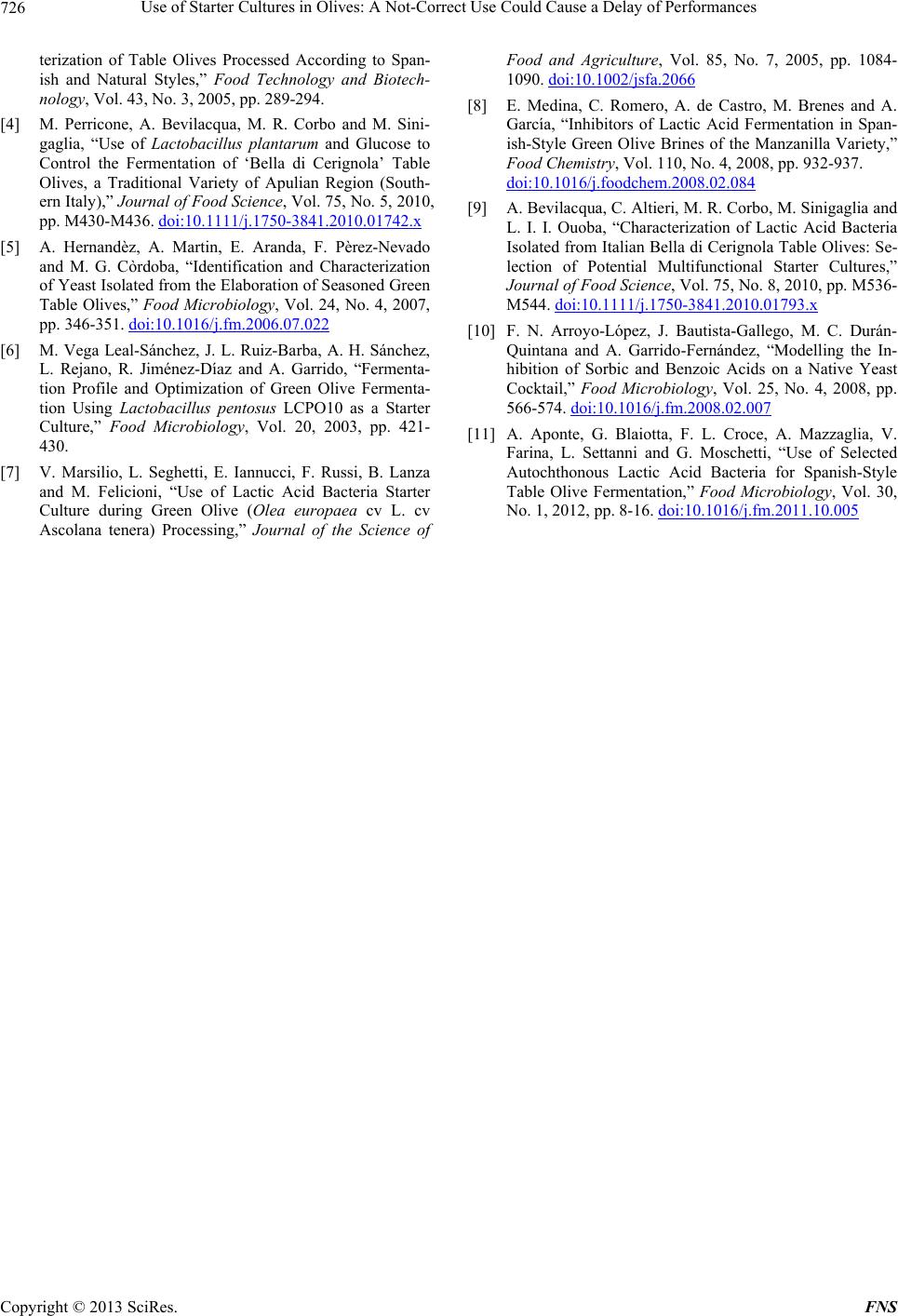

|