Open Journal of Statistics

Vol.05 No.05(2015), Article ID:58568,8 pages

10.4236/ojs.2015.55039

On the Charting Procedures: MEWMA Chart and DD-Diagram

Mekki Hajlaoui

Faculté des Sciences Economiques et de Gestion de Mahdia, Université de Monastir, Mahdia, Tunisia

Email: mekki.hajlaoui@gmail.com

Copyright © 2015 by author and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 8 April 2015; accepted 2 August 2015; published 5 August 2015

ABSTRACT

In light of rapid development of customer requirements, control procedures of quality concept use multivariate analysis. This is because of recent advances in information technology and in recording. The charting procedures are based on Mahalanobis distance but their performance needs normality and a type-I error rate choice. The DD-diagram is an alternative scheme that uses data depth to avoid these conditions rarely met in practice. For a given error-free sample, the performance of DD-diagram and that of multivariate EWMA control procedures are compared through a real example on individual observations taken from a multivariate quality process.

Keywords:

Multivariate Data, Quality Control, Mahalanobis Distance, MEWMA Chart, Data Depth, DD-Diagram

1. Introduction

Multivariate control schemes are valuable when several process features are being observed to identify instability within the manufacturing quality process that exhibits substantial cross-correlations. These control schemes use relationships between quality characteristics to generate powerful control procedures that are sensitive to shifts in position and/or in dispersion.

Multivariate Shewhart control chart was first introduced in 1947 and it is known as Hotelling’s  chart. Then, a number of multivariate control charts were designed to suit different situations such as multivariate EWMA charts and multivariate CUSUM charts. These classical monitoring charts have been developed to monitor the mean vector of quality characteristics under a number of assumptions quoted by [1] . The perfor- mance of these multivariate control charts relies heavily on the hypothesis that the underlying distribution of the quality process is multivariate normal which in practice rarely holds. To overcome this limit, a DD-diagram, suggested by [2] and discussed by [3] , is a visual procedure designed as an alternative tool. It is based on a centre-outward ranking which uses data depth plot to monitor any multivariate quality data and does not require any assumptions about the underlying distribution of the process. For a given error-free sample, the DD-diagram is used to signal out any point of another observed sample taken from a multivariate quality process. This new scheme based on data depth uses a properly chosen limiting variation line or L-value in order to evaluate the outlyingness of every point in the observed sample in all directions of the considered p-variates of quality process.

chart. Then, a number of multivariate control charts were designed to suit different situations such as multivariate EWMA charts and multivariate CUSUM charts. These classical monitoring charts have been developed to monitor the mean vector of quality characteristics under a number of assumptions quoted by [1] . The perfor- mance of these multivariate control charts relies heavily on the hypothesis that the underlying distribution of the quality process is multivariate normal which in practice rarely holds. To overcome this limit, a DD-diagram, suggested by [2] and discussed by [3] , is a visual procedure designed as an alternative tool. It is based on a centre-outward ranking which uses data depth plot to monitor any multivariate quality data and does not require any assumptions about the underlying distribution of the process. For a given error-free sample, the DD-diagram is used to signal out any point of another observed sample taken from a multivariate quality process. This new scheme based on data depth uses a properly chosen limiting variation line or L-value in order to evaluate the outlyingness of every point in the observed sample in all directions of the considered p-variates of quality process.

In this paper, an application of both MEWMA control chart and DD-diagram is conducted using individual observations taken off a real case of quality process from the industry. The data of the samples are collected during two different times of the production process. The reference sample measures are drawn from a production process during which the process is considered in control. However, the empirical sample measures are drawn later in the frame work of a quality control routine. The MEWMA control chart and the DD-diagram are given in Sections 2 and 3, respectively. In Section 4 these monitoring techniques are applied. The empirical analysis is given in Section 5 and after that we dedicate Section 6 to draw some conclusions.

2. The Multivariate EWMA Control Chart

As the number of process variables grows the traditional multivariate control charts such as the  control chart lose efficiency with respect to shift in position and/or in dispersion. The

control chart lose efficiency with respect to shift in position and/or in dispersion. The  chart is poor at detecting small and moderate shifts. However, the MEWMA control chart is known to respond quickly to small shifts and it includes the

chart is poor at detecting small and moderate shifts. However, the MEWMA control chart is known to respond quickly to small shifts and it includes the  scheme when the magnitude of its smoothing parameter goes to one, see the discussion of [4] .

scheme when the magnitude of its smoothing parameter goes to one, see the discussion of [4] .

Let  be the quality of an item X at time period i, so if this level of quality is characterized by p-quality

be the quality of an item X at time period i, so if this level of quality is characterized by p-quality

characteristics  then

then  or simply

or simply

(1)

(1)

is a vector-valued output at time . The components of the sample

. The components of the sample  are assumed to be in- dependent and identically distributed multivariate normal random variables with mean vector

are assumed to be in- dependent and identically distributed multivariate normal random variables with mean vector

and covariance matrix

and covariance matrix .

.

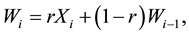

As indicated by [5] , there is no reason to weight past observations differently for the p-quality characteristics being monitored. So, the EWMA vector is the statistic

(2)

(2)

where  is the p-dimensional null vector and r is a parameter,

is the p-dimensional null vector and r is a parameter,  , that specifies the magnitude of the smoothing. The multivariate EWMA chart indicates an out-of-control signal if the quantity

, that specifies the magnitude of the smoothing. The multivariate EWMA chart indicates an out-of-control signal if the quantity

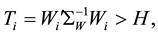

(3)

(3)

where

The statistic

and the covariance matrix

Replacing

such that

3. The DD-Diagram

Let F be a probability distribution in

Therefore, if the quality of the

According to [6] , a data depth is a way of measuring how deep or central a given point

the Mahalanobis depth at x with respect to F is defined to be

The sample version of Equation (10) is obtained by replacing

Henceforth, D or

Given a notion of data depth, one can compute the depths of all quality measures

Given the definitions (10) or (11), the sample becomes

When the depth-equivalence class contains more than one point measure,

On this basis and using data depth, the Equations (12) and (13) fix out a centre or a multivariate median. Moreover, [2] stated that if Mahalanobis depth is used, the central point defined in Equations (12) and (13) turns out to be the mean of the observed data. This suggests concepts of location which are intermediate between the mean and the median.

A data depth plots is a graphical comparison between two multivariate distributions based on data depth. So in addition to the reference sample

Since

In general, the distributions are rarely known so instead we use an empirical version of the DD-diagram. If F and G are unknown distributions for the samples X and Y, then the DD-diagram is obtained when plotting

if Equation (11) is used to compute the data depth.

If

In most cases, the departure from the diagonal line usually takes the form of pulling down from the point

In analogous manner to the classical multivariate control procedures, [8] has suggested upper and lower control limits in order to detect visually the shifts in location and/or in dispersion. The region under control is located between these two limits. This marked region turns out to be so large. In order to make the DD-diagram more sensitive, [9] has revised his study and proposed in instead a L-value as a least critical value for a data depth according to which the corresponding point will be considered to have components not satisfying the variation intervals,

It is conversely proportional to the sum of the depth of the reference sample centre,

4. Application of MEWMA Chart and DD-Diagram

In this section individual observations data are collected from a production process during which the process is considered in control. These observations are then used to estimate the parameters of the underlying distribution F of the considered process. Then, another series of individual observations are drawn when the distribution of the process has drifted to a distribution G. Both series of observations are used to construct and to argue the performance of the monitoring schemes the MEWMA chart and the DD-diagram. Based on a previous work of [9] , the observation involves the simultaneous measurement of five variables: (1) the weight, (2) the module, (3) the humidity rate, (4) the pulling resistance and (5) the density.

Processing the observed data begins with the start-up stage that consists of estimating the parameters of F, constructing the control limit of MEWMA chart and determining the centre of F as reference sample.

According to Equation (5), the vector of sample mean is

and to Equation (6), the sample covariance matrix is

To construct a multivariate EWMA control chart, [5] gave a limiting value

Figure 1 shows the corresponding MEWMA chart if

To determine the centre, data depths of all observations of the reference sample are calculated using Equation (11). As recorded in the work of [9] , the highest value of the statistic data depth is

In order to detect graphically any point that is not satisfying the limiting variation interval, the

as the least acceptable data depth value and below which the corresponding point is considered out of control i.e. at least one of the p-characteristics exceeds its limiting variation interval.

It is clear that in the reference sample, the point of order 45 is characterized by the maximum data depth in either case before and after centering with respect to the computed vector-valued centre

5. Empirical Analysis

The second stage consists of using both control schemes to evaluate the stability of the observed production process when an empirical sample is drawn. At this phase, the parameters of the reference sample F obtained in

Figure 1. Multivariate EWMA control chart for the reference sample for 2 cases of the smoothing parameter r. (a) For r = 0.5; (b) For r = 1 corresponding to multivariate Shewhart chart.

Figure 2. DD-diagram for the reference sample F versus itself and the limiting value. (a) If data of F are not centered; (b) If data of F are centred w.r. to the centre v.

the start-up stage are used to monitor any taken empirical sample in the future. Specifically, after drawing the empirical sample G given in [9] the vector-valued mean

Figure 3 shows the corresponding multivariate EWMA control chart for both cases

Hereafter, the vector-valued centre

Figure 4 shows the corresponding DD-diagram for both cases before and after centering measures. Both subplots (left and right) of Figure 4 sketch out any change in location and/or a scale increase when moving from the distribution F to the distribution G in the multivariate quality process. The out-of-control observations in

Figure 3. Multivariate EWMA control chart for an empirical sample for 2 cases of the smoothing parameter r. (a) For r = 0.5; (b) For r = 1 corresponding to multivariate Shewhart chart.

Figure 4. DD-diagram for the reference sample F versus an empirical sample G.

Table 1 are indicated with red stars in both subplots of Figure 4 in the DD-diagram. In order to determine the characteristics responsible for this drift, refer to Table 1.

The first line of Table 1 gives the specification interval for each considered variable. Reading the corresponding values one by one indicates that cigarettes 19 and 54 are considered out of control because the “module” (X2) exceeds its specified measure. The other observations (2, 3, 27, 29, 33, 39, 43, 50 and 52) are considered out of control because the humidity rate (X3) is lower than its minimum value.

For centered measures, the DD-diagram in the right subplot of Figure 4 shows the observations under the effect of a scale change only. It can be deduced that observations 3 and 50 are out of control because of a change in location only. When measures are centered, these two observations disappear from the out-of-control region in the right subplot of Figure 4. But, observations 2, 19, 27, 29, 33, 39, 43, 52 and 54 are out-of-control under the effect of a change in dispersion and of a location shift respectively. These points are indicated with red stars in the DD-diagr am in the right subplot of Figure 4.

The MEWMA control chart, for

Table 1. Out of control observations detected by DD-diagram.

Table 2. Out of control observations detected by the MEWMA chart (r = 0.5).

Comparing the realized values for the out-of-control observations with respect to their specification intervals indicated in the first line of Table 2 indicates that cigarettes 12 and 19 are considered out of control because the “module”

The investigation of Table 2 shows that there are 5 points fall out of control limit of the MEWMA chart which ar not detected by the DD-diagram. This means that the DD-diagram performs poorly with respect to the MEWMA chart. But if the coordinates of these points are revised with respect to their specification intervals they convey that they are not out of control limit in reality they are false alarms, such that observations 13, 34 and 53.

The DD-diagram is a graphical comparison that exhibits location shifts and/or scale increase when moving from the distribution F of the reference sample to the distribution G of the empirical one. And to use this dia- gram, we do not need any requirement about the nature of the observed multivariate quality process distribution. Although, this procedure looks like a non parametric method, DD-diagram does not require large samples. It suffices to have a size of the samples that goes beyond 30 to ensure a reasonable performance. So, whenever this size goes bigger the DD-diagram improves in performance.

6. Conclusions

The above application allows us to say that DD-diagram performs as better as multivariate EWMA control chart because its use does not depend on normality as for the case of MEWMA control chart. In the above application, DD-diagram detects 11 points indicating that their components exceed their specified limits whereas the MEWMA control chart gives 14 points corresponding to a smoothing parameter

When a multivariate quality process changes its distribution from F to G and if the location shift is eliminated i.e. centering the measures with respect to the centre or the deepest point of F, DD-diagram makes it possible to distinguish between the out-of-control observations that were drifted because of location shifts and scale increase respectively and those that were drifted under the effect of variations in dispersion only. This fact is not feasible when using MEWMA control chart.

In general consider the test of a null hypothesis asserting stability of a production process versus an alter- native one that concerns the existence of shifts in location and/or in scale, then the empirical sample has higher dispersion than that of the reference one. This is deduced from the fact that the resulting clouds, of centered measures or not, are located under the limiting variation level line at

Cite this paper

MekkiHajlaoui, (2015) On the Charting Procedures: MEWMA Chart and DD-Diagram. Open Journal of Statistics,05,373-381. doi: 10.4236/ojs.2015.55039

References

- 1. Alloway Jr., J.A. (1995) Visual Evaluation of Multivariate Control Chart Assumptions. Proceedings of the American Statistical Association, the Section on Quality and Productivity, 49-54.

- 2. Liu, R.Y., Parelius, J.M. and Singh, K. (1999) Multivariate Analysis by Data Depth: Descriptive Statistics, Graphics and Inference. The Annals of Statistics, 27, 783-858.

http://dx.doi.org/10.1214/aos/1018031259 - 3. Li, J. and Liu, R.Y. (2004) New Nonparametric Tests of Multivariate Locations and Scales Using Data Depth. Statistical Science, 19, 686-696.

http://dx.doi.org/10.1214/088342304000000594 - 4. Huh, I. (2010) Multivariate EWMA Control Chart and Application to a Semiconductor Manufacturing Process. A Thesis for Master of Science Degree, McMaster University, Ontario.

- 5. Lowry, C.A., Woodall, W.H., Champ, C.W. and Rigdon, S.E. (1992) A Multivariate Exponentially Weighted Moving Average Control Chart. Technometrics, 34, 46-53.

http://dx.doi.org/10.2307/1269551 - 6. Liu, R.Y. (1990) On a Notion of Data Depth Based on Random Simplices. The Annals of Statistics, 18, 405-414.

http://dx.doi.org/10.1214/aos/1176347507 - 7. Ghosh, A.K. and Chaudhuri, P. (2005) On Maximum Depth and Related Classifiers. Scandinavian Journal of Statistics, 32, 327-350.

- 8. Hajlaoui, M. (2010) A Graphical Quality Control Procedure Using Data Depth. Advances & Applications in Statistics, 19, 97-111.

- 9. Hajlaoui, M. (2011) On the Charting Procedures: T2 Chart and DD-Diagram. International Journal of Quality, Statistics, and Reliability, 2011, Article ID: 830764.

http://dx.doi.org/10.1155/2011/830764