Carbonation Resistance and Anticorrosive Properties of Organic Coatings for Concrete Structures 73

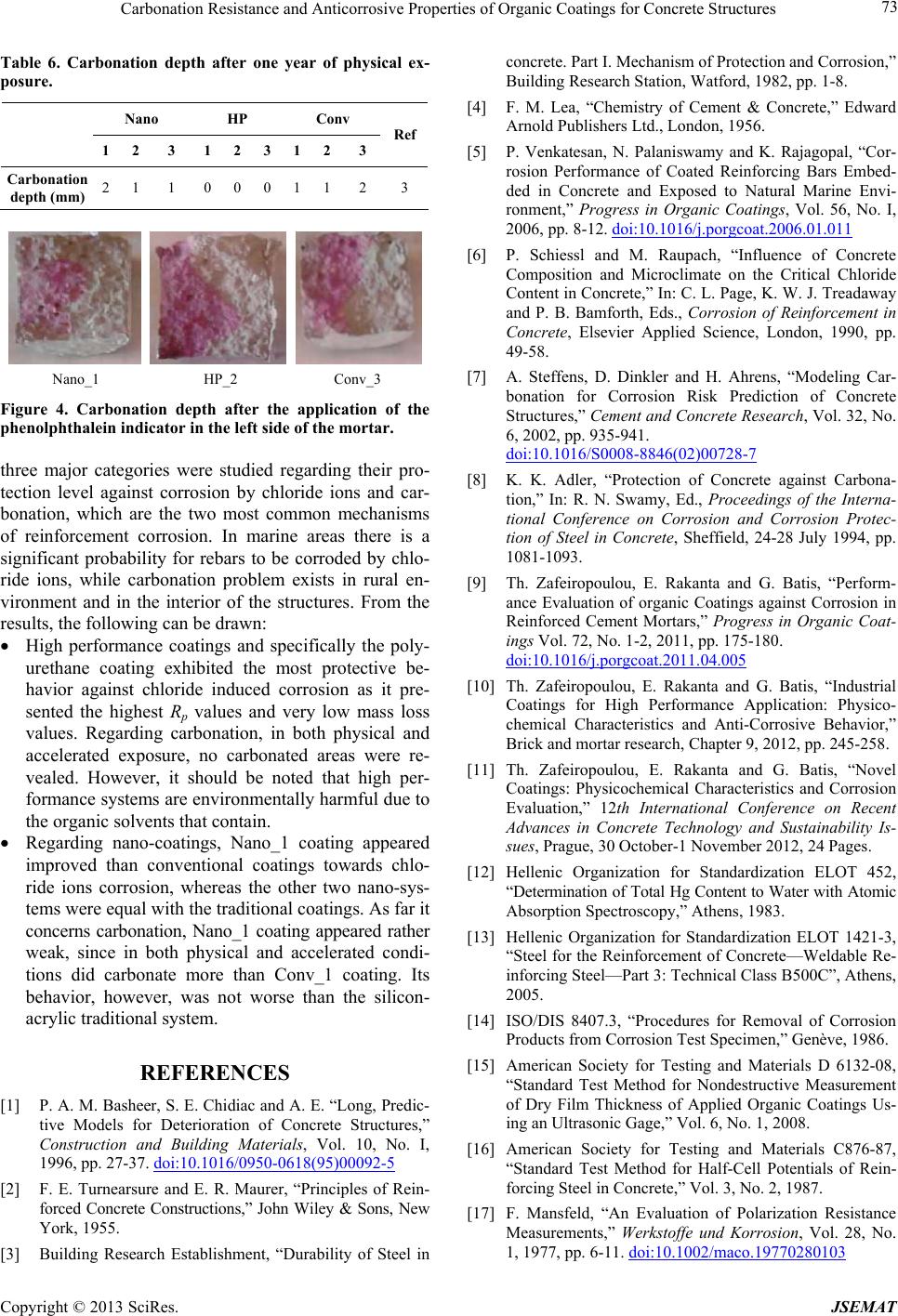

Table 6. Carbonation depth after one year of physical ex-

posure.

Nano HP Conv

1 2 3 1 2 3 1 2 3

Ref

Carbonation

depth (mm) 2 1 1 0 0 0 1 1 23

Nano_1 HP_2 Conv_3

Figure 4. Carbonation depth after the application of the

phenolphthalein indicator in the left side of the mortar.

three major categories were studied regarding their pro-

tection level against corrosion by chloride ions and car-

bonation, which are the two most common mechanisms

of reinforcement corrosion. In marine areas there is a

significant probability for rebars to be corroded by chlo-

ride ions, while carbonation problem exists in rural en-

vironment and in the interior of the structures. From the

results, the following can be drawn:

High performance coatings and specifically the poly-

urethane coating exhibited the most protective be-

havior against chloride induced corrosion as it pre-

sented the highest Rp values and very low mass loss

values. Regarding carbonation, in both physical and

accelerated exposure, no carbonated areas were re-

vealed. However, it should be noted that high per-

formance systems are environmentally harmful due to

the organic solvents that contain.

Regarding nano-coatings, Nano_1 coating appeared

improved than conventional coatings towards chlo-

ride ions corrosion, whereas the other two nano-sys-

tems were equal with the traditional coatings. As far it

concerns carbonation, Nano_1 coating appeared rather

weak, since in both physical and accelerated condi-

tions did carbonate more than Conv_1 coating. Its

behavior, however, was not worse than the silicon-

acrylic traditional system.

REFERENCES

[1] P. A. M. Basheer, S. E. Chidiac and A. E. “Long, Predic-

tive Models for Deterioration of Concrete Structures,”

Construction and Building Materials, Vol. 10, No. I,

1996, pp. 27-37. doi:10.1016/0950-0618(95)00092-5

[2] F. E. Turnearsure and E. R. Maurer, “Principles of Rein-

forced Concrete Constructions,” John Wiley & Sons, New

York, 1955.

[3] Building Research Establishment, “Durability of Steel in

concrete. Part I. Mechanism of Protection and Corrosion,”

Building Research Station, Watford, 1982, pp. 1-8.

[4] F. M. Lea, “Chemistry of Cement & Concrete,” Edward

Arnold Publishers Ltd., London, 1956.

[5] P. Venkatesan, N. Palaniswamy and K. Rajagopal, “Cor-

rosion Performance of Coated Reinforcing Bars Embed-

ded in Concrete and Exposed to Natural Marine Envi-

ronment,” Progress in Organic Coatings, Vol. 56, No. I,

2006, pp. 8-12. doi:10.1016/j.porgcoat.2006.01.011

[6] P. Schiessl and M. Raupach, “Influence of Concrete

Composition and Microclimate on the Critical Chloride

Content in Concrete,” In: C. L. Page, K. W. J. Treadaway

and P. B. Bamforth, Eds., Corrosion of Reinforcement in

Concrete, Elsevier Applied Science, London, 1990, pp.

49-58.

[7] A. Steffens, D. Dinkler and H. Ahrens, “Modeling Car-

bonation for Corrosion Risk Prediction of Concrete

Structures,” Cement and Concrete Research, Vol. 32, No.

6, 2002, pp. 935-941.

doi:10.1016/S0008-8846(02)00728-7

[8] K. K. Adler, “Protection of Concrete against Carbona-

tion,” In: R. N. Swamy, Ed., Proceedings of the Interna-

tional Conference on Corrosion and Corrosion Protec-

tion of Steel in Concrete, Sheffield, 24-28 July 1994, pp.

1081-1093.

[9] Th. Zafeiropoulou, E. Rakanta and G. Batis, “Perform-

ance Evaluation of organic Coatings against Corrosion in

Reinforced Cement Mortars,” Progress in Organic Coat-

ings Vol. 72, No. 1-2, 2011, pp. 175-180.

doi:10.1016/j.porgcoat.2011.04.005

[10] Th. Zafeiropoulou, E. Rakanta and G. Batis, “Industrial

Coatings for High Performance Application: Physico-

chemical Characteristics and Anti-Corrosive Behavior,”

Brick and mortar research, Chapter 9, 2012, pp. 245-258.

[11] Th. Zafeiropoulou, E. Rakanta and G. Batis, “Novel

Coatings: Physicochemical Characteristics and Corrosion

Evaluation,” 12th International Conference on Recent

Advances in Concrete Technology and Sustainability Is-

sues, Prague, 30 October-1 November 2012, 24 Pages.

[12] Hellenic Organization for Standardization ELOT 452,

“Determination of Total Hg Content to Water with Atomic

Absorption Spectroscopy,” Athens, 1983.

[13] Hellenic Organization for Standardization ELOT 1421-3,

“Steel for the Reinforcement of Concrete—Weldable Re-

inforcing Steel—Part 3: Technical Class B500C”, Athens,

2005.

[14] ISO/DIS 8407.3, “Procedures for Removal of Corrosion

Products from Corrosion Test Specimen,” Genève, 1986.

[15] American Society for Testing and Materials D 6132-08,

“Standard Test Method for Nondestructive Measurement

of Dry Film Thickness of Applied Organic Coatings Us-

ing an Ultrasonic Gage,” Vol. 6, No. 1, 2008.

[16] American Society for Testing and Materials C876-87,

“Standard Test Method for Half-Cell Potentials of Rein-

forcing Steel in Concrete,” Vol. 3, No. 2, 1987.

[17] F. Mansfeld, “An Evaluation of Polarization Resistance

Measurements,” Werkstoffe und Korrosion, Vol. 28, No.

1, 1977, pp. 6-11. doi:10.1002/maco.19770280103

Copyright © 2013 SciRes. JSEMAT