Paper Menu >>

Journal Menu >>

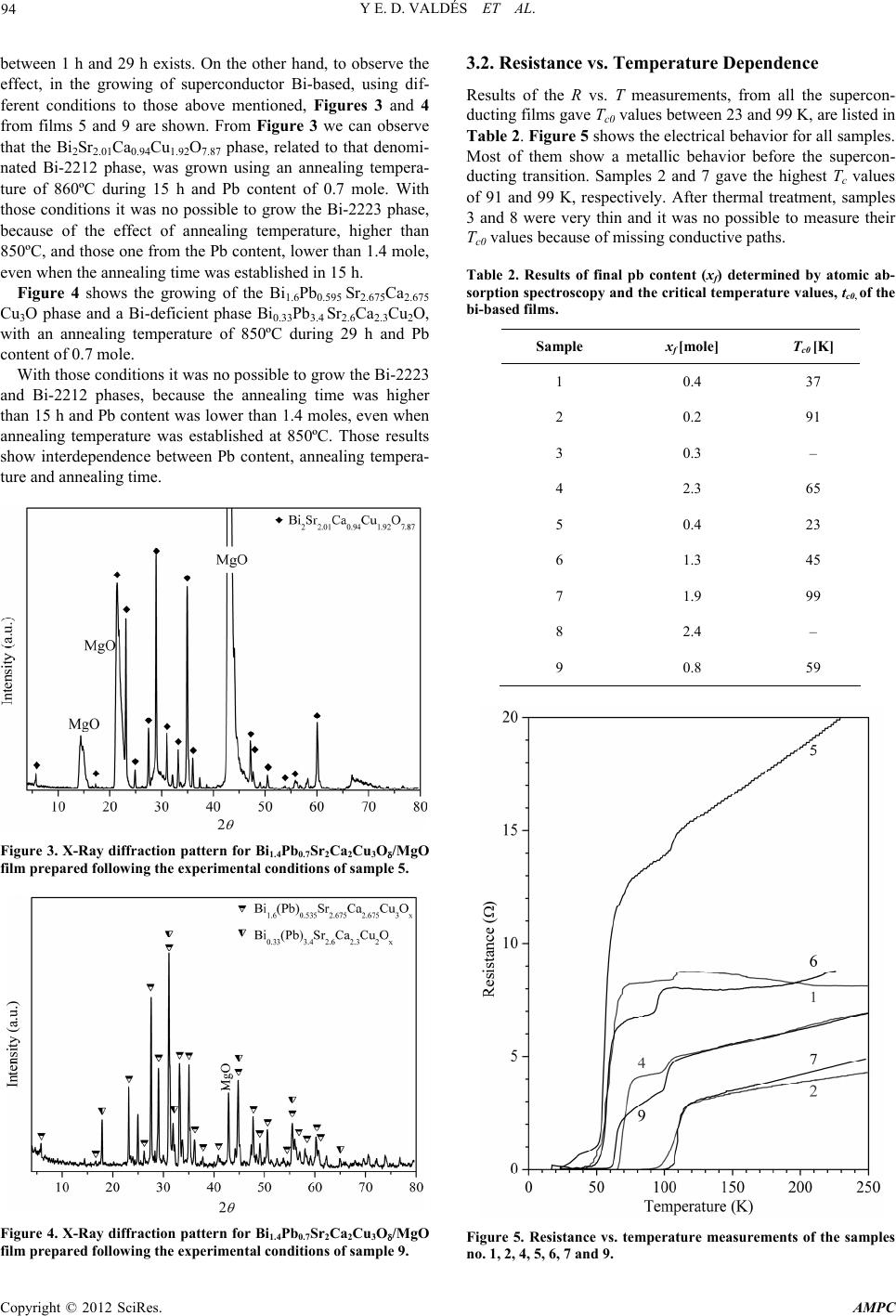

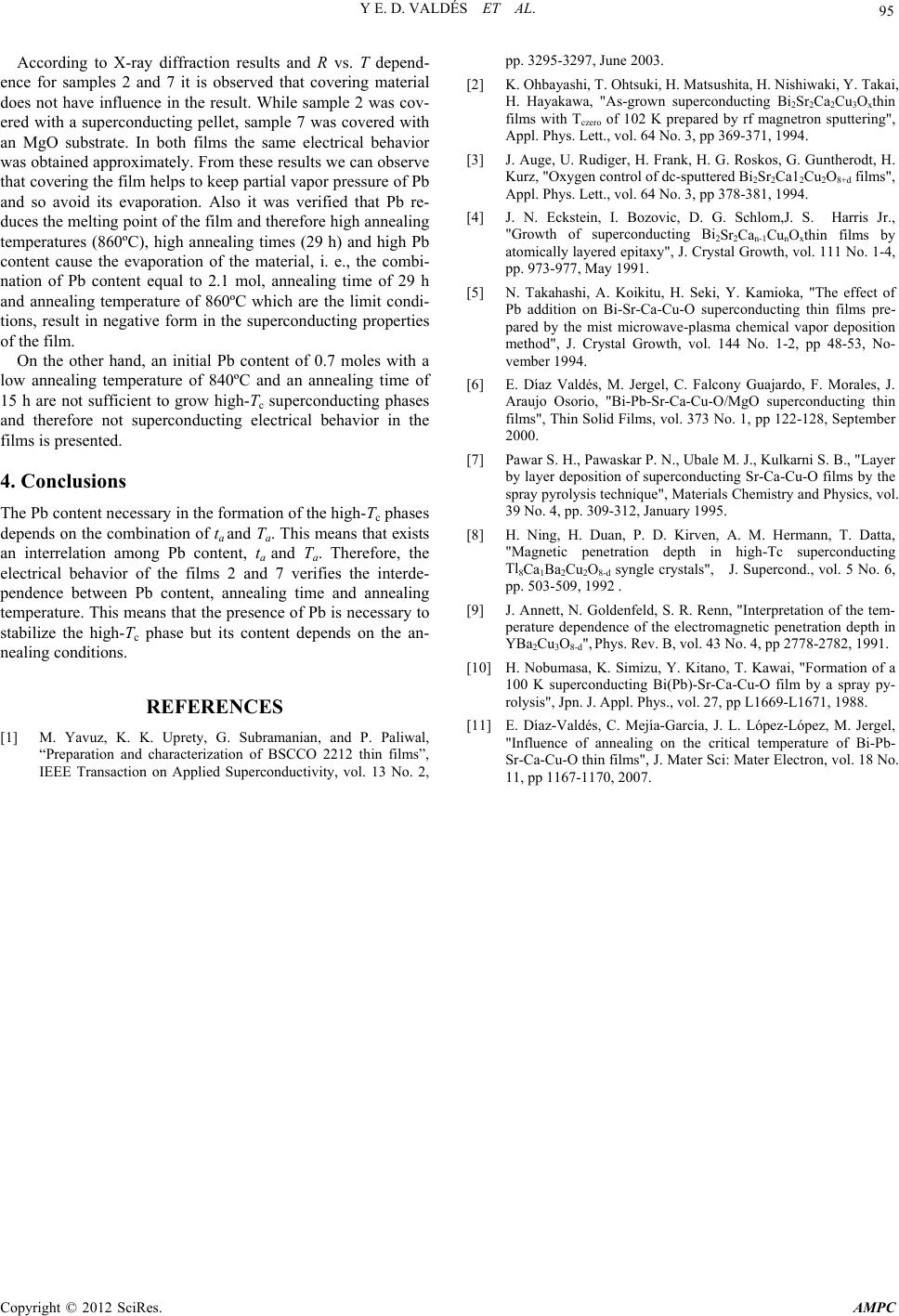

Advances in Materials Physics and Chemistry, 2012, 2, 92-95 doi:10.4236/ampc.2012.24B025 Published Online December 2012 (http://www.SciRP.org/journal/ampc) BPSCCO Superconducting Films Grown by Spray Pyrolysis Technique: Systematic Study of the Relationship between Pb Content and Annealing Conditions Y Elvia Díaz Valdés, Conce pción Mejía García, Ana María Paniagua Mercado, Arturo Méndez Sánchez Departamento de Física, Escuela Superior de Física y Matemáticas – IPN, Edif. UPALM Col. San Pedro Zacatenco, Deleg. GAM, México Email: elviadv@esfm.ipn.mx Received 2012 ABSTRACT Actually recent investigation in developing semiconducting-superconducting composites based in CdS and Bi-based superconductors has attracted interest in processing thin superconducting films. In this work are reported Bi-Pb-Sr-Ca-Cu-O (BPSCCO) thin films grown on MgO substrates by spray pyrolysis technique from a solution containing Bi(NO3)3, Pb(NO3)2, Sr(NO3)2, Ca(NO3)2 and Cu(NO3)2, with a subsequent solid state reaction for growing the Bi-based superconducting phases. Annealed films were character- ized by X-ray diffraction, atomic absorption spectroscopy and resistance measurements. Interdependence between Pb content, an- nealing time and temperature, in the formation of superconducting phases was studied applying a fractional factorial design 3III4-2. Interrelation between Pb content, ta and Ta exists. The presence of Pb is necessary to stabilize the high-Tc phase but its content de- pends on the annealing conditions. Keywords: Superconductivity; BPSCCO Superconducting Films; Spray Pyrolysis Deposition; Pb Content; Annealing Conditions; Experimental Design 1. Introduction The discovery of high-Tc superconductors has attracted much attention for their technological applications as bulk material as well as thin films, as for example, electronic devices, conductor tapes, and superconducting quantum interference devices. For the preparation of thin films, several physical and chemical techniques have been used: pulsed laser deposition [1], r. f. sputtering [2], magnetron sputtering [3], atomic layer epitaxy [4], chemical vapor deposition [5] and chemical deposition (spray pyrolysis) [6]. Most of them are high vacuum deposition techniques that produce superconductor thin films by sequential layer-by-layer deposition of the constituent elements. The pre- cursor films obtained by means of this sequential deposition needs oxidation of the deposited layer with complete evapora- tion of the volatile gases present. The spray pyrolysis technique does not need subsequent oxidation because the complete ther- mal decomposition and oxidation of the deposited layers can be controlled [7]. On the other hand, Bi-based films are already used in low current as well as power applications [8,9]. Among the high-Tc ceramic superconductors, the Bi-based system has been extensively studied because of its high critical temperature, especially with the partial substitution of Pb in Bi and Sr sites since it promotes the stabilization of the 2223 phase when grown from the 2212 phase [10]. It has been found that the nominal composition and thermal treatment parameters such as heating rate, annealing temperature, annealing time, as well as, oxygen content play an important role in the formation of high-Tc phases and the thermodynamic stability of these phases [6]. However, it has not been reported the interdependence between Pb content, annealing temperature and annealing time on growing the high-Tc superconducting Bi-phases. The influ- ence of the Bi content upon the critical temperature Tc values, the c-axis lattice parameter and the surface morphology of the synthesized films is also recognized. Studies of Pb-substituted Bi2Sr2Ca2Cu3O8+ single crystals indicate a reduction in Tc val- ues of the overdoped samples. When growing the Bi-based films, many technological parameters are involved in such a process that influences the final properties of the synthesized films. In our previous studies we observed a loss of Pb during the annealing treatment [11]. This Pb-loss led to the transfor- mation of the high-Tc (2212 and 2223) phases to the low-Tc (2201) phase or others no superconductor phases. This phe- nomenon was caused by exposition of the precursor annealing in a free air ambient into which Pb evaporates. In studies done on material in volume has been reported that in the Bi-based system the partial substitution of Pb in Bi sites promotes the stabilization of the high-Tc 2223 phase for following reasons: a) Pb diminishes the melting point of the compound which is convenient for the formation of the high-Tc (2223) phase; b) Pb can have a catalytic effect and/or of stabilization for the high-Tc phase since accelerates the reaction between the phase of low-Tc and the atoms of Ca through Ca2PbO4 and, c) Bi and Pb tend to form Bi-O, Pb-O layers in the crystalline structure of the superconducting phases because their atomic radios are very closed. By these reasons it is important to keep the Pb in the structure in order to obtain high-Tc (2223) phase [10]. In the present work, we report on the deposition of Bi-Pb- Sr-Ca-Cu-O films using the spray pyrolysis technique and the interdependence between Pb content, annealing temperature, *Work supported by Instituto Politécnico Nacional through project SIP- IPN 20121703 . Copyright © 2012 SciRes. AMPC  Y E. D. VALDÉS ET AL. 93 annealing time and covering material, applying a fractional factorial design 3III5-3. 2. Experimental Procedure Bi-Pb-Sr-Ca-Cu-O (BPSCCO) thin films grown on MgO sub- strates were prepared by the spray pyrolysis technique follow- ing the two-step procedure described in detail elsewhere [6]. An aerosol atomized ultrasonically from an aqueous nitrate solu- tion of Bi, Pb, Sr, Ca, and Cu components with a cation ratio 1.4:x:2:2:3 (where x is the nominal lead content) was sprayed for 5 min over single-crystalline MgO substrate. Three such cycles were applied with a total film thickness of approximately 5 μm. These BPSCCO precursor films were then annealed at 840ºC, 850ºC and 860ºC in air to become superconducting. The growth parameters studied by applying a fractional factorial design 3III5-3 were covering material, annealing time (ta), an- nealing temperature (Ta) and the nominal Pb content (x) before annealing. Influence of each parameter was investigated in a chosen interval for its three values i.e. minimum, medium and maximum value. Table 1 shows values of those parameters used for each experimental run. The superconducting pellets, precursor films and plate-shaped crystalline MgO were used to cover the precursor films in order to avoid the lead evaporation and to observe which type of cover helps to maintain the com- position of the superconducting film most close to the nominal composition. Annealed precursor films were in direct contact with the covering material. The superconducting pellet compo- sition was closed to Bi2Pb0.3Sr2Ca2Cu3O; the covering precur- sor film composition and the composition of the investigated precursor film were the same, i.e. with the cation ratio 1.4:x:2: 2:3 where x is the lead content before annealing. The chemical composition of the films was measured by atomic absorption spectroscopy. Samples were then characterized by X-ray dif- fraction (XRD) with CuK radiation using the Siemens D500 diffractometer. The R vs. T dependence was measured by using the standard four-point resistance method. The chemical com- position was determined by measurements of atomic absorption spectroscopy using an Analyst 300 Perkin Elmer Spectrometer. 3. Results and Disscusion 3.1. X-Ray Diffraction Patterns Figures 1 and 2 show respectively X-ray diffraction patterns from films 2 and 7. These films were prepared according to the conditions shown in Table 1. From Figure 1 we observe that in order to grow the (Bi-Pb)2Sr2Ca2Cu3O phase denominated Bi- Pb-2223 so as the Bi-2212 phase, an annealing temperature of 850ºC during 15 h and Pb content of 1.4 mole are required (film 2). This indicates that to obtain the high-Tc Bi-based supercon- ductor phases, annealing temperatures smaller than 860ºC, an- nealing times longer than 1 h and Pb content between 0.7 and 2.1 moles are required. In contrast, for the film 7, in order to grow those superconducting phases an annealing temperature of 860ºC during 1 h and Pb content of 1.4 mole are required. At the same way, this indicates that in order to obtain the high-Tc Bi-based superconducting phases, annealing temperatures longer than 850ºC, annealing times smaller than 15 h and Pb content between 0.7 and 2.1 mole are required. Therefore it can Figure 1. X-Ray diffraction pattern for Bi1.4Pb1.4Sr2Ca2Cu3O/MgO film, prepared following the experimental conditions of sample 2. Figure 2. X-Ray diffraction pattern for Bi1.4Pb1.4Sr2Ca2Cu3O/MgO film prepared following the experimental conditions of sample 7. Table 1. Growth parameter conditions, where ta is the annealing time, ta is the annealing temperature and x is the nominal lead content. Sample No Material used to cover the precursor film ta [h] Ta [C] x [mole] 1 superconducting pellet 1 840 0.7 2 superconducting pellet 15 850 1.4 3 superconducting pellet 29 860 2.1 4 precursor film 1 850 2.1 5 precursor film 15 860 0.7 6 precursor film 29 840 1.4 7 plate-shaped crystalline MgO 1 860 1.4 8 plate-shaped crystalline MgO 15 840 2.1 9 plate- shaped crystalline MgO 29 850 0.7 be observed that an adequate Pb-content of 1.4 for annealing temperatures between 840ºC and 860ºC, and annealing times Copyright © 2012 SciRes. AMPC  Y E. D. VALDÉS ET AL. 94 between 1 h and 29 h exists. On the other hand, to observe the effect, in the growing of superconductor Bi-based, using dif- ferent conditions to those above mentioned, Figures 3 and 4 from films 5 and 9 are shown. From Figure 3 we can observe that the Bi2Sr2.01Ca0.94Cu1.92O7.87 phase, related to that denomi- nated Bi-2212 phase, was grown using an annealing tempera- ture of 860ºC during 15 h and Pb content of 0.7 mole. With those conditions it was no possible to grow the Bi-2223 phase, because of the effect of annealing temperature, higher than 850ºC, and those one from the Pb content, lower than 1.4 mole, even when the annealing time was established in 15 h. Figure 4 shows the growing of the Bi1.6Pb0.595 Sr2.675Ca2.675 Cu3O phase and a Bi-deficient phase Bi0.33Pb3.4 Sr2.6Ca2.3Cu2O, with an annealing temperature of 850ºC during 29 h and Pb content of 0.7 mole. With those conditions it was no possible to grow the Bi-2223 and Bi-2212 phases, because the annealing time was higher than 15 h and Pb content was lower than 1.4 moles, even when annealing temperature was established at 850ºC. Those results show interdependence between Pb content, annealing tempera- ture and annealing time. Figure 3. X-Ray diffraction pattern for Bi1.4Pb0.7Sr2Ca2Cu3O/MgO film prepared following the experimental conditions of sample 5. Figure 4. X-Ray diffraction pattern for Bi1.4Pb0.7Sr2Ca2Cu3O/MgO film prepared following the experimental conditions of sample 9. 3.2. Resistance vs. Temperature Dependence Results of the R vs. T measurements, from all the supercon- ducting films gave Tc0 values between 23 and 99 K, are listed in Table 2. Figure 5 shows the electrical behavior for all samples. Most of them show a metallic behavior before the supercon- ducting transition. Samples 2 and 7 gave the highest Tc values of 91 and 99 K, respectively. After thermal treatment, samples 3 and 8 were very thin and it was no possible to measure their Tc0 values because of missing conductive paths. Table 2. Results of final pb content (xf) determined by atomic ab- sorption spectroscopy and the critical temperature values, tc0, of the bi-based films. Sample xf [mole] Tc0 [K] 1 0.4 37 2 0.2 91 3 0.3 – 4 2.3 65 5 0.4 23 6 1.3 45 7 1.9 99 8 2.4 – 9 0.8 59 Figure 5. Resistance vs. temperature measurements of the samples no. 1, 2, 4, 5, 6, 7 and 9. Copyright © 2012 SciRes. AMPC  Y E. D. VALDÉS ET AL. Copyright © 2012 SciRes. AMPC 95 According to X-ray diffraction results and R vs. T depend- ence for samples 2 and 7 it is observed that covering material does not have influence in the result. While sample 2 was cov- ered with a superconducting pellet, sample 7 was covered with an MgO substrate. In both films the same electrical behavior was obtained approximately. From these results we can observe that covering the film helps to keep partial vapor pressure of Pb and so avoid its evaporation. Also it was verified that Pb re- duces the melting point of the film and therefore high annealing temperatures (860ºC), high annealing times (29 h) and high Pb content cause the evaporation of the material, i. e., the combi- nation of Pb content equal to 2.1 mol, annealing time of 29 h and annealing temperature of 860ºC which are the limit condi- tions, result in negative form in the superconducting properties of the film. On the other hand, an initial Pb content of 0.7 moles with a low annealing temperature of 840ºC and an annealing time of 15 h are not sufficient to grow high-Tc superconducting phases and therefore not superconducting electrical behavior in the films is presented. 4. Conclusions The Pb content necessary in the formation of the high-Tc phases depends on the combination of ta and Ta. This means that exists an interrelation among Pb content, ta and Ta. Therefore, the electrical behavior of the films 2 and 7 verifies the interde- pendence between Pb content, annealing time and annealing temperature. This means that the presence of Pb is necessary to stabilize the high-Tc phase but its content depends on the an- nealing conditions. REFERENCES [1] M. Yavuz, K. K. Uprety, G. Subramanian, and P. Paliwal, “Preparation and characterization of BSCCO 2212 thin films”, IEEE Transaction on Applied Superconductivity, vol. 13 No. 2, pp. 3295-3297, June 2003. [2] K. Ohbayashi, T. Ohtsuki, H. Matsushita, H. Nishiwaki, Y. Takai, H. Hayakawa, "As-grown superconducting Bi2Sr2Ca2Cu3Oxthin films with Tczero of 102 K prepared by rf magnetron sputtering", Appl. Phys. Lett., vol. 64 No. 3, pp 369-371, 1994. [3] J. Auge, U. Rudiger, H. Frank, H. G. Roskos, G. Guntherodt, H. Kurz, "Oxygen control of dc-sputtered Bi2Sr2Ca12Cu2O8+d films", Appl. Phys. Lett., vol. 64 No. 3, pp 378-381, 1994. [4] J. N. Eckstein, I. Bozovic, D. G. Schlom,J. S. Harris Jr., "Growth of superconducting Bi2Sr2Can-1CunOxthin films by atomically layered epitaxy", J. Crystal Growth, vol. 111 No. 1-4, pp. 973-977, May 1991. [5] N. Takahashi, A. Koikitu, H. Seki, Y. Kamioka, "The effect of Pb addition on Bi-Sr-Ca-Cu-O superconducting thin films pre- pared by the mist microwave-plasma chemical vapor deposition method", J. Crystal Growth, vol. 144 No. 1-2, pp 48-53, No- vember 1994. [6] E. Díaz Valdés, M. Jergel, C. Falcony Guajardo, F. Morales, J. Araujo Osorio, "Bi-Pb-Sr-Ca-Cu-O/MgO superconducting thin films", Thin Solid Films, vol. 373 No. 1, pp 122-128, September 2000. [7] Pawar S. H., Pawaskar P. N., Ubale M. J., Kulkarni S. B., "Layer by layer deposition of superconducting Sr-Ca-Cu-O films by the spray pyrolysis technique", Materials Chemistry and Physics, vol. 39 No. 4, pp. 309-312, January 1995. [8] H. Ning, H. Duan, P. D. Kirven, A. M. Hermann, T. Datta, "Magnetic penetration depth in high-Tc superconducting Tl8Ca1Ba2Cu2O8-d syngle crystals", J. Supercond., vol. 5 No. 6, pp. 503-509, 1992 . [9] J. Annett, N. Goldenfeld, S. R. Renn, "Interpretation of the tem- perature dependence of the electromagnetic penetration depth in YBa2Cu3O8-d", Phys. Rev. B, vol. 43 No. 4, pp 2778-2782, 1991. [10] H. Nobumasa, K. Simizu, Y. Kitano, T. Kawai, "Formation of a 100 K superconducting Bi(Pb)-Sr-Ca-Cu-O film by a spray py- rolysis", Jpn. J. Appl. Phys., vol. 27, pp L1669-L1671, 1988. [11] E. Díaz-Valdés, C. Mejía-García, J. L. López-López, M. Jergel, "Influence of annealing on the critical temperature of Bi-Pb- Sr-Ca-Cu-O thin films", J. Mater Sci: Mater Electron, vol. 18 No. 11, pp 1167-1170, 2007. |