X. L. ZHANG ET AL. 1879

tablet as a characteristic parameter to control tablet coat-

ing quantity. In this paper, we will report the traditional

Chinese medicine tablet, a famous Fufang Danshen tablet

CP [5] as a model example, was determined using contact

angle tester by Zisman critical surface tension method.

2. Instruments and Reagents

2.1. Instruments

The JZ8002 electronic balance (Shanghai Balance In-

strument Factory); GZX-9240MBE significant number of

blast oven (Shanghai Xun Bo Industrial Co., Ltd. Medi-

cal Equipment Factory); JC2000C1 contact angle meas-

uring instrument (Shanghai Zhong Chen Technology Co.,

Ltd.).

2.2. Reagents

Pure water (Guangdong Pharmaceutical University); For-

mamide (Sino Pharmaceutical and Chemical Reagent Co.,

Ltd., AR); Glycol (Guangzhou Chemical Reagent Fac-

tory, AR); Butanol (J & K, AR).

3. The Contact Angle Measurements

3.1. Preparation of Fufang Danshen Tablet CP

and the Test Liquids

We prepare the Fufang Danshen tablet CP by weighing

the formulation 400 mg and Repressing them into 2 mm

thickness and smooth surface tablet for sparing according

to Chinese Pharmacopoeia as a model tablet study and

design several test liquids (pure water, formamide, glycol,

butanol etc.) system.

3.2. Measurements of Contact Angle of Fufang

Danshen Tablet CP

Pretreatment: Place 5 ml water, Butanol, glycol, for-

mamide in the Petri dish, respectively and then put the

Petri dish in closed desiccators. The tablets employed to

test were located in the closed desiccators for 48 h until

the surface was saturated under the steam of the test liq-

uid.

Measure: The measurements were conducted through

the way of sessile drops with a computerized JC2000A

contact angle goniometer (Shanghai Balance Instrument

Factory). When the JC2000A contact angle goniometer

was operated, the production of the sessile drops was

yielded by performing the processes as follows:

1) Control the temperature to be 25˚C.

2) The infusion needle of the instrument was coated

with paraffin to ensure that the droplet is always in the

needle position.

3) Placing the needle near the surface, the correspond-

ing volume of liquid was squeezed out of the syringe.

4) Squeezing a drop of tested liquid on the tablet sur-

face, focusing camera 5 s latter.

5) Recorded every 5 seconds until 30 seconds and test

10 times for each test liquid Contact angle was measured

using the JC2000A, which takes a video image of the

drop and uses goniometer to determine and calculate.

6) Then select the mean value as the θ.

Each measurement should be finished less than 1 min to

minimize the effects of evaporation of the liquids. It was

found experimentally that the contact angle remained

constant within this operating time. An advancing con-

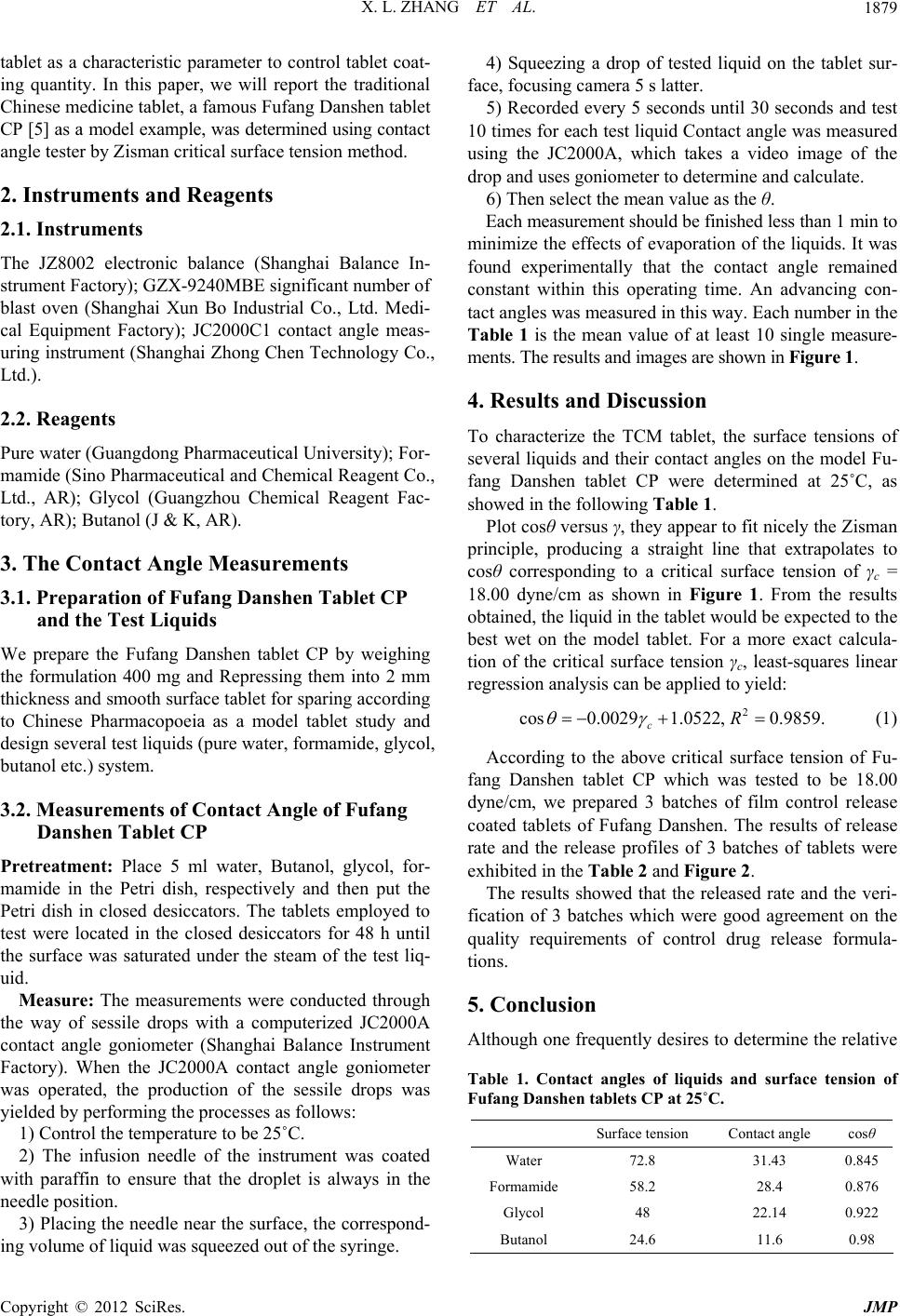

tact angles was measured in this way. Each number in the

Table 1 is the mean value of at least 10 single measure-

ments. The results and images are shown in Figure 1.

4. Results and Discussion

To characterize the TCM tablet, the surface tensions of

several liquids and their contact angles on the model Fu-

fang Danshen tablet CP were determined at 25˚C, as

showed in the following Table 1.

Plot cosθ versus γ, they appear to fit nicely the Zisman

principle, producing a straight line that extrapolates to

cosθ corresponding to a critical surface tension of γc =

18.00 dyne/cm as shown in Figure 1. From the results

obtained, the liquid in the tablet would be expected to the

best wet on the model tablet. For a more exact calcula-

tion of the critical surface tension γc, least-squares linear

regression analysis can be applied to yield:

2

cos0.0029 1.0522,0.9859.

cR

(1)

According to the above critical surface tension of Fu-

fang Danshen tablet CP which was tested to be 18.00

dyne/cm, we prepared 3 batches of film control release

coated tablets of Fufang Danshen. The results of release

rate and the release profiles of 3 batches of tablets were

exhibited in the Table 2 and Figure 2.

The results showed that the released rate and the veri-

fication of 3 batches which were good agreement on the

quality requirements of control drug release formula-

tions.

5. Conclusion

Although one frequently desires to determine the relative

Table 1. Contact angles of liquids and surface tension of

Fufang Danshen tablets CP at 25˚C.

Surface tension Contact angle cosθ

Water 72.8 31.43 0.845

Formamide 58.2 28.4 0.876

Glycol 48 22.14 0.922

Butanol 24.6 11.6 0.98

Copyright © 2012 SciRes. JMP