P. KANCHANA, C. SEKAR 987

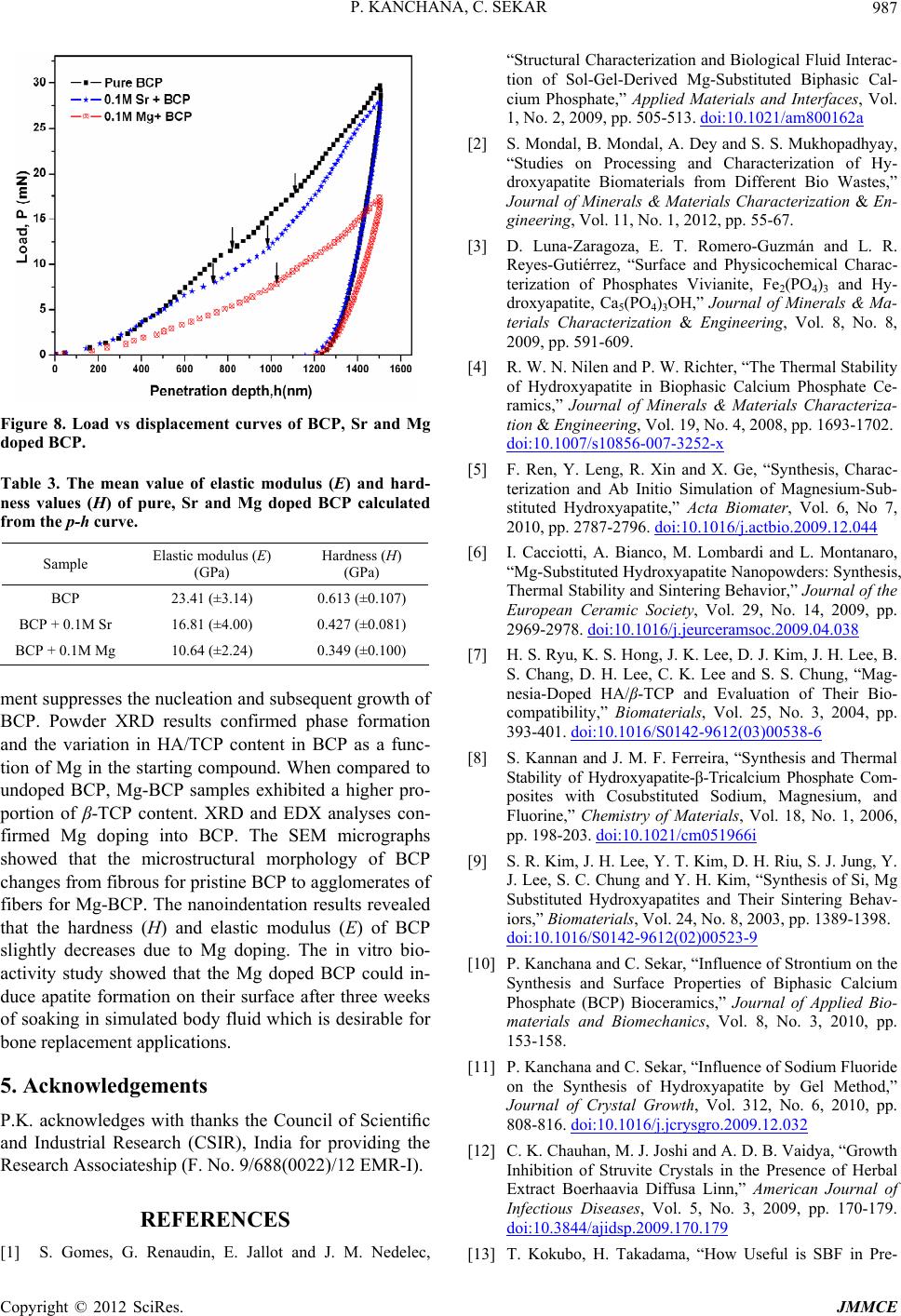

Figure 8. Load vs displacement curves of BCP, Sr and Mg

doped BCP.

Table 3. The mean value of elastic modulus (E) and hard-

ness values (H) of pure, Sr and Mg doped BCP calculated

from the p-h curve.

Sample Elastic modulus (E)

(GPa)

Hardness (H)

(GPa)

BCP 23.41 (±3.14) 0.613 (±0.107)

BCP + 0.1M Sr 16.81 (±4.00) 0.427 (±0.081)

BCP + 0.1M Mg 10.64 (±2.24) 0.349 (±0.100)

ment suppresses the nucleation and subsequent growth of

BCP. Powder XRD results confirmed phase formation

and the variation in HA/TCP content in BCP as a func-

tion of Mg in the starting compound. When compared to

undoped BCP, Mg-BCP samples exhibited a higher pro-

portion of β-TCP content. XRD and EDX analyses con-

firmed Mg doping into BCP. The SEM micrographs

showed that the microstructural morphology of BCP

changes from fibrous for pristine BCP to agglomerates of

fibers for Mg-BCP. The nanoindentation results revealed

that the hardness (H) and elastic modulus (E) of BCP

slightly decreases due to Mg doping. The in vitro bio-

activity study showed that the Mg doped BCP could in-

duce apatite formation on their surface after three weeks

of soaking in simulated body fluid which is desirable for

bone replacement applications.

5. Acknowledgements

P.K. acknowledges with thanks the Council of Scientific

and Industrial Research (CSIR), India for providing the

Research Associateship (F. No. 9/688(0022)/12 EMR-I).

REFERENCES

[1] S. Gomes, G. Renaudin, E. Jallot and J. M. Nedelec,

“Structural Characterization and Biological Fluid Interac-

tion of Sol-Gel-Derived Mg-Substituted Biphasic Cal-

cium Phosphate,” Applied Materials and Interfaces, Vol.

1, No. 2, 2009, pp. 505-513. doi:10.1021/am800162a

[2] S. Mondal, B. Mondal, A. Dey and S. S. Mukhopadhyay,

“Studies on Processing and Characterization of Hy-

droxyapatite Biomaterials from Different Bio Wastes,”

Journal of Minerals & Materials Characterization & En-

gineering, Vol. 11, No. 1, 2012, pp. 55-67.

[3] D. Luna-Zaragoza, E. T. Romero-Guzmán and L. R.

Reyes-Gutiérrez, “Surface and Physicochemical Charac-

terization of Phosphates Vivianite, Fe2(PO4)3 and Hy-

droxyapatite, Ca5(PO4)3OH,” Journal of Minerals & Ma-

terials Characterization & Engineering, Vol. 8, No. 8,

2009, pp. 591-609.

[4] R. W. N. Nilen and P. W. Richter, “The Thermal Stability

of Hydroxyapatite in Biophasic Calcium Phosphate Ce-

ramics,” Journal of Minerals & Materials Characteriza-

tion & Engineering, Vol. 19, No. 4, 2008, pp. 1693-1702.

doi:10.1007/s10856-007-3252-x

[5] F. Ren, Y. Leng, R. Xin and X. Ge, “Synthesis, Charac-

terization and Ab Initio Simulation of Magnesium-Sub-

stituted Hydroxyapatite,” Acta Biomater, Vol. 6, No 7,

2010, pp. 2787-2796. doi:10.1016/j.actbio.2009.12.044

[6] I. Cacciotti, A. Bianco, M. Lombardi and L. Montanaro,

“Mg-Substituted Hydroxyapatite Nanopowders: Synthesis,

Thermal Stability and Sintering Behavior,” Journal of the

European Ceramic Society, Vol. 29, No. 14, 2009, pp.

2969-2978. doi:10.1016/j.jeurceramsoc.2009.04.038

[7] H. S. Ryu, K. S. Hong, J. K. Lee, D. J. Kim, J. H. Lee, B.

S. Chang, D. H. Lee, C. K. Lee and S. S. Chung, “Mag-

nesia-Doped HA/β-TCP and Evaluation of Their Bio-

compatibility,” Biomaterials, Vol. 25, No. 3, 2004, pp.

393-401. doi:10.1016/S0142-9612(03)00538-6

[8] S. Kannan and J. M. F. Ferreira, “Synthesis and Thermal

Stability of Hydroxyapatite-β-Tricalcium Phosphate Com-

posites with Cosubstituted Sodium, Magnesium, and

Fluorine,” Chemistry of Materials, Vol. 18, No. 1, 2006,

pp. 198-203. doi:10.1021/cm051966i

[9] S. R. Kim, J. H. Lee, Y. T. Kim, D. H. Riu, S. J. Jung, Y.

J. Lee, S. C. Chung and Y. H. Kim, “Synthesis of Si, Mg

Substituted Hydroxyapatites and Their Sintering Behav-

iors,” Biomaterials, Vol. 24, No. 8, 2003, pp. 1389-1398.

doi:10.1016/S0142-9612(02)00523-9

[10] P. Kanchana and C. Sekar, “Influence of Strontium on the

Synthesis and Surface Properties of Biphasic Calcium

Phosphate (BCP) Bioceramics,” Journal of Applied Bio-

materials and Biomechanics, Vol. 8, No. 3, 2010, pp.

153-158.

[11] P. Kanchana and C. Sekar, “Influence of Sodium Fluoride

on the Synthesis of Hydroxyapatite by Gel Method,”

Journal of Crystal Growth, Vol. 312, No. 6, 2010, pp.

808-816. doi:10.1016/j.jcrysgro.2009.12.032

[12] C. K. Chauhan, M. J. Joshi and A. D. B. Vaidya, “Growth

Inhibition of Struvite Crystals in the Presence of Herbal

Extract Boerhaavia Diffusa Linn,” American Journal of

Infectious Diseases, Vol. 5, No. 3, 2009, pp. 170-179.

doi:10.3844/ajidsp.2009.170.179

[13] T. Kokubo, H. Takadama, “How Useful is SBF in Pre-

Copyright © 2012 SciRes. JMMCE