Open Journal of Soil Science, 2012, 2, 320-332 http://dx.doi.org/10.4236/ojss.2012.23038 Published Online September 2012 (http://www.SciRP.org/journal/ojss) A Model Study on Accelerated Consolidation of Coir Reinforced Lateritic Lithomarge Soil Blends with Vertical Sand Drains for Pavement Foundations George Varghese, Hegde Ramakrishna, A. G. Nirmal Kumar, L. Durga Prashanth, G. Santosh Department of Civil Engineering, National Institute of Technology Karnataka, Surathkal, India. Email: varghese@nitk.ac.in; yashas2all@yahoo.com Received May 12th, 2012; revised June 10th, 2012; accepted June 24th, 2012 ABSTRACT Sub-grade soils of lateritic origin encountered in the construction of highway embankments in various regions of India, often comprise intrusions of soft lithomargic soils that result in large settlements during constructions, and differential settlements at later stages. This necessitates the use of appropriate soil improvement techniques to improve the load-carrying capacity of pavements. This work deals with accelerated consolidation of un-reinforced and coir-rein- forced lateritic lithomargic soil blends, provided with three vertical sand drains. The load-settlement characteristics were studied for various preloads ranging from 50 kg (0.0013 N/mm2) to 500 kg (0.013 N/mm2) on soil specimens pre- pared in circular ferrocement moulds. It was observed that at lower preloads up to 200 kg, across the blends, the relative increase in consolidation (Rct) for randomly reinforced soil with vertical drains was significantly higher than that of un-reinforced soil without vertical drains, with an average value of 124.8%. Also, the Rct for un-reinforced soil with vertical drains was quite higher than that of un-reinforced soil without vertical drains, with an average value of 103.9%. In the case of higher preloads, the Rct values for randomly reinforced soil with vertical drains were moderate with an average value of 30.88%, while the same for un-reinforced soil with vertical drains was about 20.4%. The aspect-ratio of coir fibers used was 1:275. Keywords: Vertical Sand Drains; Accelerated Consolidation; Settlement; Coir Reinforcement; Laterite; Shedi; Lithomarge 1. Introduction Construction and maintenance of pavements in water- logged areas pose challenging problems to engineers. The defects in road sub-grades mainly arise due to poor compaction and consolidation. This is of major concern in road-works associated with submersible areas. Incor- porating the use of natural fibers in soil-stabilization, along with the laying of natural fiber reinforced vertical sand drains can contribute towards strengthening of road sub-grades especially in the construction of highway em- bankments. Differential settlement of sub-grade soils cause dam- ages to pavements in many regions. The problem as- sumes critical importance in clayey and silty soil sub- grades that have low permeability values. In such soils, the consolidation and the resultant settlements occur over a longer time-span. This work focuses on conducting extensive studies on the consolidation characteristics of weak soil sub-grades. Natural geo-textiles made of coir or jute can be effect- tively employed in the improvement of sub-grade strength by accelerating the drainage of soil-moisture content re- sulting in enhanced consolidation. The name laterite was initially suggested by Francis Buchanan [1] to describe “ferruginous, vesicular, un- stratified, and porous soil with yellow ochre’s due to high iron content, occurring in Malabar, India”. In the district of Dakshina Kannada, and Udupi, laterite soil can be found to occur above underlying shedi soil (or fine silty soil). Laterite soil is quite stronger than shedi soil due to the higher content of oxides of iron, while shedi soils are characterized by low bearing strengths under moist conditions. In India, lithomargic clays are often found to occur at depths of 1 - 3 meters below the top lateritic outcrops throughout the western coastal areas extending from Trivandrum to Mumbai, and also in the areas adjoining the Deccan Plateau. Shedi soil is the name given to the locally available whitish, pinkish or yellowish lithomar- gic soils with high silt content, and low bearing strengths. Copyright © 2012 SciRes. OJSS  A Model Study on Accelerated Consolidation of Coir Reinforced Lateritic Lithomarge Soil Blends with Vertical Sand Drains for Pavement Foundations 321 These soils are formed by weathering of soils in tropical regions, and contain hydrated alumina, primary silicates, and kaolinite. Lithomargic soils comprise 50% - 90% lateritic constituents, while soils with 25% - 50% laterite content are known as lateritic lithomarges. 2. Scope and Objectives of the Present Study In order to attain higher bearing strengths in soft soils, it may be required to resort to accelerated consolidation during the construction stage by applying incremental loads on suitably prepared sub-grades in stages. The pore-water pressure that builds up under the overburden pressure and surcharge loads, can be released with the use of natural reinforcements especially on weak soils. Additionally, the use of vertical drains will shorten the length of the horizontal drainage-paths, and accelerate the consolidation process. The enhanced dissipation of pore-water pressure due to the presence of natural fiber reinforcements and the overburden pressures, will result a further acceleration of the consolidation process in lat- eritic and shedi (L-S) soil sub-grades of embankments. The natural degradation of natural fibers after a few years [2] will not affect the strength and stability of L-S soil sub-grades due to the reason that the soil layers would have attained consolidation in the meantime. The present work deals with investigations on load- settlement characteristics due to accelerated consolida- tion of various blends of laterite and lithomargic (shedi) soils, with and without the use of reinforcements of ran- domly dispersed coir-fibers, and with and without the use of vertical sand drains randomly reinforced with coir. This study also incorporates an assessment of the im- provement in the California Bearing Ratio (CBR) values of L-S soil, when randomly mixed with coir for soaked and un-soaked conditions. The objectives of the present study include the fol- lowing: To prepare blended laterite-shedi (L-S) soil compris- ing 25% laterite and 75% shedi soil, and to perform basic laboratory investigations such as grain size analysis, Atterberg’s limits, CBR tests, tests for stan- dard and modified compaction tests for L-S soil sam- ples as specified by Indian Standard (IS) codes. To measure the load-settlement properties and con- solidation of fully saturated confined and un-rein- forced L-S soil without the use of vertical drains for soil samples drained at the top and bottom. To measure the load-settlement properties and con- solidation of fully saturated confined and un-rein- forced L-S soil with the use of 3 vertical drains. To measure the load-settlement properties and con- solidation of fully saturated confined randomly rein- forced L-S soil provided with 3 vertical drains In the case of tests on blended L-S soils, an optimum fiber content of 1.0% of coir fiber was adopted for random reinforcement. The sand-drains were fabricated using sand randomly reinforced with 1% of coir fibers. Loosely-woven jute fabric stitched at the seams was used in the installa- tion of sand-drains of 10 cm diameter. The results were compared with the same for 50% laterite + 50% shedi soil samples [3], and 100% shedi [4] obtained in similar studies. 3. Literature Review Studies on the stability of loaded footings on reinforced soil using natural “iko” vegetable fibers, reported by Ak- inumusura and Akinbolade [5] indicated that a significant improvement in soil strength could be achieved. Investigations on using vertical drains made of natural fiber such as jute and coir for soil improvement simulat- ing field conditions, was reported by Lee et al. [6]. The studies revealed that the axial filter permeability of fiber drains was higher than 10-5 m/sec for consolidation pres- sures of up to 400 kN/m2. Similar investigations in the field of application of coir-fibers [7,8] highlighted the advantages in the use of natural fibers for stabilization of embankments associ- ated with the use of fiber-reinforced vertical drains. Stapelfeldt [9] reported that preloading and the use of vertical drains, can enhance the shear strength of the soil, resulting in reduced soil compressibility, and permeabi- lity prior to construction, preventing differential settle- ments. Comparative studies on soft clay soils of Bangkok by Bergado et al. [10] revealed the use of compacted granu- lar piles (CGP), and prefabricated vertical drains (PVD). The studies indicated that in the case of soils improved with PVDs, the settlement rates were higher by 30% - 35% when compared to soils improved using CGPs. It was also noticed by Gosavi et al. [11] that the inclu- sion of randomly distributed fibers of jute and coir, in black cotton soils, increased the CBR values of clayey sands (SW) and sandy-silt (SM) by about 96%. Terzaghi [12] provides the basic theory for such one- dimensional consolidation for saturated conditions and also provides the strain formulation. The relationship be- tween the final settlement (Sf) and the settlement (St) at time t was expressed as: tv SUS f (1) The expression for Uv, the average degree of consoli- dation at depth z at any instant t was given by Terzaghi [13] as, Copyright © 2012 SciRes. OJSS  A Model Study on Accelerated Consolidation of Coir Reinforced Lateritic Lithomarge Soil Blends with Vertical Sand Drains for Pavement Foundations 322 2 0 =12 exp v m UM 2 v MT (2) where Tv = time factor (non dimensional) = (Cvt)/H2; Cv = coefficient of vertical consolidation (m2/s) = k/ (γwmv); k = permeability coefficient; mv = coefficient of volume compressibility = av/(1+e0); e0 = initial void ratio; av = coefficient of compressibility = ∆e/∆p; t = time in seconds; H = total distance of drainage path which is equal to the thickness of the layer (in m.) for soil subjected to top drainage, and is equal to half of the thickness of the layer (in m) for soils drained at the top and the bottom. The expression for M is given as, π212 for0,1,2 mm a . (3) From the above formulation, it is evident that consoli- dation is dependent on the permeability of the medium. Therefore, it is expected that the use of vertical drains will have a profound effect on accelerating the consoli- dation process. 4. Materials Used Laterite, and Shedi soil: Laterite soil (obtained from a site adjoining the newly widened National Highway-17, near NITK, Surathkal, Mangalore), and shedi soil (ob- tained from a road construction site close to Vidyanagara, Kulai, Mangalore), were collected in water-proof poly- thene bags, transported to the laboratory, and spread on flat trays of size, 1500 mm × 900 mm. The lumps were broken down using rammers, and the soil was sun-dried for 10 days, until the weight of soil on the trays was found to be constant, indicating that the soil was mois- ture-free. The laterite and shedi soil fractions were then intermixed 5 times using the technique of quartering. The basic soil properties including OMC (optimal moisture content), and MDD (maximum dry-density) were deter- mined. Sand: Locally available river-sand passing through 4.75 mm IS sieve with a coefficient of curvature (Cc) of 0.82, and a uniformity coefficient (Cu) of 1.7, was used for the preparation of vertical drains. The sand selected satisfies the general requirements of permeability and piping as suggested by Khanna and Justo [14]. Coir: In the present study, coir fibers were purchased from the local market. This comprised of brown coir fi- bers with aspect ratios of about 275 and an average di- ameter of 0.18 mm. The average length of the fibers used in this study was maintained at 50 mm. Rao et al. [15] suggested the use of 0.5% to 1% of coir fiber by weight of sand, and also proved that the use of fibers will restrict the lateral deformation at the peripheral areas of sand drains. Accordingly, in the present study, 1.0% of coir- fiber by weight of sand was used in preparing randomly distributed fiber-reinforced vertical sand drains. 5. Determination of Optimal Fiber Content for Soil Samples Using CBR Tests CBR tests were conducted as per IS 2720: Part VII (1983) [16]. with various percentages of coir fiber content ran- domly reinforced with 0.25%, 0.5%, 0.75%, 1.0%, and 1.25% of coir, and the CBR values at 2.5 mm and 5 mm penetrations were noted for soaked and un-soaked soil samples. The CBR values were determined for the soil samples, and the optimum fiber contents are reported as in Table 1. 6. Tests for Consolidation The test for accelerated consolidation involves several stages such as, preparation of the soil sample, soaking of specimens, loading, and installation of vertical drains and preloading of soil samples. The soil sample to be tested was prepared as mentioned above, and the water contents required to prepare soil beds at 80% MDD were deter- mined from the compaction curves. It was decided to perform tests at moisture content lesser than the OMC in order to study the load-settlement characteristics effect- tively. 7. Experimental Setup and Methodology Investigations were conducted for reinforced and un- reinforced soil specimens, with and without installation of vertical drains. These tests were conducted in order to evaluate the improvement in the bearing capacity due to the accelerated consolidation. 7.1. Tests for Consolidation of Un-Reinforced Soil without Using Vertical Drains In order to study the compressibility and consolidation of soil sample, a ferro-cement cylindrical test mould was used, of 740 mm internal diameter, 850 mm height, and 30 mm wall thickness. The test mould was provided with an inlet pipe at the top and an outlet pipe at the bottom, both of 20 mm diameter, to permit soaking of the soil sample, and drainage of water. The test mould was placed on leveled ground. A sand layer of 100 mm thickness was provided at the bottom of the Ferro-cement tank to act as a permeable layer, and was compacted to a density of 1.53 g/cc. Table 1. Optimum fiber contents (OFC) determined for various blends. Sl. noSoil Blends OMC (%) OFC (%) 1 100% Shedi 19 1.0 2 25% L + 75% S 15 1.0 3 50% L + 50% S 14 0.75 Copyright © 2012 SciRes. OJSS  A Model Study on Accelerated Consolidation of Coir Reinforced Lateritic Lithomarge Soil Blends with Vertical Sand Drains for Pavement Foundations 323 Above this layer, a jute textile was provided to act as a separator. Over this, three layers of the soil sample, each of 200 mm thickness, were placed and compacted to 80% of the MDD. The soil and the sand layers were com- pacted to the desired thickness, and respective densities using a steel rammer (of 885 mm height, 140 mm dia- meter, and 11.5 kg weight) and a wooden rammer (of 870 mm height, 40 mm diameter, and 1.17 kg weight). On top of the three layers of compacted soil sample, a layer of jute textile was placed. A layer of sand of 100 mm thickness compacted to a density of 1.53 g/cc was provided at the top, to act as level-surface for the appli- cation of preloads. The soil sample in the cylindrical test mould possesses the same characteristics as mentioned in the sections above. A flat surface made of treated perforated plywood (of 730 mm diameter, and 12 mm thickness) was pro- vided above the sand layer. A schematic diagram of the test set up is shown in Figure 1. The details of the com- ponents used in this experiment are listed below: 1) Ferro-cement mould of cylindrical shape 2) 100 mm thick layer of sand at the bottom 3) Bottom layer of jute-textile as a separator 4) Three layers of soil, each of 200 mm thickness 5) Top layer of jute-textile as a separator 6) Top layer of sand of 100 mm thickness 7) Loading platform of treated plywood 8) Standard steel weights 9) Dial gauges of 0.01 mm least count 10) Water inlet 11) Water outlet 7.2. Tests on Consolidation of Un-Reinforced Soil Using Three Vertical Drains The test setup and procedure for test on consolidation of un-reinforced soil sample are the same as that explained above. A Ferro-cement cylindrical test mould with verti- cal drains of 100 mm diameter and 600 mm height is installed in a triangular pattern such that the center to center distance between the adjacent drains is 350 mm. This arrangement is considered to be more effective as it is expected to result in uniform consolidation between the drains due to the uniform center to center distances, when compared to vertical drains installed in a square pattern. The radius of influence (R) of a vertical drain depends upon the spacing (S) between drains. In the case of cylindrical drains installed in triangular pattern the radius of influence (R) can be computed from the em- pirical formula, 0.546RS (4) Thus for vertical drains of 100 mm diameter and cen- ter to center spacing of 350 mm between the drains, the 4 1 5 8 9 2 3 7 6 11 10 Figure 1. Schematic diagram of the test setup without ver- tical drains. radius of influence can be obtained as 190 mm based on Equation (4). The vertical drains of 600 mm height were installed with the help of sampling tubes of 100 mm di- ameter inserted into sleeves made of jute fabric. See Figure 2, Figures 3(a)-(d) provide a clear view of the installation of vertical drains. The sampling tubes enclosed in the jute sleeves, were then filled in two layers with sand randomly mixed with 1% of coir fibers by weight of sand for a height of 200 mm by compacting with a wooden tamping tool with 15 blows per layer to obtain a compacted density of 1.08 g/cc. The tubes were gradually withdrawn when each layer of soil sample of 100 mm was compacted. Smears developed due to the disturbance to the soil while in- stalling vertical drains, can result in reduced soil perme- ability around the smear zone, restricting the rate of con- solidation. However, in this investigation, since the ver- tical drains were installed in a simultaneous build-up pro- cedure, the smear effects are assumed to be negligible. Jute Textiles Woven jute textile fabric of 600 g per sq.m and 1.43 mm thickness was used in fabricating the sleeves for the ver- tical drains. The properties of jute textiles used in this study are given in Table 2. Mild steel sleeves of 100 mm average diameter and 600 mm height were used to build- up the vertical drains to span the entire depth of laterite soil tested. Copyright © 2012 SciRes. OJSS  A Model Study on Accelerated Consolidation of Coir Reinforced Lateritic Lithomarge Soil Blends with Vertical Sand Drains for Pavement Foundations 324 200mm R = 190 mm S = 350 mm 100 mm Figure 2. Influence zone for triangular pattern of drains (Stapelfeldt, 2006). 7.3. Tests on Consolidation of Randomly Reinforced Soil Using Three Vertical Drains In this part of the experiment, the soil used in the test mould was randomly reinforced using coir. The optimum fiber content of 1.0% by weight of soil was adopted in these tests. The overall experimental setup remains the same as explained above. 8. Results 8.1. Soil Blend Type: 50% L + 50% S The load-settlement details are discussed below for un- reinforced soil samples without vertical drains (UR), un- reinforced soil samples with vertical drains (UR-VD), and reinforced soil samples with vertical drains (RR- VD). 8.1.1. Settlement for UR (50% L + 50% S) Figure 4(a) provides details on the load-settlement char- acteristics for un-reinforced soils comprising 50% laterite and 50% shedi soil. Also, Table 3(a) provides details on the coefficient of consolidation (Cv) for various preloads for the soil sample tested. It can be observed that during the initial stages of loading using preloads of 50 kg, 100 kg, 150 kg, 200 kg and 250 kg, the compaction of soil is considered to have taken place. This can be visualized from the corresponding increase in the rate of compact- tion in the above table. Thereafter, the rate of compaction for preloads of 300 kg to 500 kg shows a decreasing trend, indicating the commencement of the consolidation process. 8.1.2. Settlement for UR-VD (50% L + 50% S) Figure 4(b) provides details on the load-settlement char- (a) (b) (c) (d) Figure 3. (a) Installation of vertical drains; (b) Removal of casing for the third vertical drain; (c) Test mould with ac- cessories for vertical drains; (d) Test mould with accessories for vertical drains. Copyright © 2012 SciRes. OJSS  A Model Study on Accelerated Consolidation of Coir Reinforced Lateritic Lithomarge Soil Blends with Vertical Sand Drains for Pavement Foundations 325 0.0000 0.1000 0.2000 0.3000 0.4000 0.5000 0.6000 036912 15 18 Square-root of time [√(minute)] Dial Guage Readings (mm) 50kg100kg 150kg200kg 250kg 300kg 350kg400kg 450kg500kg (a) 0.0000 0.1000 0.2000 0.3000 0.4000 0.5000 0.6000 03691215 18 Square- root of time [√(minute)] Dial Guage Readings (mm) 50kg 100kg 150kg 200kg 250kg 300kg 350kg 400kg 450kg 500kg (b) 0.0000 0.1000 0.2000 0.3000 0.4000 0.5000 0.6000 03691215 Square- root of time [√(minute)] Dial Guage Readings (mm) 18 50kg 100kg 150kg200kg 250kg 300kg 350kg 400kg 450kg 500kg (c) Figure 4. (a) Load-settlement: UR (50% L + 50% S) soils; (b) Load-settlement: UR-VD (50% L + 50% S) soils; (c) Load-settlement: RR-VD (50% L + 50% S) soils. Table 2. Properties of jute textiles used in this investigation. Property Woven Type Weight, gm per sq.m 600 Thickness, mm 1.43 Wrap × Weft per 100 sq. mm 28 × 34 acteristics for un-reinforced vertically drained soils com- prising 50% laterite and 50% shedi soil. Table 3(b) pro- Table 3. (a) Cv values: UR (50% L+50% S) soils; (b) Cv val- ues: UR-VD (50% L + 50% S) soils; (c) Cv values: RR-VD (50% L + 50% S) soils. (a) Co-efficient of consolidation Cv Preload (kg) Cv 50 1.2351 100 1.2966 150 1.3365 200 1.4565 250 1.6830 300 1.5428 350 1.3644 400 1.2977 450 1.2711 500 1.1923 (b) Co-efficient of consolidation Cv Preload (kg) Cv 50 1.0805 100 1.4244 150 2.0567 200 1.7394 250 1.5999 300 1.5614 350 1.4898 400 1.1785 450 1.1239 500 1.1473 (c) Co-efficient of consolidation Cv Preload (kg) Cv 50 1.0894 100 1.4241 150 2.0784 200 1.9932 250 1.6400 300 1.6296 350 1.4895 400 1.2707 450 1.1574 500 1.0894 Copyright © 2012 SciRes. OJSS  A Model Study on Accelerated Consolidation of Coir Reinforced Lateritic Lithomarge Soil Blends with Vertical Sand Drains for Pavement Foundations 326 vides details on the coefficient of consolidation (Cv) for various preloads for the soil sample tested. In this case, it can be seen that during the initial stages of loading, as in the case of preloads of 50 kg, 100 kg, and 150 kg, the compaction of soil is considered to have taken place. Thereafter, the rate of compaction for preloads of 200 kg to 500 kg shows a decreasing trend, indicating the com- mencement of the consolidation process. 8.1.3. Settlement for RR-VD (50% L + 50% S) Figure 4(c) illustrates details on the load-settlement cha- racteristics for randomly-reinforced vertically drained soils comprising 50% laterite and 50% shedi soil. Table 3(c) gives details on the coefficient of consolidation (Cv) for various preloads. It can be observed that in the initial stages of loading, the behavior of the soil is almost the same as observed in the case of UR-VD (50% L + 50% S) soil. The rate of compaction for preloads of 200 kg to 500 kg shows decreasing trend, indicating the com- mencement of the consolidation process. 8.2. Soil Blend Type: 25% L + 75% S 8.2.1. Settlement for UR (25% L + 75% S) Figure 5(a) provides details on the load-settlement char- acteristics for un-reinforced soils comprising 25% laterite and 75% shedi soil. Also, Table 4(a) provides details on the coefficient of consolidation (Cv) for various preloads for the soil sample tested. Here, the compaction of soil is seen to have taken place up to preloads of 300 kg. The rate of compaction for preloads of 350 kg to 500 kg shows a decreasing trend, indicating the commencement of the consolidation process. 8.2.2. Settlement for UR-VD (25% L + 75% S) Figure 5(b) provides details on the load-settlement char- acteristics for un-reinforced vertically drained soils com- prising 25% laterite and 75% shedi soil. Table 4(b) pro- vides details on the coefficient of consolidation (Cv) for various preloads. Here, the compaction of soil is seen to have taken place up to preloads of 200 kg. The rate of compaction for preloads of 250 kg to 500 kg shows a decreasing trend, indicating the commencement of the consolidation process. 8.2.3. Settlement for RR-VD (25% L + 75% S) Figure 5(c) provides details on the load-settlement char- acteristics for randomly-reinforced vertically drained soils comprising 25% laterite and 75% shedi soil. Table 4(c) provides details on the coefficient of consolidation (Cv) for various preloads. Here too, the compaction of soil is seen to have taken place up to preloads of 200kg as in the case of UR-VD (50% L + 50% S) and UR-VD (25% L + 75% S) soils. The rate of compaction for preloads of Table 4. (a) Cv values: UR (25% L + 75% S) soils; (b) Cv values: UR-VD (25% L + 75% S) soils; (c) Cv values: RR-VD (25% L + 75% S) soils. (a) Co-efficient of consolidation Cv Preload (kg) Cv 50 1.0380 100 1.1331 150 1.2415 200 1.2813 250 1.3224 300 1.4770 350 1.2966 400 1.2035 450 1.1946 500 1.1673 (b) Co-efficient of consolidation Cv Preload (kg) Cv 50 1.0379 100 1.2812 150 1.4602 200 1.6798 250 1.5103 300 1.4600 350 1.3661 400 1.1326 450 1.0994 500 1.0681 (c) Co-efficient of consolidation Cv Preload (kg) Cv 50 1.0378 100 1.3664 150 1.8790 200 1.9538 250 1.5642 300 1.5104 350 1.4601 400 1.2033 450 1.1327 500 1.0996 Copyright © 2012 SciRes. OJSS  A Model Study on Accelerated Consolidation of Coir Reinforced Lateritic Lithomarge Soil Blends with Vertical Sand Drains for Pavement Foundations 327 0.0000 0.1000 0.2000 0.3000 0.4000 0.5000 0.6000 03691215 Square- root of time [√(minute)] Dial Guage Readings (mm) 18 50kg 100kg 150kg200kg250kg 300kg 350kg 400kg 450kg500kg (a) 0.0000 0.1000 0.2000 0.3000 0.4000 0.5000 0.6000 036912 15 18 Square-root of time [√(minute)] Dial Guage Readings (mm) 50kg100kg 150kg200kg 250kg 300kg 350kg400kg 450kg500kg (b) 0.0000 0.1000 0.2000 0.3000 0.4000 0.5000 0.6000 036912 15 18 Square-root of time [√(minute)] Dial Guage Readings (mm) 50kg100kg 150kg200kg 250kg 300kg 350kg 400kg 450kg500kg (c) Figure 5. (a) Load-settlement: UR (25% L + 75% S) soils; (b) Load-settlement: UR-VD (25% L + 75% S) soils; (c) Load-settlement: RR-VD (25% L + 75% S) soils. 250 kg to 500 kg shows a decreasing trend, indicating the commencement of the consolidation process. 8.3. Soil Blend Type: 0% L+100% S 8.3.1. Settlement for UR (0% L + 100% S) Figure 6(a) provides details on the load-settlement char- acteristics for un-reinforced soils comprising 100% shedi soil. Also, Table 5(a) provides details on the coefficient of consolidation (Cv) for various preloads for the soil sample tested. Here, the compaction of soil is seen to have taken place up to preloads of 300 kg. The rate of compaction for preloads of 350 kg to 500 kg shows a decreasing trend, indicating the commencement of the consolidation process. 0.0000 0.1000 0.2000 0.3000 0.4000 0.5000 0.6000 03691215 18 Square- root of time [√(minute)] Dial Guage Readings (mm) 50kg 100kg 150kg200kg 250kg 300kg 350kg 400kg450kg 500kg (a) 0.0000 0.1000 0.2000 0.3000 0.4000 0.5000 0.6000 0 36 9121518 Square- root of time [√(minute)] Dial Guage Readimgs (mm) 50kg100kg150kg 200kg250kg 300kg 350kg400kg 450kg500kg (b) 0.0000 0.1000 0.2000 0.3000 0.4000 0.5000 0.6000 036912 1518 Square- root of time [√(minute)] Dial Guage Readings (mm) 50kg 100kg 150kg 200kg 250kg 300kg 350kg 400kg450kg 500kg (c) Figure 6. (a) Load-settlement: UR (0% L + 100% S) soils; (b) Load-settlement: UR-VD (0% L + 100% S) soils; (c) Load-settlement: RR-VD (0% L + 100% S) soils. Copyright © 2012 SciRes. OJSS  A Model Study on Accelerated Consolidation of Coir Reinforced Lateritic Lithomarge Soil Blends with Vertical Sand Drains for Pavement Foundations 328 Table 5. (a) Cv values: UR (0% L+100% S) soils; (b) Cv val- ues: UR-VD (0% L + 100% S) soils; (c) Cv values: RR-VD (0% L + 100% S) soils. (a) Co-efficient of consolidation Cv Preload (kg) Cv 50 1.0176 100 1.0216 150 1.0467 200 1.0821 250 1.1250 300 1.4349 350 1.2517 400 1.2219 450 1.1768 500 1.1555 (b) Co-efficient of consolidation Cv Preload (kg) Cv 50 1.0214 100 1.1673 150 1.3661 200 1.5951 250 1.4939 300 1.4598 350 1.3233 400 1.1326 450 1.0375 500 1.0088 (c) Co-efficient of consolidation Cv Preload (kg) Cv 50 1.0092 100 1.3240 150 1.8277 200 1.8782 250 1.5638 300 1.5101 350 1.4113 400 1.2032 450 1.0993 500 1.0208 8.3.2. Settlement for UR-VD (0% L + 100% S) Figure 6(b) provides details on the load-settlement cha- racteristics for un-reinforced vertically drained soils comprising 100% shedi soil. Table 5(b) provides details on the coefficient of consolidation (Cv) for various pre- loads. Here, the compaction of soil is seen to have taken place up to preloads of 200 kg. The rate of compaction for preloads of 250 kg to 500 kg shows a decreasing trend, indicating the commencement of the consolidation process. 8.3.3. Settlement for RR-VD (0% L + 100% S) Figure 6(c) provides details on the load-settlement char- acteristics for randomly-reinforced vertically drained soils comprising 100% shedi soil. Table 5(c) provides details on the coefficient of consolidation (Cv) for various preloads. Here too, the compaction of soil is seen to have taken place up to preloads of 200kg as in the case of UR-VD (50% L + 50% S) and UR-VD (25% L + 75% S) soils. The rate of compaction for preloads of 250 kg to 500 kg shows a decreasing trend, indicating the com- mencement of the consolidation process. 9. Comparisons of Settlements of UR with UR-VD, and RR-VD Soils for Blends of Lateritic Lithomarge 9.1. UR vs UR-VD, and RR-VD: 50% L + 50% S Soils Figure 7(a) provides details of the load-settlement trends for a preload of 50 kg for UR, UR-VD, and RR-VD test conditions for 50% L + 50% S soils. Similar figures can be obtained and studied for preloads of 100 kg, 150 kg, 200 kg, 250 kg, 300 kg, 350 kg, 400 kg, 450 kg, and 500 kg. On observation of the load-settlement trends for vari- ous pre-loads, it was found that the 169th minute could be taken as a reference for comparison, since the soil was found to attain stability at this instance. In other words, the soil can be assumed to have been consolidated at this point in time. The relative increase in consolidation achieved by un- reinforced soil samples provided with vertical drains, when compared to un-reinforced soil samples without vertical drains is expressed using the percentage of the increase in settlement of the soil sample provided with vertical drains, to the settlement of the un-reinforced soil without vertical drains. This is denoted as, Rct (UR v/s UR-VD). Similarly, the relative increase in consolidation achi- eved by randomly reinforced soil samples provided with vertical drains, when compared to un-reinforced soil samples without vertical drains is expressed using the percentage of the increase in settlement of the randomly Copyright © 2012 SciRes. OJSS  A Model Study on Accelerated Consolidation of Coir Reinforced Lateritic Lithomarge Soil Blends with Vertical Sand Drains for Pavement Foundations 329 Table 6. (a) Relative increase in consolidation at different preloads at the 169thminute of L-S; (b) Relative increase in consolidation at different preloads at the 196th minute of L-S; (c) Relative increase in consolidation at different pre- loads at the 225th minute of L-S. (a) Preload (kg) Rct (UR vs UR-VD) (%) Rct (UR vs RR-VD) (%) 50 38.61 64.64 100 50.17 79.65 150 65.16 87.33 200 37.44 61.32 250 02.12 15.44 300 12.21 14.33 350 14.25 31.13 400 11.36 24.24 450 08.22 18.53 500 10.73 18.79 (b) Preload (kg) Rct (UR vs UR-VD) (%) Rct (UR vs RR-VD) (%) 50 40.91 61.36 100 59.95 85.15 150 120.85 149.15 200 102.52 106.43 250 58.96 61.68 300 5.20 13.98 350 11.96 26.5 400 18.29 24.32 450 8.1 21.64 500 15.1 24.25 (c) Preload (kg) Rct (UR vs UR-VD) (%) Rct (UR vs RR-VD) (%) 50 40.61 57.73 100 120.49 172.84 150 275.26 325.15 200 294.55 321.6 250 152.02 168.44 300 5.95 15.33 350 7.37 20.40 400 4.01 18.69 450 7.98 17.65 500 13.06 20.10 reinforced soil sample provided with vertical drains, to the settlement of the un-reinforced soil without vertical drains. This is denoted as, Rct (UR vs RR-VD). Table 6(a) provides details on the relative increase in consolidation at different preloads at the 169th minute of the load settlements for UR v/s UR-VD, and UR v/s RR-VD observations. In this table, it is observed that for pre-loads ranging from 50 kg to 200 kg, the effect of pro- viding vertical drains was significant when compared to the rate of settlement in the case of UR soils. The Rct (UR v/s UR-VD) values within this range of pre-loads vary from 37.14% to 65.29%. But for pre-loads higher than 200 kg, the effect of providing vertical sand drains was not significant as it was found to vary between 2.13% to 14.35%. Also, for the pre-loads ranging from 50 kg to 200 kg, the effect of randomly reinforcing the soil was significant when compared to the rate of settlement in the case of UR soils. The Rct (UR v/s RR-VD) values were found to range between 60.12% to 86.13%, whereas for pre-loads greater than 200 kg, the increase was found to be moder- ate with Rct (UR v/s RR-VD) values ranging between 14.33% to 31.04%. Therefore, it can be seen that the combined effect of vertical drains and random reinforcement with coir fibers resulted in considerable increase in the rate of consolida- tion at lower pre-loads. 9.2. UR vs UR-VD, and RR-VD: 25% L + 75% S Soils Figure 7(b) provides details of the load-settlement trends for a preload of 50 kg for UR, UR-VD, and RR-VD test conditions for 50% L + 50% S soils. Similar figures can be obtained and studied for preloads of 100 kg, 150 kg, 200 kg, 250 kg, 300 kg, 350 kg, 400 kg, 450 kg, and 500 kg. On observation of the load-settlement trends for vari- ous pre-loads, it was found that the 169th minute could be taken as a reference for comparison, since the soil was found to attain stability at this instance. Table 6(b) provides details on the relative increase in consolidation at different preloads at the 169th minute of the load settlements for UR v/s UR-VD, and UR v/s RR-VD observations. In this table, it is observed that for pre-loads ranging from 50 kg to 250 kg, the effect of pro- viding vertical drains was significant when compared to the rate of settlement in the case of UR soils. The Rct (UR v/s UR-VD) values within this range of pre-loads vary from 40.91% to 120.85%. But for pre-loads higher than 200 kg, the effect of providing vertical sand drains was insignificant as it varied between 5.2% and 18.29%. Also, for the pre-loads ranging from 50 kg to 250 kg, the effect of randomly reinforcing the soil was significant Copyright © 2012 SciRes. OJSS  A Model Study on Accelerated Consolidation of Coir Reinforced Lateritic Lithomarge Soil Blends with Vertical Sand Drains for Pavement Foundations Copyright © 2012 SciRes. OJSS 330 0.0000 0.0500 0.1000 0.1500 0.2000 0.2500 0.3000 0.3500 0.4000 0.4500 0.5000 0.5500 0.6000 0123456789101112131415161718 Dial Gauge Readings (mm) Sqrt Time [√(minute)] LoadSettlementCurve UR_100kg UR‐VD_100kg RR‐VD_100kg (a) 0.0000 0.0500 0.1000 0.1500 0.2000 0.2500 0.3000 0.3500 0.4000 0.4500 0.5000 0.5500 0.6000 0123456789101112131415161718 DialGaugeRead i ng s(mm) SqrtTime[√(minute)] LoadSettlementCurve UR_100kg UR‐VD_100kg RR‐VD_100kg (b) 0.0000 0.0500 0.1000 0.1500 0.2000 0.2500 0.3000 0.3500 0.4000 0.4500 0.5000 0.5500 0.6000 0123456789101112131415161718 DialGaugeReadings(mm) SqrtTime[√(minute)] LoadSettlementCurve UR_100kg UR‐VD_100kg RR‐VD_100kg (c) Figure 7. (a) Load-settlement trend for preload of 100 kg for 50% L + 50% S soil; (b) Load-settlement trend for preload of 100kg for 25% L + 75% S soil; (c) Load-settlement trend for preload of 100kg for 0% L + 100% S soil.  A Model Study on Accelerated Consolidation of Coir Reinforced Lateritic Lithomarge Soil Blends with Vertical Sand Drains for Pavement Foundations 331 when compared to the rate of settlement in the case of UR soils. The Rct (UR v/s RR-VD) values were found to range from 61.36% to 149.15%, whereas for pre-loads greater than 250 kg, the increase was found to be moder- ate with Rct (UR v/s RR-VD) values ranging from 13.98% to 24.32%. Therefore, it can be seen that the combined effect of vertical drains and random reinforcement with coir fibers resulted in considerable increase in the rate of consolida- tion at lower pre-loads. 9.3. UR vs UR-VD, and RR-VD: 0% L + 100% S Soils Figure 7(c) provides details of the load-settlement trends for a preload of 50 kg for UR, UR-VD, and RR-VD test conditions for 50% L + 50% S soils. Similar figures can be obtained and studied for preloads of 100 kg, 150 kg, 200 kg, 250 kg, 300 kg, 350 kg, 400 kg, 450 kg, and 500 kg. On observation of the load-settlement trends for vari- ous pre-loads, it was found that the 225th minute could be taken as a reference for comparison, since the soil was found to attain stability at this instance. Table 6(c) provides details on the relative increase in consolidation at different preloads at the225th minute of the load settlements for UR v/s UR-VD, and UR v/s RR-VD observations. In this table, it is observed that for pre-loads ranging from 50 kg to 250 kg, the effect of providing vertical drains was significant when compared to the rate of settlement in the case of UR soils. The Rct (UR v/s UR-VD) values within this range of pre-loads vary from 40.61% to 294.55%. But for pre-loads higher than 200kg, the effect of providing vertical sand drains was not significant as it was found to vary between 4.01% and 13.06%. Also, for the pre-loads ranging from 50 kg to 250 kg, the effect of randomly reinforcing the soil was significant when compared to the rate of settlement in the case of UR soils. The Rct (UR v/s RR-VD) values were found to range from 57.73% to 325.15%, whereas for pre-loads greater than 250 kg, the increase was found to be moder- ate with Rct (UR v/s RR-VD) values ranging from 15.33% to 20.40%. Therefore, it can be seen that the combined effect of vertical drains and random reinforcement with coir fibers resulted in considerable increase in the rate of consolida- tion at lower pre-loads, whereas a moderate increase was observed at higher pre-loads. 10. Conclusions The above sections focused on examining the rate of consolidation for various types of soil mixes for various test conditions using vertical drains. The observations made as part of this work will have an important bearing on the construction of road and railway embankments on lateritic soil sub-grades. Also, natural fibers of coir can be effectively used in further accelerating consolidation since the fibers allow pore-water pressures to dissipate easily when subjected to overburden pressures. Also, coir, being a natural fiber, undergoes decomposition once the soil attains sufficient strength through consolidation. Laboratory investigations were performed in this study, for soil compacted in cylindrical moulds of 70 cm dia- meter and 85 cm internal height for laterite soil blended with 50% shedi soil (50% L + 50%S ), laterite soil blended with 75% shedi soil (25% L+75% S) and shedi soil (0% L + 100% S).Tests on drained soil samples were per- formed by providing 3 vertical sand drains reinforced with 1% coir fiber. The following are the conclusions drawn from this study. 10.1. Soil Type: 50% L + 50% S From Sections 8.1 and 9.1, and Table 6(a), it is seen that the 50% L + 50% S soil type attained stability at around the 169th minute after application of the preloads. Using this as datum, it can be observed that for the pre-loads ranging from 50 kg to 200 kg, the effect of randomly reinforcing the soil was significant when compared to the rate of settlement in the case of UR soils. The relative increase in settlement of RR-VD soils when compared to that of UR soils (Rct (UR v/s RR-VD)), was found to range between 60.12% to 86.13%, with an average in- crease of 71.73%, whereas for pre-loads greater than 200 kg, the increase was found to be moderate with Rct (UR v/s RR-VD) values ranging between 14.13% to 31.04%, with an average increase of 20.51%. Considering the average values, for pre-loads ranging from 50 kg to 200 kg, there is an additional increase of 24.8% in the settle- ment of randomly reinforced soil blends when compared to that of soil blends with vertical drains alone. Hence it can be concluded that in the soil blend of 50% L+50% S, there is a significant increase in settlement due to random reinforcement with coir fibers in addition to the vertical drains. 10.2. Soil Type: 25% L + 75% S From Sections 8.2 and 9.2, and Table 6(b), it is seen that the 25% L+75% S soil type attained stability at around the 196th minute after application of the preloads. Using the same 196th minute as datum, it can be observed that for the pre-loads ranging from 50 kg to 250 kg, the effect of randomly reinforcing the soil in addition to providing vertical sand drains, was significant when compared to Copyright © 2012 SciRes. OJSS  A Model Study on Accelerated Consolidation of Coir Reinforced Lateritic Lithomarge Soil Blends with Vertical Sand Drains for Pavement Foundations 332 the rate of settlement in the case of UR soils. The relative increase in settlement of RR-VD soils when compared to that of UR soils (Rct (UR v/s RR-VD)), was found to range between 61.36% and 149.15%, with an average increase of 92.7%, whereas for pre-loads greater than 150 kg, the increase was found to be moderate, with Rct (UR v/s RR-VD) values ranging between 13.98% to 24.32% with an average increase of 22.1%. Considering the average values, for pre-loads ranging from 50 kg to 250 kg, there is an additional increase of 16.1% in the settlement of randomly reinforced soil blends when com- pared to that of soil blends with vertical drains alone. Hence it can be said that for the soil blend of 25%L + 75% S, there is a significant increase in settlement due to random reinforcement with coir fibers in addition to the vertical drains. 10.3. Soil Type: 0% L + 100% S From Sections 8.3 and 9.3, and Table 6(c), it is seen that the 0% L+100% S soil type attained stability at around the 225th minute after application of the preloads. The 225th minute is taken as a reference since the graphical trends indicate that for the pre-loads ranging from 50 kg to 250 kg, the effect of randomly reinforcing the soil in addition to providing vertical sand drains, was significant when compared to the rate of settlement in the case of UR soils. The relative increase in settlement of RR-VD soils when compared to that of UR soils (Rct (UR v/s RR-VD)), was found to range between 57.73% and 325.15%, with an average increase of 209.1%, whereas for pre-loads greater than 250 kg, the increase was found to be moderate, with Rct (UR v/s RR-VD) values ranging between 15.33% to 20.4% with an average increase of 18.43%. Considering the average values, for pre-loads ranging from 50 kg to 250 kg, there is an additional in- crease of 32.6% in the settlement of randomly reinforced soil blends when compared to that of soil blends with vertical drains alone. Hence it can be concluded that in the soil blend of 0% L + 100% S, there is a significant increase in settlement due to random reinforcement with coir fibers in addition to the vertical drains. REFERENCES [1] F. Buchanan, “A Journey from Madras through the Coun- tries of Mysore, Canara and Malabar,” Asian Educational Services, New Delhi, 1807. [2] K. Balan, “Studies on Engineering Behavior and Uses of Geo-Textiles with Natural Fibers,” Ph.D. Thesis, Indian Institute of Technology Delhi, New Delhi, 1995. [3] Santosh, “A Model Study on Accelerated Consolidation of Coir Reinforced Laterite and Blended Shedi Soil with Vertical Sand Drains for Pavement Foundations,” M.Tech. Thesis, National Institute of Technology Karnataka, Su- rathkal, 2010. [4] L. D. Prashanth, “Studies on Accelerated Consolidation of Coir Reinforced Laterite and Shedi Soil with Vertical Sand Drains for Pavement Foundations,” M.Tech. Thesis, National Institute of Technology Karnataka, Surathkal, 2010. [5] J. O. Akinumusura and J. A. Akinbolade, “Stability of Loaded Footings on Reinforced Soil,” Journal of Geo- technical and Geoenvironmental Engineering, Vol. 107, No. 6, 1981, pp. 819-827. [6] S. L. Lee, G. P. Karunaratne, N. C. Dasgupta, S. D. Ramas- wamy and M. A. Aziz, “A Vertical Drain Made of Natu- ral Fiber for Soil Improvement Projects,” Proceedings of International Workshopon Geotextiles, Bangalore, 1989, pp. 271-276. [7] H. D. Charan, G. Ranjan and R. M. Vasan, “Strength Characteristics of Coir Fibers Reinforced Sand,” Pro- ceeding Indian Geotechnical Conference, Bangalore, De- cember 1995, pp. 339-342. [8] J. N. Mandal and M. V. R. Murthi, “Potential Use of Natural Fibers in Geotechnical Engineering,” Proceed- ings of International Workshopon Geotextiles, Bangalore, 22-29 November 1989, pp. 251-254. [9] T. Stapelfeldt, “Preloading and Vertical Drains,” 2006. http://wwwtkk.fi/Yksikot/Rakennus/Pohja/Preloading_an d_vertical_ drains.pdf [10] D. T. Bergado, A. S. Enriquez, C. L. Sampaco, M. C. Alfaro and A. S. Balasubramaniam, “Inverse Analysis of Geotechnical Parameters on Improved Soft Bangkok Clay,” Journal of Geotechnical Engineering Journal of Geotechnical Engineering, Vol. 118, No. 7, 1992, pp. 1012-1030. [11] M. Gosavi, K. A. Patil and S. Mittal, “Improvement of Properties of Black Cotton Soil Sub-Grade through Natu- ral Reinforcement,” Proceeding of Indian Geotechnical Conference, Roorkee, 18-20 December 2003, pp. 379- 383. [12] K. Terzaghi, Erbaumechanik auf Bodenphysi-kalisher Grundlagen, Deuticke, Vienna, Austria (in German), 1923. [13] K. Terzaghi, “Theoretical Soil Mechanics,” John Wiley & Sons, Inc., New York, 1943. doi:10.1002/9780470172766 [14] S. K. Khanna and C. E. G. Justo, “Highway Engineer- ing,” Nem Chand & Bros, Roorkee, 2001. [15] G. Venkatappa Rao, R. K. Dutta and D. Ujwala, “Strength Characteristics of Sand Reinforced with Coir Fibers and Coir GeoTextiles,” Electronic Journal of Geo- technical Engineering, Vol. 10, 2005. http://www.ejge.com/2005/ JourTOC10G.htm [16] Bureau of Indian Standards, “Indian Standard Methods of Tests for Soils, Part XVI, Laboratory Determination of CBR,” Bureau of Indian Standards, New Delhi, 1987. Copyright © 2012 SciRes. OJSS

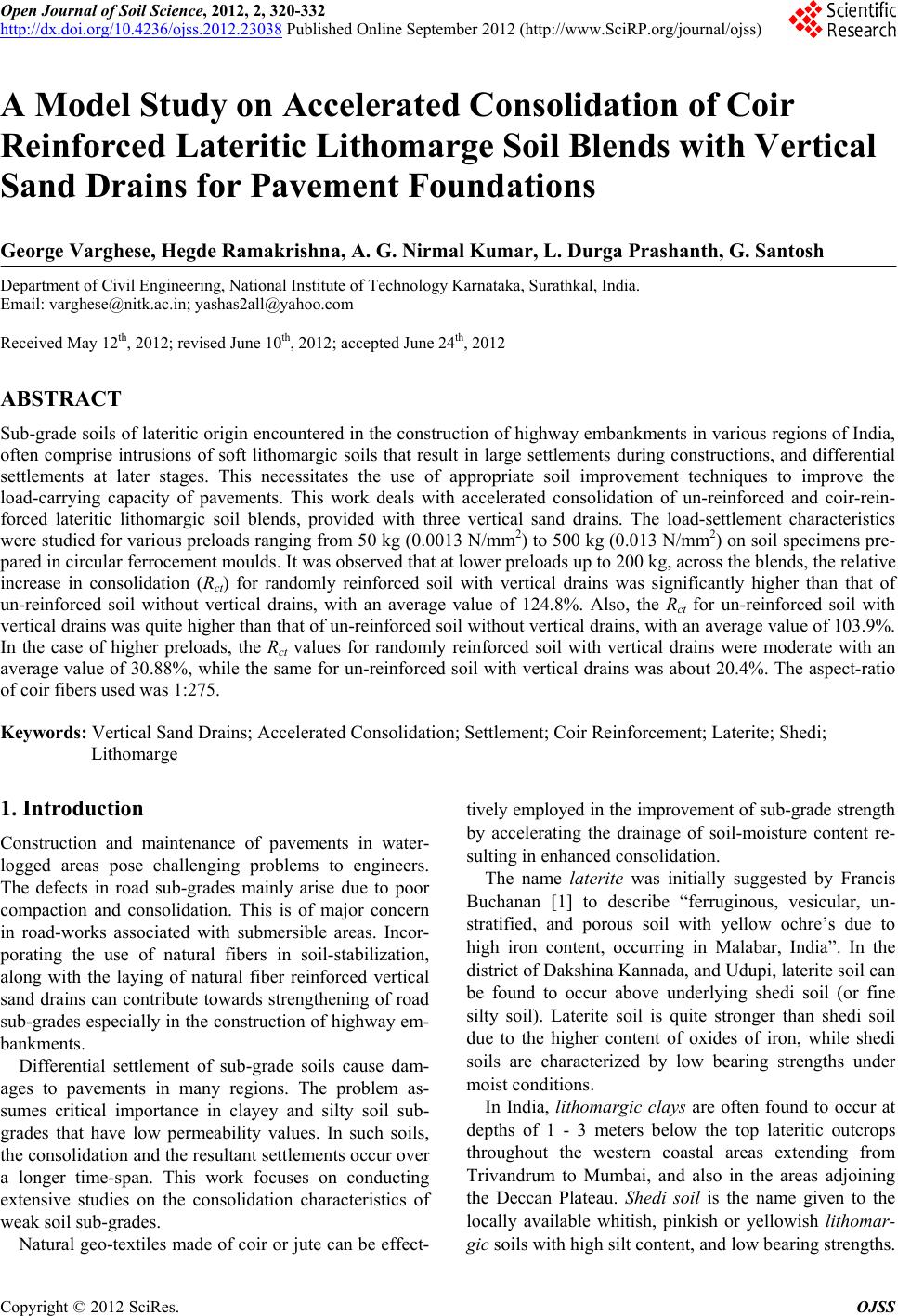

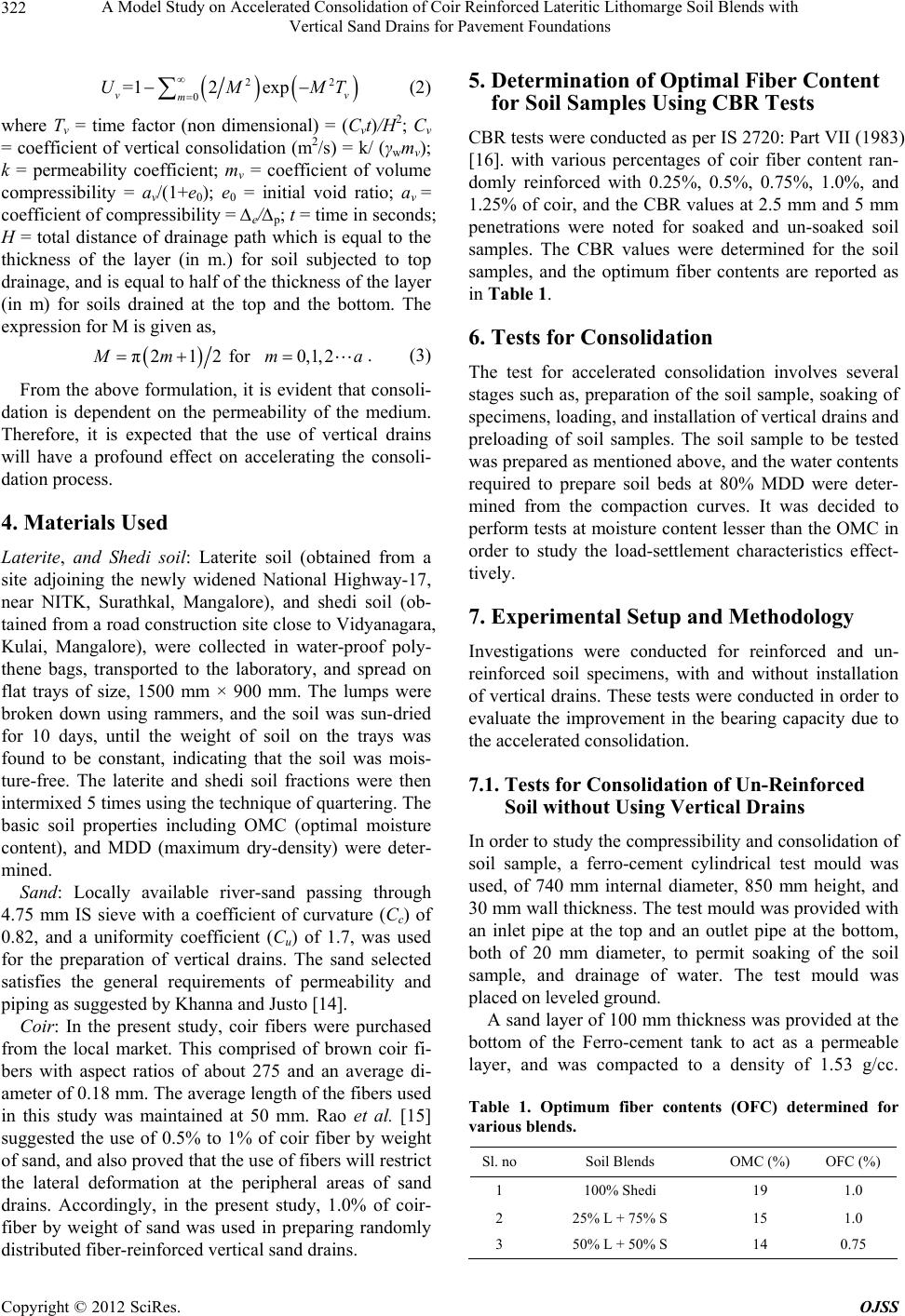

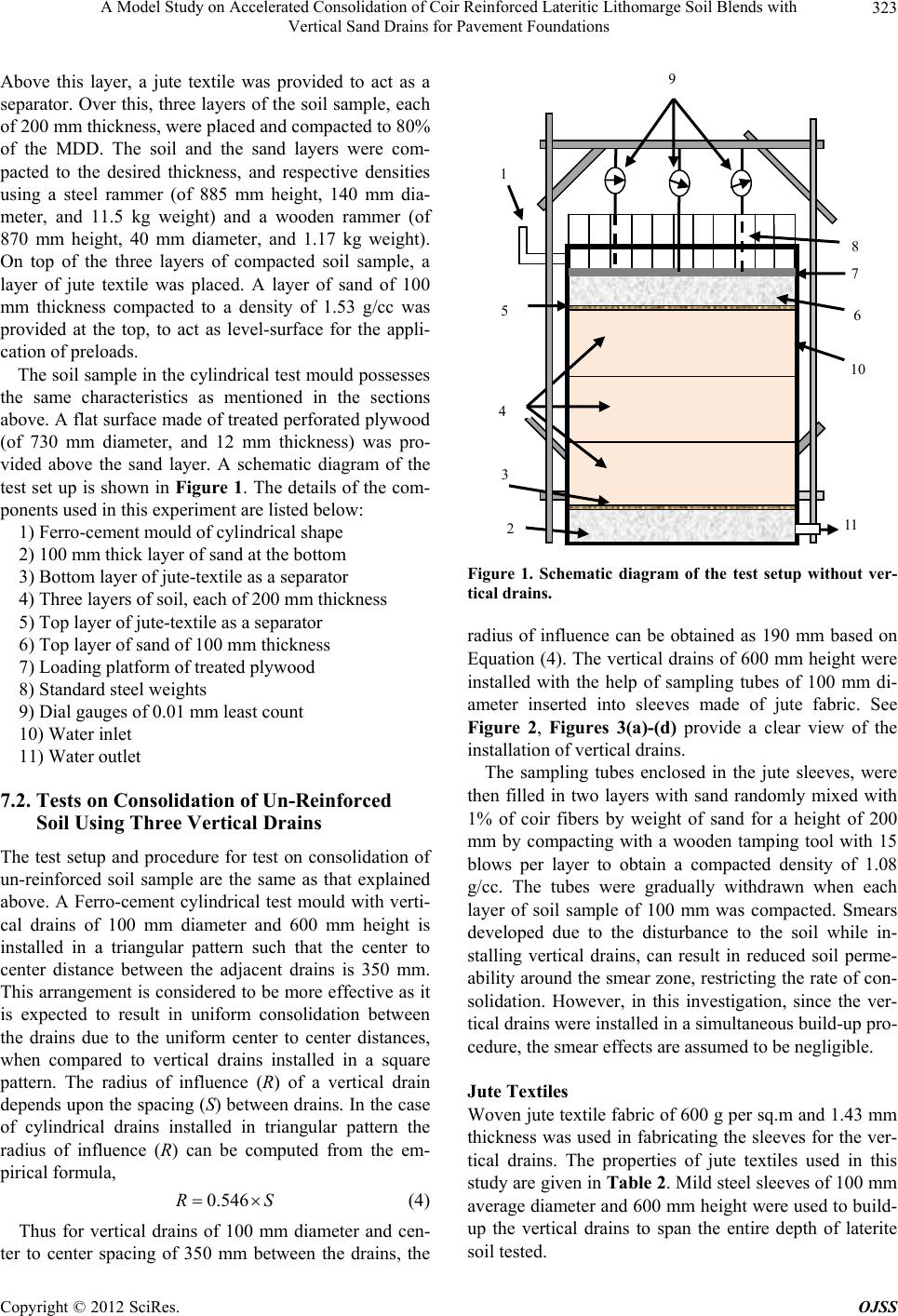

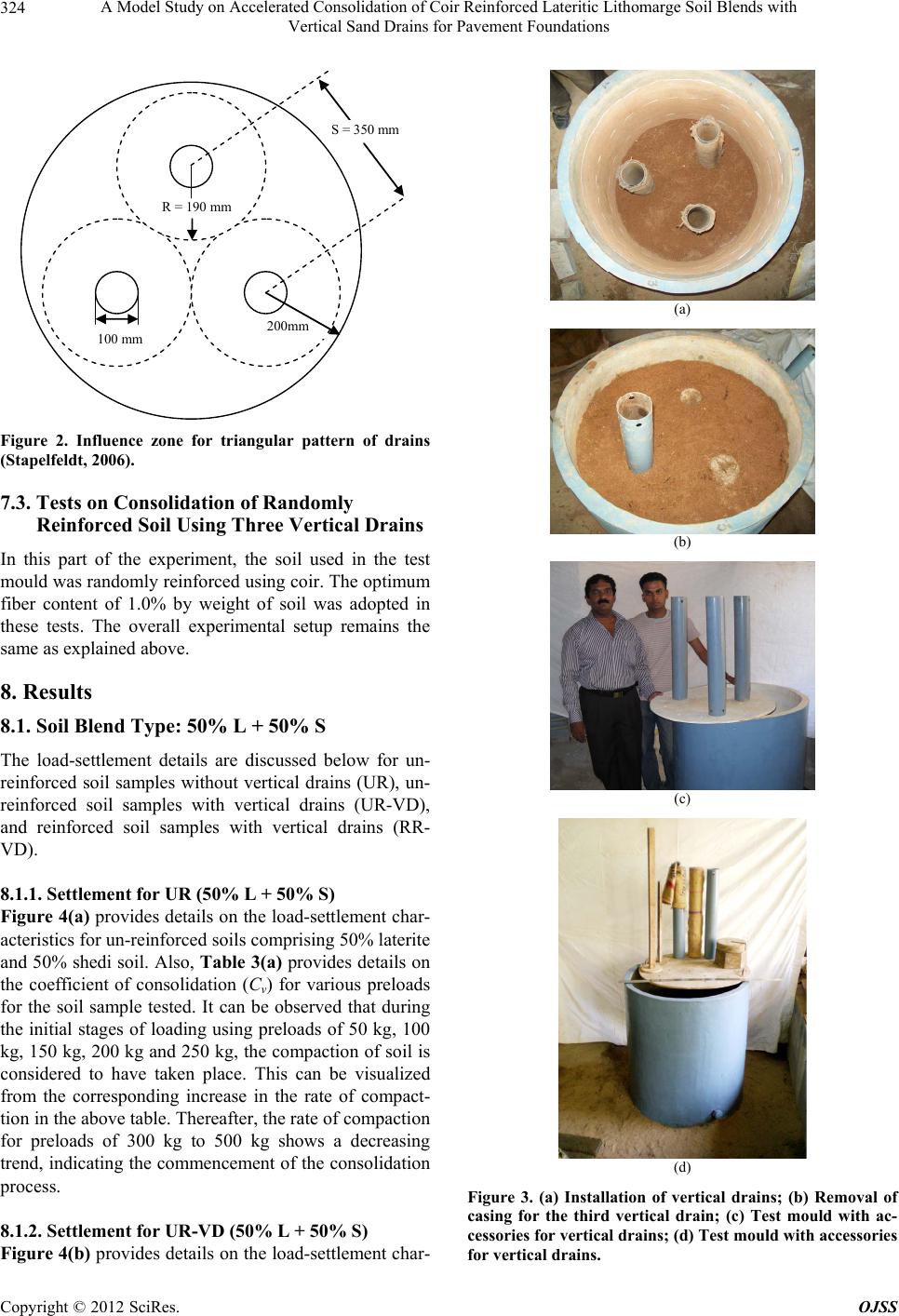

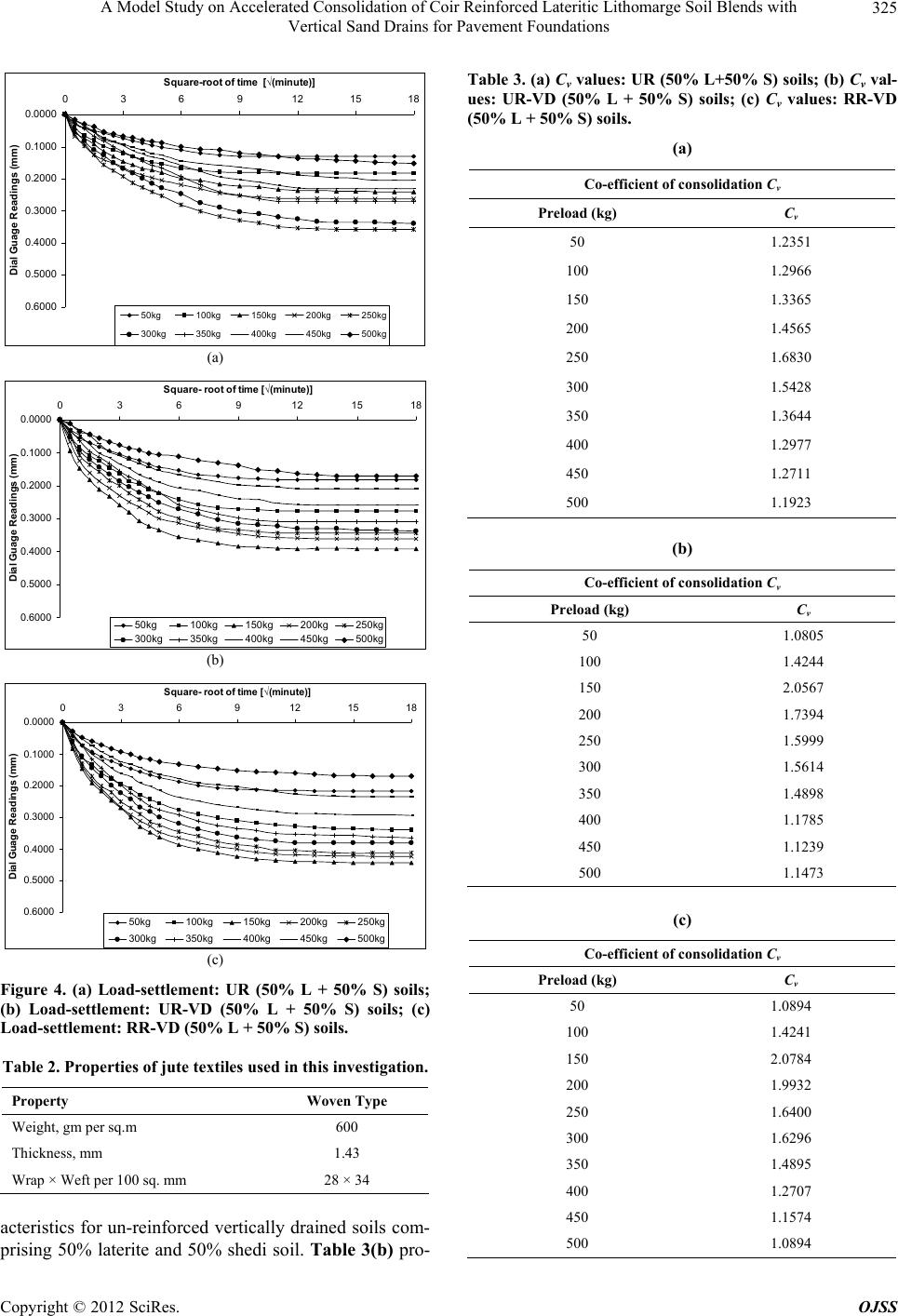

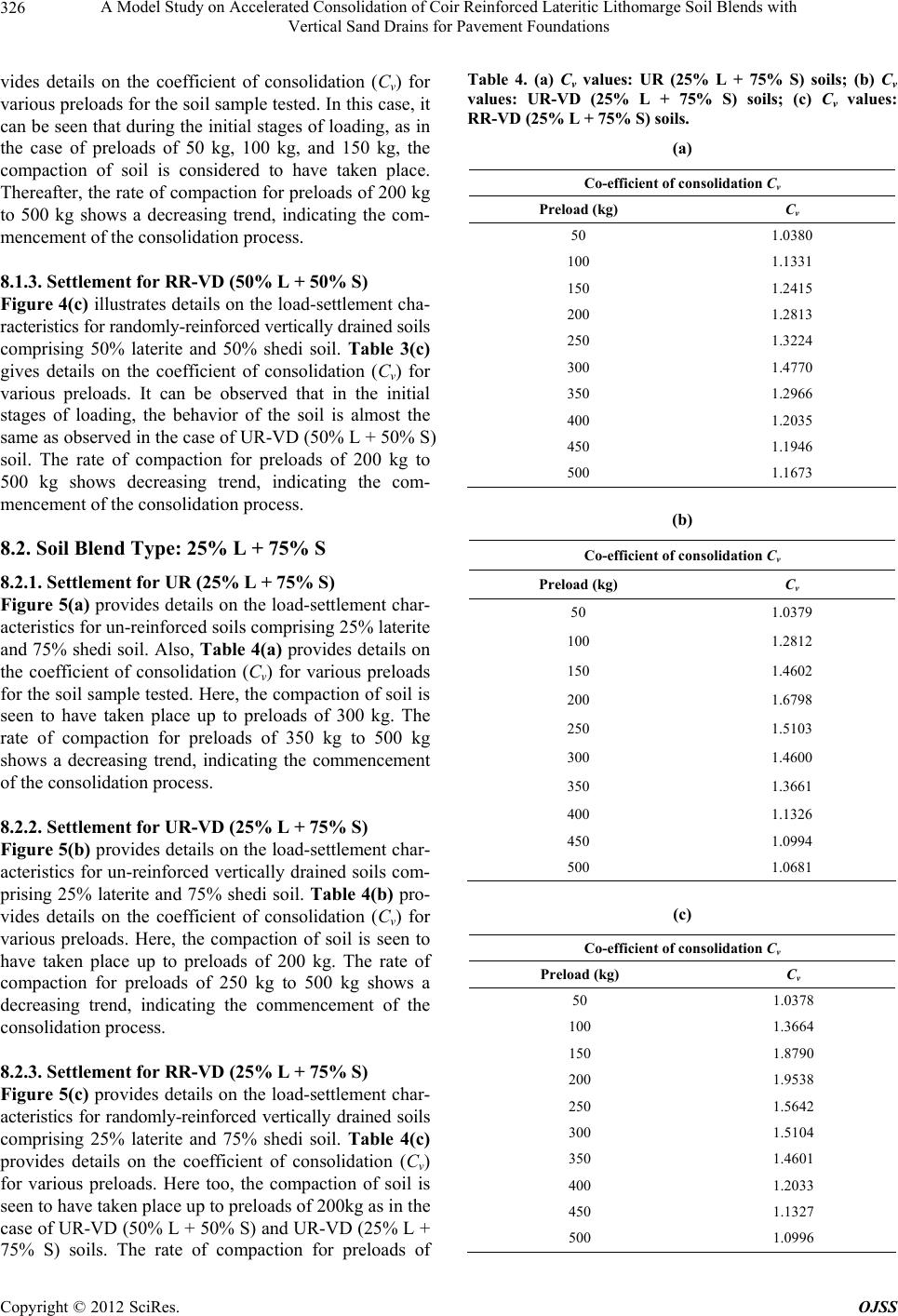

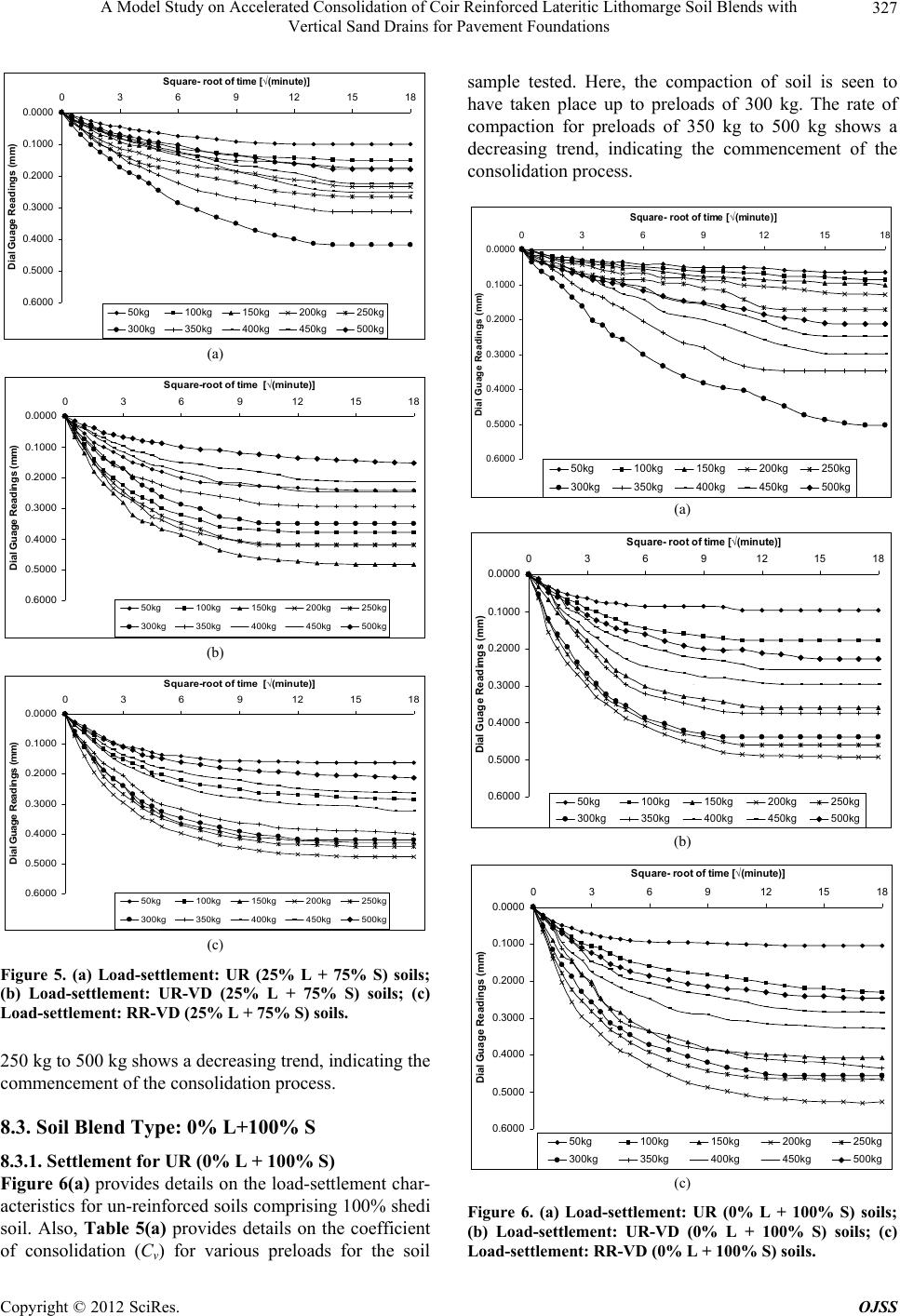

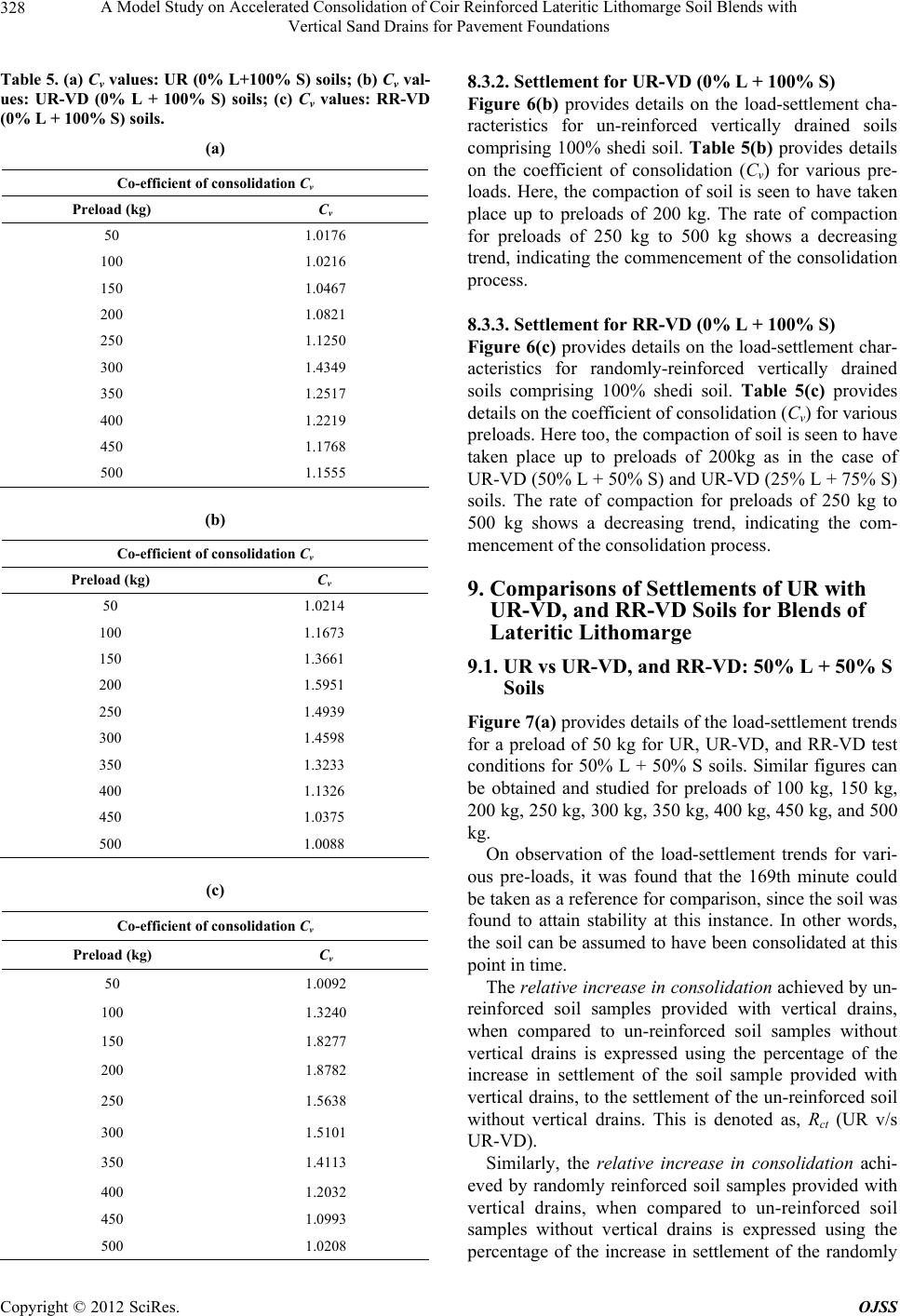

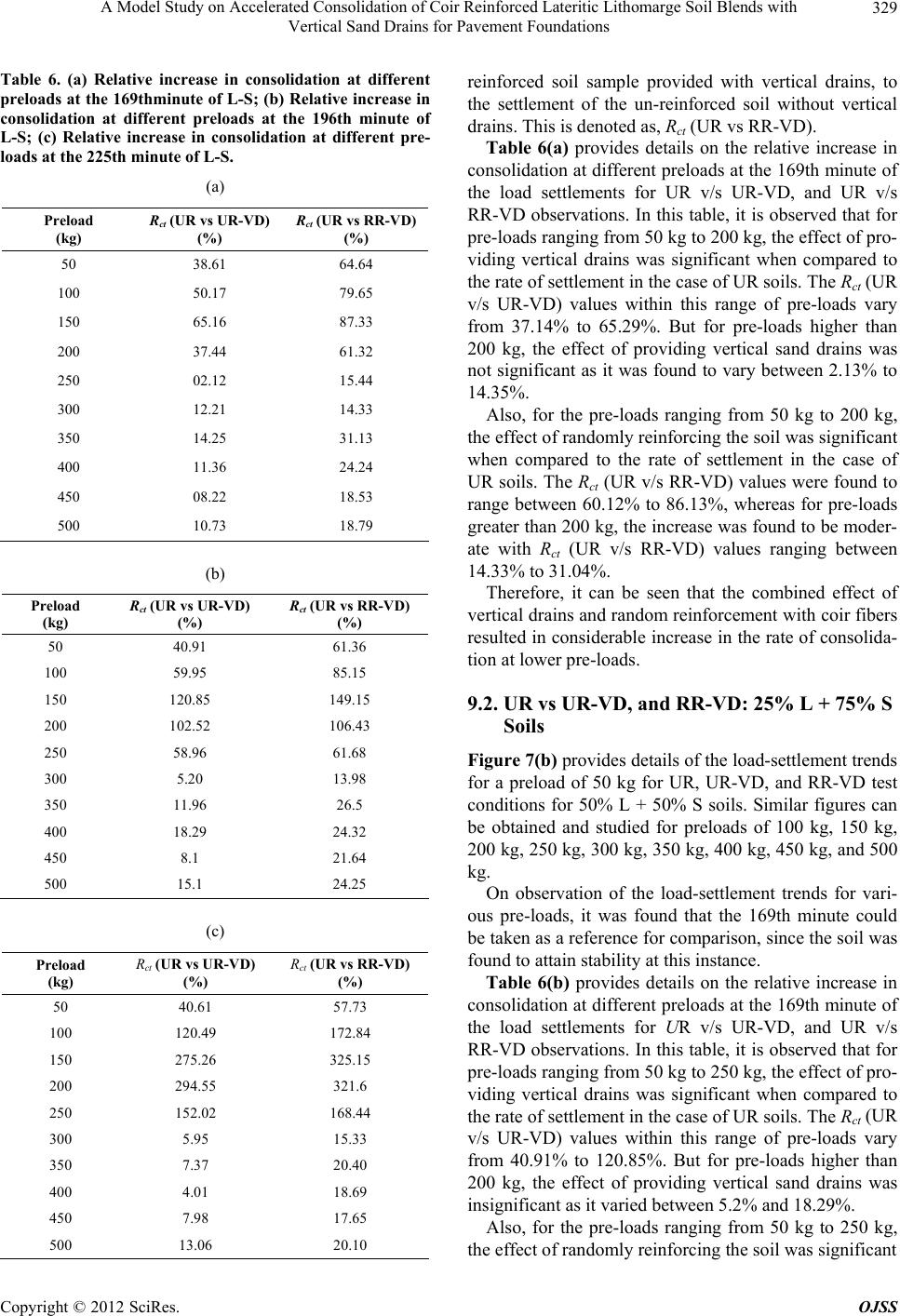

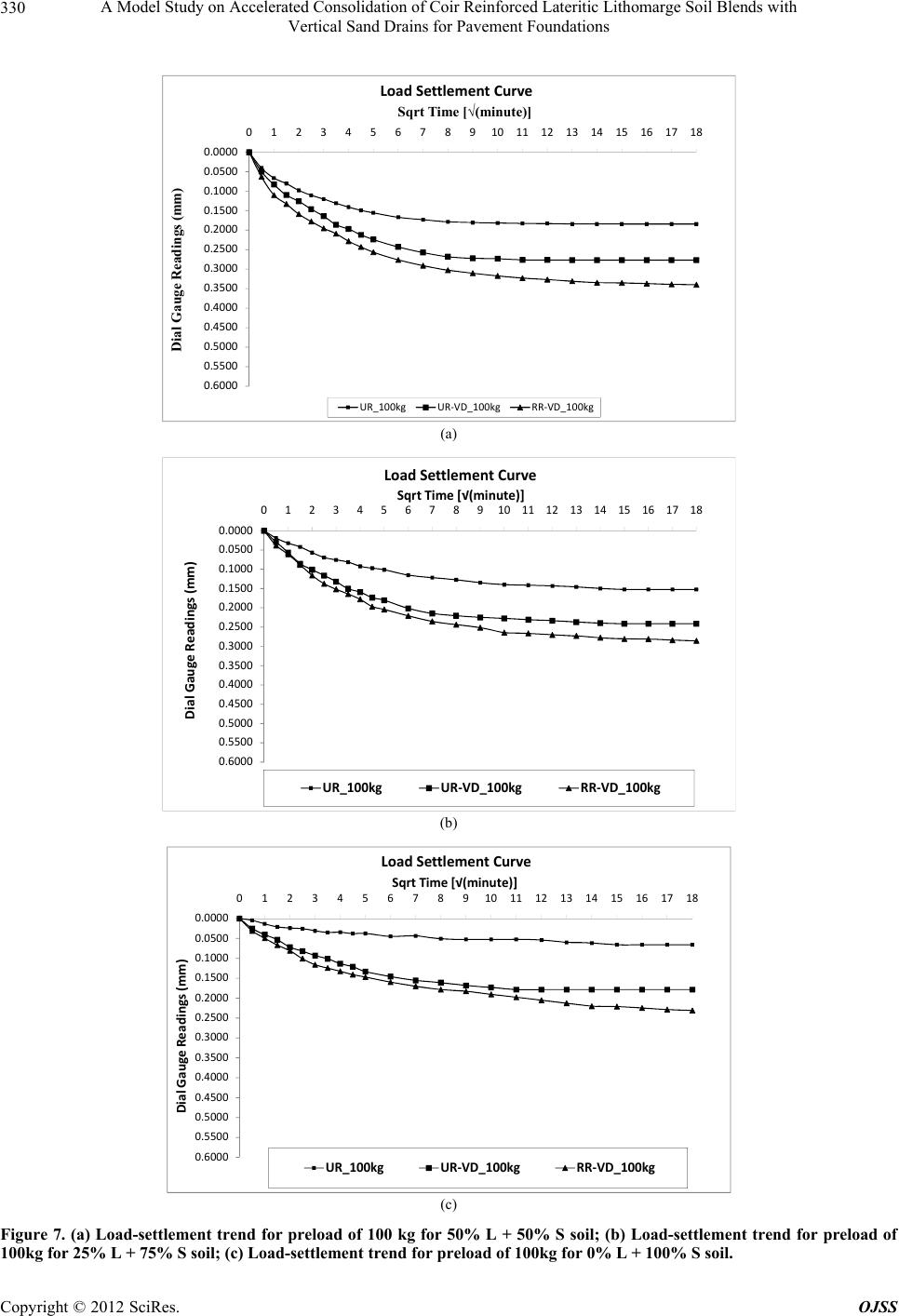

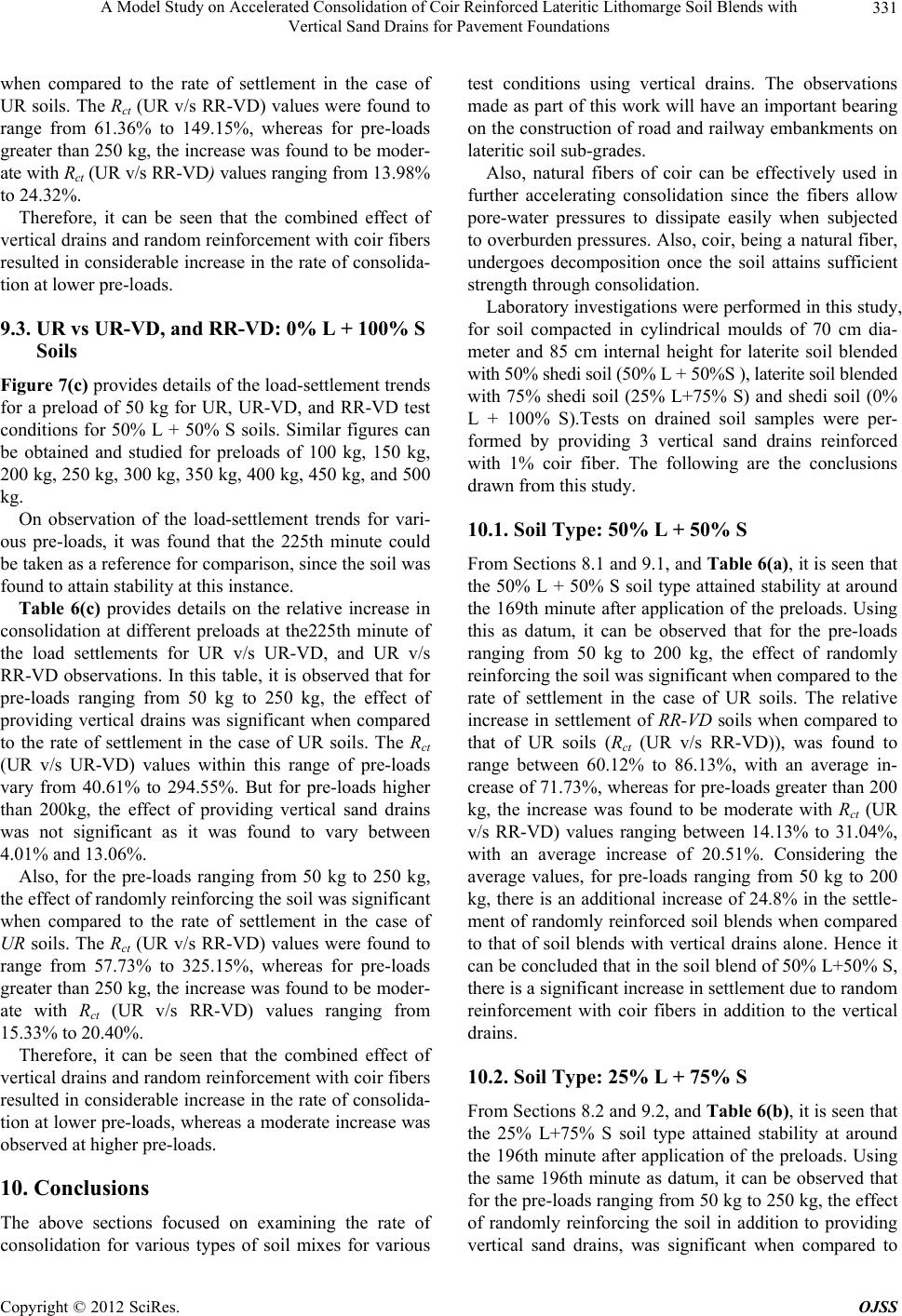

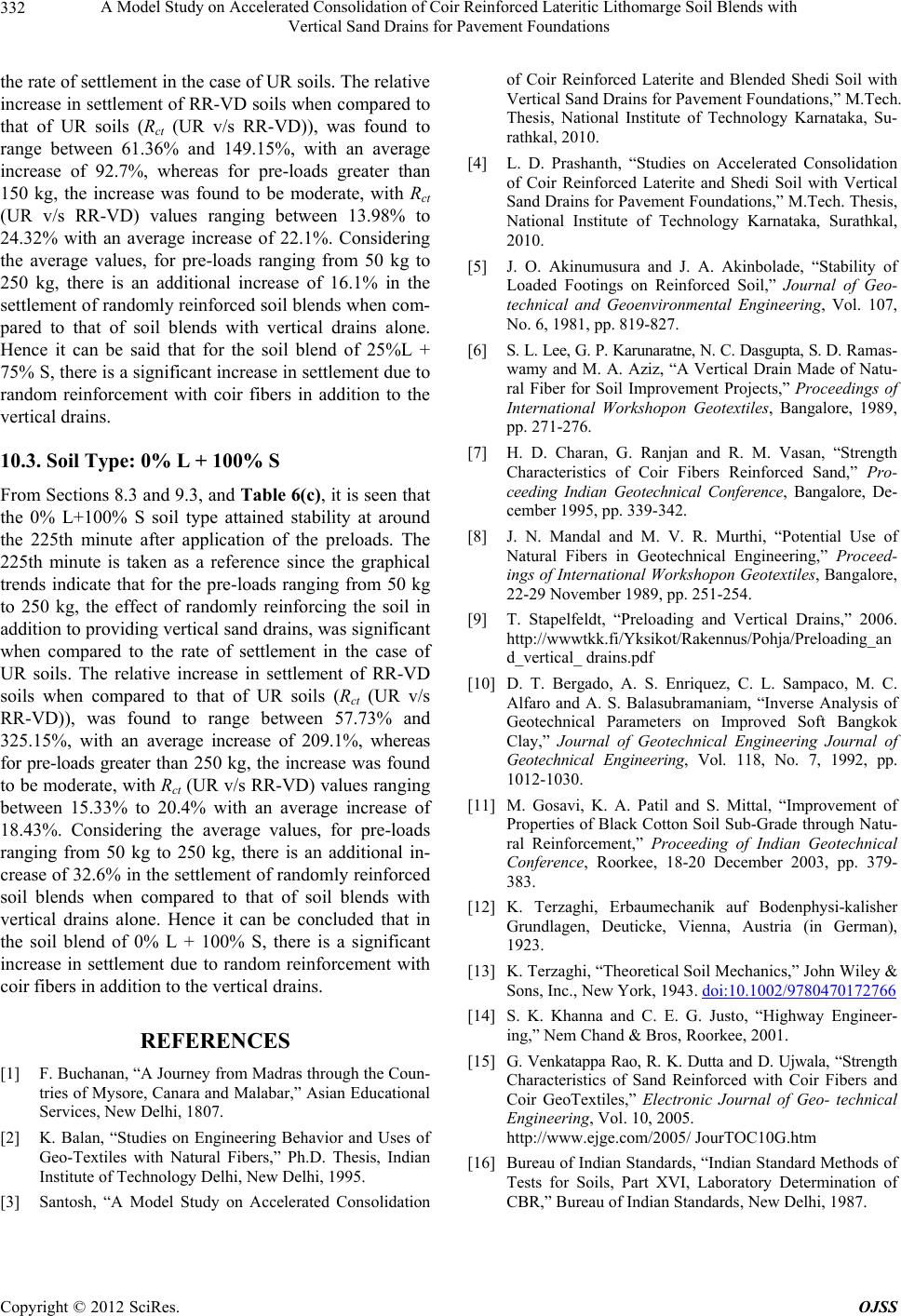

|