A. S. Naik, S. S. Lele / Advances in Bioscience and Biotechnology 3 (2012) 643-647

Copyright © 2012 SciRes.

647

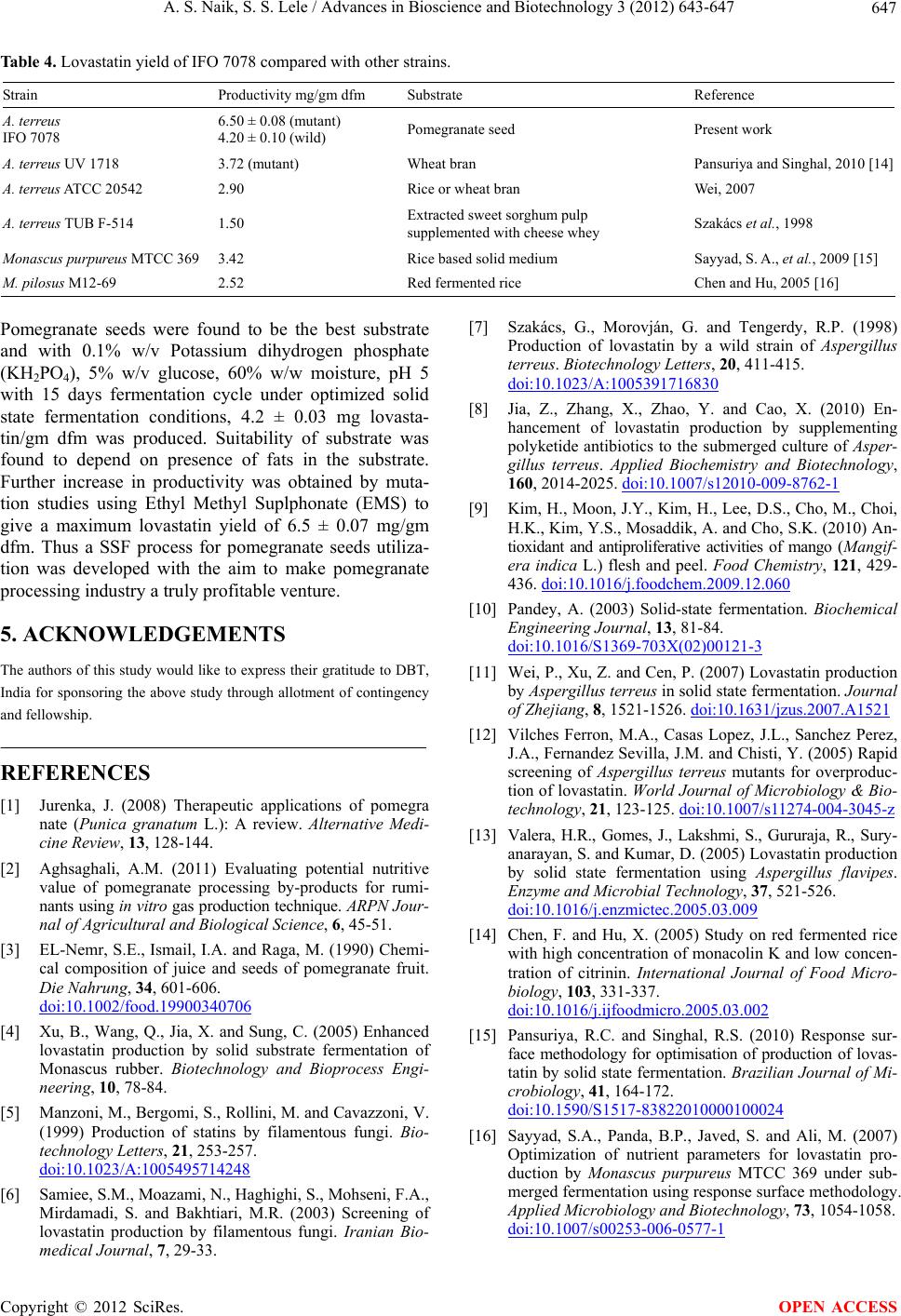

Table 4. Lovastatin yield of IFO 7078 compared with other strains.

Strain Productivity mg/gm dfm Substrate Reference

A. terreus

IFO 7078 6.50 ± 0.08 (mutant)

4.20 ± 0.10 (wild) Pomegranate seed Present work

A. terreus UV 1718 3.72 (mutant) Wheat bran Pansuriya and Singhal, 2010 [14]

A. terreus ATCC 20542 2.90 Rice or wheat bran Wei, 2007

A. terreus TUB F-514 1.50 Extracted sweet sorghum pulp

supplemented with cheese whey Szakács et al., 1998

Monascus purpureus MTCC 369 3.42 Rice based solid medium Sayyad, S. A., et al., 2009 [15]

M. pilosus M12-69 2.52 Red fermented rice Chen and Hu, 2005 [16]

[7] Szakács, G., Morovján, G. and Tengerdy, R.P. (1998)

Production of lovastatin by a wild strain of Aspergillus

terreus. Biotechnology Letters, 20, 411-415.

doi:10.1023/A:1005391716830

Pomegranate seeds were found to be the best substrate

and with 0.1% w/v Potassium dihydrogen phosphate

(KH2PO4), 5% w/v glucose, 60% w/w moisture, pH 5

with 15 days fermentation cycle under optimized solid

state fermentation conditions, 4.2 ± 0.03 mg lovasta-

tin/gm dfm was produced. Suitability of substrate was

found to depend on presence of fats in the substrate.

Further increase in productivity was obtained by muta-

tion studies using Ethyl Methyl Suplphonate (EMS) to

give a maximum lovastatin yield of 6.5 ± 0.07 mg/gm

dfm. Thus a SSF process for pomegranate seeds utiliza-

tion was developed with the aim to make pomegranate

processing industry a truly profitable venture.

[8] Jia, Z., Zhang, X., Zhao, Y. and Cao, X. (2010) En-

hancement of lovastatin production by supplementing

polyketide antibiotics to the submerged culture of Asper-

gillus terreus. Applied Biochemistry and Biotechnology,

160, 2014-2025. doi:10.1007/s12010-009-8762-1

[9] Kim, H., Moon, J.Y., Kim, H., Lee, D.S., Cho, M., Choi,

H.K., Kim, Y.S., Mosaddik, A. and Cho, S.K. (2010) An-

tioxidant and antiproliferative activities of mango (Mangif-

era indica L.) flesh and peel. Food Chemistry, 12 1, 429-

436. doi:10.1016/j.foodchem.2009.12.060

[10] Pandey, A. (2003) Solid-state fermentation. Biochemical

Engineering Journal, 13, 81-84.

doi:10.1016/S1369-703X(02)00121-3

5. ACKNOWLEDGEMENTS

The authors of this study would like to express their gratitude to DBT,

India for sponsoring the above study through allotment of contingency

and fellowship.

[11] Wei, P., Xu, Z. and Cen, P. (2007) Lovastatin production

by Aspergillus terreus in solid state fermentation. Journal

of Zhejiang, 8, 1521-1526. doi:10.1631/jzus.2007.A1521

[12] Vilches Ferron, M.A., Casas Lopez, J.L., Sanchez Perez,

J.A., Fernandez Sevilla, J.M. and Chisti, Y. (2005) Rapid

screening of Aspergillus terreus mutants for overproduc-

tion of lovastatin. World Journal of Microbiology & Bio-

technology, 21, 123-125. doi:10.1007/s11274-004-3045-z

REFERENCES

[1] Jurenka, J. (2008) Therapeutic applications of pomegra

nate (Punica granatum L.): A review. Alternative Medi-

cine Review, 13, 128-144. [13] Valera, H.R., Gomes, J., Lakshmi, S., Gururaja, R., Sury-

anarayan, S. and Kumar, D. (2005) Lovastatin production

by solid state fermentation using Aspergillus flavipes.

Enzyme and Microbial Technology, 37, 521-526.

doi:10.1016/j.enzmictec.2005.03.009

[2] Aghsaghali, A.M. (2011) Evaluating potential nutritive

value of pomegranate processing by-products for rumi-

nants using in vitro gas productio n technique. ARPN Jou r-

nal of Agricultural and Biological Science, 6, 45-51. [14] Chen, F. and Hu, X. (2005) Study on red fermented rice

with high concentration of monacolin K and low concen-

tration of citrinin. International Journal of Food Micro-

biology, 103, 331-337.

doi:10.1016/j.ijfoodmicro.2005.03.002

[3] EL-Nemr, S.E., Ismail, I.A. and Raga, M. (1990) Chemi-

cal composition of juice and seeds of pomegranate fruit.

Die Nahrung, 34, 601-606.

doi:10.1002/food.19900340706

[4] Xu, B., Wang, Q., Jia, X. and Sung, C. (2005) Enhanced

lovastatin production by solid substrate fermentation of

Monascus rubber. Biotechnology and Bioprocess Engi-

neering, 10, 78-84.

[15] Pansuriya, R.C. and Singhal, R.S. (2010) Response sur-

face methodology for optimisation of production of lovas-

tatin by solid state fermentation. Brazilian Journal of Mi-

crobiology, 41, 164-172.

doi:10.1590/S1517-83822010000100024

[5] Manzoni, M., Bergomi, S., Rollini, M. and Cavazzoni, V.

(1999) Production of statins by filamentous fungi. Bio-

technology Letters, 21, 253-257.

doi:10.1023/A:1005495714248

[16] Sayyad, S.A., Panda, B.P., Javed, S. and Ali, M. (2007)

Optimization of nutrient parameters for lovastatin pro-

duction by Monascus purpureus MTCC 369 under sub-

merged fermentation using response surface methodology.

Applied Microbiology and Biotechnology, 73, 1054-1058.

doi:10.1007/s00253-006-0577-1

[6] Samiee, S.M., Moazami, N., Haghighi, S., Mohseni, F.A.,

Mirdamadi, S. and Bakhtiari, M.R. (2003) Screening of

lovastatin production by filamentous fungi. Iranian Bio-

medical Journal, 7, 29-33.

OPEN ACCESS