Paper Menu >>

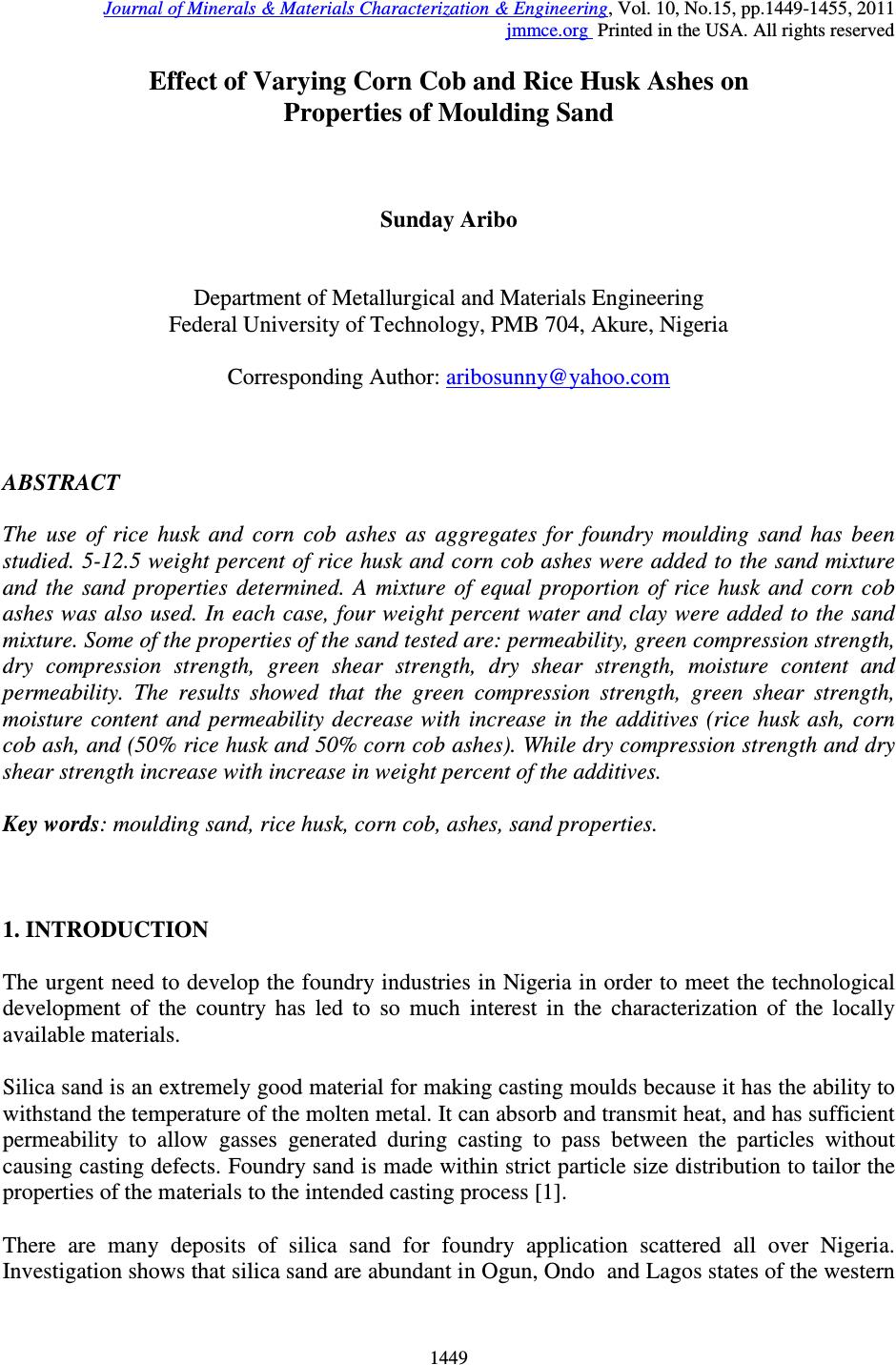

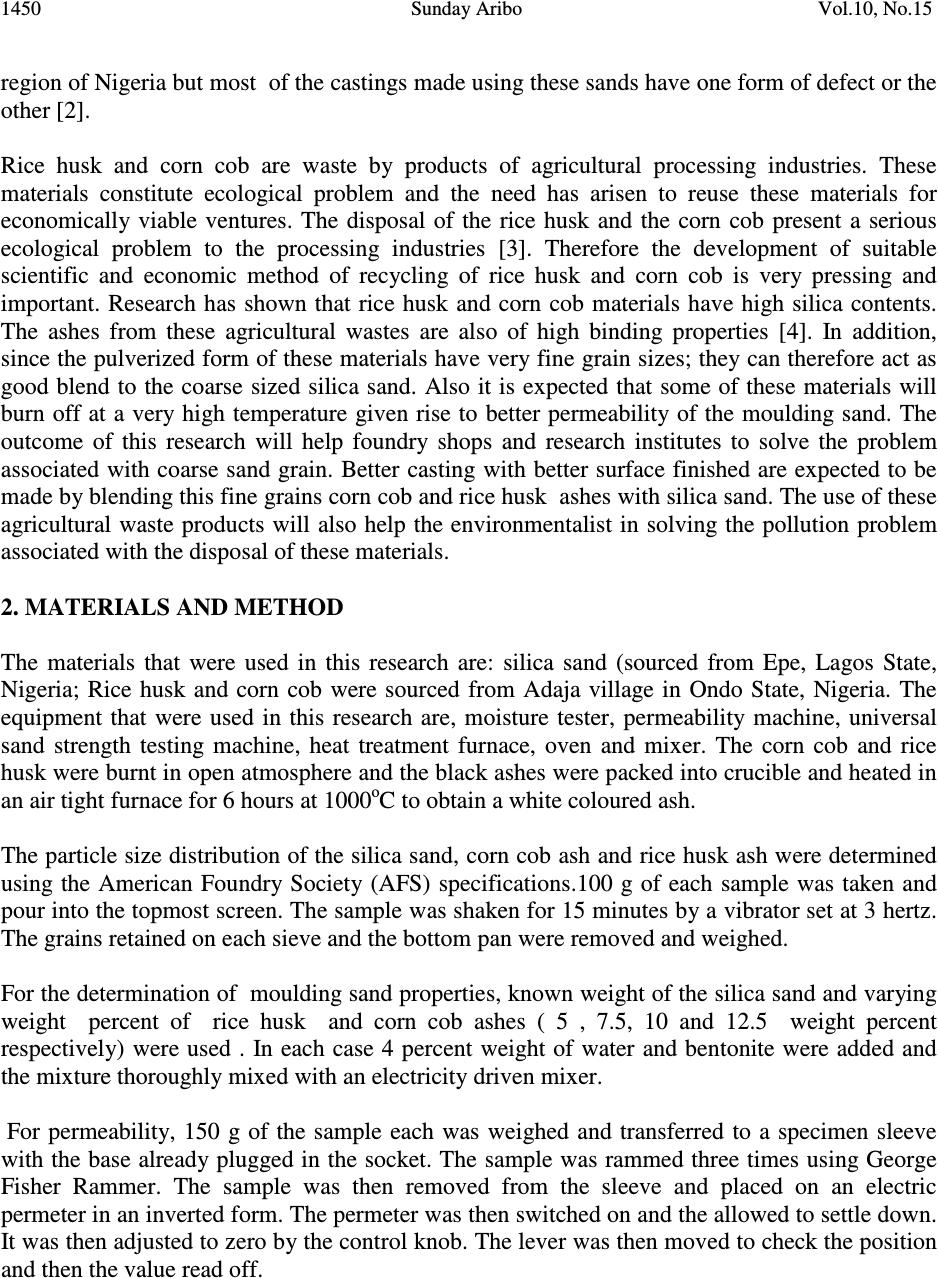

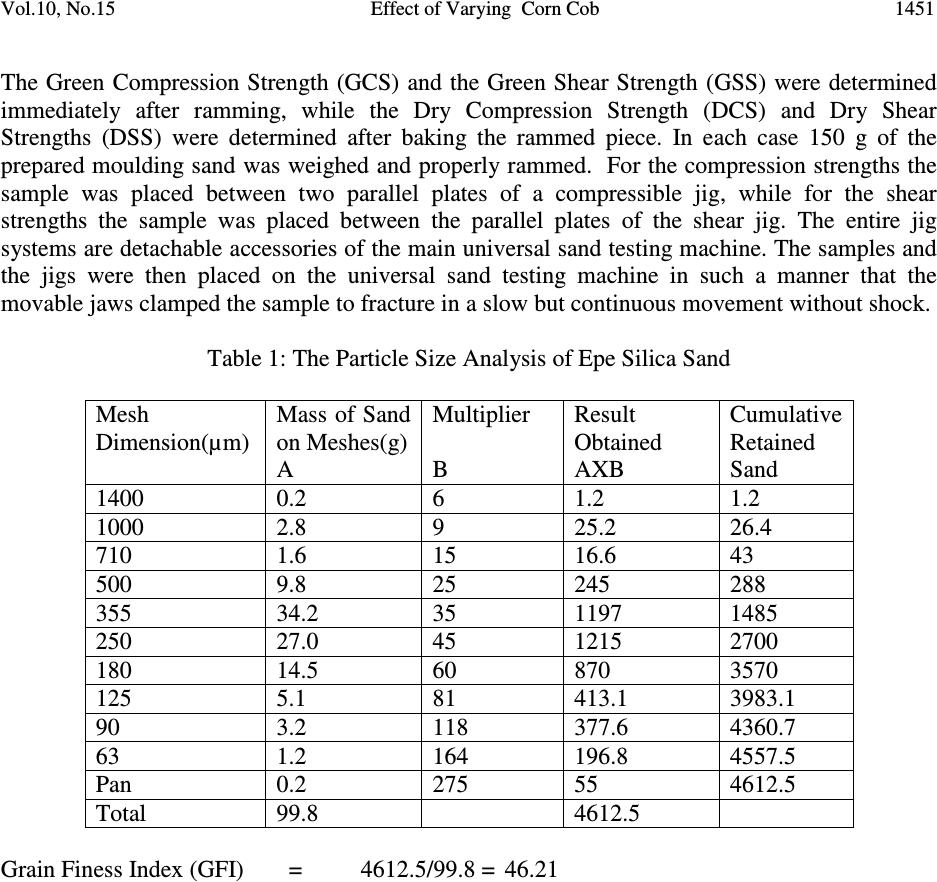

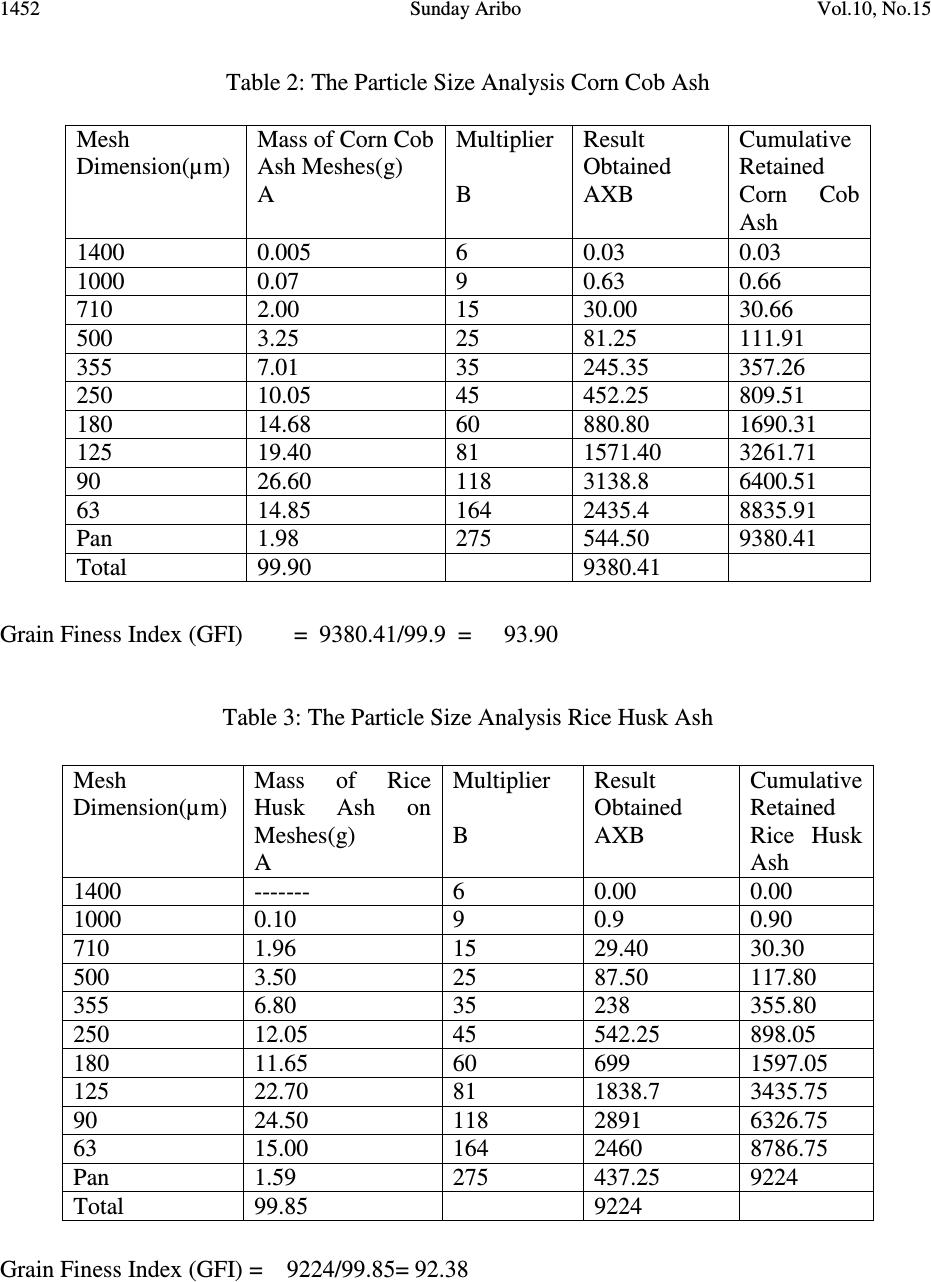

Journal Menu >>

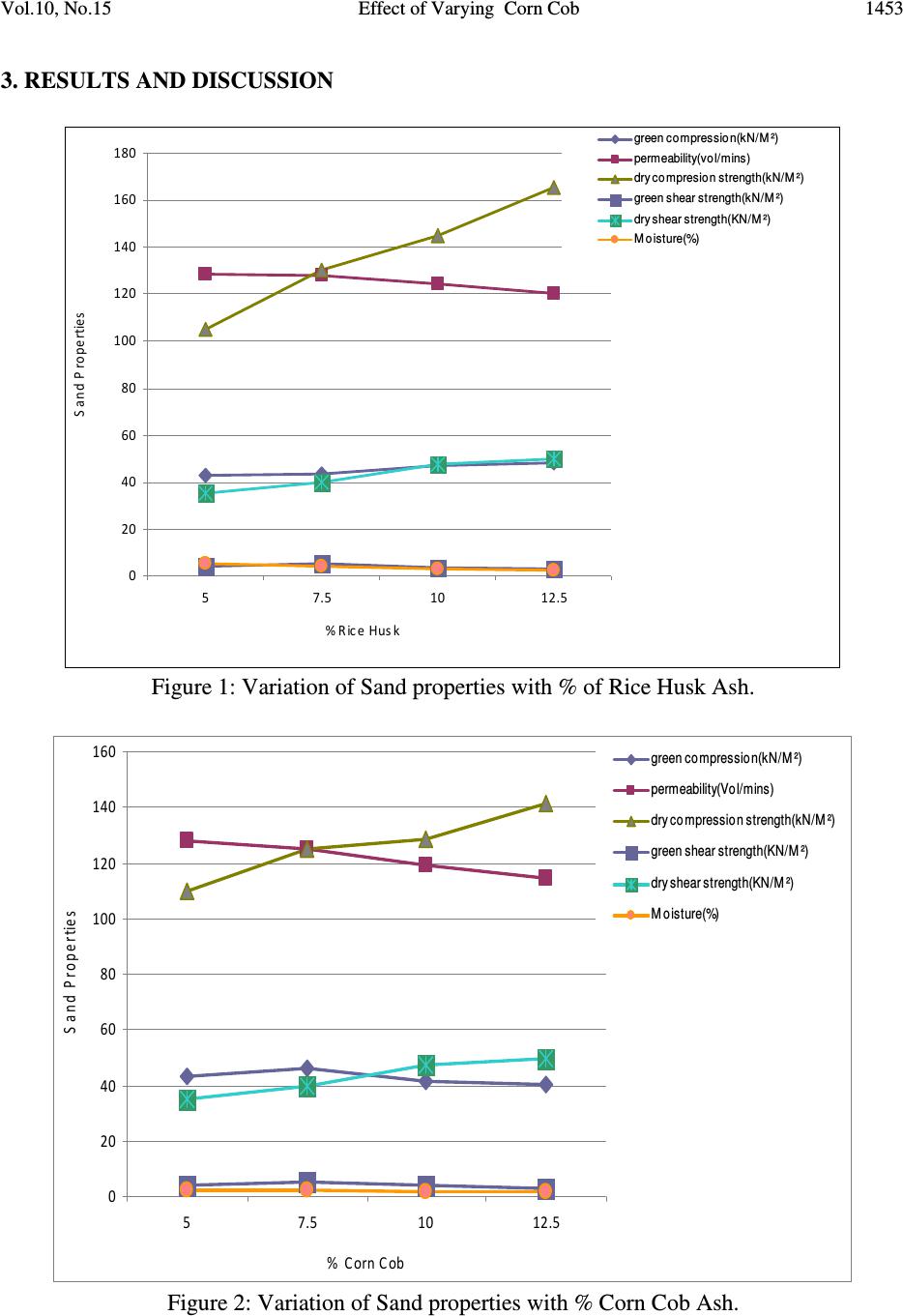

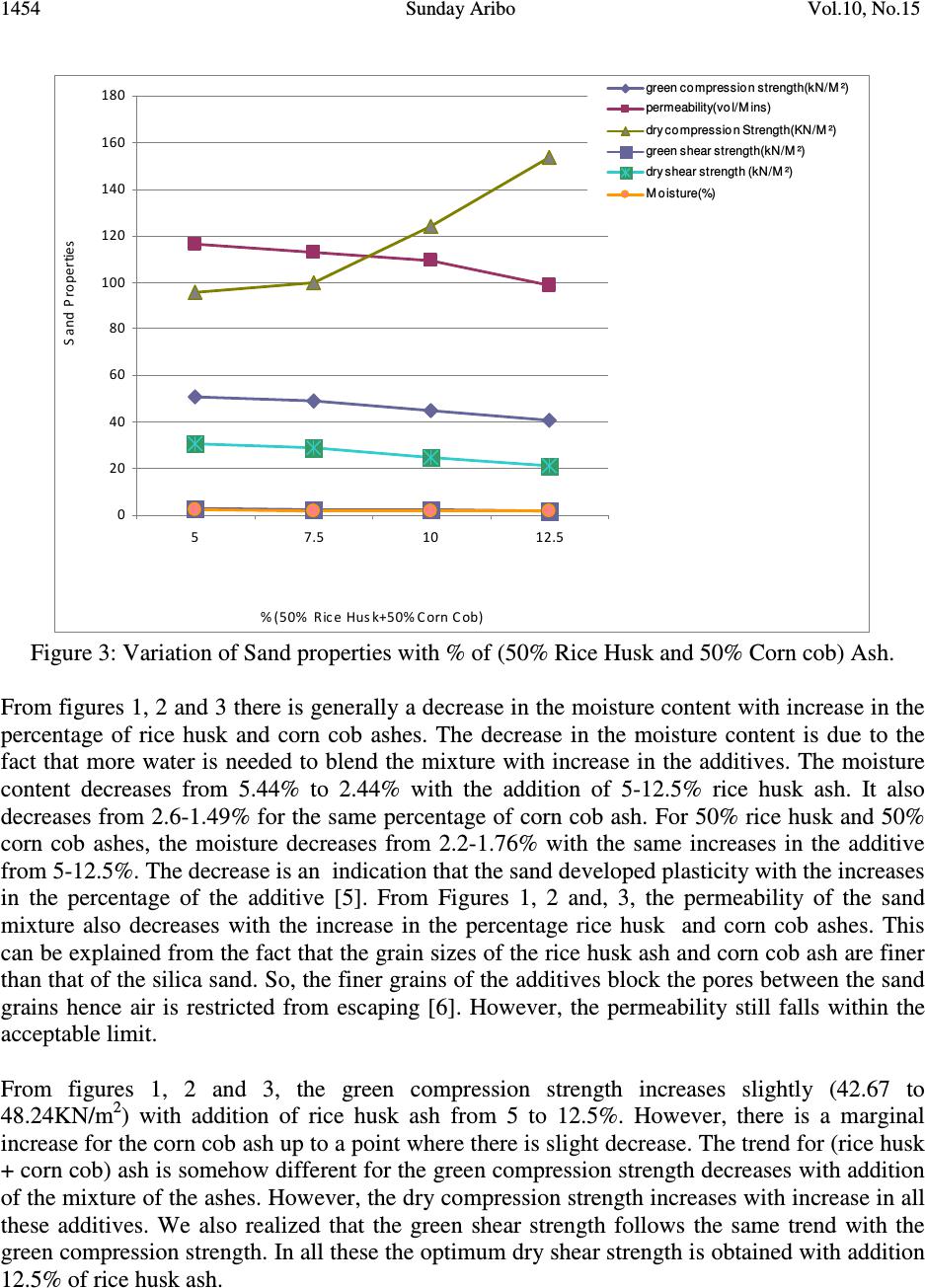

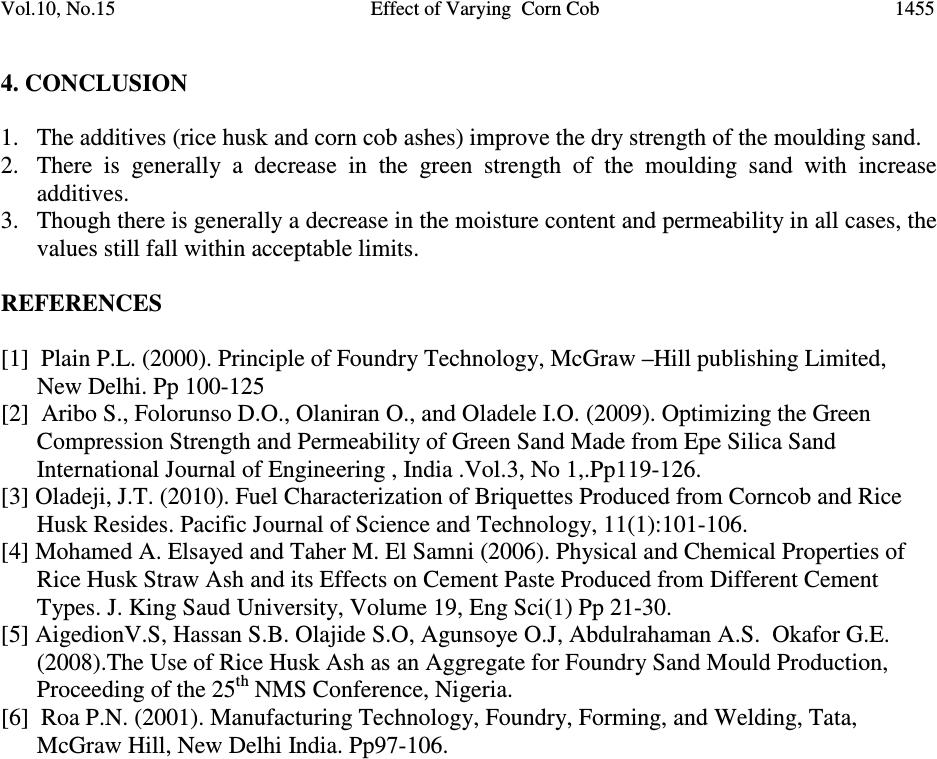

Journal of Minerals & Materials Characterization & Engineering, Vol. 10, No.15, pp.1449-1455, 2011 jmmce.org Printed in the USA. All rights reserved 1449 Effect of Varying Corn Cob and Rice Husk Ashes on Properties of Moulding Sand Sunday Aribo Department of Metallurgical and Materials Engineering Federal University of Technology, PMB 704, Akure, Nigeria Corresponding Author: aribosunny@yahoo.com ABSTRACT The use of rice husk and corn cob ashes as aggregates for foundry moulding sand has been studied. 5-12.5 weight percent of rice husk and corn cob ashes were added to the sand mixture and the sand properties determined. A mixture of equal proportion of rice husk and corn cob ashes was also used. In each case, four weight percent water and clay were added to the sand mixture. Some of the properties of the sand tested are: permeability, green compression strength, dry compression strength, green shear strength, dry shear strength, moisture content and permeability. The results showed that the green compression strength, green shear strength, moisture content and permeability decrease with increase in the additives (rice husk ash, corn cob ash, and (50% rice husk and 50% corn cob ashes). While dry compression strength and dry shear strength increase with increase in weight percent of the additives. Key words: moulding sand, rice husk, corn cob, ashes, sand properties. 1. INTRODUCTION The urgent need to develop the foundry industries in Nigeria in order to meet the technological development of the country has led to so much interest in the characterization of the locally available materials. Silica sand is an extremely good material for making casting moulds because it has the ability to withstand the temperature of the molten metal. It can absorb and transmit heat, and has sufficient permeability to allow gasses generated during casting to pass between the particles without causing casting defects. Foundry sand is made within strict particle size distribution to tailor the properties of the materials to the intended casting process [1]. There are many deposits of silica sand for foundry application scattered all over Nigeria. Investigation shows that silica sand are abundant in Ogun, Ondo and Lagos states of the western  1450 Sunday Aribo Vol.10, No.15 region of Nigeria but most of the castings made using these sands have one form of defect or the other [2]. Rice husk and corn cob are waste by products of agricultural processing industries. These materials constitute ecological problem and the need has arisen to reuse these materials for economically viable ventures. The disposal of the rice husk and the corn cob present a serious ecological problem to the processing industries [3]. Therefore the development of suitable scientific and economic method of recycling of rice husk and corn cob is very pressing and important. Research has shown that rice husk and corn cob materials have high silica contents. The ashes from these agricultural wastes are also of high binding properties [4]. In addition, since the pulverized form of these materials have very fine grain sizes; they can therefore act as good blend to the coarse sized silica sand. Also it is expected that some of these materials will burn off at a very high temperature given rise to better permeability of the moulding sand. The outcome of this research will help foundry shops and research institutes to solve the problem associated with coarse sand grain. Better casting with better surface finished are expected to be made by blending this fine grains corn cob and rice husk ashes with silica sand. The use of these agricultural waste products will also help the environmentalist in solving the pollution problem associated with the disposal of these materials. 2. MATERIALS AND METHOD The materials that were used in this research are: silica sand (sourced from Epe, Lagos State, Nigeria; Rice husk and corn cob were sourced from Adaja village in Ondo State, Nigeria. The equipment that were used in this research are, moisture tester, permeability machine, universal sand strength testing machine, heat treatment furnace, oven and mixer. The corn cob and rice husk were burnt in open atmosphere and the black ashes were packed into crucible and heated in an air tight furnace for 6 hours at 1000 o C to obtain a white coloured ash. The particle size distribution of the silica sand, corn cob ash and rice husk ash were determined using the American Foundry Society (AFS) specifications.100 g of each sample was taken and pour into the topmost screen. The sample was shaken for 15 minutes by a vibrator set at 3 hertz. The grains retained on each sieve and the bottom pan were removed and weighed. For the determination of moulding sand properties, known weight of the silica sand and varying weight percent of rice husk and corn cob ashes ( 5 , 7.5, 10 and 12.5 weight percent respectively) were used . In each case 4 percent weight of water and bentonite were added and the mixture thoroughly mixed with an electricity driven mixer. For permeability, 150 g of the sample each was weighed and transferred to a specimen sleeve with the base already plugged in the socket. The sample was rammed three times using George Fisher Rammer. The sample was then removed from the sleeve and placed on an electric permeter in an inverted form. The permeter was then switched on and the allowed to settle down. It was then adjusted to zero by the control knob. The lever was then moved to check the position and then the value read off.  Vol.10, No.15 Effect of Varying Corn Cob 1451 The Green Compression Strength (GCS) and the Green Shear Strength (GSS) were determined immediately after ramming, while the Dry Compression Strength (DCS) and Dry Shear Strengths (DSS) were determined after baking the rammed piece. In each case 150 g of the prepared moulding sand was weighed and properly rammed. For the compression strengths the sample was placed between two parallel plates of a compressible jig, while for the shear strengths the sample was placed between the parallel plates of the shear jig. The entire jig systems are detachable accessories of the main universal sand testing machine. The samples and the jigs were then placed on the universal sand testing machine in such a manner that the movable jaws clamped the sample to fracture in a slow but continuous movement without shock. Table 1: The Particle Size Analysis of Epe Silica Sand Mesh Dimension(µm) Mass of Sand on Meshes(g) A Multiplier B Result Obtained AXB Cumulative Retained Sand 1400 0.2 6 1.2 1.2 1000 2.8 9 25.2 26.4 710 1.6 15 16.6 43 500 9.8 25 245 288 355 34.2 35 1197 1485 250 27.0 45 1215 2700 180 14.5 60 870 3570 125 5.1 81 413.1 3983.1 90 3.2 118 377.6 4360.7 63 1.2 164 196.8 4557.5 Pan 0.2 275 55 4612.5 Total 99.8 4612.5 Grain Finess Index (GFI) = 4612.5/99.8 = 46.21  1452 Sunday Aribo Vol.10, No.15 Table 2: The Particle Size Analysis Corn Cob Ash Grain Finess Index (GFI) = 9380.41/99.9 = 93.90 Table 3: The Particle Size Analysis Rice Husk Ash Grain Finess Index (GFI) = 9224/99.85= 92.38 Mesh Dimension(µm) Mass of Corn Cob Ash Meshes(g) A Multiplier B Result Obtained AXB Cumulative Retained Corn Cob Ash 1400 0.005 6 0.03 0.03 1000 0.07 9 0.63 0.66 710 2.00 15 30.00 30.66 500 3.25 25 81.25 111.91 355 7.01 35 245.35 357.26 250 10.05 45 452.25 809.51 180 14.68 60 880.80 1690.31 125 19.40 81 1571.40 3261.71 90 26.60 118 3138.8 6400.51 63 14.85 164 2435.4 8835.91 Pan 1.98 275 544.50 9380.41 Total 99.90 9380.41 Mesh Dimension(µm) Mass of Rice Husk Ash on Meshes(g) A Multiplier B Result Obtained AXB Cumulative Retained Rice Husk Ash 1400 ------- 6 0.00 0.00 1000 0.10 9 0.9 0.90 710 1.96 15 29.40 30.30 500 3.50 25 87.50 117.80 355 6.80 35 238 355.80 250 12.05 45 542.25 898.05 180 11.65 60 699 1597.05 125 22.70 81 1838.7 3435.75 90 24.50 118 2891 6326.75 63 15.00 164 2460 8786.75 Pan 1.59 275 437.25 9224 Total 99.85 9224  Vol.10, No.15 Effect of Varying Corn Cob 1453 3. RESULTS AND DISCUSSION 0 20 40 60 80 100 120 140 160 180 57.510 12.5 % Rice Husk S and P roperties green compression(kN/M²) permeability(vol/mins) dry compresion strength(kN/M²) green shear strength(kN/M²) dry shear strength(KN/M²) M oisture(%) Figure 1: Variation of Sand properties with % of Rice Husk Ash. 0 20 40 60 80 100 120 140 160 57.510 12.5 % Corn Cob Sand Properties green compression(kN/M²) permeability(V ol/mins) dry compression strength(kN/M²) green shear strength(KN/M²) dry shear strength(KN/M²) M oisture(%) Figure 2: Variation of Sand properties with % Corn Cob Ash.  1454 Sunday Aribo Vol.10, No.15 0 20 40 60 80 100 120 140 160 180 57.510 12.5 %(50% Rice Husk+50% Corn Cob) Sand Properties green compression strength(kN/M²) permeability(vo l/M ins) dry compression Strength(KN/M²) green shear strength(kN/M²) dry shear strength (kN/M²) M o isture(%) Figure 3: Variation of Sand properties with % of (50% Rice Husk and 50% Corn cob) Ash. From figures 1, 2 and 3 there is generally a decrease in the moisture content with increase in the percentage of rice husk and corn cob ashes. The decrease in the moisture content is due to the fact that more water is needed to blend the mixture with increase in the additives. The moisture content decreases from 5.44% to 2.44% with the addition of 5-12.5% rice husk ash. It also decreases from 2.6-1.49% for the same percentage of corn cob ash. For 50% rice husk and 50% corn cob ashes, the moisture decreases from 2.2-1.76% with the same increases in the additive from 5-12.5%. The decrease is an indication that the sand developed plasticity with the increases in the percentage of the additive [5]. From Figures 1, 2 and, 3, the permeability of the sand mixture also decreases with the increase in the percentage rice husk and corn cob ashes. This can be explained from the fact that the grain sizes of the rice husk ash and corn cob ash are finer than that of the silica sand. So, the finer grains of the additives block the pores between the sand grains hence air is restricted from escaping [6]. However, the permeability still falls within the acceptable limit. From figures 1, 2 and 3, the green compression strength increases slightly (42.67 to 48.24KN/m 2 ) with addition of rice husk ash from 5 to 12.5%. However, there is a marginal increase for the corn cob ash up to a point where there is slight decrease. The trend for (rice husk + corn cob) ash is somehow different for the green compression strength decreases with addition of the mixture of the ashes. However, the dry compression strength increases with increase in all these additives. We also realized that the green shear strength follows the same trend with the green compression strength. In all these the optimum dry shear strength is obtained with addition 12.5% of rice husk ash.  Vol.10, No.15 Effect of Varying Corn Cob 1455 4. CONCLUSION 1. The additives (rice husk and corn cob ashes) improve the dry strength of the moulding sand. 2. There is generally a decrease in the green strength of the moulding sand with increase additives. 3. Though there is generally a decrease in the moisture content and permeability in all cases, the values still fall within acceptable limits. REFERENCES [1] Plain P.L. (2000). Principle of Foundry Technology, McGraw –Hill publishing Limited, New Delhi. Pp 100-125 [2] Aribo S., Folorunso D.O., Olaniran O., and Oladele I.O. (2009). Optimizing the Green Compression Strength and Permeability of Green Sand Made from Epe Silica Sand International Journal of Engineering , India .Vol.3, No 1,.Pp119-126. [3] Oladeji, J.T. (2010). Fuel Characterization of Briquettes Produced from Corncob and Rice Husk Resides. Pacific Journal of Science and Technology, 11(1):101-106. [4] Mohamed A. Elsayed and Taher M. El Samni (2006). Physical and Chemical Properties of Rice Husk Straw Ash and its Effects on Cement Paste Produced from Different Cement Types. J. King Saud University, Volume 19, Eng Sci(1) Pp 21-30. [5] AigedionV.S, Hassan S.B. Olajide S.O, Agunsoye O.J, Abdulrahaman A.S. Okafor G.E. (2008).The Use of Rice Husk Ash as an Aggregate for Foundry Sand Mould Production, Proceeding of the 25 th NMS Conference, Nigeria. [6] Roa P.N. (2001). Manufacturing Technology, Foundry, Forming, and Welding, Tata, McGraw Hill, New Delhi India. Pp97-106. |