Paper Menu >>

Journal Menu >>

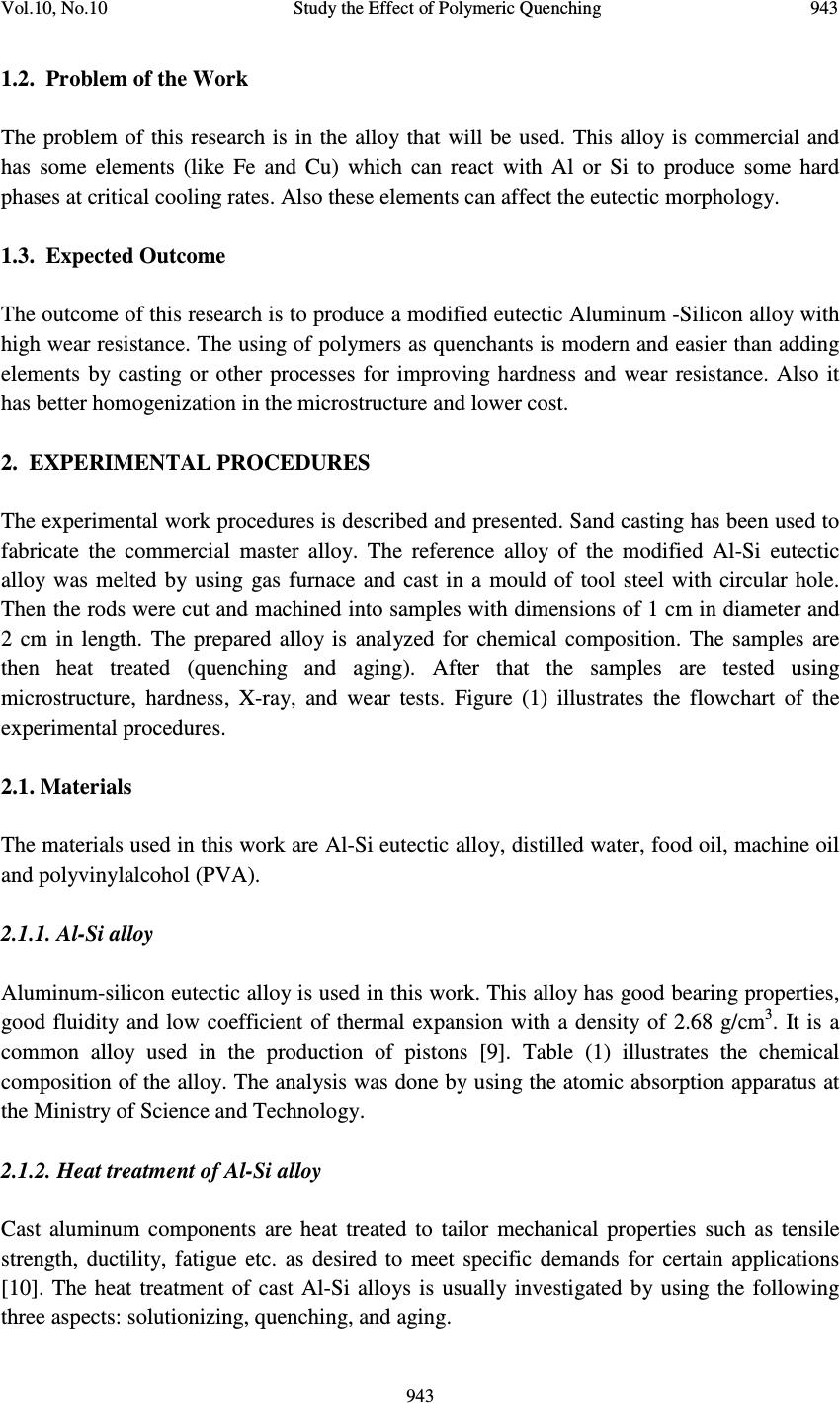

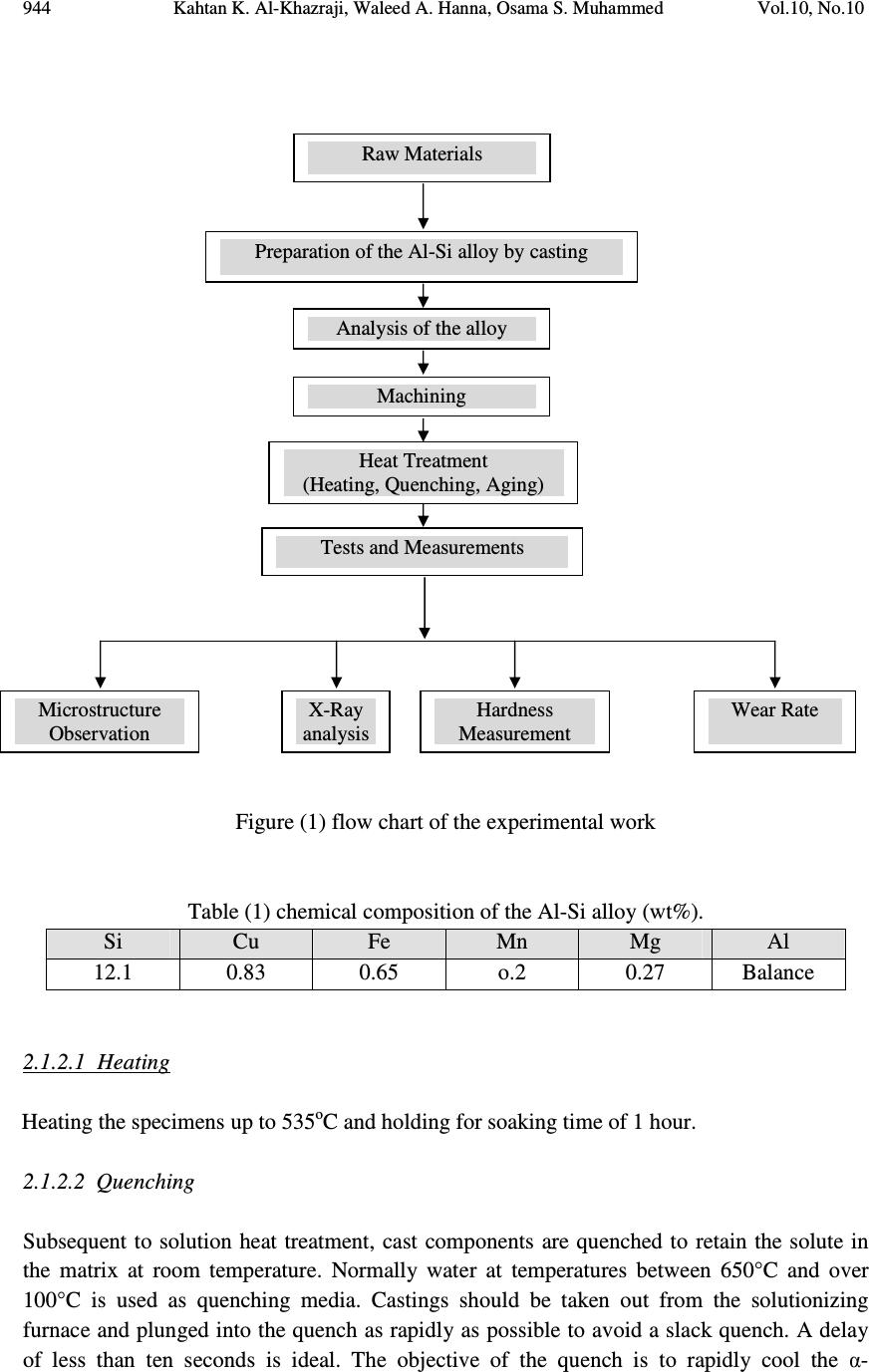

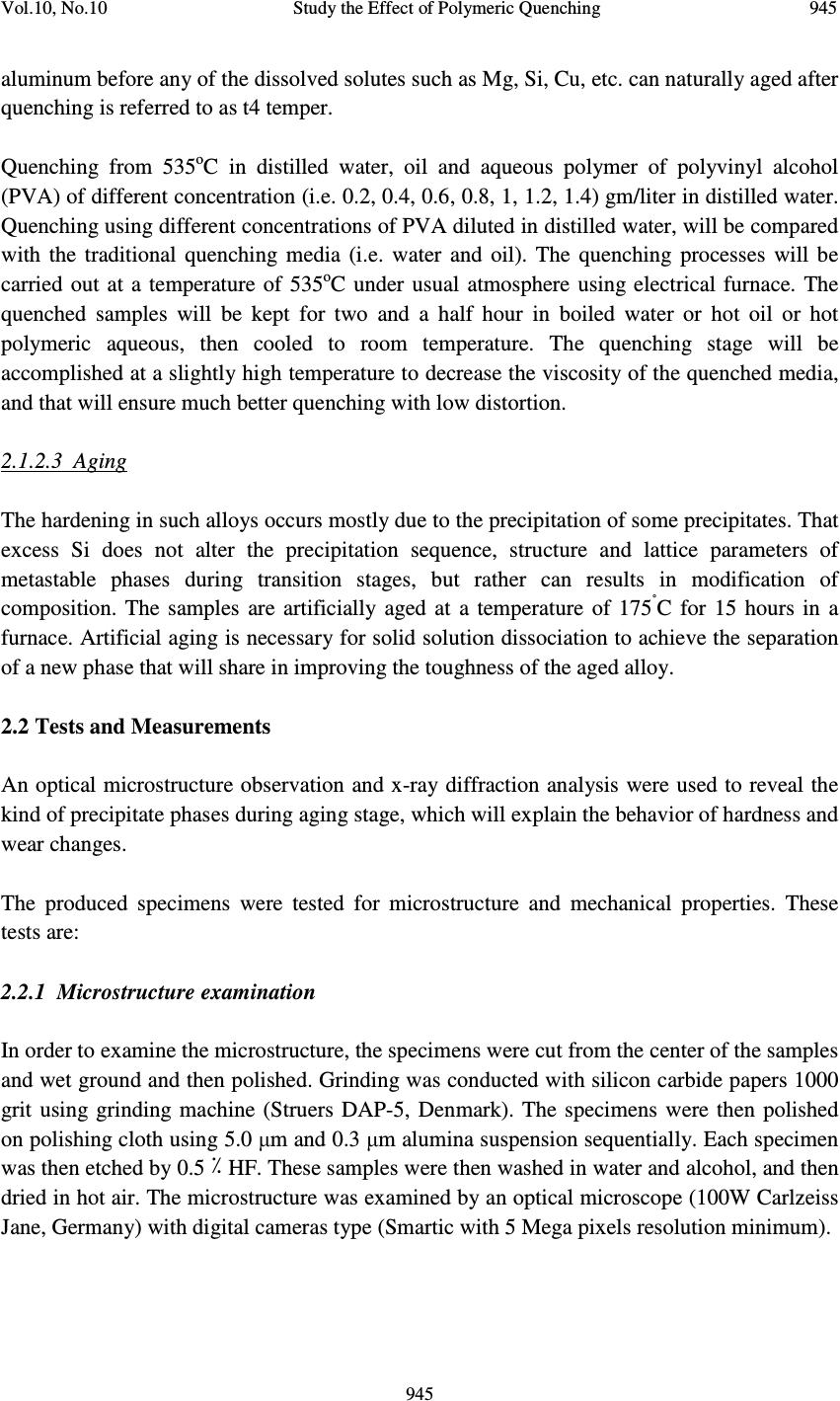

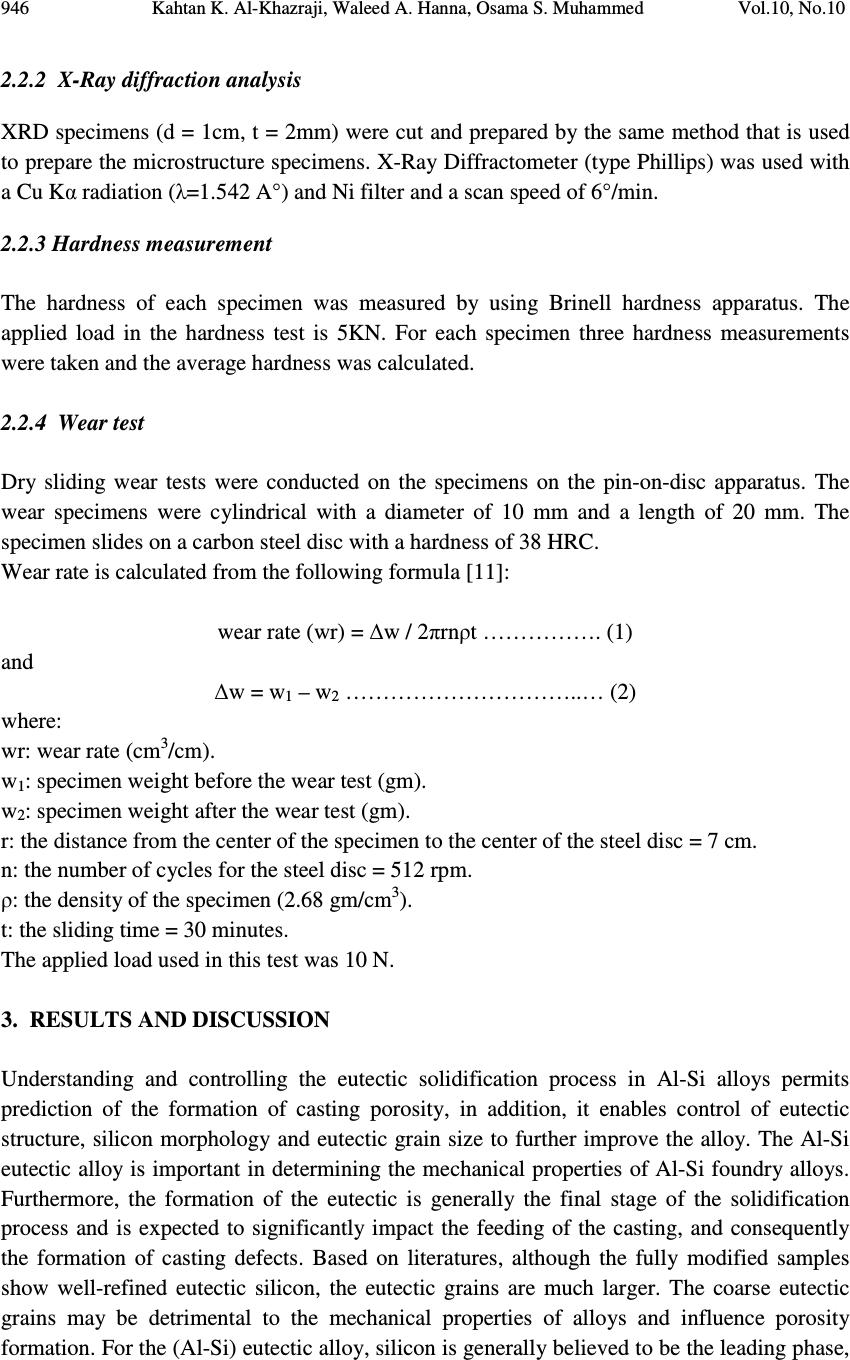

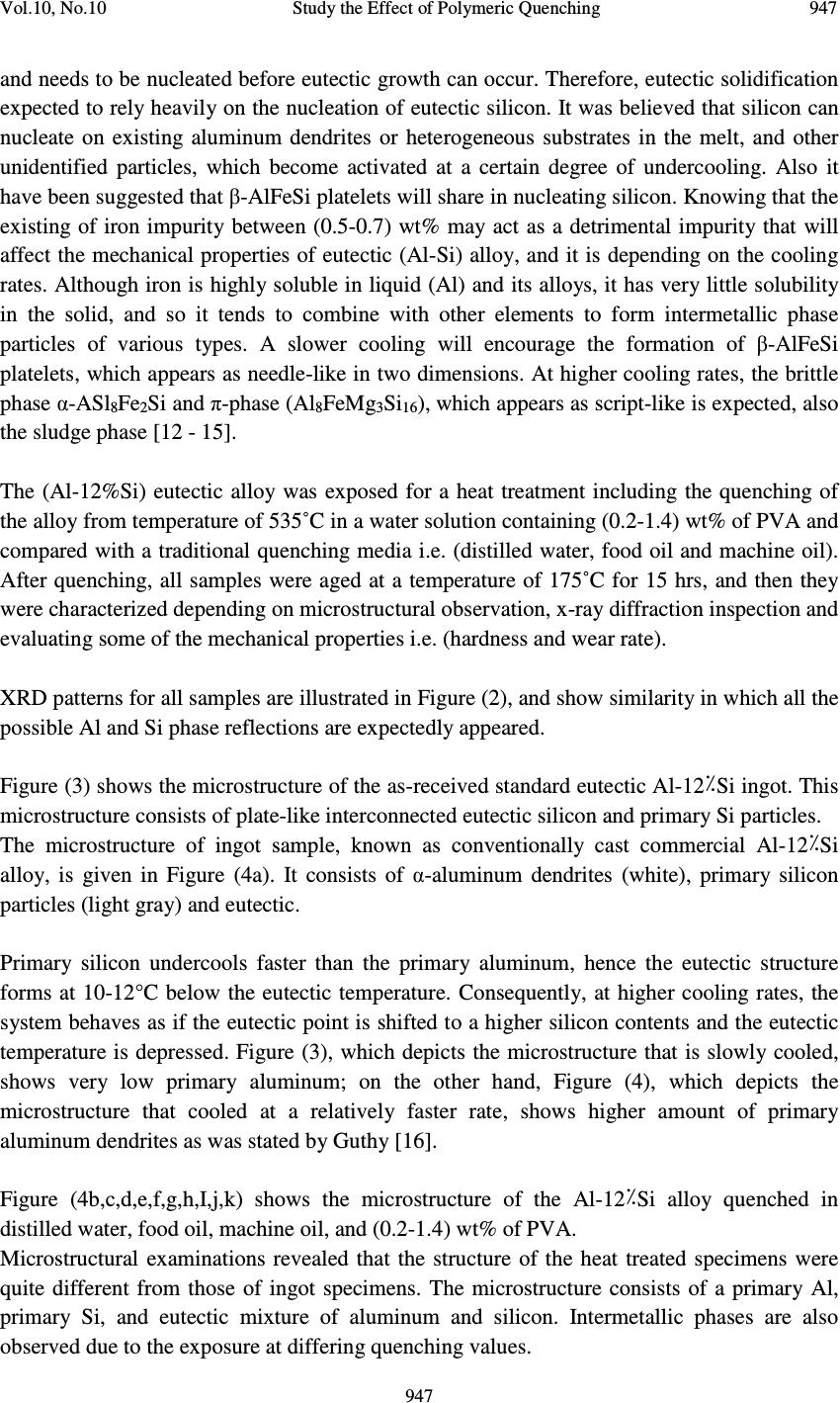

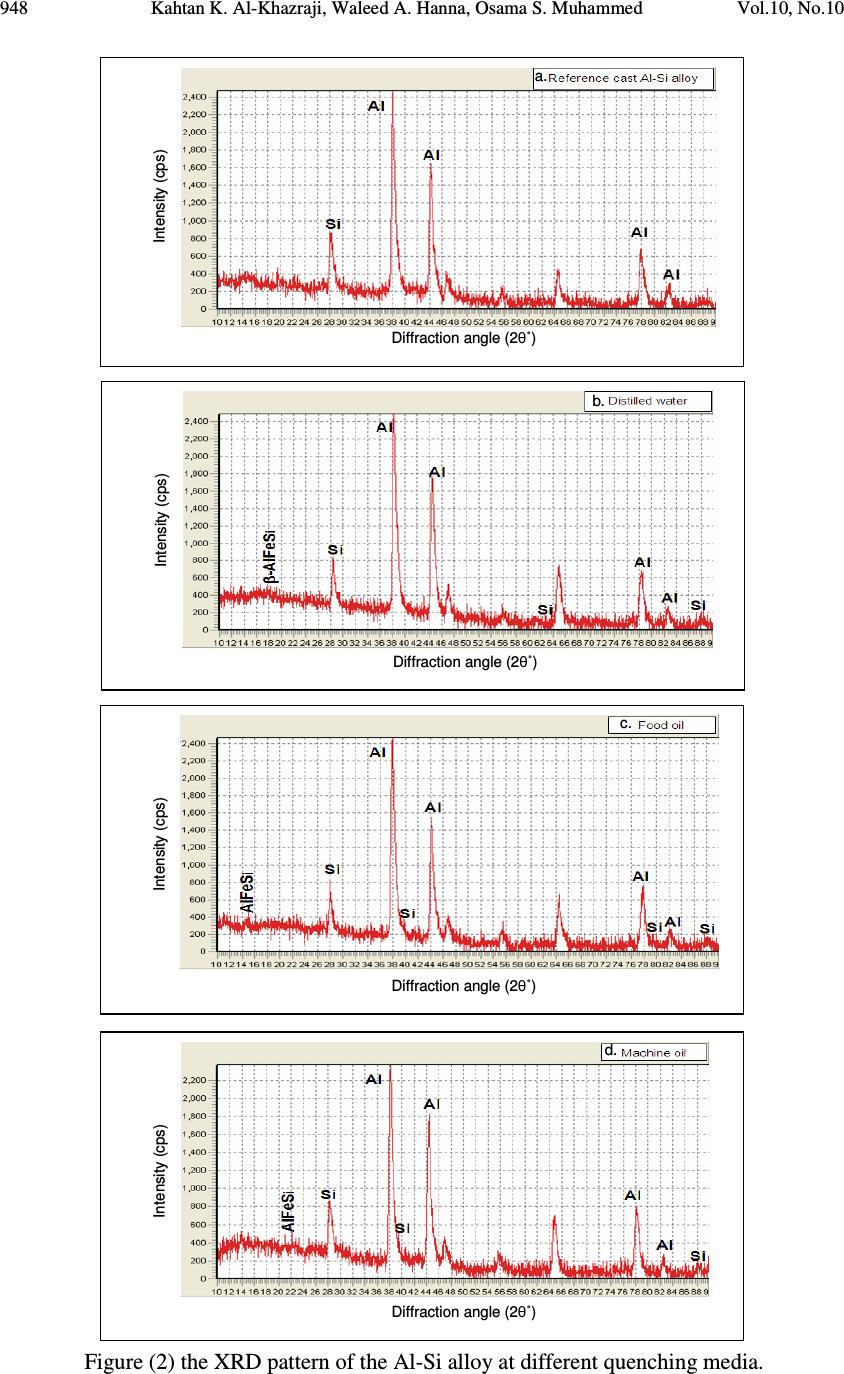

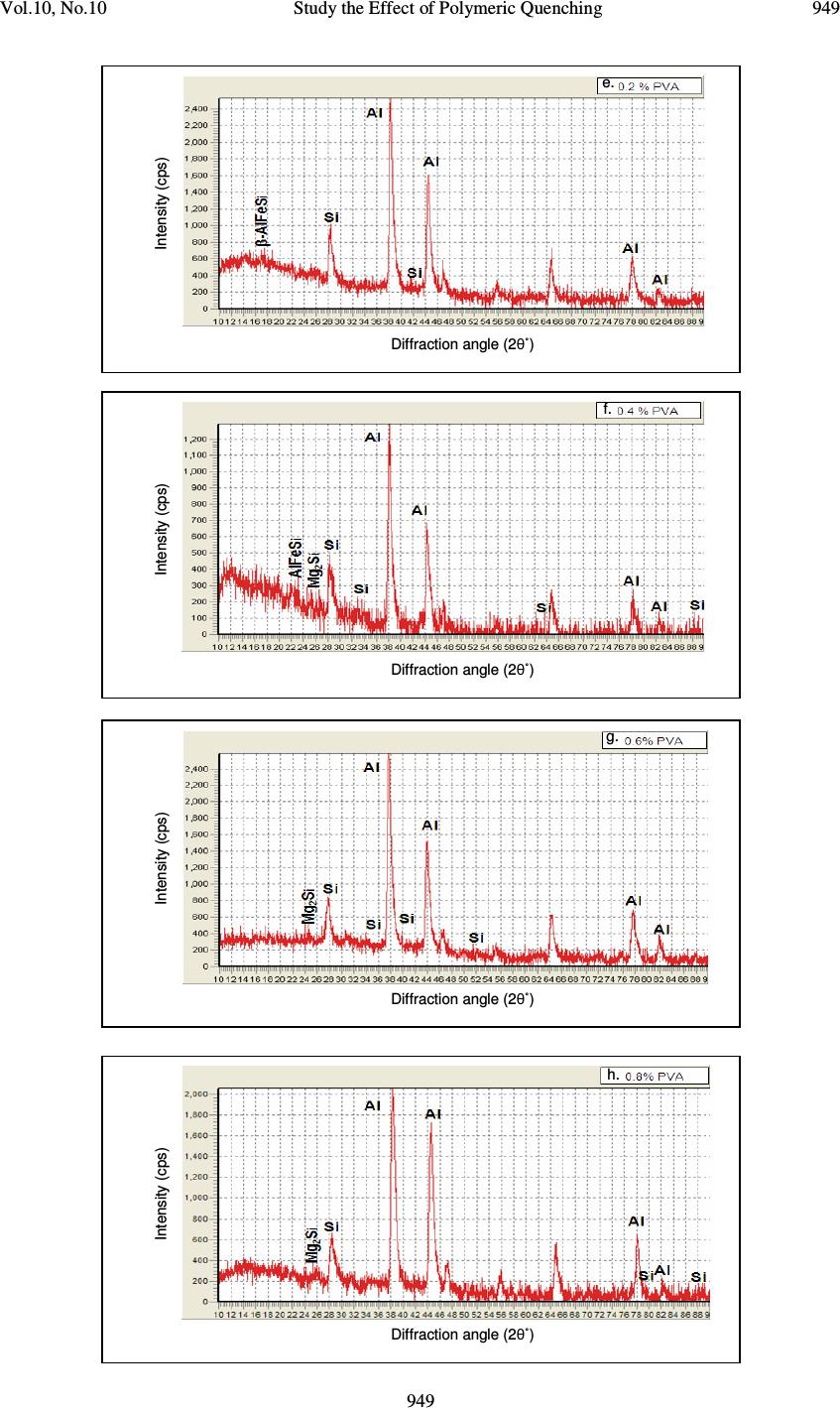

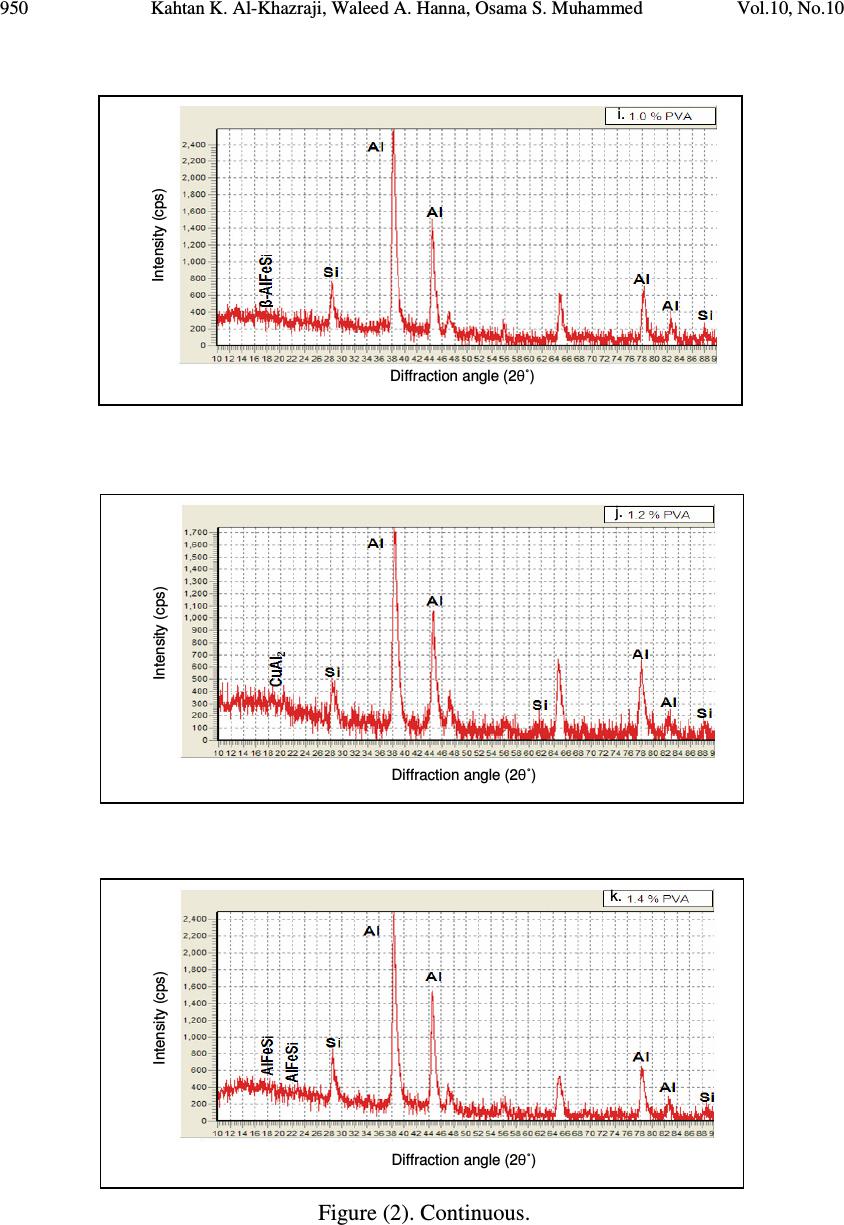

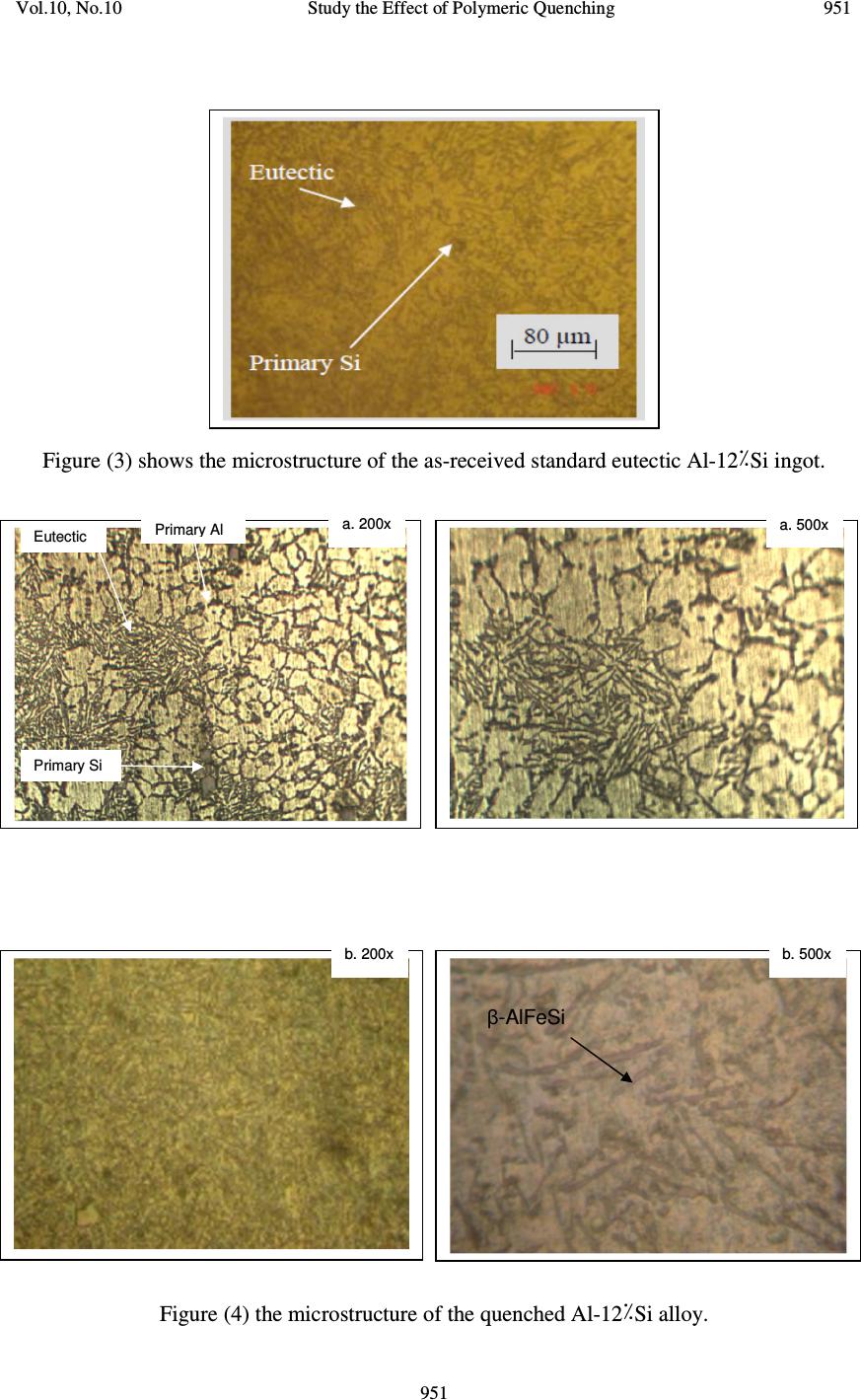

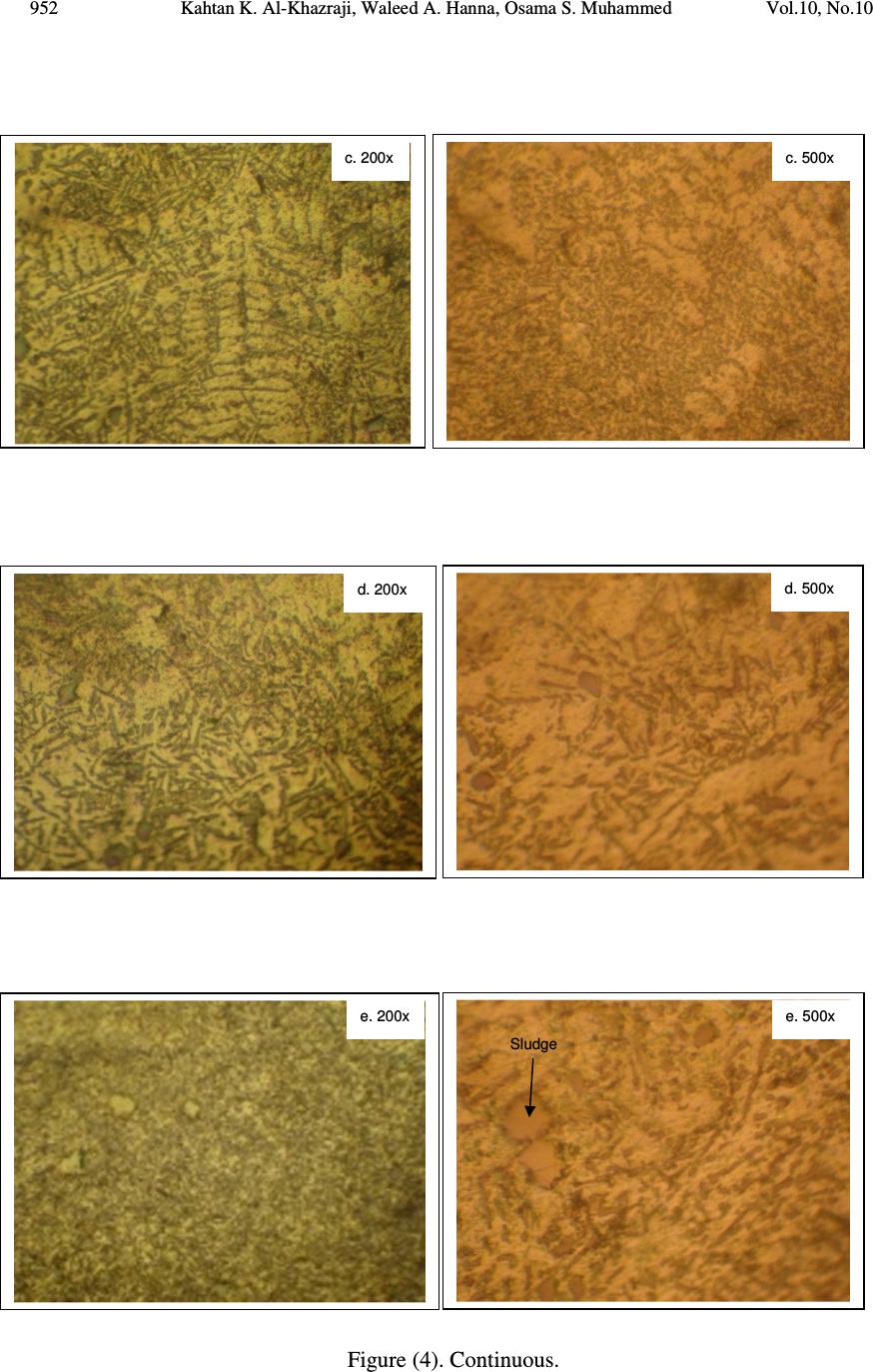

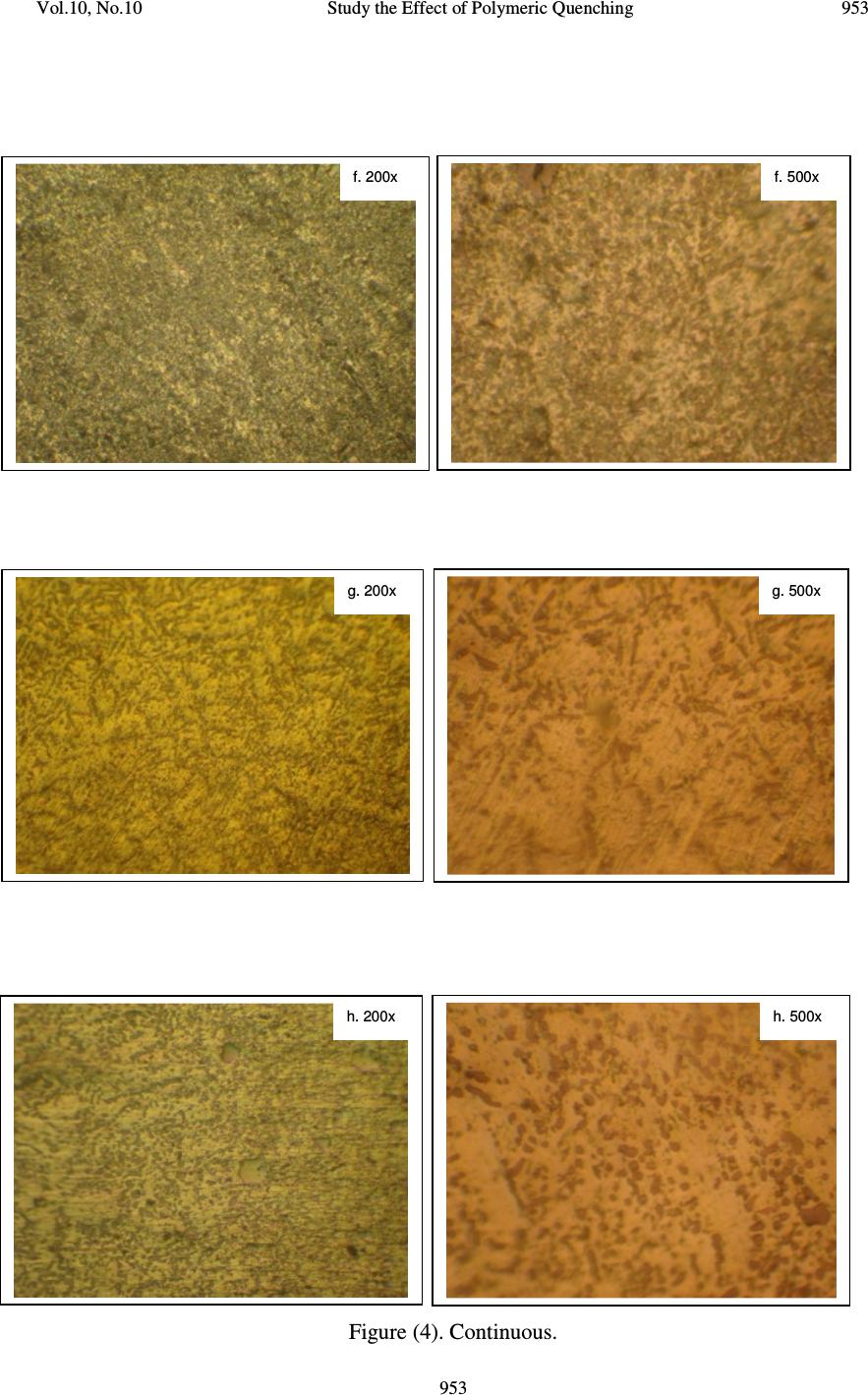

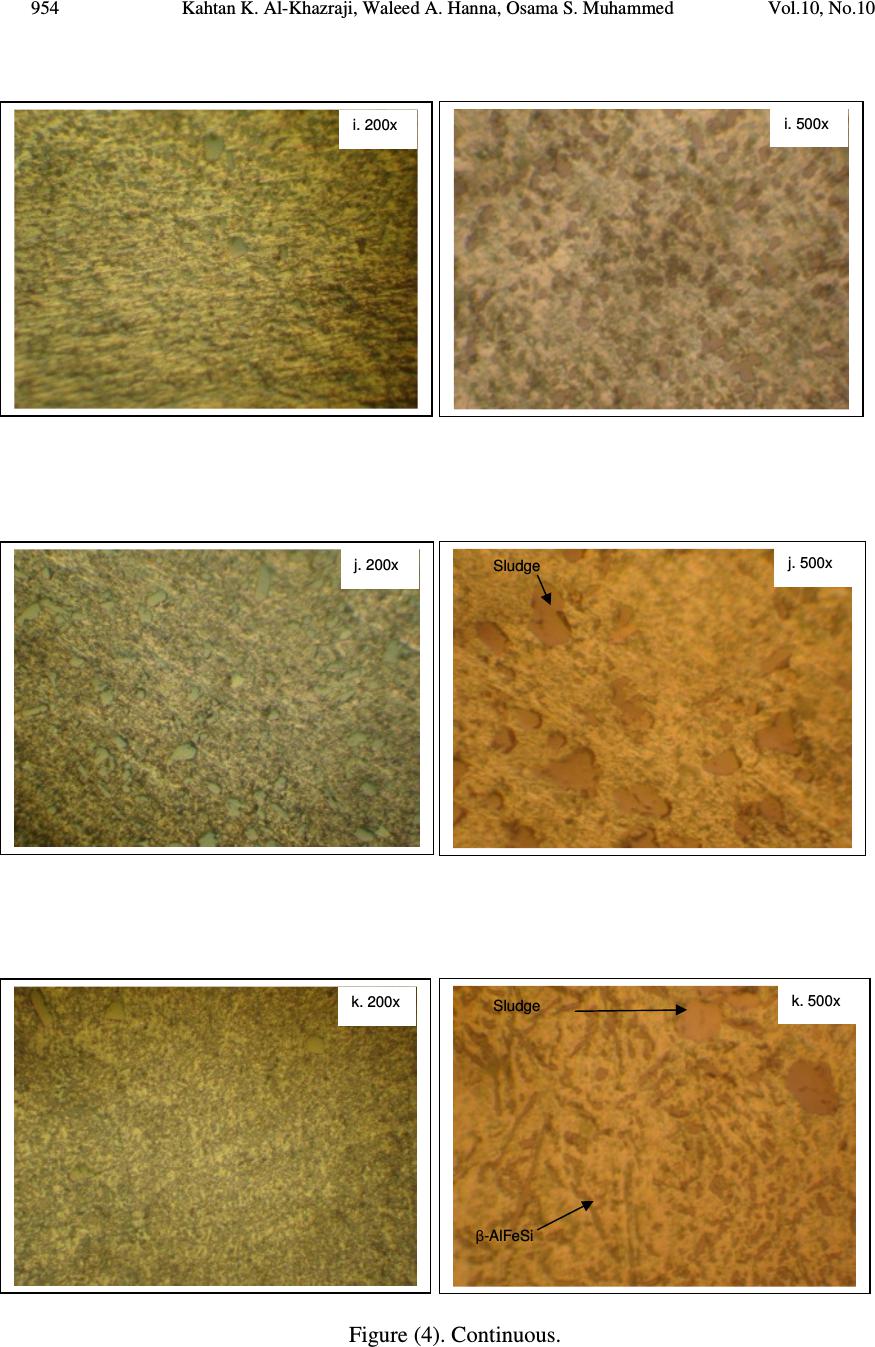

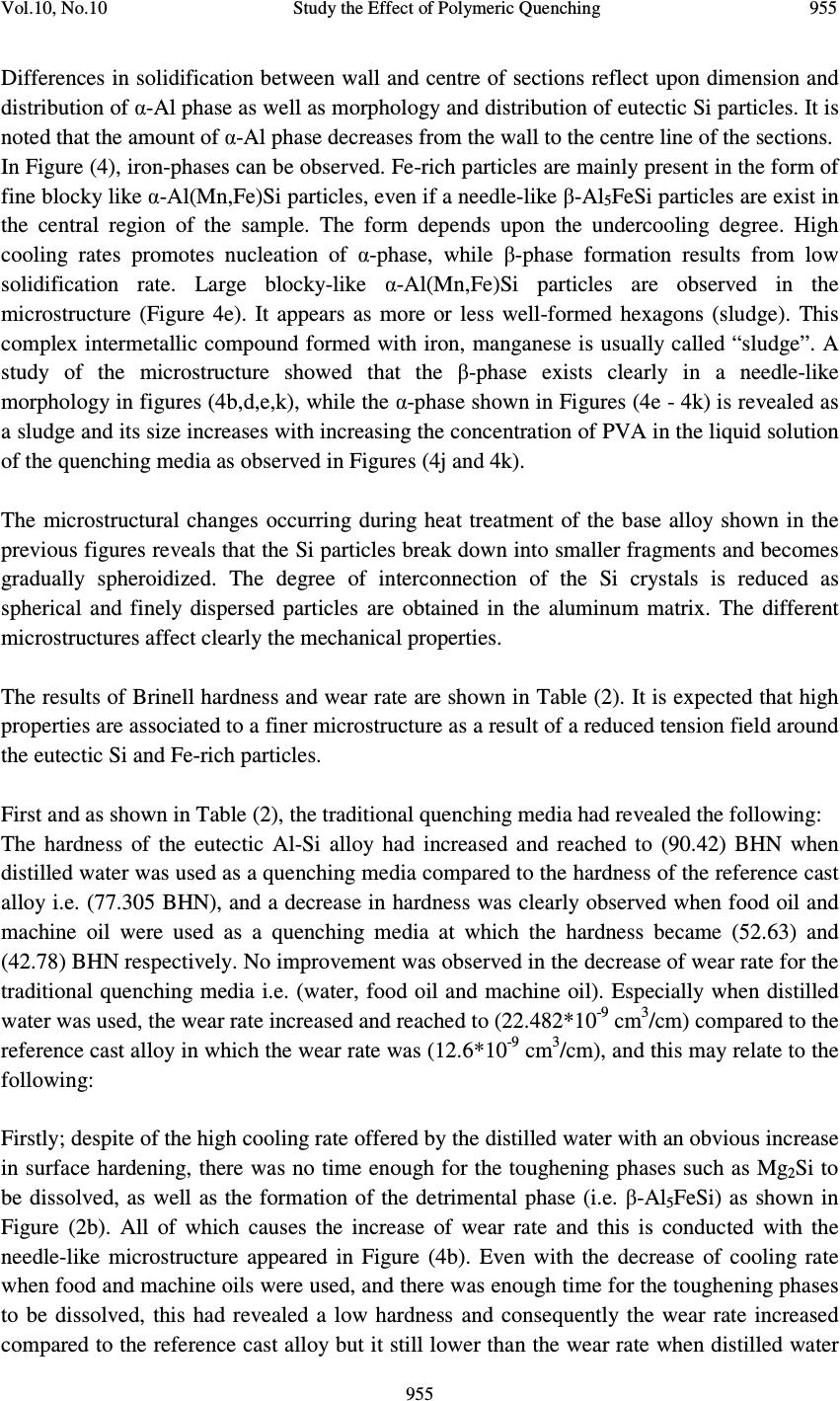

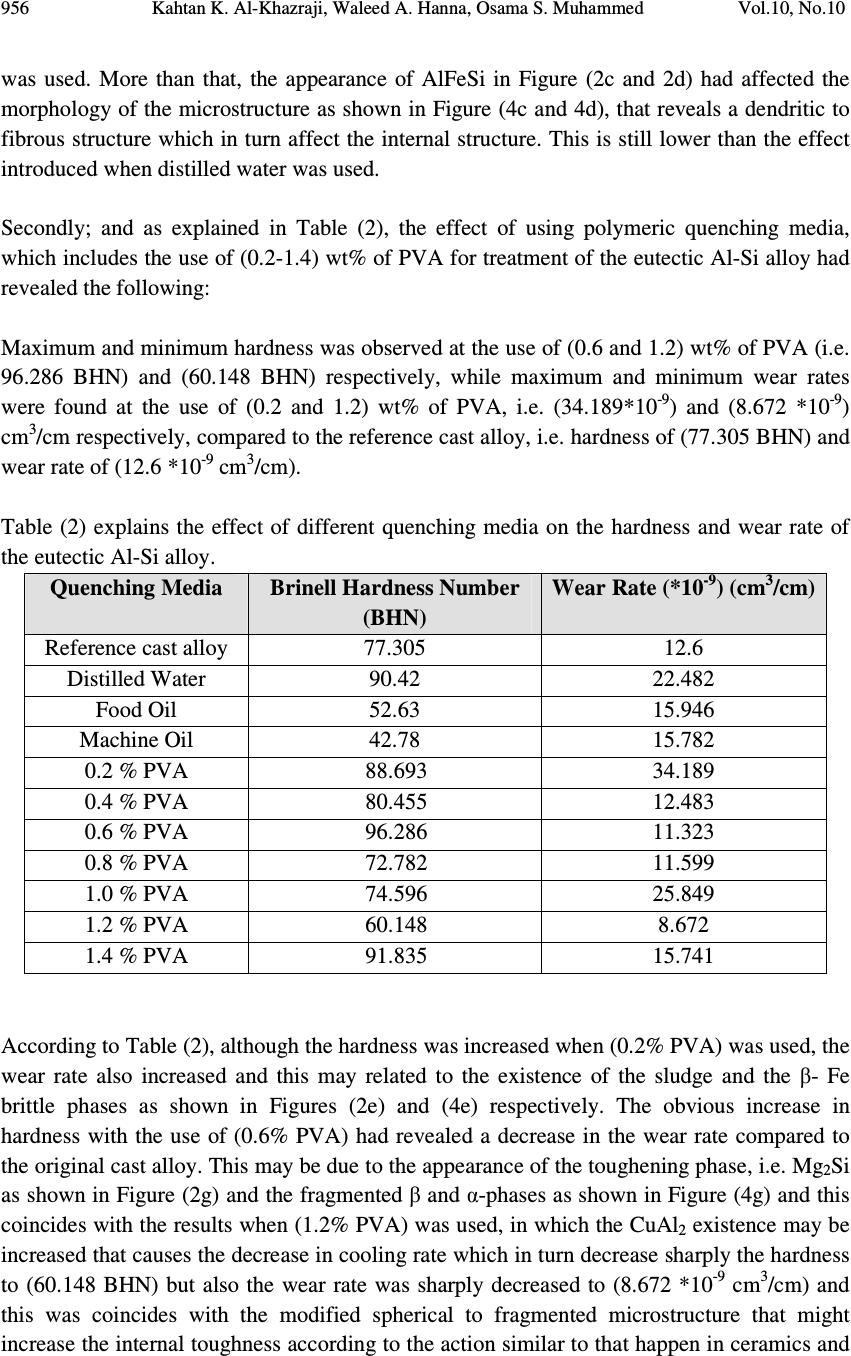

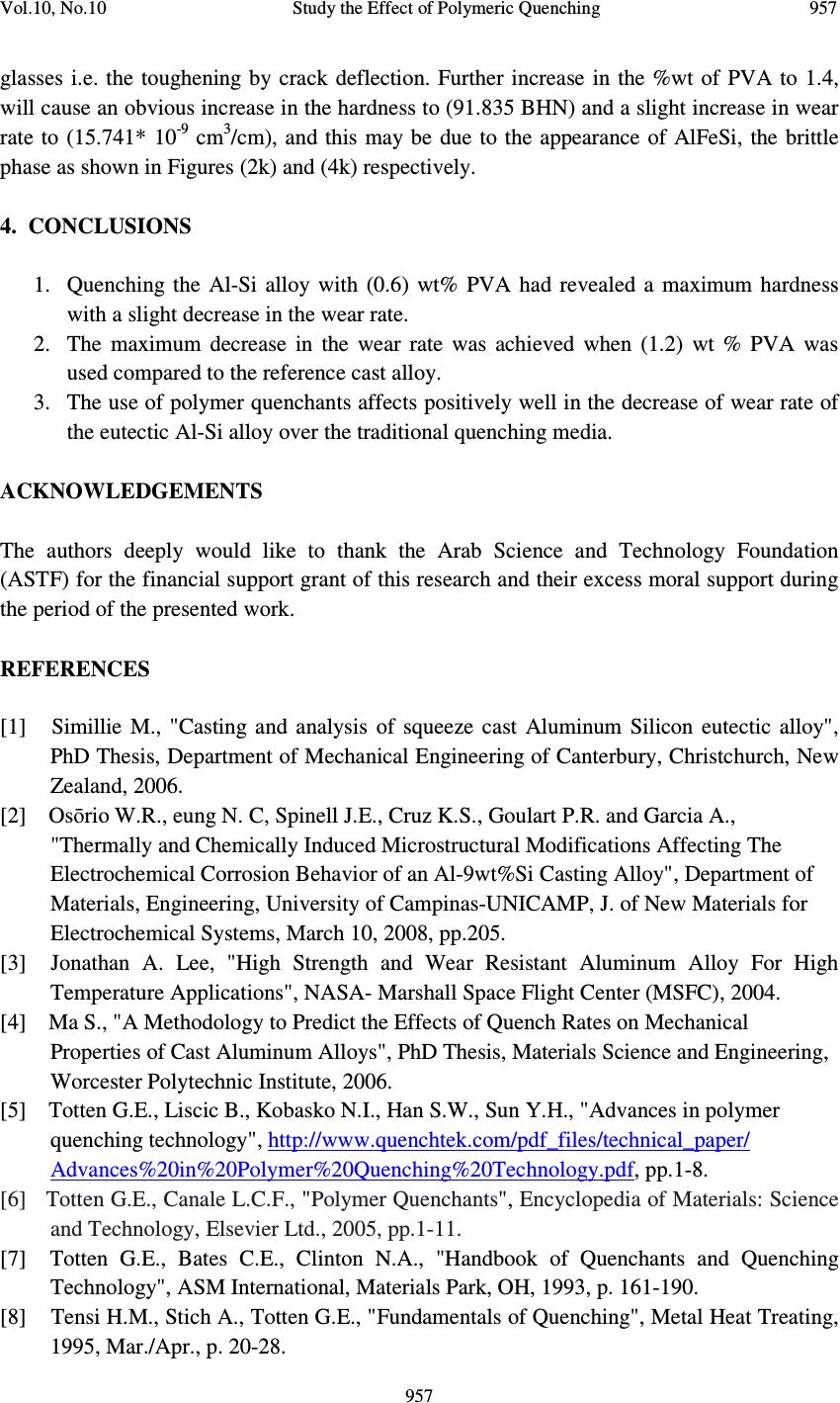

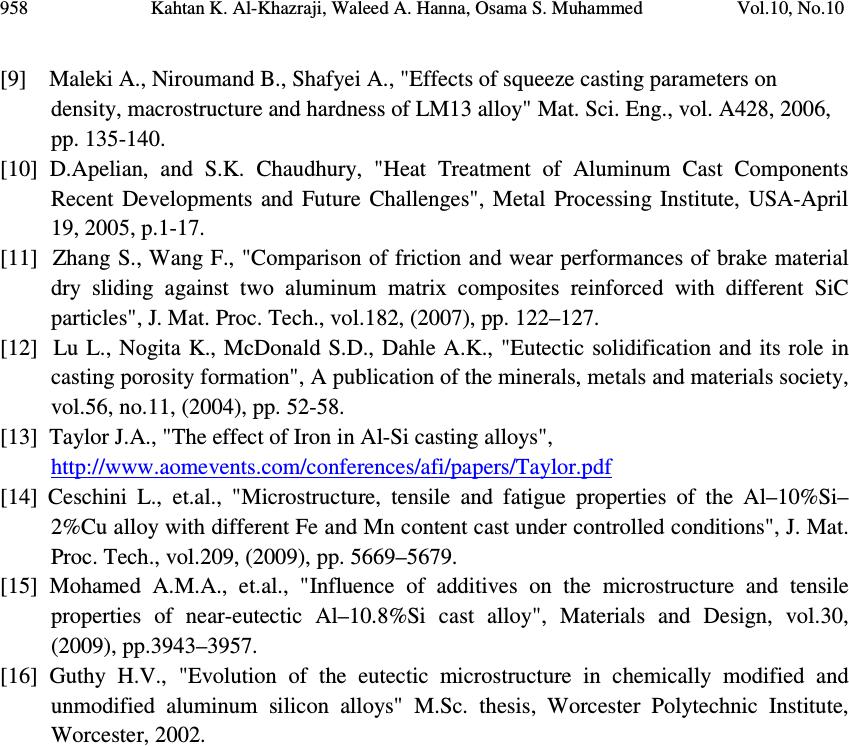

Journal of Minerals & Materials Characterization & Engineering, Vol. 10, No.10, pp.941-958, 2011 jmmce.org Printed in the USA. All rights reserved 941 Study the Effect of Polymeric Quenching on Wear Resistance of Eutectic Modified Aluminium – Silicon Alloy Kahtan K. Al-Khazraji, Waleed A. Hanna, Osama S. Muhammed * Materials Eng. Department, University of Technology, Baghdad – Iraq. * Corresponding Author: oalaamiri@yahoo.com ABSTRACT Polymer quenchants are being used increasingly in the heat treating industry. One reason for this increase is the continual engineering advancements that facilitate their replacement for quench oils and water. The physical properties of a polymer quench bath directly affect the cooling rate of a quenched part. These properties include the type of quenchant, concentration, and agitation. These parameters must be controlled to optimize the quenching process in terms of alloy microstructure, properties, and performance. Such data is scarce for cast aluminum alloys in the literatures and a quantitative measurement of the effects from individual process parameter is not available. In this study a master alloy of modified eutectic (Al-12%Si) was prepared and used. The specimens were quenched and heat treated in distilled water, food oil, machine oil and (0.2-1.4) wt% concentrations of polyvinylalcohol (PVA). The specimens are characterized for x-ray diffraction, microstructure, hardness, and wear rate. The results had shown that the use of (0.6) wt% PVA revealed a maximum hardness with a slight decrease in the wear rate, and a maximum decrease in the wear rate was achieved when (1.2) wt % PVA was used compared to the reference cast alloy, also results had revealed that the use of polymer quenchants affect positively well in the decrease in the wear rate of the eutectic Al-Si alloy over the traditional quenching media. Keywords: Al-Si alloy; polymer quenching; wear resistance. 1. INTRODUCTION 1.1. Background Aluminum alloys are widely used in castings because they possess many desirable properties. These include high fluidity, light weight, low melting points, high thermal conductivity and good surface finish [1].  942 Kahtan K. Al-Khazraji, Waleed A. Hanna, Osama S. Muhammed Vol.10, No.10 Aluminum castings have played an integral role in the growth of aluminum industry. Silicon is the main alloying element; it imparts high fluidity and low shrinkage, which result in a good castability and weldability. Aluminum alloys with silicon as a major alloying element constitute a class of material, which provides the most significant part of all shaped castings manufactured especially in the aerospace and automotive industries [2]. It is an ideal low cost material for cast automotive components such as pistons, cylinder heads, cylinder liners, connecting rods, turbo chargers, impellers, actuators and brake calipers. At high silicon levels, the alloy exhibits excellent thermal growth stability, surface hardness and wear resistant properties [3]. Intensive studies of the cast aluminum family have been found in the literature in terms of enhancing the mechanical properties. It is well known that the heat treatment is one of the important methods for improving the mechanical properties of aluminum alloys. The heat treatment of age hardenable aluminum alloys involves solutionizing the alloys, quenching, and then either aging at room temperature (natural aging) or at an elevated temperature (artificial aging) [4]. Quenching is a crucial step to suppress the precipitation to retain the supersaturating of solid solution, control the distortion, and minimize the residual stress in aluminum alloys. Quenching media commonly used for aluminum alloys include brine solution, water, and polymer solutions. The physical properties of polymer quench bath directly affect the cooling rate of a quenched part. These properties include the type of quenchant, its temperature, concentration, and agitation level. These parameters must be controlled to optimize the quenching process in terms of alloy microstructure, properties, and performance. Polymer quenchants are being used increasingly in the heat treating industry. One reason for this increase is the continual engineering advancements that facilitate their replacement of quench oils and also water. However, integration of the fundamental understanding of this technology into more traditional understanding of quenchants such as water and oil has been relatively slow. This is evident in proper treatment of the use of aqueous polymer solutions as quenchants in heat-treating and metallurgy textbooks, standards development, and industrial process design [5, 6]. The use of aqueous polymer quenchants is increasingly more common in some challenging applications in view of their fire safety, environmental and toxicological advantages. Perhaps the most significant reason for the increased use of polymer quenchants is their relatively more uniform heat removal during quenching resulting in reduced thermal gradients and distortion [7, 8]. The objective of this work is to heat treating the modified eutectic Al-Si alloy and quenching it in water, two types of oil and different concentrations of poly vinyl alcohol (PVA), and then aging it. Finally comparing the results and discussing it to find the better quenching media.  Vol.10, No.10 Study the Effect of Polymeric Quenching 943 943 1.2. Problem of the Work The problem of this research is in the alloy that will be used. This alloy is commercial and has some elements (like Fe and Cu) which can react with Al or Si to produce some hard phases at critical cooling rates. Also these elements can affect the eutectic morphology. 1.3. Expected Outcome The outcome of this research is to produce a modified eutectic Aluminum -Silicon alloy with high wear resistance. The using of polymers as quenchants is modern and easier than adding elements by casting or other processes for improving hardness and wear resistance. Also it has better homogenization in the microstructure and lower cost. 2. EXPERIMENTAL PROCEDURES The experimental work procedures is described and presented. Sand casting has been used to fabricate the commercial master alloy. The reference alloy of the modified Al-Si eutectic alloy was melted by using gas furnace and cast in a mould of tool steel with circular hole. Then the rods were cut and machined into samples with dimensions of 1 cm in diameter and 2 cm in length. The prepared alloy is analyzed for chemical composition. The samples are then heat treated (quenching and aging). After that the samples are tested using microstructure, hardness, X-ray, and wear tests. Figure (1) illustrates the flowchart of the experimental procedures. 2.1. Materials The materials used in this work are Al-Si eutectic alloy, distilled water, food oil, machine oil and polyvinylalcohol (PVA). 2.1.1. Al-Si alloy Aluminum-silicon eutectic alloy is used in this work. This alloy has good bearing properties, good fluidity and low coefficient of thermal expansion with a density of 2.68 g/cm 3 . It is a common alloy used in the production of pistons [9]. Table (1) illustrates the chemical composition of the alloy. The analysis was done by using the atomic absorption apparatus at the Ministry of Science and Technology. 2.1.2. Heat treatment of Al-Si alloy Cast aluminum components are heat treated to tailor mechanical properties such as tensile strength, ductility, fatigue etc. as desired to meet specific demands for certain applications [10]. The heat treatment of cast Al-Si alloys is usually investigated by using the following three aspects: solutionizing, quenching, and aging.  944 Kahtan K. Al-Khazraji, Waleed A. Hanna, Osama S. Muhammed Vol.10, No.10 Figure (1) flow chart of the experimental work Table (1) chemical composition of the Al-Si alloy (wt%). Si Cu Fe Mn Mg Al 12.1 0.83 0.65 o.2 0.27 Balance 2.1.2.1 Heating Heating the specimens up to 535 o C and holding for soaking time of 1 hour. 2.1.2.2 Quenching Subsequent to solution heat treatment, cast components are quenched to retain the solute in the matrix at room temperature. Normally water at temperatures between 650°C and over 100°C is used as quenching media. Castings should be taken out from the solutionizing furnace and plunged into the quench as rapidly as possible to avoid a slack quench. A delay of less than ten seconds is ideal. The objective of the quench is to rapidly cool the α- Raw Materials Preparation of the Al-Si alloy by casting Analysis of the alloy Machining Tests and Measurements Wear Rate X-Ray analysis Hardness Measurement Microstructure Observation Heat Treatment (Heating, Quenching, A ging)  Vol.10, No.10 Study the Effect of Polymeric Quenching 945 945 aluminum before any of the dissolved solutes such as Mg, Si, Cu, etc. can naturally aged after quenching is referred to as t4 temper. Quenching from 535 o C in distilled water, oil and aqueous polymer of polyvinyl alcohol (PVA) of different concentration (i.e. 0.2, 0.4, 0.6, 0.8, 1, 1.2, 1.4) gm/liter in distilled water. Quenching using different concentrations of PVA diluted in distilled water, will be compared with the traditional quenching media (i.e. water and oil). The quenching processes will be carried out at a temperature of 535 o C under usual atmosphere using electrical furnace. The quenched samples will be kept for two and a half hour in boiled water or hot oil or hot polymeric aqueous, then cooled to room temperature. The quenching stage will be accomplished at a slightly high temperature to decrease the viscosity of the quenched media, and that will ensure much better quenching with low distortion. 2.1.2.3 Aging The hardening in such alloys occurs mostly due to the precipitation of some precipitates. That excess Si does not alter the precipitation sequence, structure and lattice parameters of metastable phases during transition stages, but rather can results in modification of composition. The samples are artificially aged at a temperature of 175 ˚ C for 15 hours in a furnace. Artificial aging is necessary for solid solution dissociation to achieve the separation of a new phase that will share in improving the toughness of the aged alloy. 2.2 Tests and Measurements An optical microstructure observation and x-ray diffraction analysis were used to reveal the kind of precipitate phases during aging stage, which will explain the behavior of hardness and wear changes. The produced specimens were tested for microstructure and mechanical properties. These tests are: 2.2.1 Microstructure examination In order to examine the microstructure, the specimens were cut from the center of the samples and wet ground and then polished. Grinding was conducted with silicon carbide papers 1000 grit using grinding machine (Struers DAP-5, Denmark). The specimens were then polished on polishing cloth using 5.0 µm and 0.3 µm alumina suspension sequentially. Each specimen was then etched by 0.5 ٪ HF. These samples were then washed in water and alcohol, and then dried in hot air. The microstructure was examined by an optical microscope (100W Carlzeiss Jane, Germany) with digital cameras type (Smartic with 5 Mega pixels resolution minimum).  946 Kahtan K. Al-Khazraji, Waleed A. Hanna, Osama S. Muhammed Vol.10, No.10 2.2.2 X-Ray diffraction analysis XRD specimens (d = 1cm, t = 2mm) were cut and prepared by the same method that is used to prepare the microstructure specimens. X-Ray Diffractometer (type Phillips) was used with a Cu Kα radiation (λ=1.542 A°) and Ni filter and a scan speed of 6°/min. 2.2.3 Hardness measurement The hardness of each specimen was measured by using Brinell hardness apparatus. The applied load in the hardness test is 5KN. For each specimen three hardness measurements were taken and the average hardness was calculated. 2.2.4 Wear test Dry sliding wear tests were conducted on the specimens on the pin-on-disc apparatus. The wear specimens were cylindrical with a diameter of 10 mm and a length of 20 mm. The specimen slides on a carbon steel disc with a hardness of 38 HRC. Wear rate is calculated from the following formula [11]: wear rate (wr) = ∆w / 2πrnρt ……………. (1) and ∆w = w 1 – w 2 …………………………..… (2) where: wr: wear rate (cm 3 /cm). w 1 : specimen weight before the wear test (gm). w 2 : specimen weight after the wear test (gm). r: the distance from the center of the specimen to the center of the steel disc = 7 cm. n: the number of cycles for the steel disc = 512 rpm. ρ: the density of the specimen (2.68 gm/cm 3 ). t: the sliding time = 30 minutes. The applied load used in this test was 10 N. 3. RESULTS AND DISCUSSION Understanding and controlling the eutectic solidification process in Al-Si alloys permits prediction of the formation of casting porosity, in addition, it enables control of eutectic structure, silicon morphology and eutectic grain size to further improve the alloy. The Al-Si eutectic alloy is important in determining the mechanical properties of Al-Si foundry alloys. Furthermore, the formation of the eutectic is generally the final stage of the solidification process and is expected to significantly impact the feeding of the casting, and consequently the formation of casting defects. Based on literatures, although the fully modified samples show well-refined eutectic silicon, the eutectic grains are much larger. The coarse eutectic grains may be detrimental to the mechanical properties of alloys and influence porosity formation. For the (Al-Si) eutectic alloy, silicon is generally believed to be the leading phase,  Vol.10, No.10 Study the Effect of Polymeric Quenching 947 947 and needs to be nucleated before eutectic growth can occur. Therefore, eutectic solidification expected to rely heavily on the nucleation of eutectic silicon. It was believed that silicon can nucleate on existing aluminum dendrites or heterogeneous substrates in the melt, and other unidentified particles, which become activated at a certain degree of undercooling. Also it have been suggested that β-AlFeSi platelets will share in nucleating silicon. Knowing that the existing of iron impurity between (0.5-0.7) wt% may act as a detrimental impurity that will affect the mechanical properties of eutectic (Al-Si) alloy, and it is depending on the cooling rates. Although iron is highly soluble in liquid (Al) and its alloys, it has very little solubility in the solid, and so it tends to combine with other elements to form intermetallic phase particles of various types. A slower cooling will encourage the formation of β-AlFeSi platelets, which appears as needle-like in two dimensions. At higher cooling rates, the brittle phase α-ASl 8 Fe 2 Si and π-phase (Al 8 FeMg 3 Si 16 ), which appears as script-like is expected, also the sludge phase [12 - 15]. The (Al-12%Si) eutectic alloy was exposed for a heat treatment including the quenching of the alloy from temperature of 535˚C in a water solution containing (0.2-1.4) wt% of PVA and compared with a traditional quenching media i.e. (distilled water, food oil and machine oil). After quenching, all samples were aged at a temperature of 175˚C for 15 hrs, and then they were characterized depending on microstructural observation, x-ray diffraction inspection and evaluating some of the mechanical properties i.e. (hardness and wear rate). XRD patterns for all samples are illustrated in Figure (2), and show similarity in which all the possible Al and Si phase reflections are expectedly appeared. Figure (3) shows the microstructure of the as-received standard eutectic Al-12٪Si ingot. This microstructure consists of plate-like interconnected eutectic silicon and primary Si particles. The microstructure of ingot sample, known as conventionally cast commercial Al-12٪Si alloy, is given in Figure (4a). It consists of α-aluminum dendrites (white), primary silicon particles (light gray) and eutectic. Primary silicon undercools faster than the primary aluminum, hence the eutectic structure forms at 10-12°C below the eutectic temperature. Consequently, at higher cooling rates, the system behaves as if the eutectic point is shifted to a higher silicon contents and the eutectic temperature is depressed. Figure (3), which depicts the microstructure that is slowly cooled, shows very low primary aluminum; on the other hand, Figure (4), which depicts the microstructure that cooled at a relatively faster rate, shows higher amount of primary aluminum dendrites as was stated by Guthy [16]. Figure (4b,c,d,e,f,g,h,I,j,k) shows the microstructure of the Al-12٪Si alloy quenched in distilled water, food oil, machine oil, and (0.2-1.4) wt% of PVA. Microstructural examinations revealed that the structure of the heat treated specimens were quite different from those of ingot specimens. The microstructure consists of a primary Al, primary Si, and eutectic mixture of aluminum and silicon. Intermetallic phases are also observed due to the exposure at differing quenching values.  948 Kahtan K. Al-Khazraji, Waleed A. Hanna, Osama S. Muhammed Vol.10, No.10 Figure (2) the XRD pattern of the Al-Si alloy at different quenching media. Intensity (cps) Diffraction angle (2θ˚) Intensity (cps) Diffraction angle (2θ˚) Intensity (cps) Diffraction angle (2θ˚) Intensity (cps) Diffraction angle (2θ˚) a. b. c. d.  Vol.10, No.10 Study the Effect of Polymeric Quenching 949 949 Intensity (cps) Diffraction angle (2θ˚) Intensity (cps) Diffraction angle (2θ˚) Intensity (cps) Diffraction angle (2θ˚) Intensity (cps) Diffraction angle (2θ˚) e. f. g. h.  950 Kahtan K. Al-Khazraji, Waleed A. Hanna, Osama S. Muhammed Vol.10, No.10 Figure (2). Continuous. Intensity (cps) Diffraction angle (2θ˚) Intensity (cps) Diffraction angle (2θ˚) Intensity (cps) Diffraction angle (2θ˚) i. j. k.  Vol.10, No.10 Study the Effect of Polymeric Quenching 951 951 Figure (3) shows the microstructure of the as-received standard eutectic Al-12٪Si ingot. Figure (4) the microstructure of the quenched Al-12٪Si alloy. β-AlFeSi Eutectic Primary Si Prim ary Al a. 200x a. 500x b. 200x b. 500x  952 Kahtan K. Al-Khazraji, Waleed A. Hanna, Osama S. Muhammed Vol.10, No.10 Figure (4). Continuous. Sludge c. 500x c. 200x d. 500x d. 200x e. 500x e. 200x  Vol.10, No.10 Study the Effect of Polymeric Quenching 953 953 Figure (4). Continuous. f. 500x f. 200x g. 500x g. 200x h. 200x h. 500x  954 Kahtan K. Al-Khazraji, Waleed A. Hanna, Osama S. Muhammed Vol.10, No.10 Figure (4). Continuous. Sludge Sludge β-AlFeSi i. 500x i. 200x k. 200x j. 500x k. 500x j. 200x  Vol.10, No.10 Study the Effect of Polymeric Quenching 955 955 Differences in solidification between wall and centre of sections reflect upon dimension and distribution of α-Al phase as well as morphology and distribution of eutectic Si particles. It is noted that the amount of α-Al phase decreases from the wall to the centre line of the sections. In Figure (4), iron-phases can be observed. Fe-rich particles are mainly present in the form of fine blocky like α-Al(Mn,Fe)Si particles, even if a needle-like β-Al 5 FeSi particles are exist in the central region of the sample. The form depends upon the undercooling degree. High cooling rates promotes nucleation of α-phase, while β-phase formation results from low solidification rate. Large blocky-like α-Al(Mn,Fe)Si particles are observed in the microstructure (Figure 4e). It appears as more or less well-formed hexagons (sludge). This complex intermetallic compound formed with iron, manganese is usually called “sludge”. A study of the microstructure showed that the β-phase exists clearly in a needle-like morphology in figures (4b,d,e,k), while the α-phase shown in Figures (4e - 4k) is revealed as a sludge and its size increases with increasing the concentration of PVA in the liquid solution of the quenching media as observed in Figures (4j and 4k). The microstructural changes occurring during heat treatment of the base alloy shown in the previous figures reveals that the Si particles break down into smaller fragments and becomes gradually spheroidized. The degree of interconnection of the Si crystals is reduced as spherical and finely dispersed particles are obtained in the aluminum matrix. The different microstructures affect clearly the mechanical properties. The results of Brinell hardness and wear rate are shown in Table (2). It is expected that high properties are associated to a finer microstructure as a result of a reduced tension field around the eutectic Si and Fe-rich particles. First and as shown in Table (2), the traditional quenching media had revealed the following: The hardness of the eutectic Al-Si alloy had increased and reached to (90.42) BHN when distilled water was used as a quenching media compared to the hardness of the reference cast alloy i.e. (77.305 BHN), and a decrease in hardness was clearly observed when food oil and machine oil were used as a quenching media at which the hardness became (52.63) and (42.78) BHN respectively. No improvement was observed in the decrease of wear rate for the traditional quenching media i.e. (water, food oil and machine oil). Especially when distilled water was used, the wear rate increased and reached to (22.482*10 -9 cm 3 /cm) compared to the reference cast alloy in which the wear rate was (12.6*10 -9 cm 3 /cm), and this may relate to the following: Firstly; despite of the high cooling rate offered by the distilled water with an obvious increase in surface hardening, there was no time enough for the toughening phases such as Mg 2 Si to be dissolved, as well as the formation of the detrimental phase (i.e. β-Al 5 FeSi) as shown in Figure (2b). All of which causes the increase of wear rate and this is conducted with the needle-like microstructure appeared in Figure (4b). Even with the decrease of cooling rate when food and machine oils were used, and there was enough time for the toughening phases to be dissolved, this had revealed a low hardness and consequently the wear rate increased compared to the reference cast alloy but it still lower than the wear rate when distilled water  956 Kahtan K. Al-Khazraji, Waleed A. Hanna, Osama S. Muhammed Vol.10, No.10 was used. More than that, the appearance of AlFeSi in Figure (2c and 2d) had affected the morphology of the microstructure as shown in Figure (4c and 4d), that reveals a dendritic to fibrous structure which in turn affect the internal structure. This is still lower than the effect introduced when distilled water was used. Secondly; and as explained in Table (2), the effect of using polymeric quenching media, which includes the use of (0.2-1.4) wt% of PVA for treatment of the eutectic Al-Si alloy had revealed the following: Maximum and minimum hardness was observed at the use of (0.6 and 1.2) wt% of PVA (i.e. 96.286 BHN) and (60.148 BHN) respectively, while maximum and minimum wear rates were found at the use of (0.2 and 1.2) wt% of PVA, i.e. (34.189*10 -9 ) and (8.672 *10 -9 ) cm 3 /cm respectively, compared to the reference cast alloy, i.e. hardness of (77.305 BHN) and wear rate of (12.6 *10 -9 cm 3 /cm). Table (2) explains the effect of different quenching media on the hardness and wear rate of the eutectic Al-Si alloy. Quenching Media Brinell Hardness Number (BHN) Wear Rate (*10 -9 ) (cm 3 /cm) Reference cast alloy 77.305 12.6 Distilled Water 90.42 22.482 Food Oil 52.63 15.946 Machine Oil 42.78 15.782 0.2 % PVA 88.693 34.189 0.4 % PVA 80.455 12.483 0.6 % PVA 96.286 11.323 0.8 % PVA 72.782 11.599 1.0 % PVA 74.596 25.849 1.2 % PVA 60.148 8.672 1.4 % PVA 91.835 15.741 According to Table (2), although the hardness was increased when (0.2% PVA) was used, the wear rate also increased and this may related to the existence of the sludge and the β- Fe brittle phases as shown in Figures (2e) and (4e) respectively. The obvious increase in hardness with the use of (0.6% PVA) had revealed a decrease in the wear rate compared to the original cast alloy. This may be due to the appearance of the toughening phase, i.e. Mg 2 Si as shown in Figure (2g) and the fragmented β and α-phases as shown in Figure (4g) and this coincides with the results when (1.2% PVA) was used, in which the CuAl 2 existence may be increased that causes the decrease in cooling rate which in turn decrease sharply the hardness to (60.148 BHN) but also the wear rate was sharply decreased to (8.672 *10 -9 cm 3 /cm) and this was coincides with the modified spherical to fragmented microstructure that might increase the internal toughness according to the action similar to that happen in ceramics and  Vol.10, No.10 Study the Effect of Polymeric Quenching 957 957 glasses i.e. the toughening by crack deflection. Further increase in the %wt of PVA to 1.4, will cause an obvious increase in the hardness to (91.835 BHN) and a slight increase in wear rate to (15.741* 10 -9 cm 3 /cm), and this may be due to the appearance of AlFeSi, the brittle phase as shown in Figures (2k) and (4k) respectively. 4. CONCLUSIONS 1. Quenching the Al-Si alloy with (0.6) wt% PVA had revealed a maximum hardness with a slight decrease in the wear rate. 2. The maximum decrease in the wear rate was achieved when (1.2) wt % PVA was used compared to the reference cast alloy. 3. The use of polymer quenchants affects positively well in the decrease of wear rate of the eutectic Al-Si alloy over the traditional quenching media. ACKNOWLEDGEMENTS The authors deeply would like to thank the Arab Science and Technology Foundation (ASTF) for the financial support grant of this research and their excess moral support during the period of the presented work. REFERENCES [1] Simillie M., "Casting and analysis of squeeze cast Aluminum Silicon eutectic alloy", PhD Thesis, Department of Mechanical Engineering of Canterbury, Christchurch, New Zealand, 2006. [2] Osōrio W.R., eung N. C, Spinell J.E., Cruz K.S., Goulart P.R. and Garcia A., "Thermally and Chemically Induced Microstructural Modifications Affecting The Electrochemical Corrosion Behavior of an Al-9wt%Si Casting Alloy", Department of Materials, Engineering, University of Campinas-UNICAMP, J. of New Materials for Electrochemical Systems, March 10, 2008, pp.205. [3] Jonathan A. Lee, "High Strength and Wear Resistant Aluminum Alloy For High Temperature Applications", NASA- Marshall Space Flight Center (MSFC), 2004. [4] Ma S., "A Methodology to Predict the Effects of Quench Rates on Mechanical Properties of Cast Aluminum Alloys", PhD Thesis, Materials Science and Engineering, Worcester Polytechnic Institute, 2006. [5] Totten G.E., Liscic B., Kobasko N.I., Han S.W., Sun Y.H., "Advances in polymer quenching technology", http://www.quenchtek.com/pdf_files/technical_paper/ Advances%20in%20Polymer%20Quenching%20Technology.pdf, pp.1-8. [6] Totten G.E., Canale L.C.F., "Polymer Quenchants", Encyclopedia of Materials: Science and Technology, Elsevier Ltd., 2005, pp.1-11. [7] Totten G.E., Bates C.E., Clinton N.A., "Handbook of Quenchants and Quenching Technology", ASM International, Materials Park, OH, 1993, p. 161-190. [8] Tensi H.M., Stich A., Totten G.E., "Fundamentals of Quenching", Metal Heat Treating, 1995, Mar./Apr., p. 20-28.  958 Kahtan K. Al-Khazraji, Waleed A. Hanna, Osama S. Muhammed Vol.10, No.10 [9] Maleki A., Niroumand B., Shafyei A., "Effects of squeeze casting parameters on density, macrostructure and hardness of LM13 alloy" Mat. Sci. Eng., vol. A428, 2006, pp. 135-140. [10] D.Apelian, and S.K. Chaudhury, "Heat Treatment of Aluminum Cast Components Recent Developments and Future Challenges", Metal Processing Institute, USA-April 19, 2005, p.1-17. [11] Zhang S., Wang F., "Comparison of friction and wear performances of brake material dry sliding against two aluminum matrix composites reinforced with different SiC particles", J. Mat. Proc. Tech., vol.182, (2007), pp. 122–127. [12] Lu L., Nogita K., McDonald S.D., Dahle A.K., "Eutectic solidification and its role in casting porosity formation", A publication of the minerals, metals and materials society, vol.56, no.11, (2004), pp. 52-58. [13] Taylor J.A., "The effect of Iron in Al-Si casting alloys", http://www.aomevents.com/conferences/afi/papers/Taylor.pdf [14] Ceschini L., et.al., "Microstructure, tensile and fatigue properties of the Al–10%Si– 2%Cu alloy with different Fe and Mn content cast under controlled conditions", J. Mat. Proc. Tech., vol.209, (2009), pp. 5669–5679. [15] Mohamed A.M.A., et.al., "Influence of additives on the microstructure and tensile properties of near-eutectic Al–10.8%Si cast alloy", Materials and Design, vol.30, (2009), pp.3943–3957. [16] Guthy H.V., "Evolution of the eutectic microstructure in chemically modified and unmodified aluminum silicon alloys" M.Sc. thesis, Worcester Polytechnic Institute, Worcester, 2002. |