Paper Menu >>

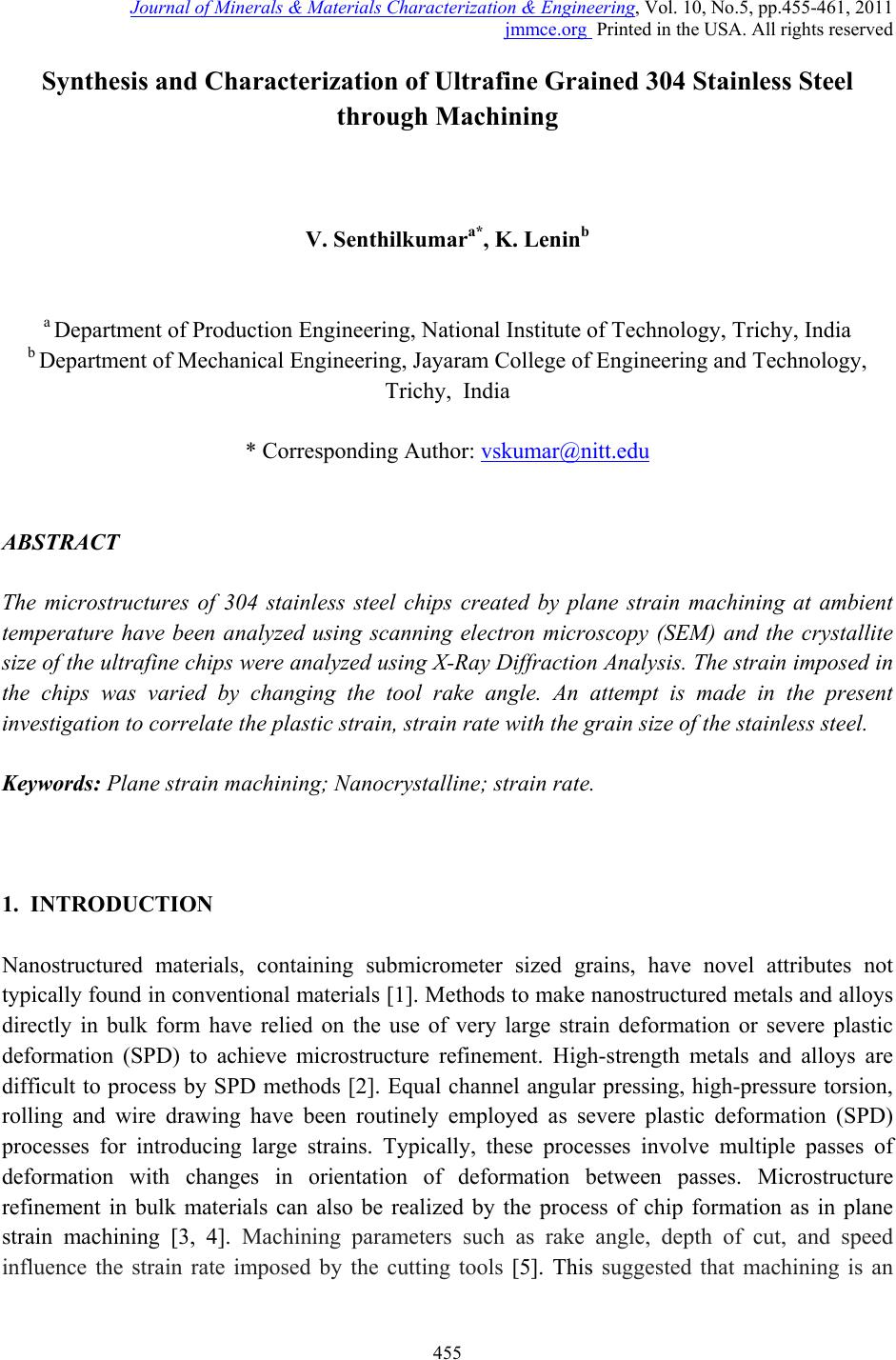

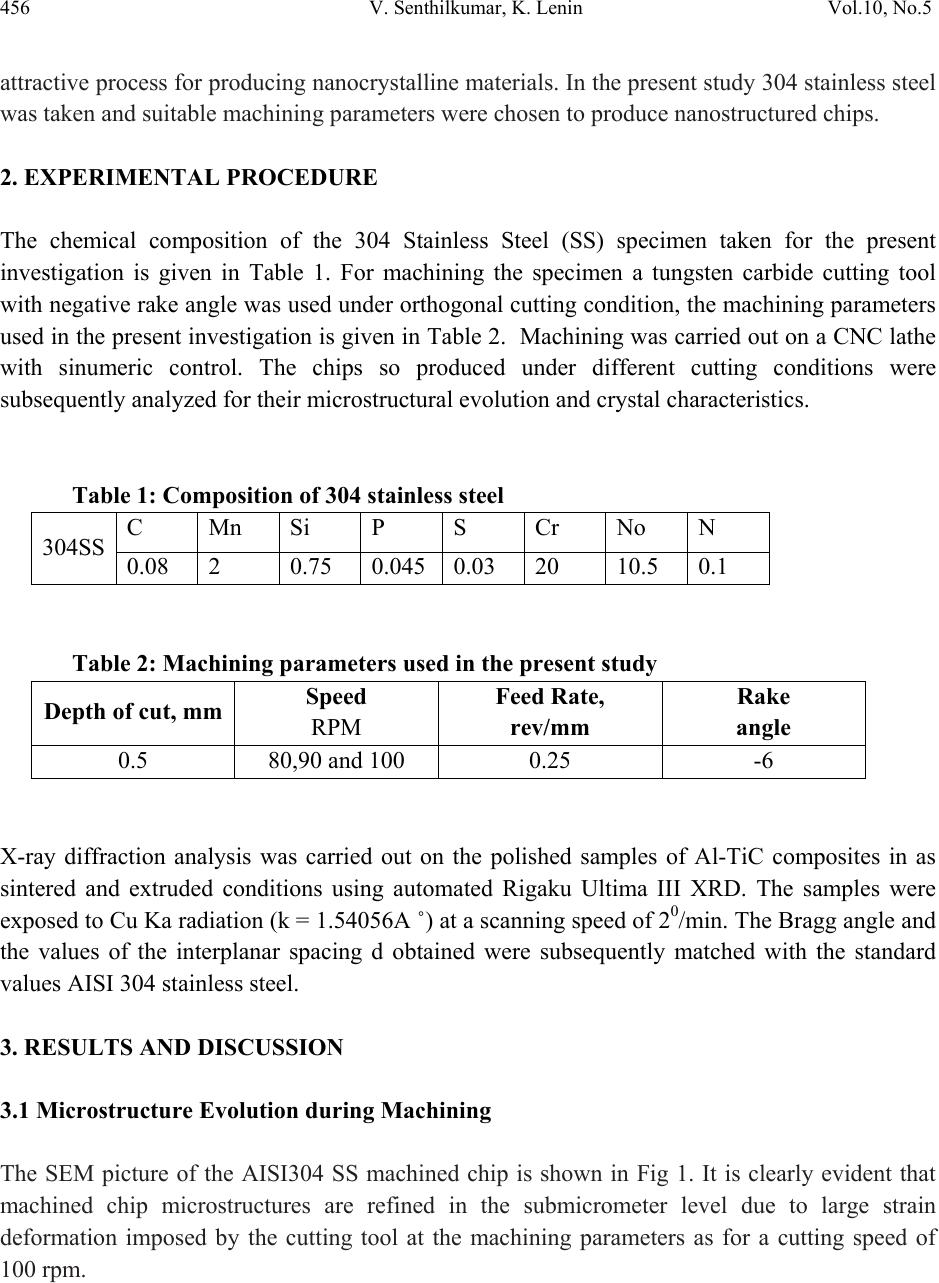

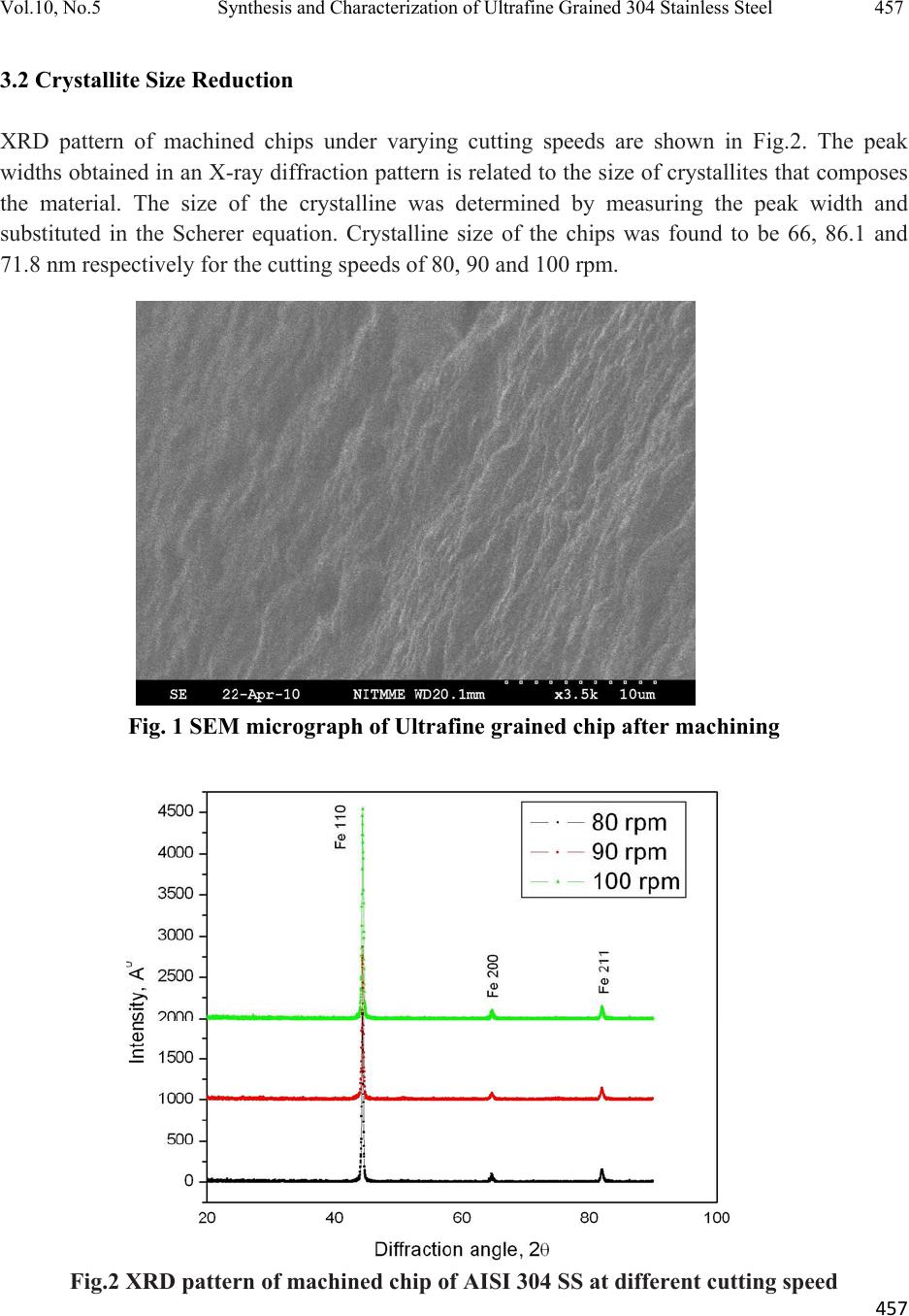

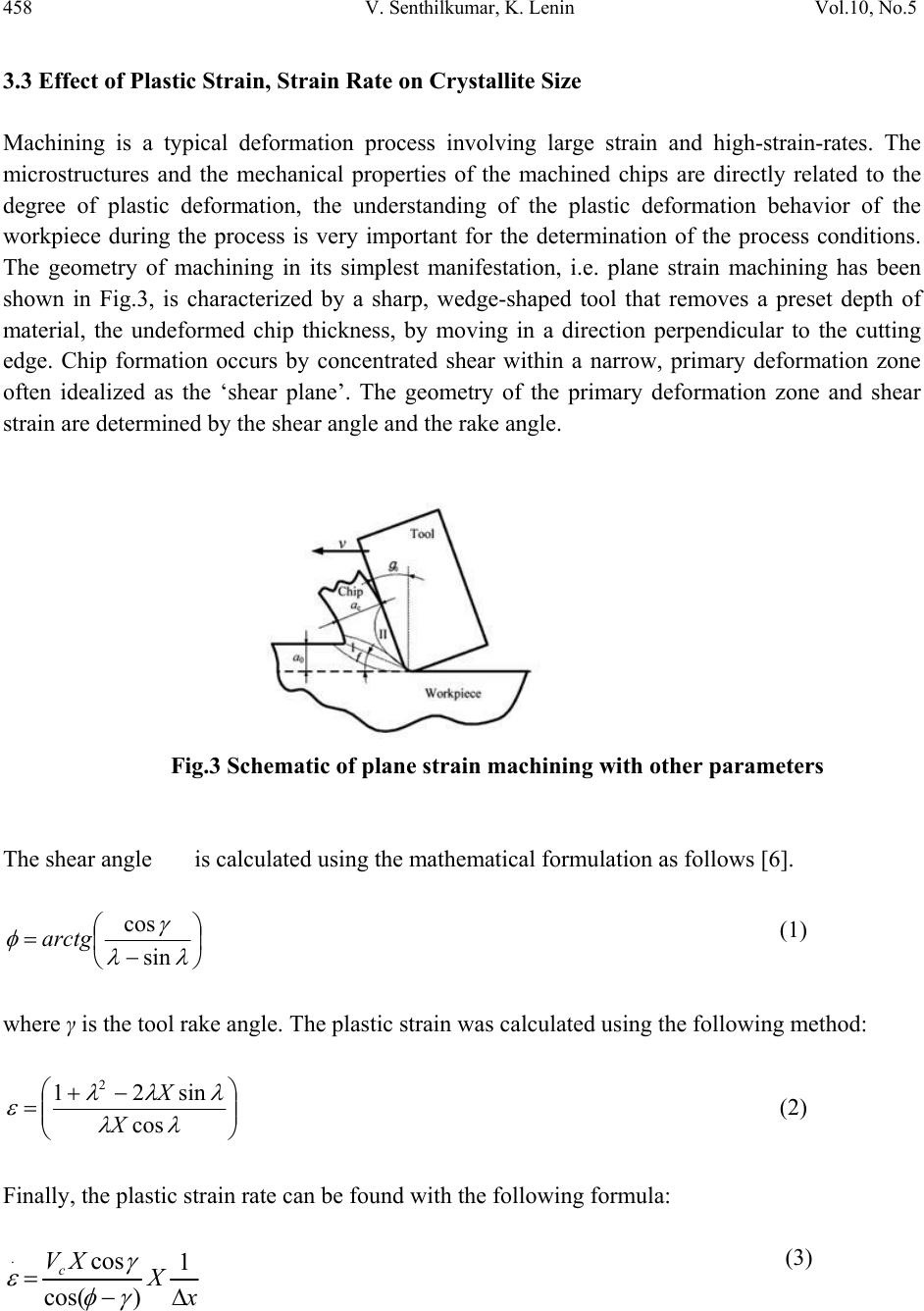

Journal Menu >>

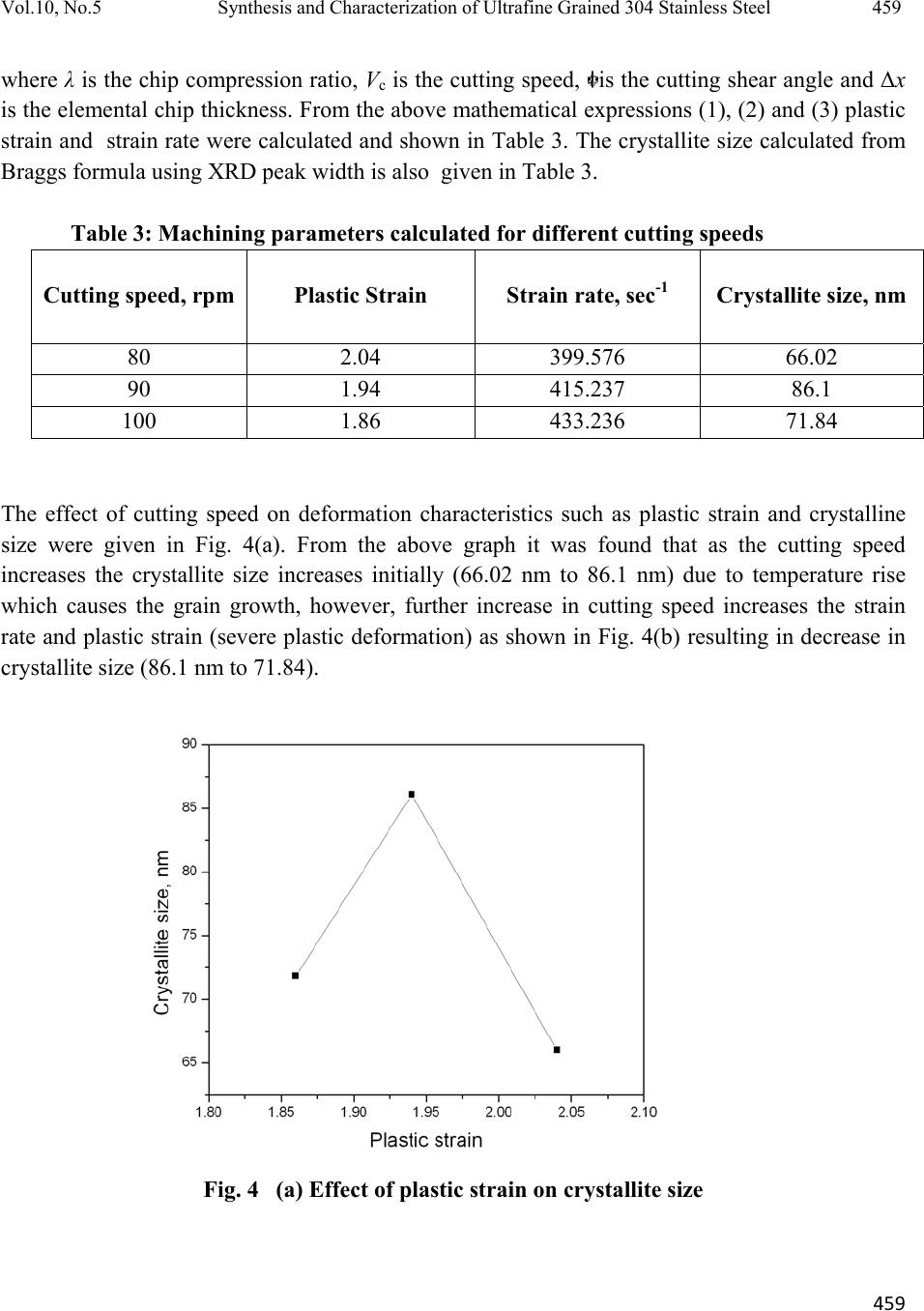

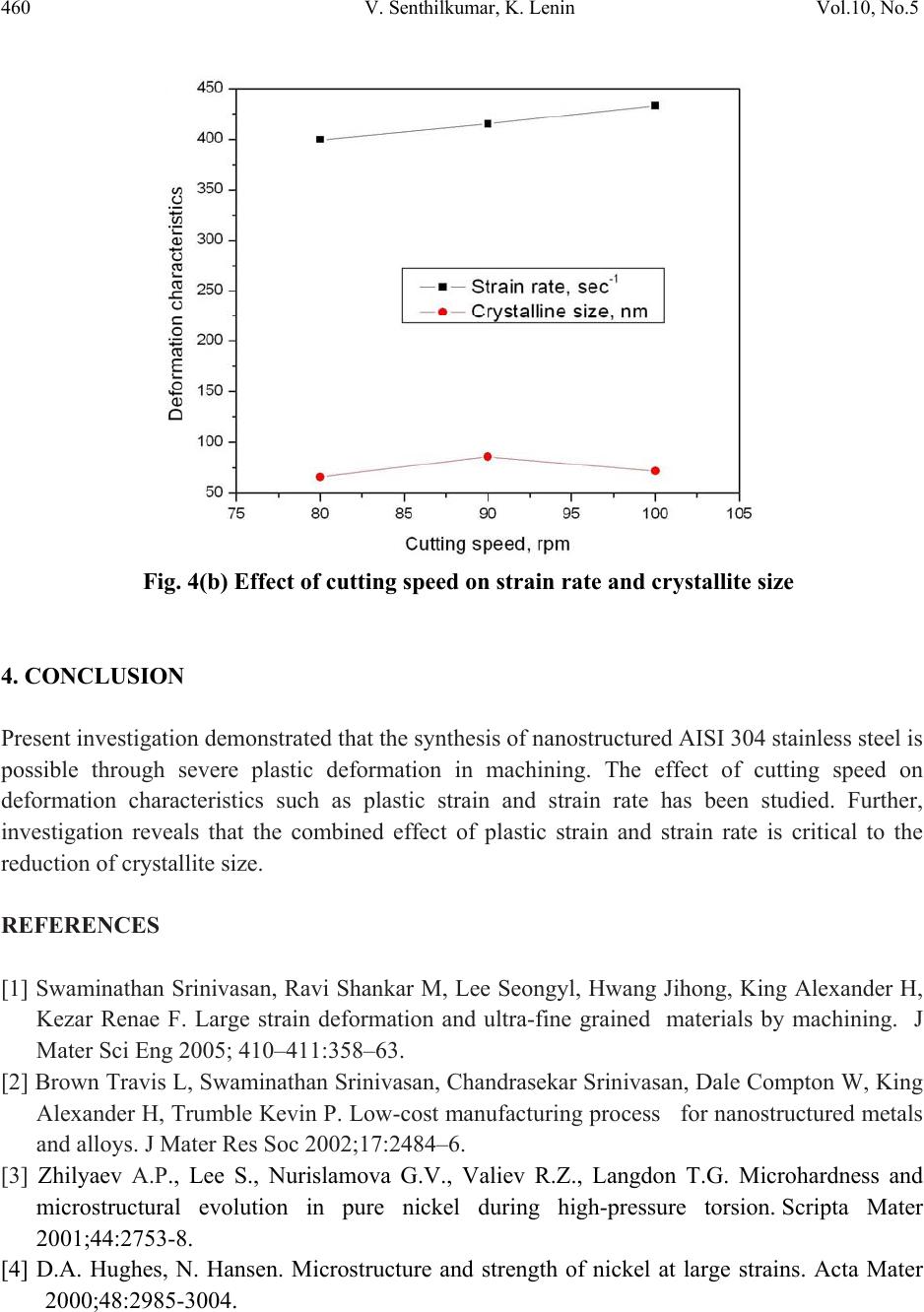

Journal of Minerals & Materials Characterization & Engineering, Vol. 10, No.5, pp.455-461, 2011 jmmce.org Printed in the USA. All rights reserved 455 Synthesis and Characterization of Ultrafine Grained 304 Stainless Steel through Machining V. Senthilkumara*, K. Leninb a Department of Production Engineering, National Institute of Technology, Trichy, India b Department of Mechanical Engineering, Jayaram College of Engineering and Technology, Trichy, India * Corresponding Author: vskumar@nitt.edu ABSTRACT The microstructures of 304 stainless steel chips created by plane strain machining at ambient temperature have been analyzed using scanning electron microscopy (SEM) and the crystallite size of the ultrafine chips were analyzed using X-Ray Diffraction Analysis. The strain imposed in the chips was varied by changing the tool rake angle. An attempt is made in the present investigation to correlate the plastic strain, strain rate with the grain size of the stainless steel. Keywords: Plane strain machining; Nanocrystalline; strain rate. 1. INTRODUCTION Nanostructured materials, containing submicrometer sized grains, have novel attributes not typically found in conventional materials [1]. Methods to make nanostructured metals and alloys directly in bulk form have relied on the use of very large strain deformation or severe plastic deformation (SPD) to achieve microstructure refinement. High-strength metals and alloys are difficult to process by SPD methods [2]. Equal channel angular pressing, high-pressure torsion, rolling and wire drawing have been routinely employed as severe plastic deformation (SPD) processes for introducing large strains. Typically, these processes involve multiple passes of deformation with changes in orientation of deformation between passes. Microstructure refinement in bulk materials can also be realized by the process of chip formation as in plane strain machining [3, 4]. Machining parameters such as rake angle, depth of cut, and speed influence the strain rate imposed by the cutting tools [5]. This suggested that machining is an  456 V. Senthilkumar, K. Lenin Vol.10, No.5 attractive process for producing nanocrystalline materials. In the present study 304 stainless steel was taken and suitable machining parameters were chosen to produce nanostructured chips. 2. EXPERIMENTAL PROCEDURE The chemical composition of the 304 Stainless Steel (SS) specimen taken for the present investigation is given in Table 1. For machining the specimen a tungsten carbide cutting tool with negative rake angle was used under orthogonal cutting condition, the machining parameters used in the present investigation is given in Table 2. Machining was carried out on a CNC lathe with sinumeric control. The chips so produced under different cutting conditions were subsequently analyzed for their microstructural evolution and crystal characteristics. Table 1: Composition of 304 stainless steel 304SS C Mn Si P S Cr No N 0.08 2 0.75 0.045 0.03 20 10.5 0.1 Table 2: Machining parameters used in the present study Depth of cut, mmSpeed RPM Feed Rate, rev/mm Rake angle 0.5 80,90 and 100 0.25 -6 X-ray diffraction analysis was carried out on the polished samples of Al-TiC composites in as sintered and extruded conditions using automated Rigaku Ultima III XRD. The samples were exposed to Cu Ka radiation (k = 1.54056A ˚) at a scanning speed of 20/min. The Bragg angle and the values of the interplanar spacing d obtained were subsequently matched with the standard values AISI 304 stainless steel. 3. RESULTS AND DISCUSSION 3.1 Microstructure Evolution during Machining The SEM picture of the AISI304 SS machined chip is shown in Fig 1. It is clearly evident that machined chip microstructures are refined in the submicrometer level due to large strain deformation imposed by the cutting tool at the machining parameters as for a cutting speed of 100 rpm.  Vol.10, No.5 Synthesis and Characterization of Ultrafine Grained 304 Stainless Steel 457 457 3.2 Crystallite Size Reduction XRD pattern of machined chips under varying cutting speeds are shown in Fig.2. The peak widths obtained in an X-ray diffraction pattern is related to the size of crystallites that composes the material. The size of the crystalline was determined by measuring the peak width and substituted in the Scherer equation. Crystalline size of the chips was found to be 66, 86.1 and 71.8 nm respectively for the cutting speeds of 80, 90 and 100 rpm. Fig. 1 SEM micrograph of Ultrafine grained chip after machining Fig.2 XRD pattern of machined chip of AISI 304 SS at different cutting speed  458 V. Senthilkumar, K. Lenin Vol.10, No.5 3.3 Effect of Plastic Strain, Strain Rate on Crystallite Size Machining is a typical deformation process involving large strain and high-strain-rates. The microstructures and the mechanical properties of the machined chips are directly related to the degree of plastic deformation, the understanding of the plastic deformation behavior of the workpiece during the process is very important for the determination of the process conditions. The geometry of machining in its simplest manifestation, i.e. plane strain machining has been shown in Fig.3, is characterized by a sharp, wedge-shaped tool that removes a preset depth of material, the undeformed chip thickness, by moving in a direction perpendicular to the cutting edge. Chip formation occurs by concentrated shear within a narrow, primary deformation zone often idealized as the ‘shear plane’. The geometry of the primary deformation zone and shear strain are determined by the shear angle and the rake angle. Fig.3 Schematic of plane strain machining with other parameters The shear angle is calculated using the mathematical formulation as follows [6]. sin cos arctg (1) where γ is the tool rake angle. The plastic strain was calculated using the following method: cos sin21 2 X X (2) Finally, the plastic strain rate can be found with the following formula: (3) x X XVc 1 )cos( cos .  Vol.10, No.5 Synthesis and Characterization of Ultrafine Grained 304 Stainless Steel 459 459 where λ is the chip compression ratio, Vc is the cutting speed, is the cutting shear angle and Δx is the elemental chip thickness. From the above mathematical expressions (1), (2) and (3) plastic strain and strain rate were calculated and shown in Table 3. The crystallite size calculated from Braggs formula using XRD peak width is also given in Table 3. Table 3: Machining parameters calculated for different cutting speeds Cutting speed, rpm Plastic Strain Strain rate, sec-1 Crystallite size, n m 80 2.04 399.576 66.02 90 1.94 415.237 86.1 100 1.86 433.236 71.84 The effect of cutting speed on deformation characteristics such as plastic strain and crystalline size were given in Fig. 4(a). From the above graph it was found that as the cutting speed increases the crystallite size increases initially (66.02 nm to 86.1 nm) due to temperature rise which causes the grain growth, however, further increase in cutting speed increases the strain rate and plastic strain (severe plastic deformation) as shown in Fig. 4(b) resulting in decrease in crystallite size (86.1 nm to 71.84). Fig. 4 (a) Effect of plastic strain on crystallite size  460 V. Senthilkumar, K. Lenin Vol.10, No.5 Fig. 4(b) Effect of cutting speed on strain rate and crystallite size 4. CONCLUSION Present investigation demonstrated that the synthesis of nanostructured AISI 304 stainless steel is possible through severe plastic deformation in machining. The effect of cutting speed on deformation characteristics such as plastic strain and strain rate has been studied. Further, investigation reveals that the combined effect of plastic strain and strain rate is critical to the reduction of crystallite size. REFERENCES [1] Swaminathan Srinivasan, Ravi Shankar M, Lee Seongyl, Hwang Jihong, King Alexander H, Kezar Renae F. Large strain deformation and ultra-fine grained materials by machining. J Mater Sci Eng 2005; 410–411:358–63. [2] Brown Travis L, Swaminathan Srinivasan, Chandrasekar Srinivasan, Dale Compton W, King Alexander H, Trumble Kevin P. Low-cost manufacturing process for nanostructured metals and alloys. J Mater Res Soc 2002;17:2484–6. [3] Zhilyaev A.P., Lee S., Nurislamova G.V., Valiev R.Z., Langdon T.G. Microhardness and microstructural evolution in pure nickel during high-pressure torsion. Scripta Mater 2001;44:2753-8. [4] D.A. Hughes, N. Hansen. Microstructure and strength of nickel at large strains. Acta Mater 2000;48:2985-3004.  Vol.10, No.5 Synthesis and Characterization of Ultrafine Grained 304 Stainless Steel 461 461 [5] Ravi Shankar M, Verma R, Rao BC, Chandrasekar S, Compton WD, King AH. Severe plastic deformation of difficult-to-deform materials at near-ambient temperatures. Metall Mater Trans 2007; 38A:1903. [6] Manufacturing Processes, ASM Hand Book, Volume 16, 1993. |