Paper Menu >>

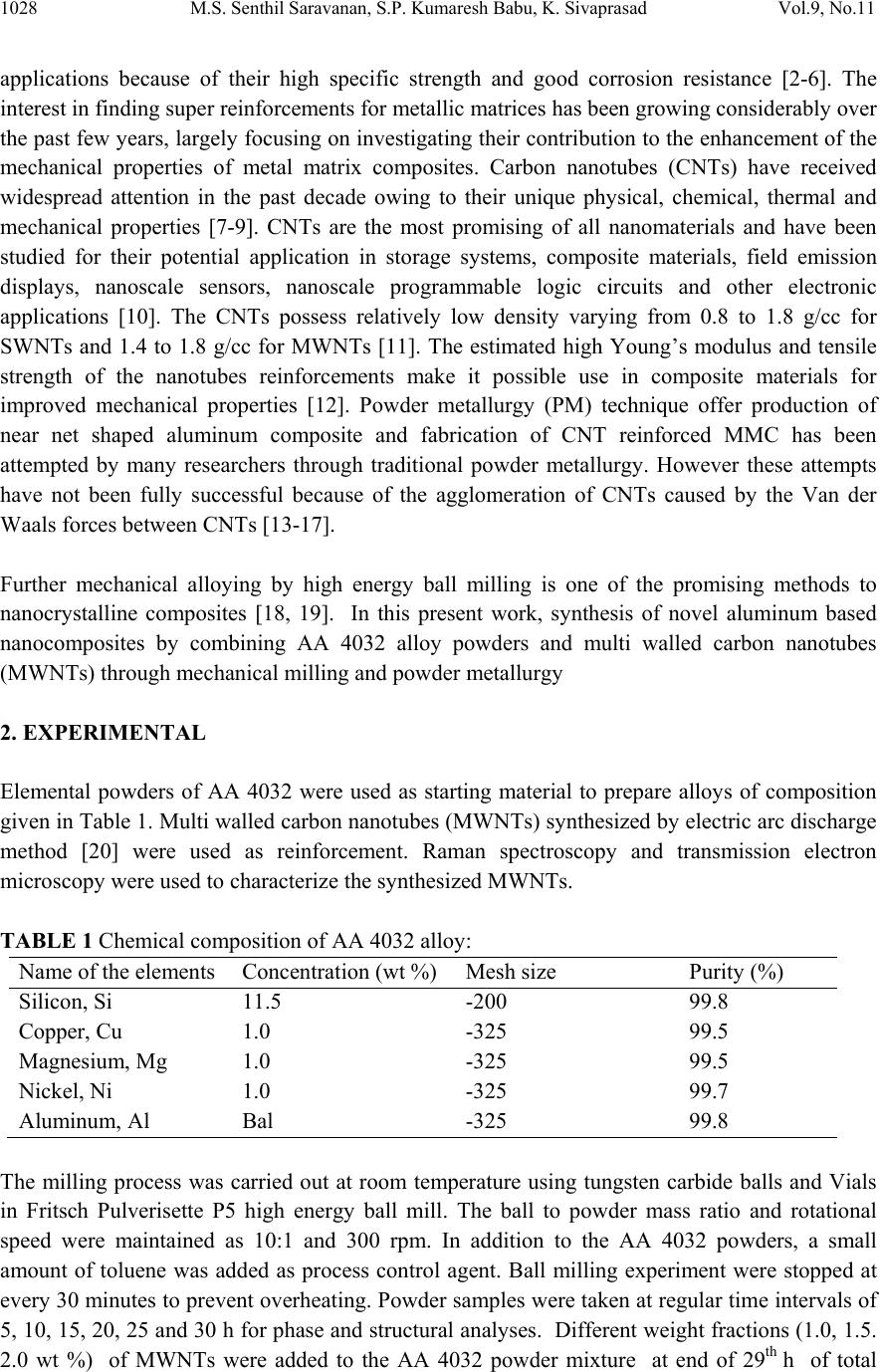

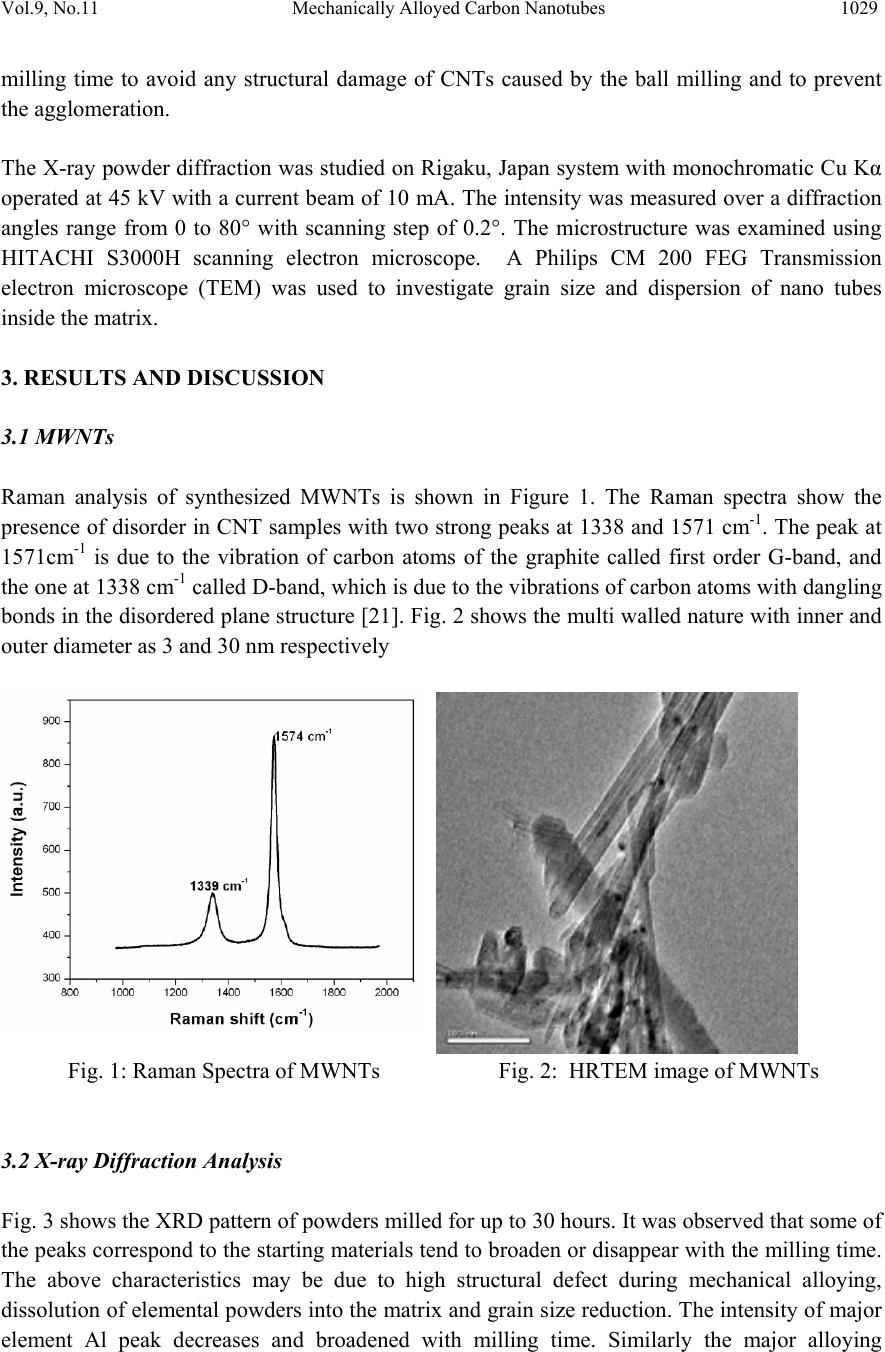

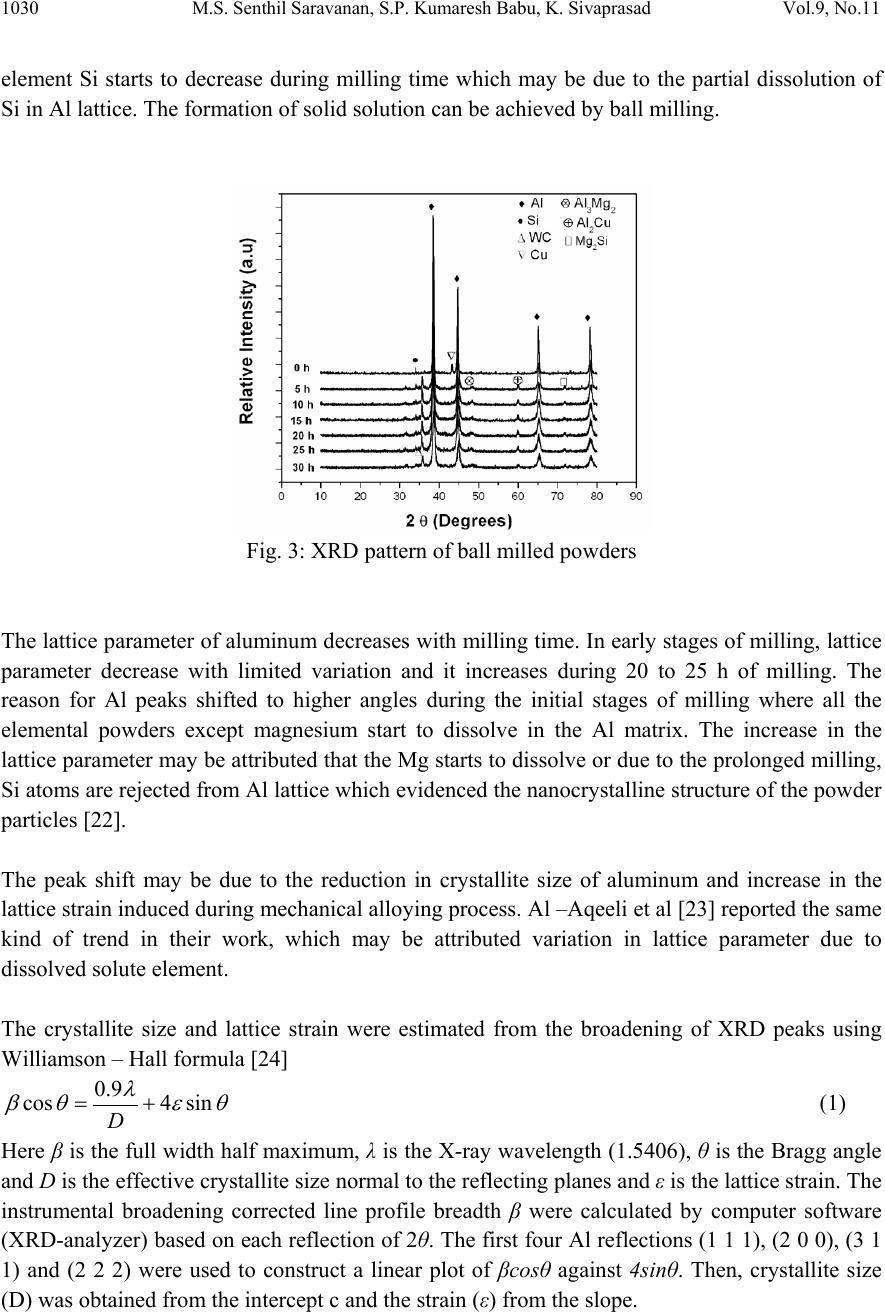

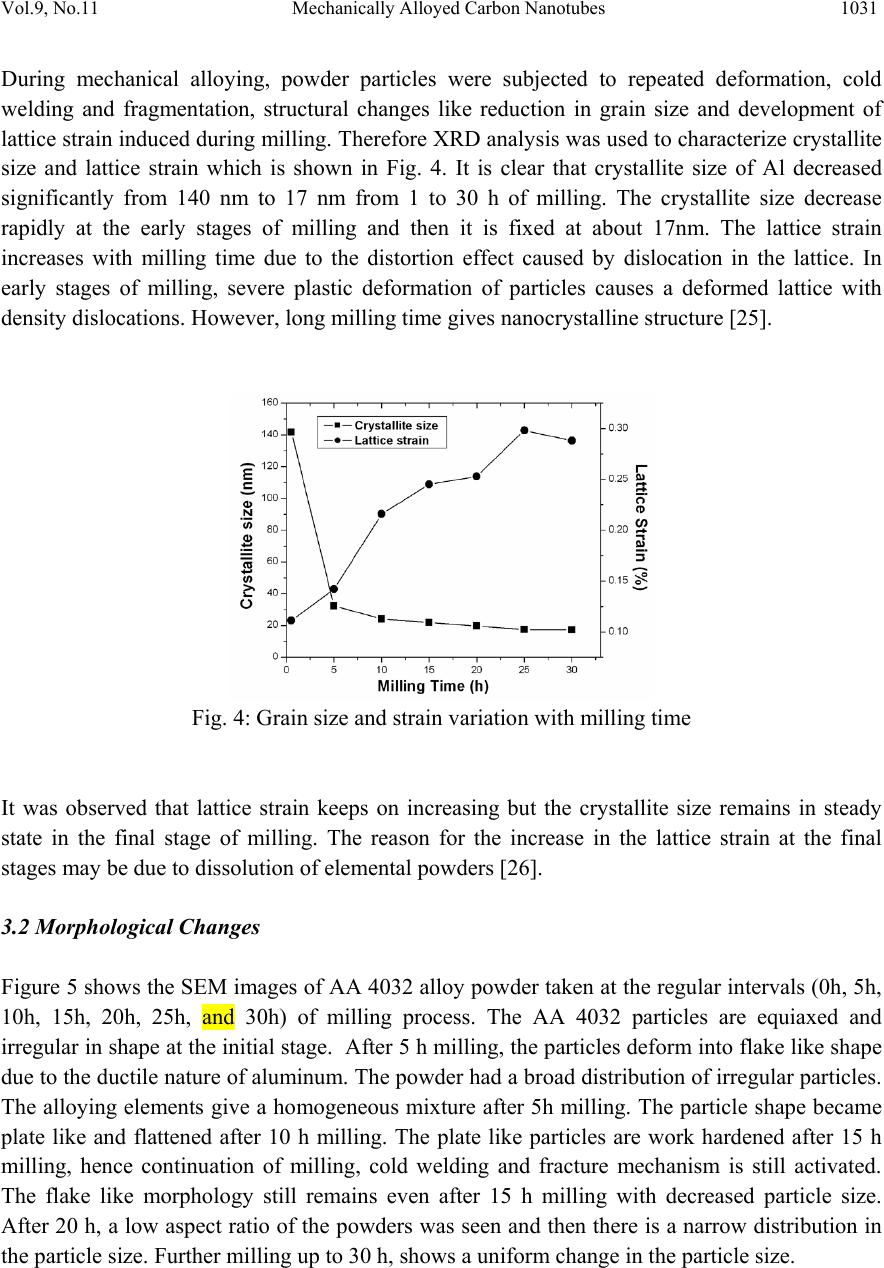

Journal Menu >>

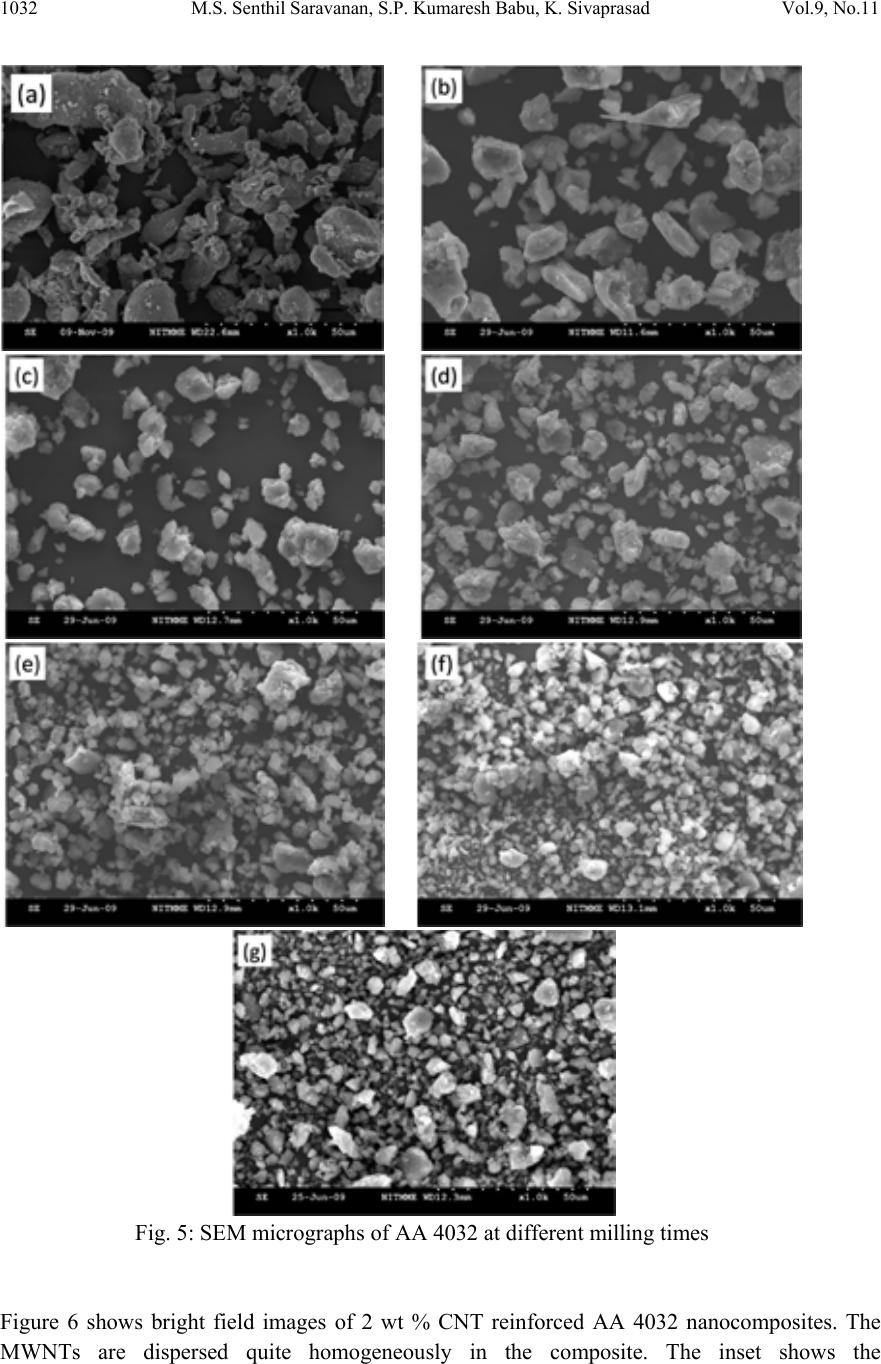

Journal of Minerals & Materials Characterization & Engineering, Vol. 9, No.11, pp.1027-1035, 2010 jmmce.org Printed in the USA. All rights reserved 1027 Mechanically Alloyed Carbon Nanotubes (CNT) Reinforced Nanocrystalline AA 4032: Synthesis and Characterization M.S. Senthil Saravanan, S.P. Kumaresh Babu*, K. Sivaprasad Advanced Materials processing laboratory, Department of Metallurgical and Materials Engineering, National Institute of Technology, Tiruchirappalli- 620 015, India *Corresponding author: babu@nitt.edu ABSTRACT Powder metallurgy has emerged as a promising technique to develop carbon nanotubes reinforced metal matrix composites. In this work, high energy ball mill was used to disperse multi-walled carbon nanotubes in AA 4032 alloy. The nanocrystalline nature of AA 4032 was obtained by milling the elemental powders for 30 hours. Different mass fractions of carbon nanotubes were added in the matrix at end of 29th hour. The phase evolution and changes in crystallite size and lattice strain were analyzed using X- ray diffractometer (XRD). SEM analysis reveals the morphological changes during the milling process. Transmission electron microscopy (TEM) studies reveal the presence of CNTs in the matrix and evidenced the uniform distribution of CNTs inside the matrix. Keywords: Multi walled carbon nanotubes, Nanocrystalline, AA 4032, XRD, SEM and TEM 1. INTRODUCTION In recent years considerable scientific research has been carried out to develop ultra high strength light weight, stiffer and wear-resistant engineering materials for extraordinary performance. Metal matrix composites (MMC) are regarded as excellent materials to obtain superior properties to those of the constituent phases and also to satisfy the above requirements [1]. Aluminum alloys have a great diversity of industrial application because of their low density and good workability but the use of these alloys is limited due to their relatively low yield stress. The interest in developing new aluminium based alloys has grown largely in the past years as part of the ongoing research for new advanced materials to meet the challenges and demands for high performance alloys. These alloys are used in automotive, aerospace and many other structural  1028 M.S. Senthil Saravanan, S.P. Kumaresh Babu, K. Sivaprasad Vol.9, No.11 applications because of their high specific strength and good corrosion resistance [2-6]. The interest in finding super reinforcements for metallic matrices has been growing considerably over the past few years, largely focusing on investigating their contribution to the enhancement of the mechanical properties of metal matrix composites. Carbon nanotubes (CNTs) have received widespread attention in the past decade owing to their unique physical, chemical, thermal and mechanical properties [7-9]. CNTs are the most promising of all nanomaterials and have been studied for their potential application in storage systems, composite materials, field emission displays, nanoscale sensors, nanoscale programmable logic circuits and other electronic applications [10]. The CNTs possess relatively low density varying from 0.8 to 1.8 g/cc for SWNTs and 1.4 to 1.8 g/cc for MWNTs [11]. The estimated high Young’s modulus and tensile strength of the nanotubes reinforcements make it possible use in composite materials for improved mechanical properties [12]. Powder metallurgy (PM) technique offer production of near net shaped aluminum composite and fabrication of CNT reinforced MMC has been attempted by many researchers through traditional powder metallurgy. However these attempts have not been fully successful because of the agglomeration of CNTs caused by the Van der Waals forces between CNTs [13-17]. Further mechanical alloying by high energy ball milling is one of the promising methods to nanocrystalline composites [18, 19]. In this present work, synthesis of novel aluminum based nanocomposites by combining AA 4032 alloy powders and multi walled carbon nanotubes (MWNTs) through mechanical milling and powder metallurgy 2. EXPERIMENTAL Elemental powders of AA 4032 were used as starting material to prepare alloys of composition given in Table 1. Multi walled carbon nanotubes (MWNTs) synthesized by electric arc discharge method [20] were used as reinforcement. Raman spectroscopy and transmission electron microscopy were used to characterize the synthesized MWNTs. TABLE 1 Chemical composition of AA 4032 alloy: Name of the elements Concentration (wt %) Mesh size Purity (%) Silicon, Si Copper, Cu Magnesium, Mg Nickel, Ni Aluminum, Al 11.5 1.0 1.0 1.0 Bal -200 -325 -325 -325 -325 99.8 99.5 99.5 99.7 99.8 The milling process was carried out at room temperature using tungsten carbide balls and Vials in Fritsch Pulverisette P5 high energy ball mill. The ball to powder mass ratio and rotational speed were maintained as 10:1 and 300 rpm. In addition to the AA 4032 powders, a small amount of toluene was added as process control agent. Ball milling experiment were stopped at every 30 minutes to prevent overheating. Powder samples were taken at regular time intervals of 5, 10, 15, 20, 25 and 30 h for phase and structural analyses. Different weight fractions (1.0, 1.5. 2.0 wt %) of MWNTs were added to the AA 4032 powder mixture at end of 29th h of total  Vol.9, No.11 Mechanically Alloyed Carbon Nanotubes 1029 milling time to avoid any structural damage of CNTs caused by the ball milling and to prevent the agglomeration. The X-ray powder diffraction was studied on Rigaku, Japan system with monochromatic Cu Kα operated at 45 kV with a current beam of 10 mA. The intensity was measured over a diffraction angles range from 0 to 80° with scanning step of 0.2°. The microstructure was examined using HITACHI S3000H scanning electron microscope. A Philips CM 200 FEG Transmission electron microscope (TEM) was used to investigate grain size and dispersion of nano tubes inside the matrix. 3. RESULTS AND DISCUSSION 3.1 MWNTs Raman analysis of synthesized MWNTs is shown in Figure 1. The Raman spectra show the presence of disorder in CNT samples with two strong peaks at 1338 and 1571 cm-1. The peak at 1571cm-1 is due to the vibration of carbon atoms of the graphite called first order G-band, and the one at 1338 cm-1 called D-band, which is due to the vibrations of carbon atoms with dangling bonds in the disordered plane structure [21]. Fig. 2 shows the multi walled nature with inner and outer diameter as 3 and 30 nm respectively Fig. 1: Raman Spectra of MWNTs Fig. 2: HRTEM image of MWNTs 3.2 X-ray Diffraction Analysis Fig. 3 shows the XRD pattern of powders milled for up to 30 hours. It was observed that some of the peaks correspond to the starting materials tend to broaden or disappear with the milling time. The above characteristics may be due to high structural defect during mechanical alloying, dissolution of elemental powders into the matrix and grain size reduction. The intensity of major element Al peak decreases and broadened with milling time. Similarly the major alloying  1030 M.S. Senthil Saravanan, S.P. Kumaresh Babu, K. Sivaprasad Vol.9, No.11 element Si starts to decrease during milling time which may be due to the partial dissolution of Si in Al lattice. The formation of solid solution can be achieved by ball milling. Fig. 3: XRD pattern of ball milled powders The lattice parameter of aluminum decreases with milling time. In early stages of milling, lattice parameter decrease with limited variation and it increases during 20 to 25 h of milling. The reason for Al peaks shifted to higher angles during the initial stages of milling where all the elemental powders except magnesium start to dissolve in the Al matrix. The increase in the lattice parameter may be attributed that the Mg starts to dissolve or due to the prolonged milling, Si atoms are rejected from Al lattice which evidenced the nanocrystalline structure of the powder particles [22]. The peak shift may be due to the reduction in crystallite size of aluminum and increase in the lattice strain induced during mechanical alloying process. Al –Aqeeli et al [23] reported the same kind of trend in their work, which may be attributed variation in lattice parameter due to dissolved solute element. The crystallite size and lattice strain were estimated from the broadening of XRD peaks using Williamson – Hall formula [24] θε λ θβ sin4 9.0 cos += D (1) Here β is the full width half maximum, λ is the X-ray wavelength (1.5406), θ is the Bragg angle and D is the effective crystallite size normal to the reflecting planes and ε is the lattice strain. The instrumental broadening corrected line profile breadth β were calculated by computer software (XRD-analyzer) based on each reflection of 2θ. The first four Al reflections (1 1 1), (2 0 0), (3 1 1) and (2 2 2) were used to construct a linear plot of βcosθ against 4sinθ. Then, crystallite size (D) was obtained from the intercept c and the strain (ε) from the slope.  Vol.9, No.11 Mechanically Alloyed Carbon Nanotubes 1031 During mechanical alloying, powder particles were subjected to repeated deformation, cold welding and fragmentation, structural changes like reduction in grain size and development of lattice strain induced during milling. Therefore XRD analysis was used to characterize crystallite size and lattice strain which is shown in Fig. 4. It is clear that crystallite size of Al decreased significantly from 140 nm to 17 nm from 1 to 30 h of milling. The crystallite size decrease rapidly at the early stages of milling and then it is fixed at about 17nm. The lattice strain increases with milling time due to the distortion effect caused by dislocation in the lattice. In early stages of milling, severe plastic deformation of particles causes a deformed lattice with density dislocations. However, long milling time gives nanocrystalline structure [25]. Fig. 4: Grain size and strain variation with milling time It was observed that lattice strain keeps on increasing but the crystallite size remains in steady state in the final stage of milling. The reason for the increase in the lattice strain at the final stages may be due to dissolution of elemental powders [26]. 3.2 Morphological Changes Figure 5 shows the SEM images of AA 4032 alloy powder taken at the regular intervals (0h, 5h, 10h, 15h, 20h, 25h, and 30h) of milling process. The AA 4032 particles are equiaxed and irregular in shape at the initial stage. After 5 h milling, the particles deform into flake like shape due to the ductile nature of aluminum. The powder had a broad distribution of irregular particles. The alloying elements give a homogeneous mixture after 5h milling. The particle shape became plate like and flattened after 10 h milling. The plate like particles are work hardened after 15 h milling, hence continuation of milling, cold welding and fracture mechanism is still activated. The flake like morphology still remains even after 15 h milling with decreased particle size. After 20 h, a low aspect ratio of the powders was seen and then there is a narrow distribution in the particle size. Further milling up to 30 h, shows a uniform change in the particle size.  1032 M.S. Senthil Saravanan, S.P. Kumaresh Babu, K. Sivaprasad Vol.9, No.11 Fig. 5: SEM micrographs of AA 4032 at different milling times Figure 6 shows bright field images of 2 wt % CNT reinforced AA 4032 nanocomposites. The MWNTs are dispersed quite homogeneously in the composite. The inset shows the  Vol.9, No.11 Mechanically Alloyed Carbon Nanotubes 1033 corresponding selected area diffraction (SAED) pattern of AA 4032 reinforced with 2 wt % MWNTs. The obtained ring pattern in SAED evidenced the formation of nanostructured composite phase. It was found that no additional spots were formed, which confirms absence of other phases. In conventional Carbon/aluminium composites, Al4C3 was grown on the prismatic planes of carbon fiber. In our work, no carbides were detected at the Al/CNT interfaces, which show a better chemical stability of MWNT. In the present work, MWNTs were added to the matrix at the end of 29th h of milling which may be the reason for the homogeneous dispersion. When CNTs were added at the early hrs, agglomeration and clustering occur due to lengthy milling hours. Another noticeable observation in TEM picture was less structural damage of CNTs. The uniform distribution of MWNTs in the composite effectively inhibits matrix deformation and produces strengthening effect [27]. Fig. 6: TEM micrograph of CNT reinforced AA 4032 alloy powders; inset shows the SAED pattern 4. CONCLUSION Multi-walled carbon nanotubes reinforced AA4032 alloy nanocomposites have been successfully synthesized by high energy ball milling. TEM analysis shows that MWNTs posses high mechanical and chemical stability. MWNTs were dispersed homogeneously in the AA4032 matrix composites. Effect of milling time on grain size and lattice strain was clearly studied and there was decrease in grain size and increase in strain with increase in milling time. REFERENCES [1] H.T.Son, H.T., Kim, T.S., Suryanarayana, C and Chun, B.S., 2003, “Homogeneous dispersion of graphite in a 6061 aluminum alloy by ball milling”, Material Science and Engineering A, Vol. 348, pp. 163-169. [2] Yoshihito Kawamura, Hideo Mano and Akihisa Inoue, 2001, “Nanocrystalline aluminum bulk alloys with a high strength of 1420 MPa produced by the consolidation of amorphous powders”, Scripta Materialia, Vol. 44, pp. 1599-1604.  1034 M.S. Senthil Saravanan, S.P. Kumaresh Babu, K. Sivaprasad Vol.9, No.11 [3] Hu Lianxi, Liu Zuyan and Wang Erde, 2002, “Microstructure and mechanical properties of 2024 aluminum alloy consolidated from rapidly solidified alloy powders”, Materials Science and Engineering A, Vol. 323, pp.213-217. [4] So,H., Li, W.C., and Hsieh, H.K., 2001, “Assessment of the powder extrusion of silicon- aluminium alloy”, Journal of Materials Processing Technology, Vol. 114, pp. 18-21. [5] Heard, D.W., Donaldson, I.W and Bishop, D.P., 2009, “Metallurgical assessment of a hypereutectic aluminum–silicon P/M alloy”, Journal of Materials Processing Technology, Vol. 209, pp. 5902-5911. [6] Hasegaw, T., Yasuno, T., Nagai, T and Takahashi, T., 1998, “Origin of superplastic elongation in aluminum alloys produced by mechanical milling”, Acta Materialia Vol. 46, pp. 6001-6007. [7] Ruof, R.S and Lorents, D.C., 1995, “Mechanical and thermal-properties of carbon nanotubes”, Carbon, Vol.33, pp. 925-930. [8] Iijima,S., 1991, “Helical Microtubules of graphitic carbon”, Nature, Vol. 354, pp.56-58. [9] Iijima, S and Ichihasi, T., 1993, “Single-shell carbon nanotubes of 1-nm diameter”, Nature, Vol. 363 (1993) pp.603-605. [10] Valentin N.Popov, 2004, “Carbon nanotubes: Properties and applications”, Material Science and Engineering R, Vol. 43, pp. 61-102. [11] Yu M. F., Files B. S., Arepalli S., and Ruoff, R. S., 2000, “Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties”, Physical Review Letters, Vol. 84, pp. 5552-5555. [12] Overney, G., Zhong, W. and Dománek, D., 1993, “Structural Rigidity and Low Frequency Vibrational Modes of Long Carbon Tubules”, Zeitschrift für Physik D, Vol. 27, pp.93-96. [13] Cha, S.I., Kim, K.T., Arshad, S.N., Mo, C.B and Hong, S.H., 2005, “Extraordinary Strengthening Effect of Carbon Nanotubes in Metal-Matrix Nanocomposites Processed by Molecular-Level Mixing”, Advance Materials, Vol.17, pp. 1377-1381. [14] George, R., Kashyap, K.T., Rahul, R., and Yamdagni, S., 2005, “Strengthening in Aluminium/CNT Composites”, Scripta Materialia, Vol. 53, pp. 1159-1163. [15] Deng, C.F., Zhang, X.X., Wang, D.Z., Lin, Q and Li, A., 2007, “Preparation and characterization of carbon nanotubes / aluminium matrix composites”, Materials Letters, Vol. 61, pp.1725-1728. [16] Deng, C.F., Zhang, X.X., Wang, D.Z and Ma, Y.X; 2007, “Calorimetric study of carbon nanotubes and aluminum”, Materials Letters, Vol. 61, pp. 3221-3221. [17] Deng, C.F., Zhang, X.X., Wang, D.Z and Ma, Y.X, 2008, “Thermal expansion behaviors of aluminium composites reinforced with carbon nanotubes”, Materials Letters, Vol. 62, pp. 2301-2303. [18] Suryanarayana, C., Ivanaov, E and Boldyrev, V.V., 2001, “The science and technology of mechanical alloying”, Material Science and Engineering A, Vol. 304, pp. 151-158. [19] Zhang, D.L., 2004, “Processing of advanced materials using high energy ball milling”, Progress in Materials Science, Vol.49, pp. 537-560. [20] Senthil Saravanan, MS., Kumaresh Babu, SP., Sivaprasad, K., Jagannatham, M., 2010, “Techno-economics of carbon nanotubes produced by open air arc discharge method”, Intl. J of Engineering, Science and Technology, Vol. 2, No. 5, pp. 100-108.  Vol.9, No.11 Mechanically Alloyed Carbon Nanotubes 1035 [21] Dingsheng Yuan., Yinglian Liu., Yong Xia and Liqiang Chen., 2008, “Preparation and characterization of Z-shaped carbon nanotubes via decomposing magnesium acetate”, Materials Chemistry and Physics, Vol.112, pp.27-30. [22] Tavoosi,M., Enayani, M.H and Karimzadeh, F., 2008, “Softening behavior of nanostructured Al-14wt % Zn alloy during mechanical alloying”, J.Alloys and compounds, Vol. 464, pp 107-110. [23] Al-Aqeeli, N., Mendoza saurez, G., Suryanarayana, C and Drew, R.A.L., 2008, “Development of new Al-based nanocomposites by mechanical milling”, Material Science and Engineering A, Vol. 480, pp. 392-396. [24] Williamson, G.K and Hall, W.H., 1953, “X-ray line broadening from filed aluminum and wolfram”, Acta Metallurgica, Vol. 1, pp. 22-31. [25] Razavi Tousi, S.S., Yazdani Rad, R., Salahi, E., Mobasherpour, I and Razavi, M., 2009, “Production of Al–20 wt.% Al2O3 composite powder using high energy milling”, Powder Technology, Vol. 192, pp. 346–351. [26] Parvin, N., Assadifard, R., Safarzadeh, P., Sheibani, S and Marashi, P., 2008, “Preparation and mechanical properties of SiC reinforced Al6061 composite by mechanical alloying”, Material Science and Engineering A, Vol. 492, pp. 134-140. [27] Perez-Bustamante, R., Guel, I.E., Flores, W.A., Yoshida, M.M., Ferreira, P.J., and Sanchez, R.M., 2008, “Novel Al-Matrix nanocomposies reinforced with multi walled carbon nanotubes”, J.Alloys and Compounds, Vol.450, pp.323-326. |