Journal of Minerals & Materials Characterization & Engineering, Vol. 8, No.2, pp 149-159, 2009 jmmce.org Printed in the USA. All rights reserved Recovery of Ilmenite and Other Heavy Minerals from Teri Sands (Red Sands) of Tamil Nadu, India N. Babu1, N. Vasumathi2 and R. Bhima Rao2* 1National Institute for Interdisciplinary Science and Technology (CSIR), Trivandrum – 695019, India Email: geobns@gmail.com and 2Institute of Minerals and Materials Technology (CSIR) Bhubaneswar 751 013, India *Email: bhimarao@gmail.com ABSTRACT The red sand which is known as Teri sand in Tamil Nadu consists of 5.5% Total Heavy Minerals (THM) out of which 3.7% is ilmenite. The other min e r a l s, zircon, sillimanite and garnet are in the order of abundance identified. On processing this feed to recover ilmenite by using spirals followed by dry high intensity magnetic separator and high tension separator, the ilmenite concentrate obtained contains 99.1% ilmenite with 3.5% yield and 94% recovery. The other heavy minerals, including zircon (53.3%) and sillimanite (31.7%), could be further processed for recovery of individual mineral of zircon and sillimanite by judicious combination of gravity and flotation processes. KEY WORDS: Teri sand, ilmenite, zircon, sillimanite, spiral concentration, high tension separation, tabling, total heavy minerals. 1. INTRODUCTION Inland red Teri sands of southeast India have formed from weathering in situ of coastal dune sands. The term Teri, which means red, is derived from Tamil, a regional language in south India. Teri sands are very lean placer deposits for heavy mineral concentration. The beach and in land placer deposits exhibit a considerable variation in mineralogy and chemical composition 149  150 N. Babu, N. Vasumathi and R. Bhima Rao Vol.8, No.2 depending on the location. The flowsheets for their beneficiation are therefore variable in detail. The literature reveals[1-10] that lot of research work carried out on Teri sands but most of the publications restricted to resource evaluation, geology, geochemistry, mineralogy etc. The general practice to recover Total Heavy Minerals from such a lean beach sand deposit containing 2-5% THMs is first concentrated to 20 –30% THMs on cone concentrators. This product is then fed to spirals, which gave a concentrate of more than 80% THMs. In India the highest concentration of Total Heavy Minerals (THM) in beach sand is found in the Chavara deposit (70 –80% THM with 60% TiO2) and Manavalakurichi (60 –80% THM with 50% TiO2). Pre-concentration by wet methods is generally not required for these deposits. With the Orissa deposits (~ 20% THM with ~ 48% TiO2) and for most other deposits throughout the world, bulk concentration of THMs are needed before actual separation of individual minerals is carried out. In general, the red sands of Orissa and Andhrapradesh coasts contain on an average 4% to 10% heavy minerals. Ilmenite constitutes around 60 -75% among heavies. Garnet is almost negligible amount. Sillimanite is about 5%. Zircon, monazite and rutile constitute around 10%. The rest is pyriboles (hypersthene and augite are common minerals; staurolite and kyanite are less common minerals). The beach placers and inland 'Teri' sands of Tamil Nadu containing, principally, ilmenite, rutile, leucoxene, zircon, monazite, garnet, sillimanite, amphibole, pyroxene and magnetite are classified into three distinct mineralogical provinces based on the predominance of: (i) ilmenite, (ii) garnet, and (iii) mixed ilmenite - garnet. Mineral assemblages in 'Teri' sands directly reflect composition of the bed rocks. The average grade of Teri sands of Tamil Nadu, are about 10% with a total heavy mineral reserves of 96 MT and an ilmenite reserves of 77 MT (grade of ilmenite 6% in raw soil). In spite the inland deposits have a complex mineral assemblage compared to the beach washings and the heavy minerals are finer in size moreover the major gangue mineral quartz is of wider size range and the content of fine quartz is relatively higher in the inland deposits, it is essential to process such inland deposits as over the years, the quality of beach washings has come down drastically. The limited availability of these seasonal accruals has forced the future beach sand mineral industry to depend on the inland beach deposits as the primary source of feed material. In view of this, an attempt is made to recover valuable minerals such as ilmenite, zircon and sillimanite from Teri sands of Tamil Nadu. 2. MATERIALS AND METHODS Representative raw placer samples were collected from the Teri sands of Tamil Nadu for beneficiation studies. Samples were processed in order to estimate and separate THM from the bulk sand of red sand. Petro-mineralogical studies were carried out using a Leica petrological optical microscope, to identify the components of the total heavy mineral content. Powdered feed, magnetic and non-magnetic sink were subjected to X-ray diffraction (XRD) using  Vol.8, No.2 Recovery of Ilmenite and Other Heavy Minerals 151 PANalytical (X’pert) powder diffractometer, (scan speed - 1.2°/min from 6° to 40°, by Mo Kα radiation) to identify the mineral phases in the corresponding fractions. Magnetic and non- magnetic fractions of heavy minerals were observed using scanning electron microscope (SEM) for morphological studies. The grains were mounted on a SEM brass stub. The mounted quartz grains were coated with gold in a vacuum evaporator while the sample was being slowly rotated. Usually 15-20 grains were studied in detail and typical micrographs were taken by using JEOL JSM-5800 scanning electron microscope. Initially the samples were subjected to spiral separation to recover heavy minerals. Concentrate and tailings were collected from spiral separation and the weight percentages were recorded. Further, the samples were subjected to magnetic separation using Permroll (14,000 Gauss) to separate magnetic and non-magnetic fractions and the representative weight percentages were recorded. The magnetic fraction was subjected to Carpco high tension separator (laboratory model, drum type) to recover conducting minerals (ilmenite and rutile). The non magnetic fraction was subjected to Denver gravity table for recovery of heavy minerals such as zircon, sillimanite etc., The above samples were processed for the estimation of total heavy mineral (THM) content using Bromoform (CHBr3; specific gravity 2.89), as a medium for separation of heavier fractions from the lighter. Methylene iodide (di-ido methane, 3.3 sp.gr.,) heavy medium was used to determine very heavy minerals and light heavy minerals from the total heavy minerals obtained by using bromoform heavy medium. 3. RESULTS AND DISCUSSION 3.1 Physical Properties of Teri Sand Physical properties of the Teri sand of Tamil Nadu area are summarized in Table 1. Bulk density of the Teri sands are 1.45 g/cc and the true density is 2.89 g/cc. Angle of repose for the same is 30.3 degree. Passing size of the d80 particle size is 360 μm. The total heavy minerals present in the as received samples are 5.5% by weight, in which the very heavy minerals (>3.3 sp. gr.,) are 4.8% by weight and the light heavy minerals (<3.3 sp.gr.,) are 0.7% by weight. The magnetic minerals (TMM) are 3.9% by weight. The light mineral (<2.89 sp. gr.,) is the quartz and has 94.5% by weight in the feed. Particle size distribution of the feed (Teri sand sample) as well as total heavy minerals from Teri sand of Tamil Nadu area, (Table 2 and Figure 1) shows that most of the feed (as received) samples has particle size distribution between -500 +100 μm size range. The size of the total heavy minerals falls in the group of finer fractions predominately -300 +50 μm size range.  152 N. Babu, N. Vasumathi and R. Bhima Rao Vol.8, No.2 Table. 1. Physical properties of Teri sand sample (as received sample). Bulk density, g/cc 1.45 True density, g/cc 2.89 Porosity, % 49.8 Angle of repose, degree 30.3 d80 passing size , µm 360 Moisture content, % 0.5 -50 µm , Wt % 4.7 Total Heavy Minerals (THM), Wt., % 5.5 Total Magnetic Minerals (TMM), Wt., % 3.9 Very Heavy Minerals (VHM), Wt., % 4.8 Light Heavy Minerals (LHM), Wt., % 0.7 Quartz, Wt., % 94.5 Table. 2. Size analysis of teri sand sample and total heavy minerals (as received sample) Size in µm As received sample Total heavy minerals in as received sample Wt., % Cum., % passingWt., %Cum., % passing -1000 + 600 1.7 100.0 0.3 100.0 -600 + 420 7.7 98.3 0.5 99.7 -420 + 300 26.1 90.6 2.2 99.2 -300 + 210 22.9 64.5 17.8 97.0 -210 + 150 11.6 41.6 22.1 79.2 -150 + 100 22.0 30.0 27.4 57.1 -100 + 50 3.3 8.0 20.5 29.7 -50 4.7 4.7 9.2 9.2 Total 100.0 100.0 d80 passing size , µm 360 210 3.2 Mineralogy Mineralogy of the Teri sands determined by XRD, petrological optical microscope and scanning electron microscope are shown in Figs. 2 - 5. 3.3 Microscopic and SEM Studies Teri sands of Tamil Nadu have been subjected to microscopic studies before and after the beneficiation studies. The feed samples are shown predominantly of quartz minerals followed by ilmenite, sillimanite and zircon. Whereas ilmenite, zircon, sillimanite and garnet were the order identified after the beneficiation techniques (Table 3) and (Figs. 3 - 5). The ilmenite occurs  Vol.8, No.2 Recovery of Ilmenite and Other Heavy Minerals 153 mostly as rounded to semi-rounded grains (Fig. 3). Well developed elongated zircon with out- growth nature was observed (Fig. 4) in the red sand of Tamil Nadu. The out-growth nature might have formed during re-crystallization of the sediments. The garnet grains (Fig. 4) were found to be angular to subangular with occasional subrounded grains and are characterized by conchoidal fracture. Table. 3. Mineralogical composition of teri sand sample (as received sample) and total heavy mineral distribution in sink. Minerals Feed, % Sink, % Ilmenite 3.7 67.5 Zircon 0.9 15.6 Sillimanite 0.7 12.3 Others Garnet Rutile Monazite Pyribols 0.2 4.6 Quartz 94.5 0 Total 100.0 100.0  154 N. Babu, N. Vasumathi and R. Bhima Rao Vol.8, No.2  Vol.8, No.2 Recovery of Ilmenite and Other Heavy Minerals 155 SEM studies reveals that the ilmenite marked by numerous surface pits, etch marks, irregular blocks and solution pits (Fig. 5) were created by mechanical abrasion and chemical processes. The grain may belong to paleo-sediments and might have been brought to the beach environment due to reworking of bottom sediments. Very often, zircon is present as well developed crystals (Fig. 5). Sillimanite shows concodial blockage due to mechanical weathering during transportation. Well rounded monazite with pitted nature (Figs. 4 & 5) was observed. The grain might have undergone surface chemical activity and reworking of sediments under favorable condition. 3.4 Recovery of Ilmenite and Other Heavy Minerals Results of spiral separation on recovery of total heavy minerals (THM) such as ilmenite, zircon, sillimanite etc., from feed sample are given in Table 4. The data indicate that the concentrate obtained contain 19.2% by weight. The distribution of THM is 5.2% by weight and the overall recovery is 95%. The THM loss in tailings is 0.3% and hence it can be rejected. The spiral concentrate was subjected to dry high intensity magnetic separation (DHIMS) to recover total magnetic minerals (mostly ilmenite). The data are given in Table 5. The total magnetics obtained by DHIMS is 19.8% by weight and 98.7% sink. The overall weight distribution is 3.8% and THM distribution is 19.5% with overall recovery 68%. The magnetic fraction of DHIM is further subjected to high tension separator (HTS) to recover total ilmenite. The data are given in Table 6. The total conducting fraction obtained contains 92% by weight and 99.4% sink. The overall distribution of weight is 3.5% and the THM distribution is 91.5% with overall recovery 63%.  156 N. Babu, N. Vasumathi and R. Bhima Rao Vol.8, No.2 Table. 4. Results of spiral separation Details Weight, % Sink, % THM, % Rec., % Concentrate 19.2 27.1 5.2 95 Tailing 80.8 0.4 0.3 5 Total 100.0 5.5 5.5 100.0 Table. 5. Results of Dry High Intensity Magnetic Separator (DHIMS) on spiral concentrate (Table 4) Details Weight, % Weight dist., % Sink, % THM, % Over all Rec., % Magnetic 19.8 3.8 98.7 19.5 68 Non-Magnetic 80.2 5.4 9.4 7.6 27 Total 100.0 19.2 27.1 27.1 95  Vol.8, No.2 Recovery of Ilmenite and Other Heavy Minerals 157 Table. 6. Results of High Tension Separator (HTS) on DHIMS magnetic fraction (Table 5) Details Weight, % Weight dist., % Sink, % THM, % Over all Rec., % Conducting 92.1 3.5 99.4 91.5 63 Non Conducting 7.9 0.3 90.5 7.2 5 Total 100.0 3.8 98.7 98.7 68 The non magnetic fraction of DHIMS subjected to gravity table and the results are given in Table 7. The data indicate that gravity table concentrate (mostly zircon and sillimanite) obtained contain 9.7% by weight and the sink is 93.9%. The overall weight distribution is 1.5% and the THM distribution is 9.1% with overall 26% recovery. The gravity table tailings contain 0.3% sink and 0.3%THM and hence this can be rejected. Table. 7. Results of tabling studies on DHIMS non magnetic fraction (Table 5) Details Weight, % Weight dist., % Sink, % THM, % Over all Rec, % Concentrate 9.7 1.5 93.9 9.1 26 Tailing 90.3 13.9 0.3 0.3 01 Total 100.0 15.4 9.4 9.4 27 Results on recovery of ilmenite and distribution of other heavy minerals in different products obtained by magnetic, electrostatic and gravity separators are given in Table 8. The data indicate that by using DHIMS about 97% ilmenite could be recovered and by cleaning this product using HTS, 99.1% ilmenite could be recovered. Gravity table heavies contain 53.3% zircon, 31.7% sillimanite and with other impurities can be further subjected to recover individual concentrates of zircon and sillimanite. The conceptual flow sheet with material balance on recovery of ilmenite and other heavy minerals like zircon and sillimanite is shown in Fig. 6. The feed contain 5.5% THM out of which 3.7% ilmenite. On processing this feed through spirals followed by DHIMS and HTS, a concentrate obtained contain 99.1% ilmenite with 3.5% yield and 94% recovery. The gravity table concentrate associated majorly with zircon (53.3%), sillimanite (31.7%) and other heavy minerals which can be reprocessed for recovery of individual mineral concentrates of zircon and sillimanite by judicious combination of gravity and flotation processes.  158 N. Babu, N. Vasumathi and R. Bhima Rao Vol.8, No.2 Table. 8. Recovery of Ilmenite and distribution of heavy minerals in different products obtained by magnetic, electro static and gravity separators Minerals Mags., of DHIMS Conducts of HTS Heavies of Table % Ilmenite 97.0 99.1 5.3 Zircon 0.3 0.3 53.3 Sillimanite 31.7 Others Garnet Rutile Monazite Pyribols 1.4 3.6 Quartz 1.3 0.6 6.1 Total 100.0 100.0 100.0 4. CONCLUSIONS The red sand which is known as Teri sand in Tamil Nadu consists of 5.5% Total Heavy Minerals (THM) out of which 3.7% is ilmenite. On processing this feed to recover ilmenite by using  Vol.8, No.2 Recovery of Ilmenite and Other Heavy Minerals 159 spirals followed by dry high intensity magnetic separator and high tension separator, ilmenite concentrate obtained contain 99.1% ilmenite with 3.5% yield and 94% recovery. The other heavy minerals zircon (53.3%) and sillimanite (31.7%) could be further reprocessed for recovery of individual mineral concentrates of zircon and sillimanite by judicious combination of gravity and flotation processes. ACKNOWLEDGEMENTS The authors are thankful to the Director of National Institute for Interdisciplinary Science and Technology (CSIR), Trivandrum and also to the Director of Institute of Minerals and Materials Technology (CSIR), Bhubaneswar for constant encouragement to carry out this work for publication. REFERENCES 1. Rita A. M. Gardner, (1981), Reddening of dune sands - evidence from southeast India, Earth Surface Processes and Landforms, Vol. 6, Issue 5 , pp 459 – 468. 2. Rao, J.M and Krishna Rao, J.S.R, (1984), Textural and mineralogical studies on red sediments of visakhapatnam-bhimunipatnam coast, Geoviews, 12 (2), 57-64 3. Krishnan.S, Chandrasekharan.S, Anil Kumar.V, Rajgopal.N and Hoda.S.Q, (1994), Delineation of Heavy Mineral Provinces in The Beach Placer and Inland Teri Sands of Tamil Nadu, Journal of Atomic Minerals, Vol. 2, pp 57-71. 4. Dwivedy., K.K. (1995), Reserves, resources and geology of titanium deposits of India, Titanium, Vol. 1, No. 1, pp 16-39. 5. Rao.Y, Ravi., G.S, Rao, Prabhakar. A, Rao Gajapathi. R and Ali M.A.,(1997), Heavy minerals potential of red sediments, Chatrapur, Ganjam Dt., Orissa, Indian Minerals, Vol.5, No. 4, pp 255-260. 6. Chandrasekharan.S and Murugan.C, (2001), Heavy minerals in the beach and the costal sand (teri) of Tamil Nadu, Exploration and research for atomic minerals, Vol.13, pp 97-109. 7. Antoine.F.M.B, David.M.N and Frans.B.W (2002), Ilmenite minerals recovery from beach sand tailings. Hyperfine Interactions, 139/140, pp 485-494. 8. Rao.D.S, Vijayakumar.T.V, Prabhalar.S, Bhaskararaju.G and Ghosh.T.K, (2005) Alteration Characteristics of Ilmenites from Sounth India, Journal of minerals and materials characterization & engineering, Vol. 4, No. 1, pp 47-59. 9. Sahoo, A.K., Swain, R and Rao, Bhima R, (2006), Applications of static screens for recovery of placer values from spiral tailings, The journal of Solid waste technology and management, Vol. 32, No.2, 109-118. 10. Murty.V.G.K,Upadhyay.R and Asokan.S (2007), recovery of zircon from Sattankulam deposit in India – Problems & prospects, The 6th International heavy minerals conference “Back to basics’, The South African Institute of Mining and Metallurgy, pp 69-74.

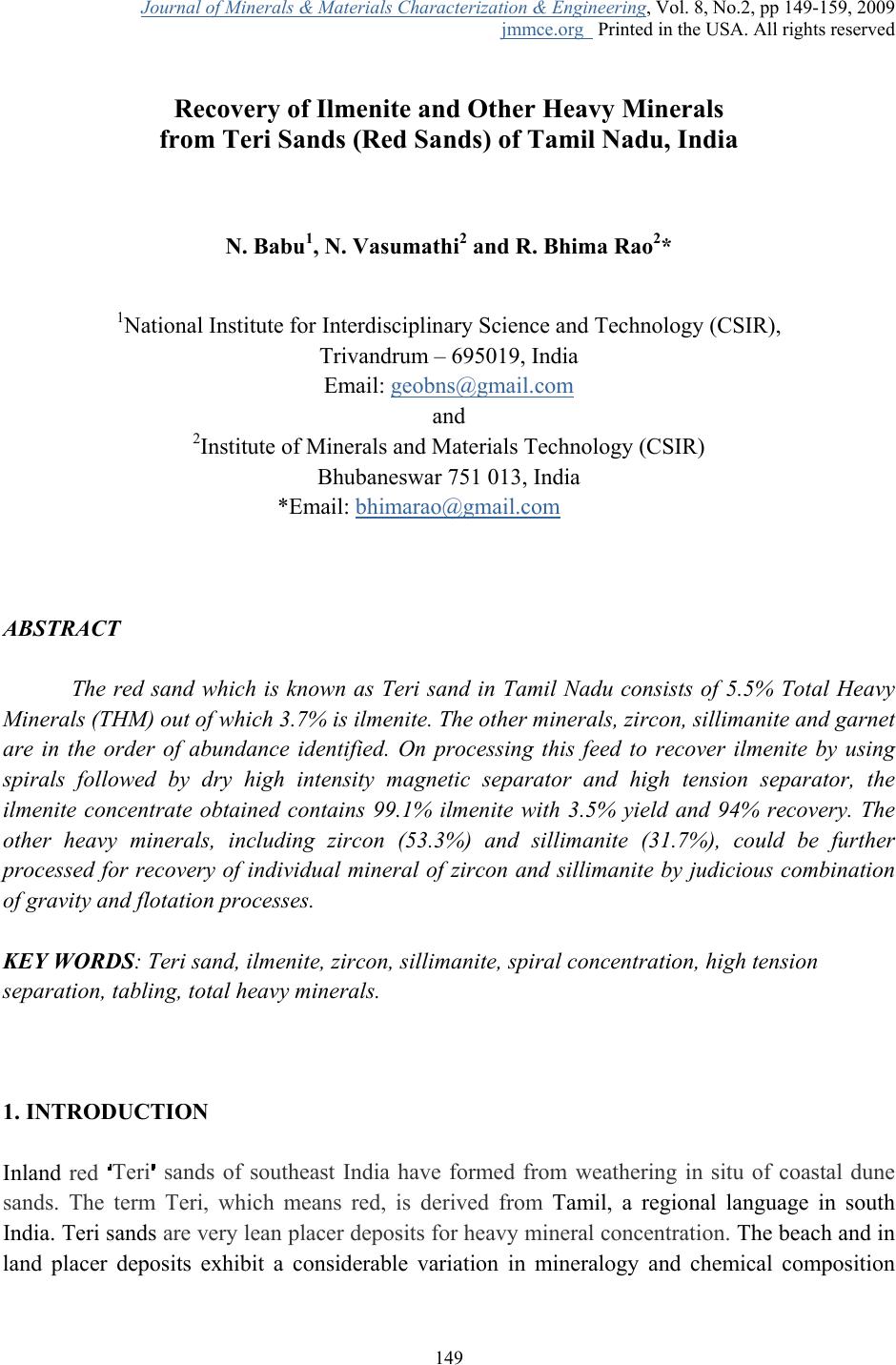

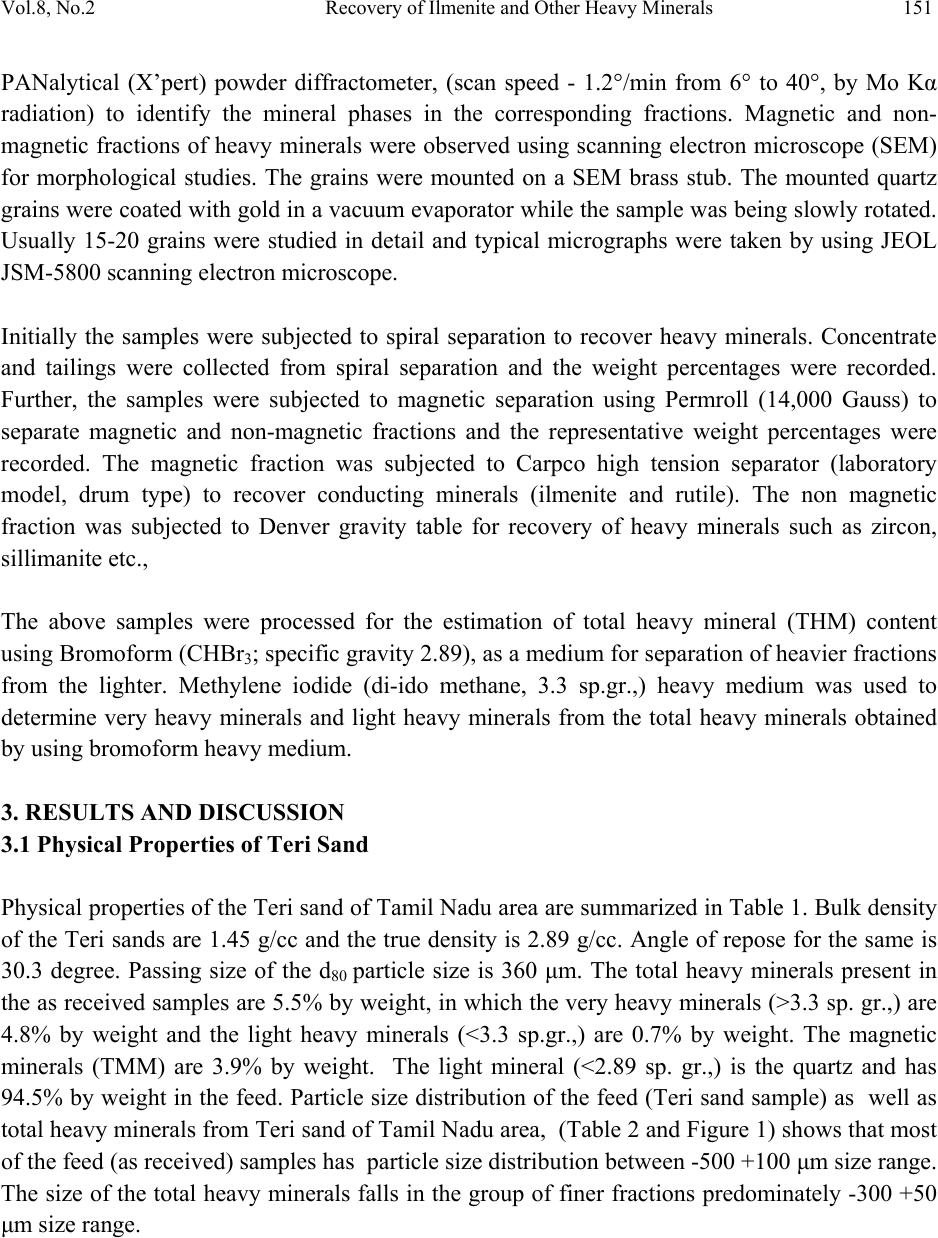

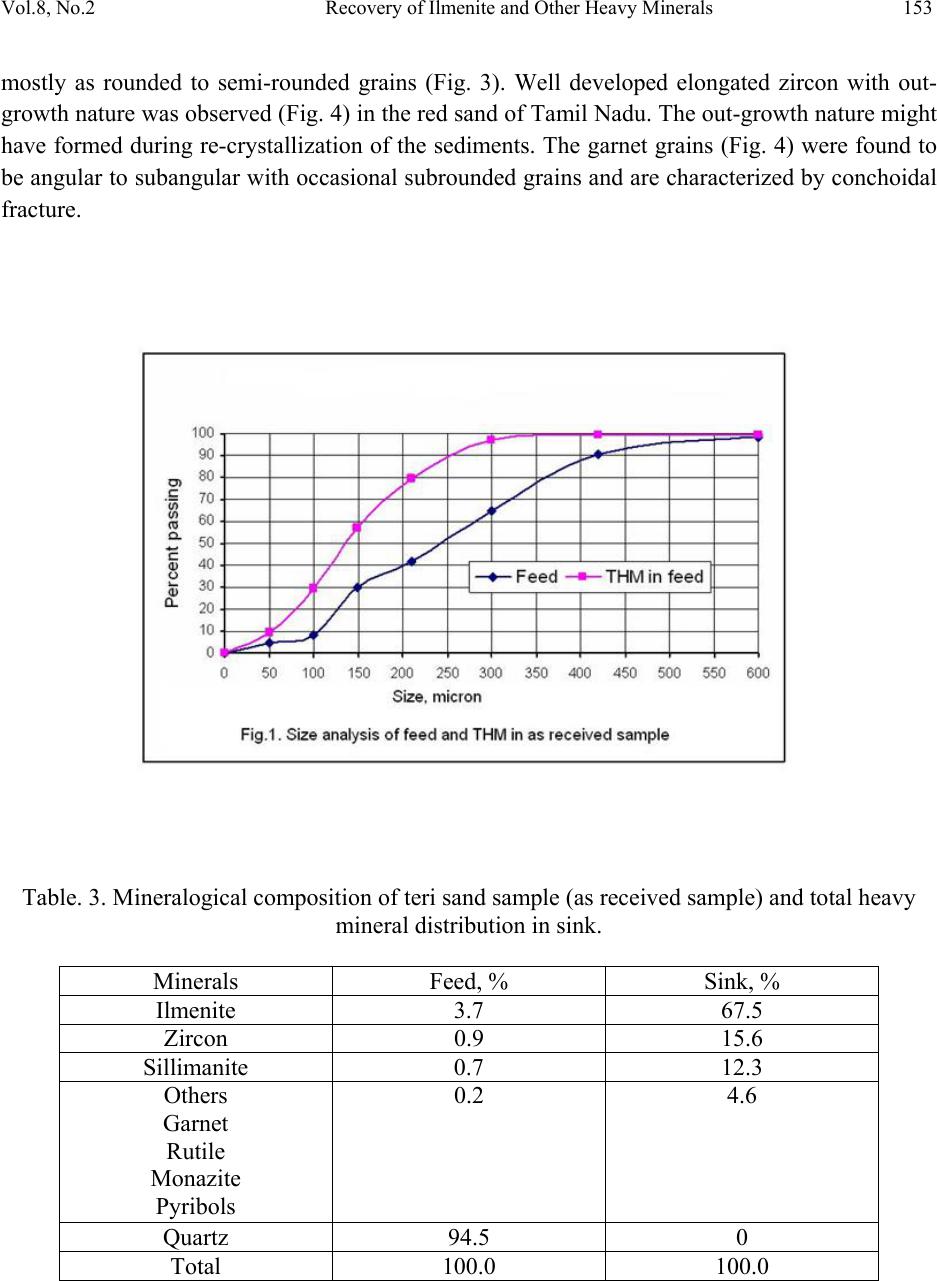

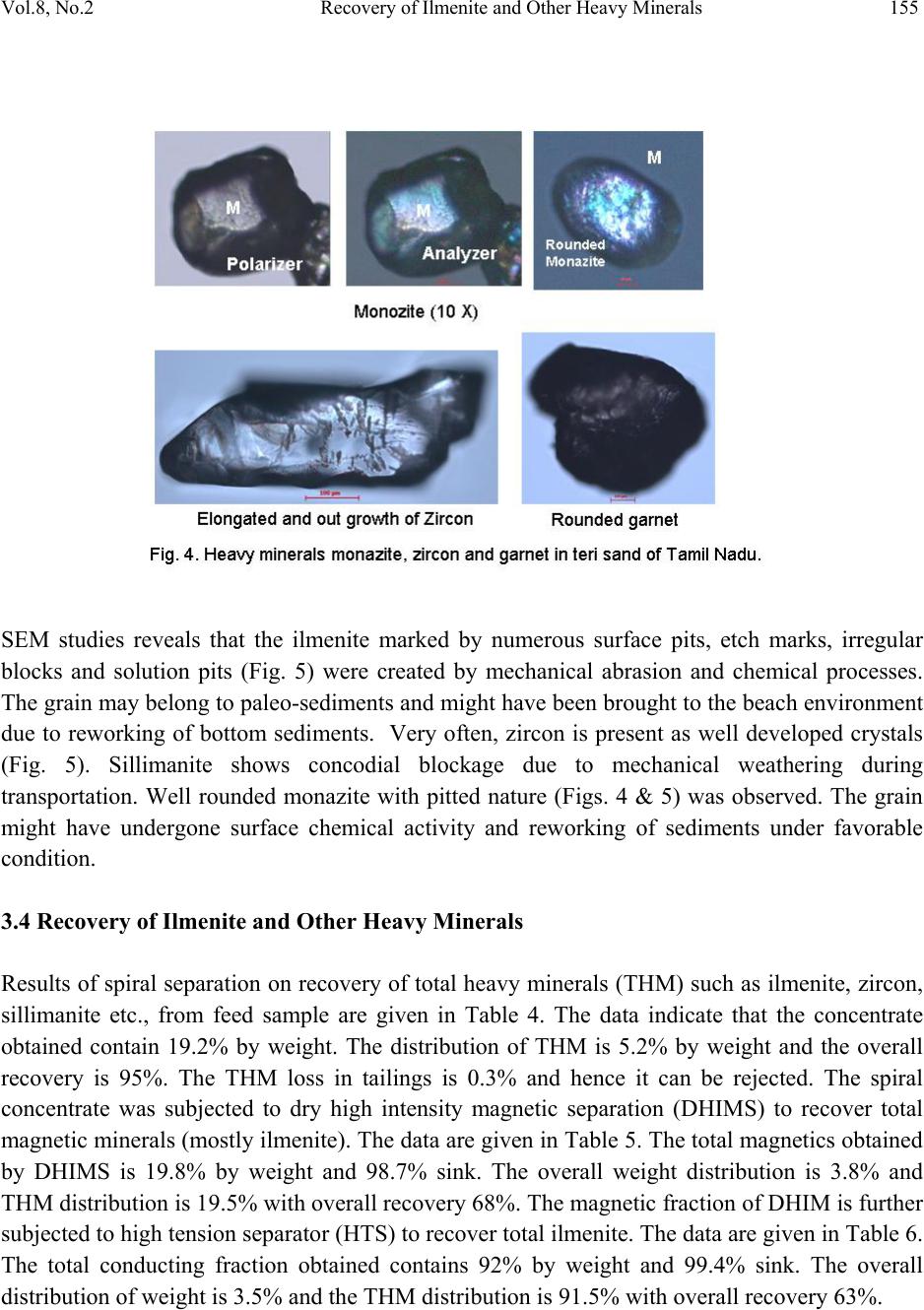

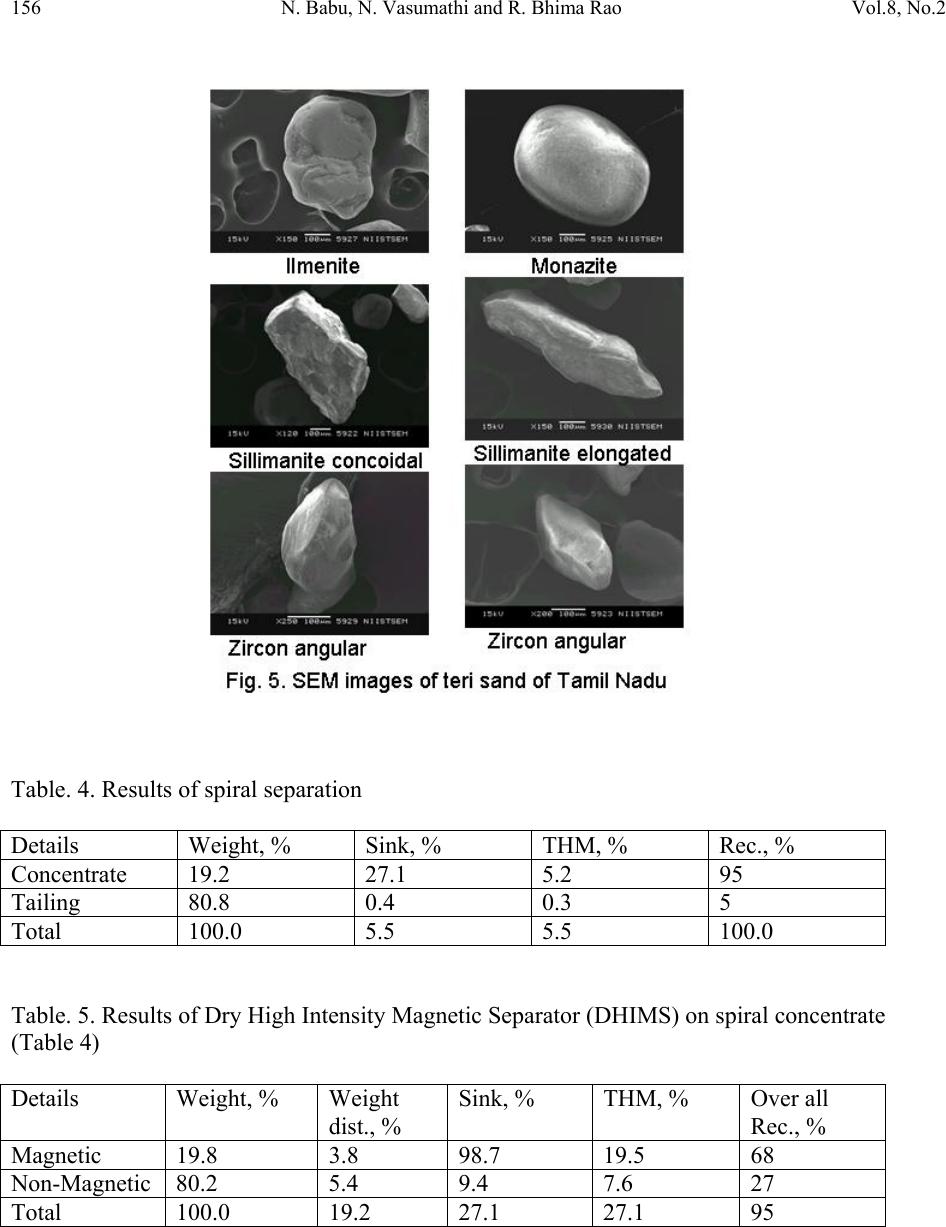

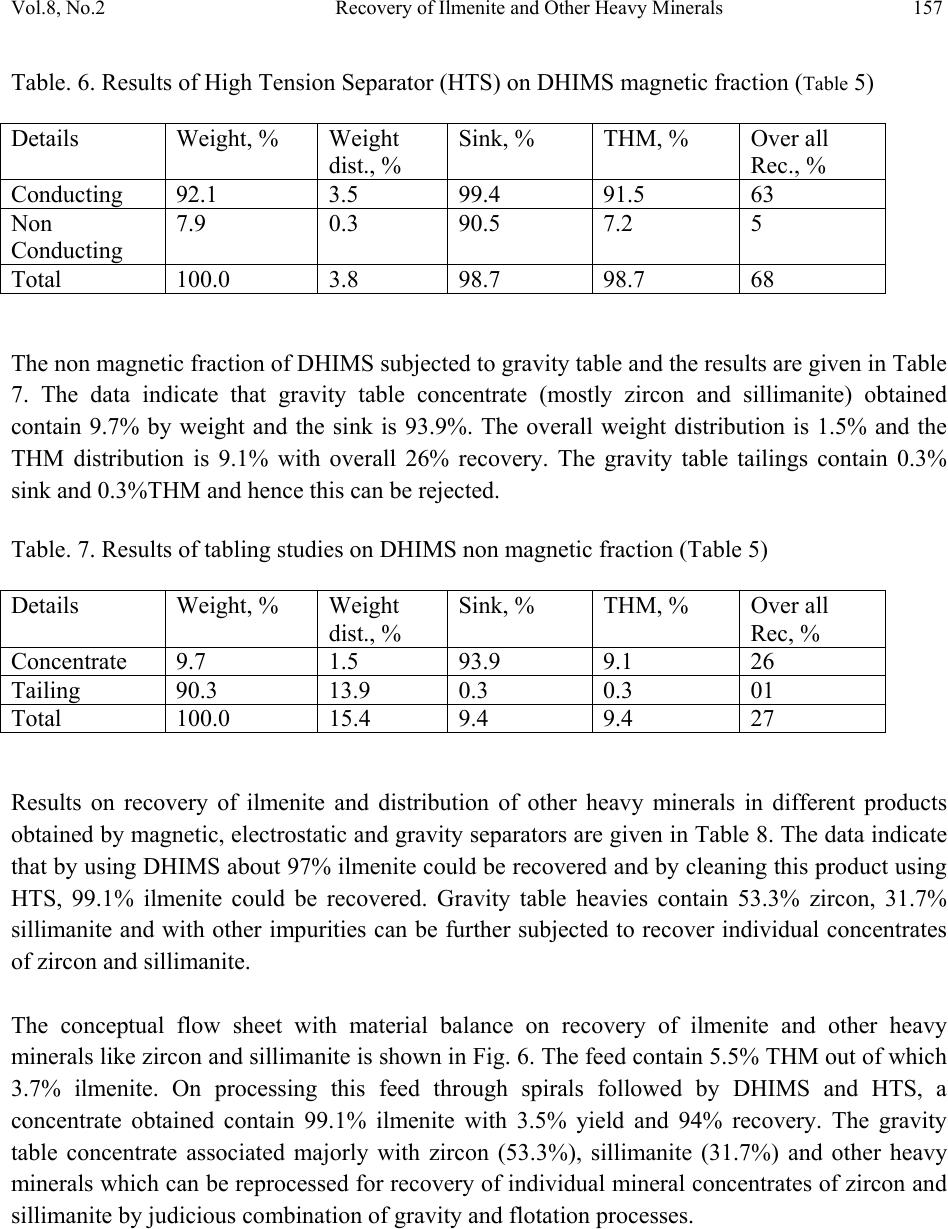

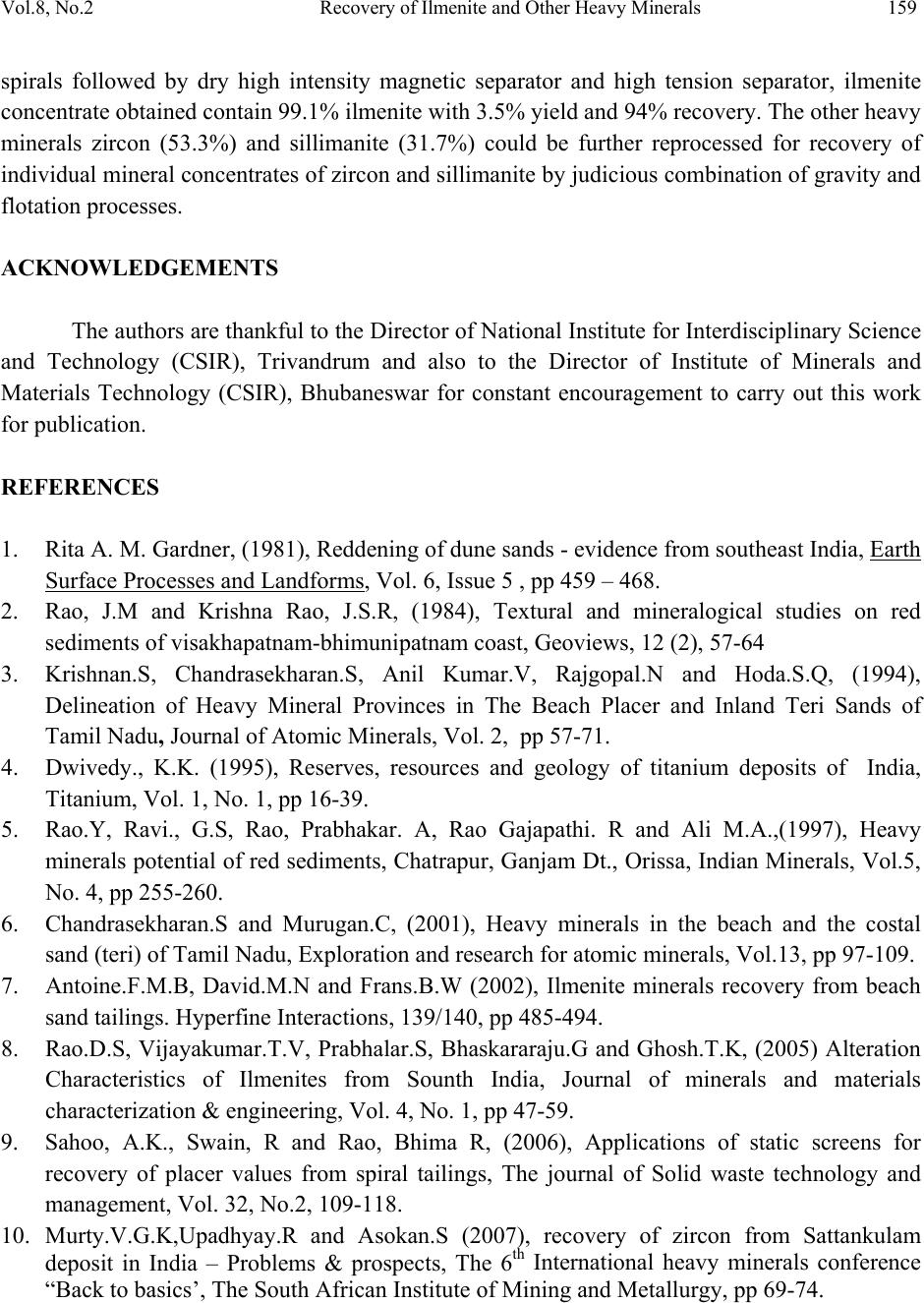

|