Paper Menu >>

Journal Menu >>

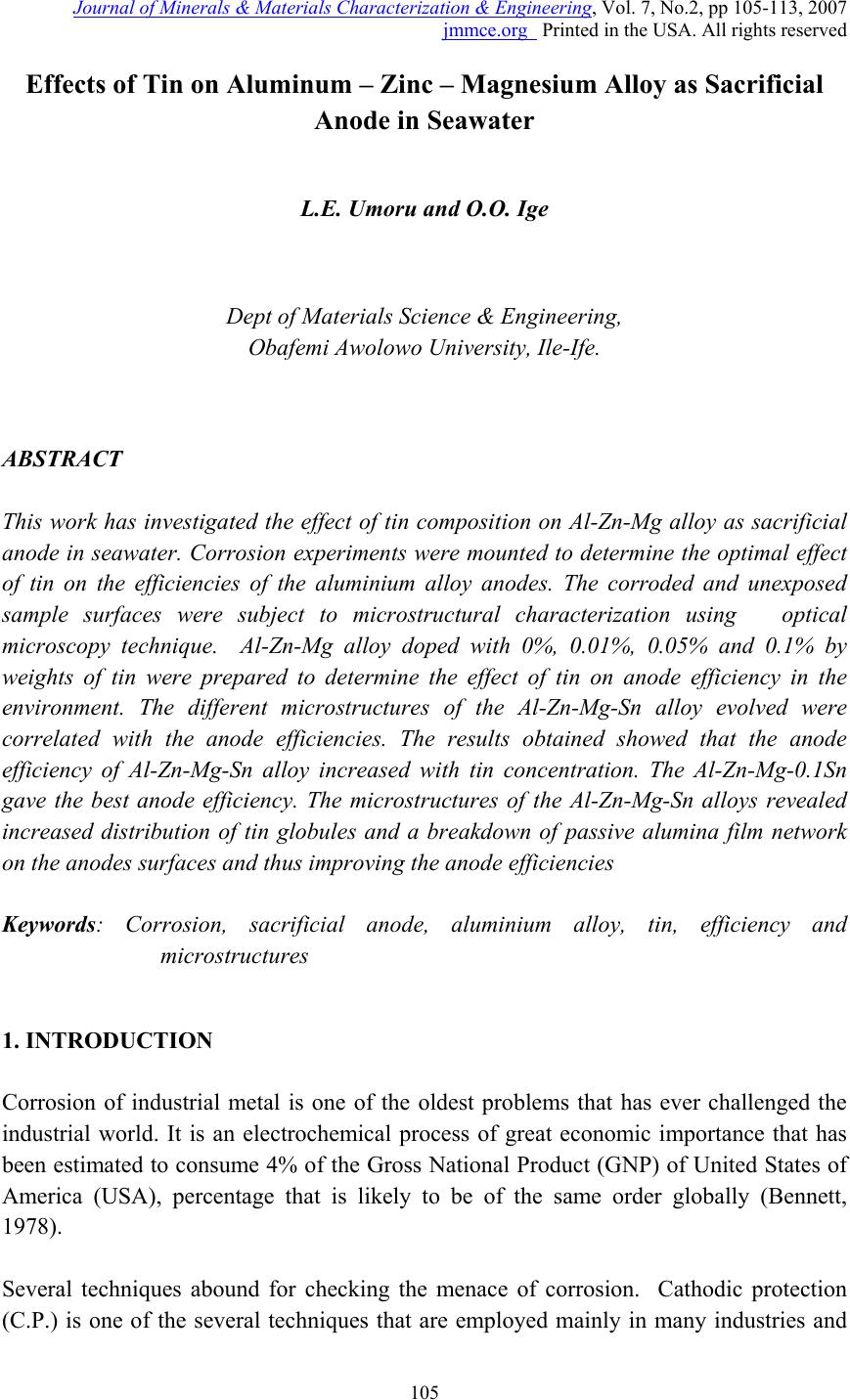

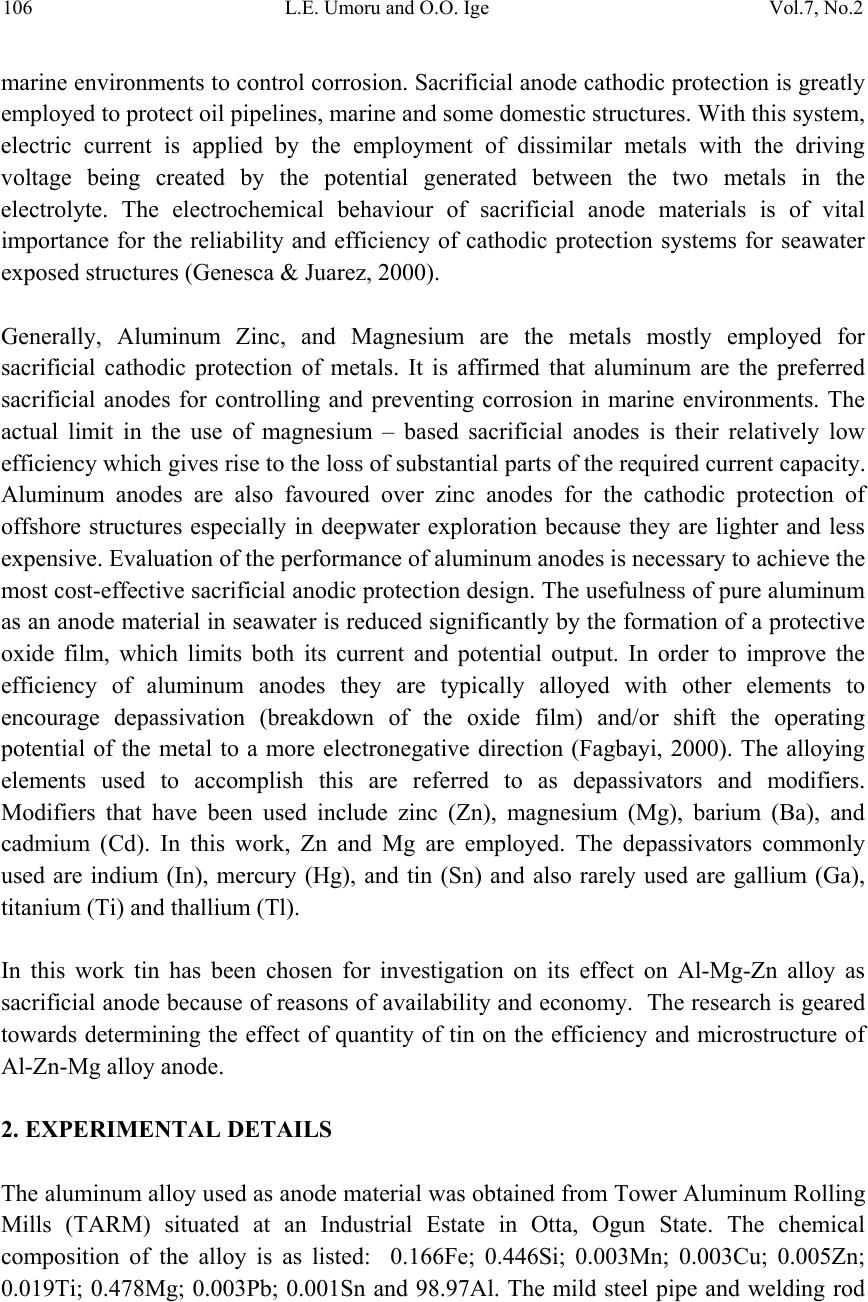

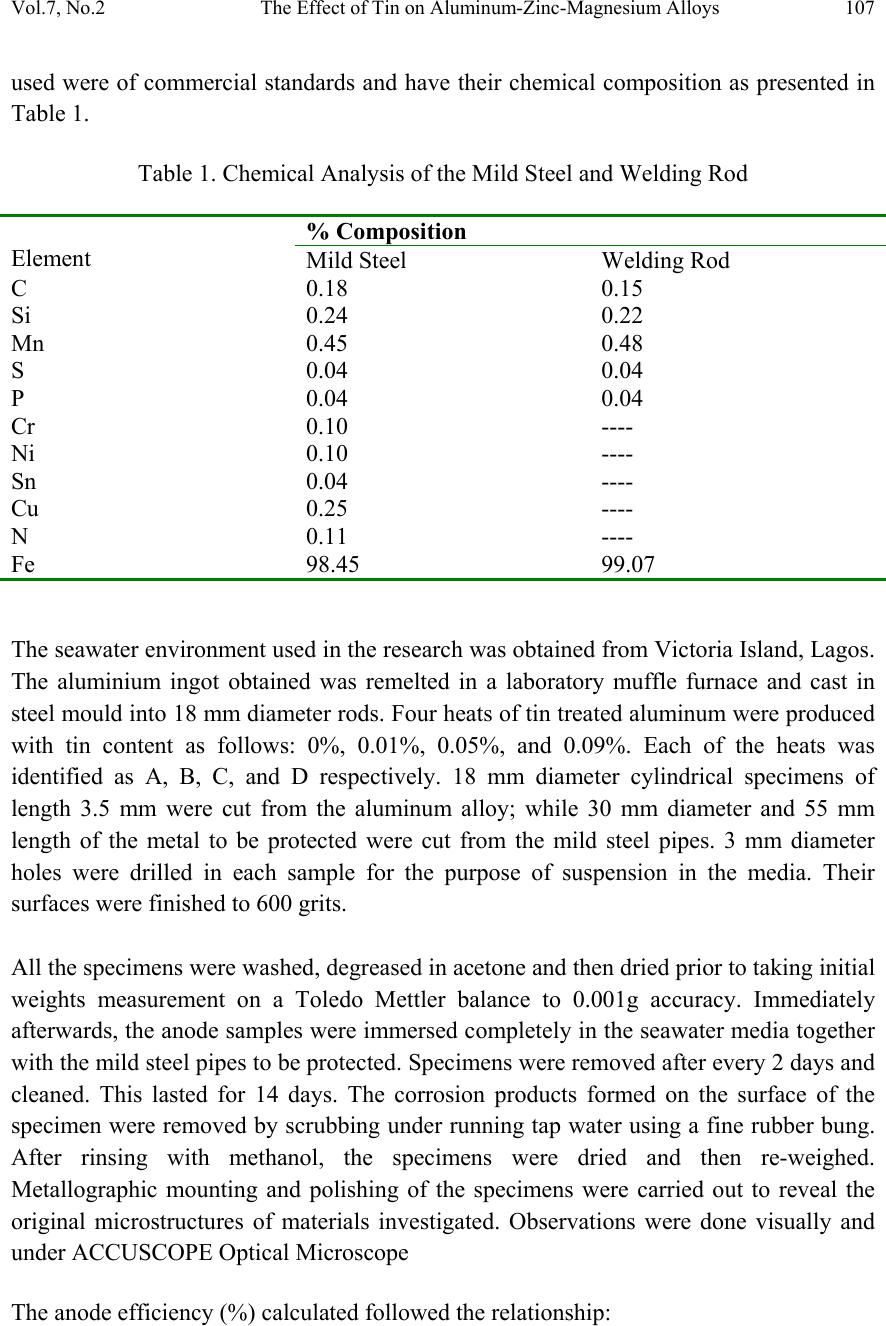

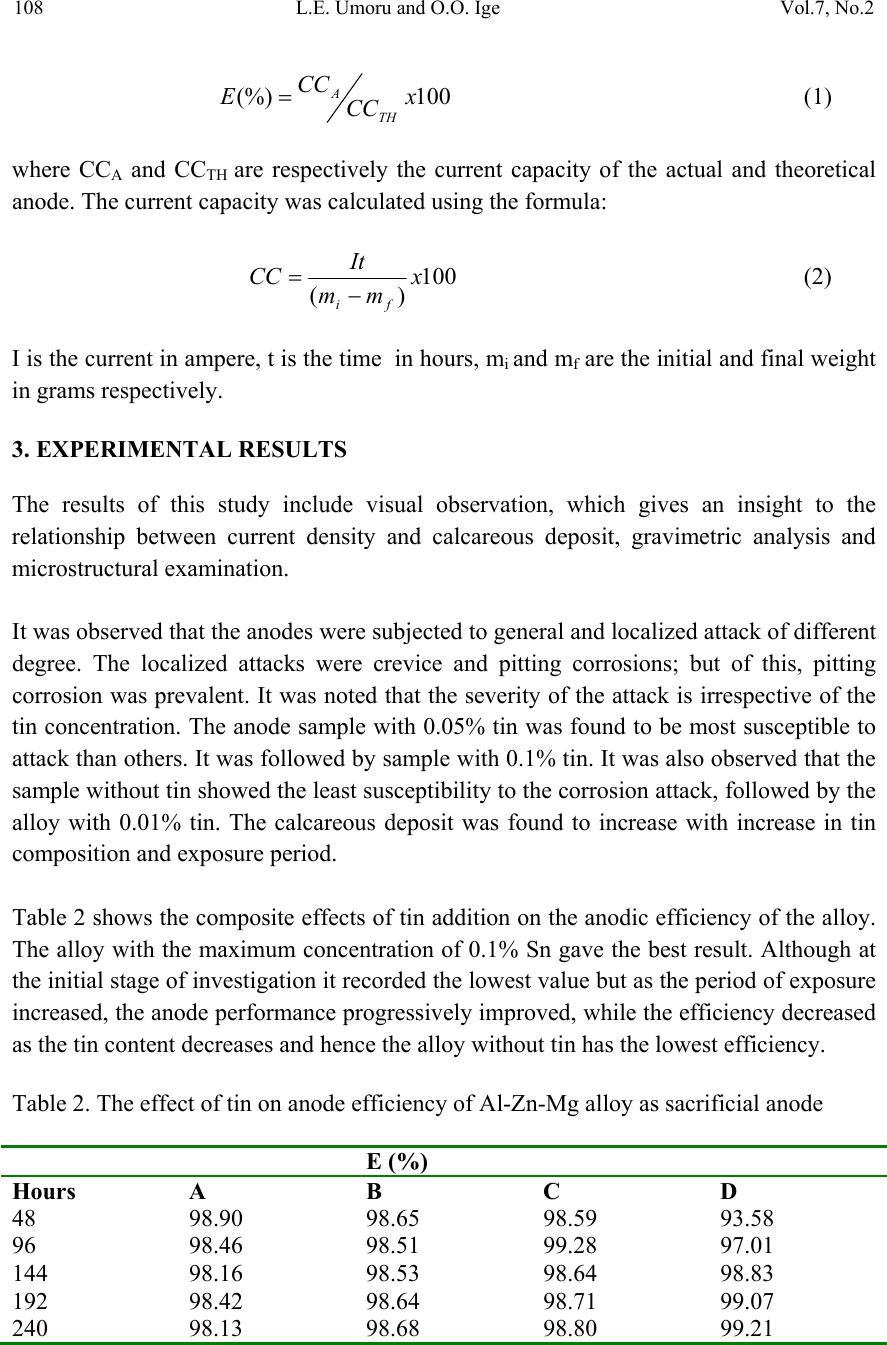

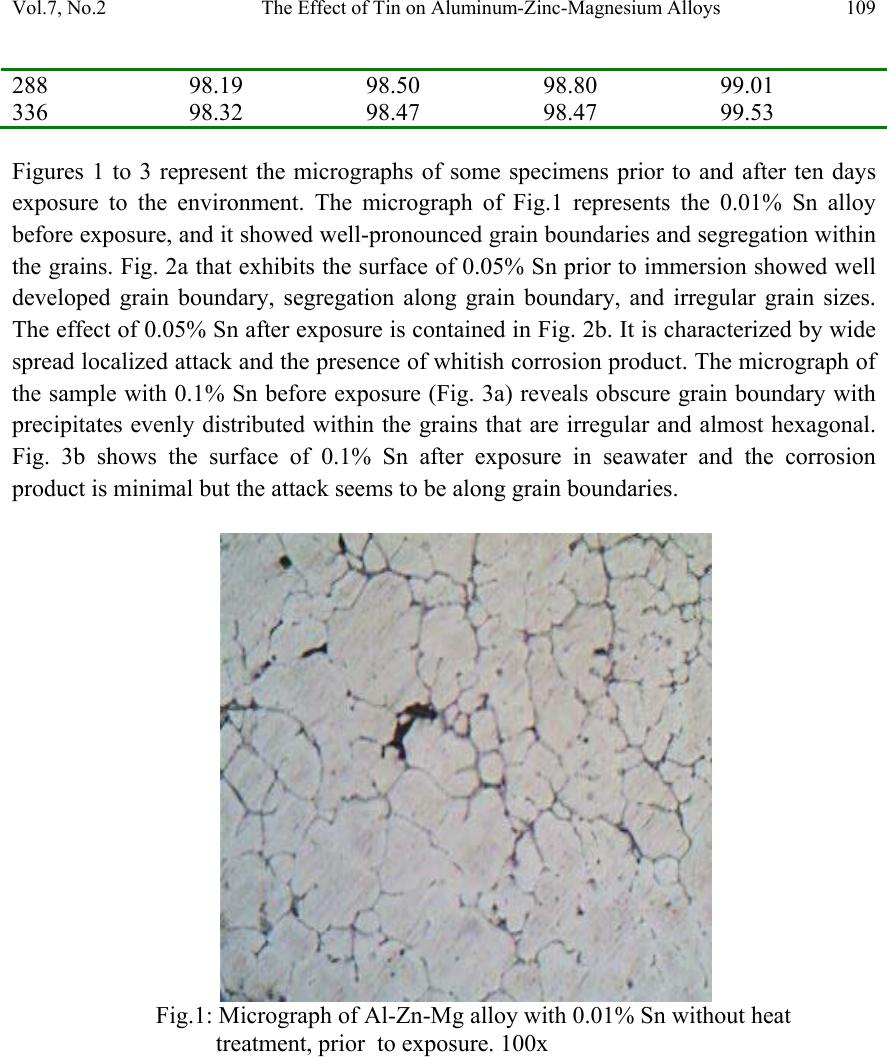

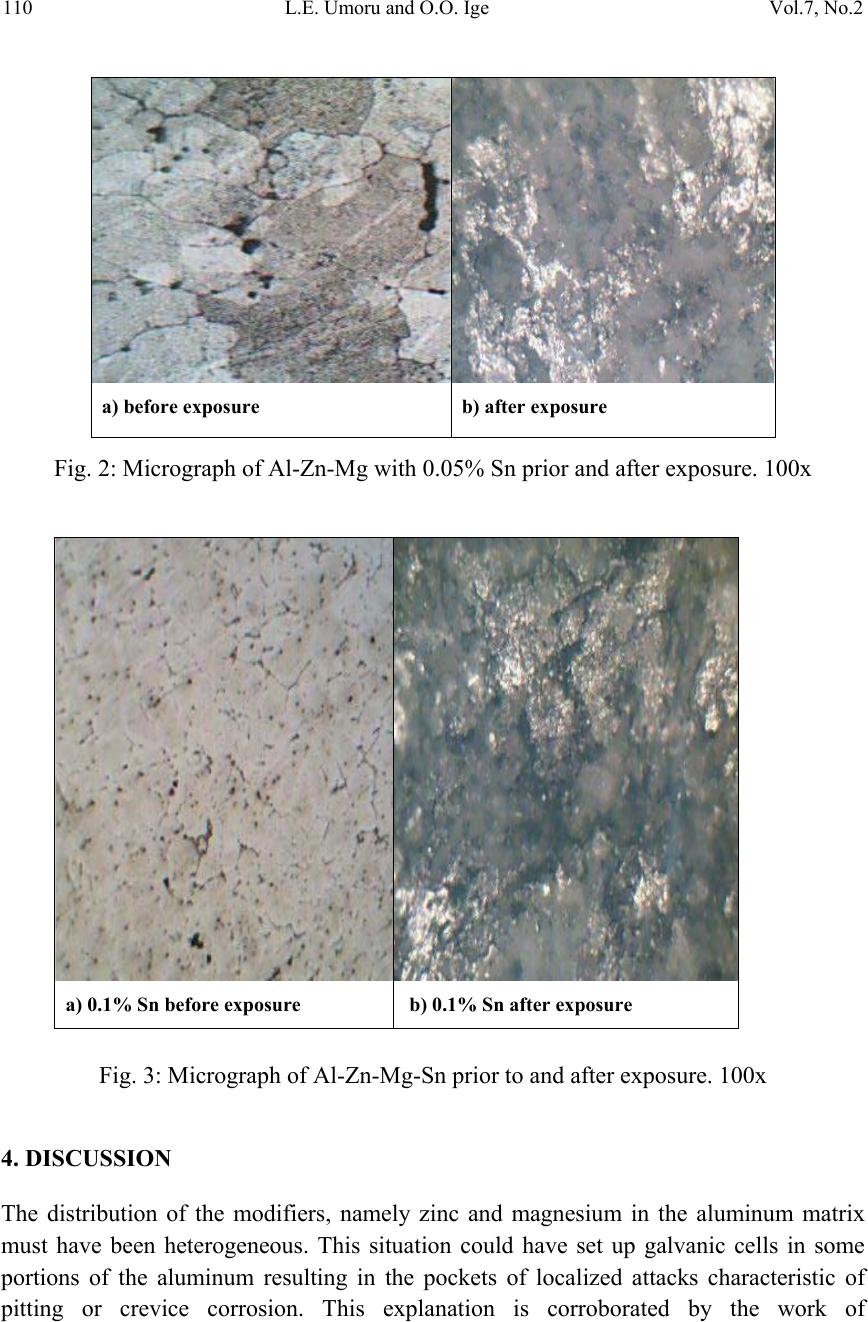

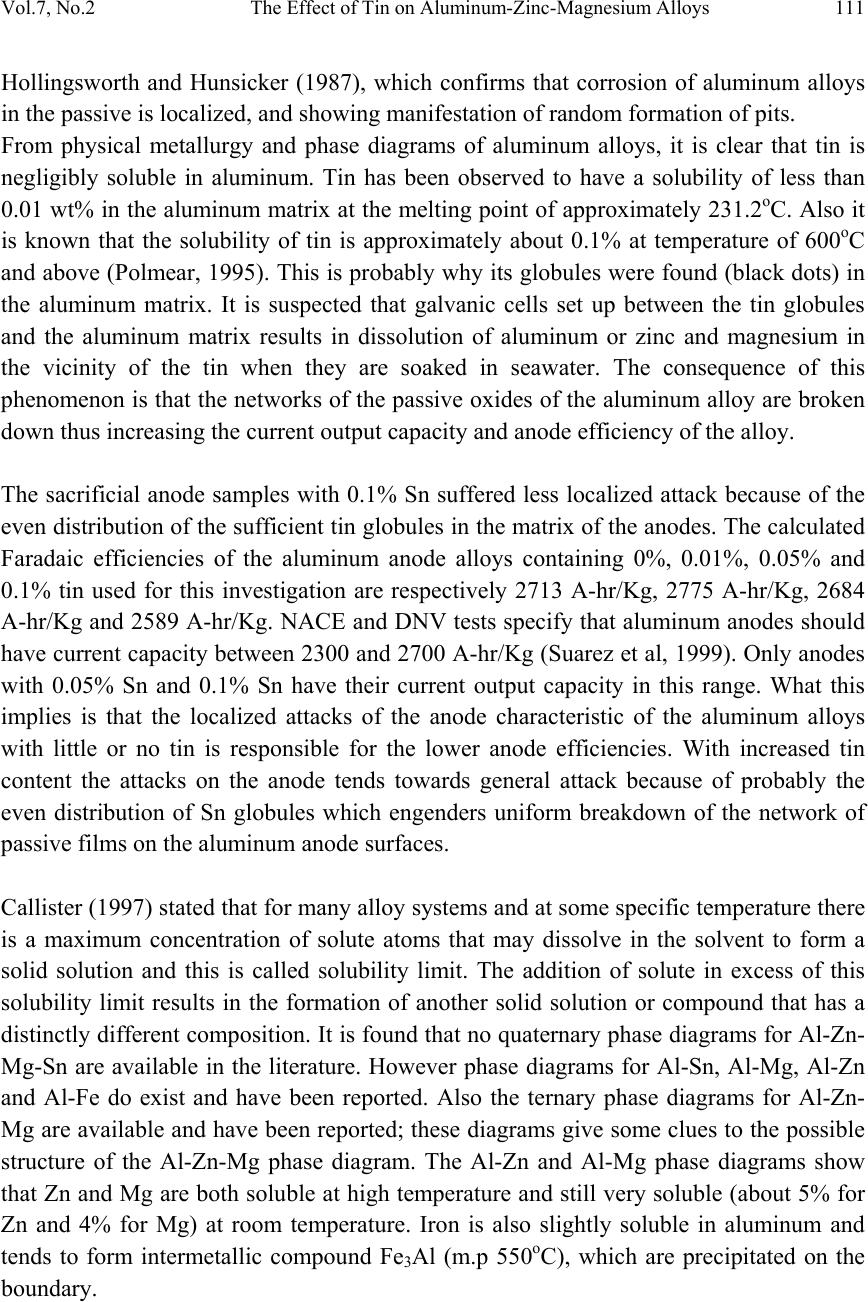

Journal of Minerals & Materials Characterization & Engineering, Vol. 7, No.2, pp 105-113, 2007 jmmce.org Printed in the USA. All rights reserved Effects of Tin on Aluminum – Zinc – Magnesium Alloy as Sacrificial Anode in Seawater L.E. Umoru and O.O. Ige Dept of Materials Science & Engineering, Obafemi Awolowo University, Ile-Ife. ABSTRACT This work has investigated the effect of tin composition on Al-Zn-Mg alloy as sacrificial anode in seawater. Corrosion experiments were mounted to determine the optimal effect of tin on the efficiencies of the aluminium alloy anodes. The corroded and unexposed sample surfaces were subject to microstructural characterization using optical microscopy technique. Al-Zn-Mg alloy doped with 0%, 0.01%, 0.05% and 0.1% by weights of tin were prepared to determine the effect of tin on anode efficiency in the environment. The different microstructures of the Al-Zn-Mg-Sn alloy evolved were correlated with the anode efficiencies. The results obtained showed that the anode efficiency of Al-Zn-Mg-Sn alloy increased with tin concentration. The Al-Zn-Mg-0.1Sn gave the best anode efficiency. The microstructures of the Al-Zn-Mg-Sn alloys revealed increased distribution of tin globules and a breakdown of passive alumina film network on the anodes surfaces and thus improving the anode efficiencies Keywords: Corrosion, sacrificial anode, aluminium alloy, tin, efficiency and microstructures 1. INTRODUCTION Corrosion of industrial metal is one of the oldest problems that has ever challenged the industrial world. It is an electrochemical process of great economic importance that has been estimated to consume 4% of the Gross National Product (GNP) of United States of America (USA), percentage that is likely to be of the same order globally (Bennett, 1978). Several techniques abound for checking the menace of corrosion. Cathodic protection (C.P.) is one of the several techniques that are employed mainly in many industries and 105  106 L.E. Umoru and O.O. Ige Vol.7, No.2 marine environments to control corrosion. Sacrificial anode cathodic protection is greatly employed to protect oil pipelines, marine and some domestic structures. With this system, electric current is applied by the employment of dissimilar metals with the driving voltage being created by the potential generated between the two metals in the electrolyte. The electrochemical behaviour of sacrificial anode materials is of vital importance for the reliability and efficiency of cathodic protection systems for seawater exposed structures (Genesca & Juarez, 2000). Generally, Aluminum Zinc, and Magnesium are the metals mostly employed for sacrificial cathodic protection of metals. It is affirmed that aluminum are the preferred sacrificial anodes for controlling and preventing corrosion in marine environments. The actual limit in the use of magnesium – based sacrificial anodes is their relatively low efficiency which gives rise to the loss of substantial parts of the required current capacity. Aluminum anodes are also favoured over zinc anodes for the cathodic protection of offshore structures especially in deepwater exploration because they are lighter and less expensive. Evaluation of the performance of aluminum anodes is necessary to achieve the most cost-effective sacrificial anodic protection design. The usefulness of pure aluminum as an anode material in seawater is reduced significantly by the formation of a protective oxide film, which limits both its current and potential output. In order to improve the efficiency of aluminum anodes they are typically alloyed with other elements to encourage depassivation (breakdown of the oxide film) and/or shift the operating potential of the metal to a more electronegative direction (Fagbayi, 2000). The alloying elements used to accomplish this are referred to as depassivators and modifiers. Modifiers that have been used include zinc (Zn), magnesium (Mg), barium (Ba), and cadmium (Cd). In this work, Zn and Mg are employed. The depassivators commonly used are indium (In), mercury (Hg), and tin (Sn) and also rarely used are gallium (Ga), titanium (Ti) and thallium (Tl). In this work tin has been chosen for investigation on its effect on Al-Mg-Zn alloy as sacrificial anode because of reasons of availability and economy. The research is geared towards determining the effect of quantity of tin on the efficiency and microstructure of Al-Zn-Mg alloy anode. 2. EXPERIMENTAL DETAILS The aluminum alloy used as anode material was obtained from Tower Aluminum Rolling Mills (TARM) situated at an Industrial Estate in Otta, Ogun State. The chemical composition of the alloy is as listed: 0.166Fe; 0.446Si; 0.003Mn; 0.003Cu; 0.005Zn; 0.019Ti; 0.478Mg; 0.003Pb; 0.001Sn and 98.97Al. The mild steel pipe and welding rod  Vol.7, No.2 The Effect of Tin on Aluminum-Zinc-Magnesium Alloys 107 used were of commercial standards and have their chemical composition as presented in Table 1. Table 1. Chemical Analysis of the Mild Steel and Welding Rod Element % Composition Mild Steel Welding Rod C 0.18 0.15 Si 0.24 0.22 Mn 0.45 0.48 S 0.04 0.04 P 0.04 0.04 Cr 0.10 ---- Ni 0.10 ---- Sn 0.04 ---- Cu 0.25 ---- N 0.11 ---- Fe 98.45 99.07 The seawater environment used in the research was obtained from Victoria Island, Lagos. The aluminium ingot obtained was remelted in a laboratory muffle furnace and cast in steel mould into 18 mm diameter rods. Four heats of tin treated aluminum were produced with tin content as follows: 0%, 0.01%, 0.05%, and 0.09%. Each of the heats was identified as A, B, C, and D respectively. 18 mm diameter cylindrical specimens of length 3.5 mm were cut from the aluminum alloy; while 30 mm diameter and 55 mm length of the metal to be protected were cut from the mild steel pipes. 3 mm diameter holes were drilled in each sample for the purpose of suspension in the media. Their surfaces were finished to 600 grits. All the specimens were washed, degreased in acetone and then dried prior to taking initial weights measurement on a Toledo Mettler balance to 0.001g accuracy. Immediately afterwards, the anode samples were immersed completely in the seawater media together with the mild steel pipes to be protected. Specimens were removed after every 2 days and cleaned. This lasted for 14 days. The corrosion products formed on the surface of the specimen were removed by scrubbing under running tap water using a fine rubber bung. After rinsing with methanol, the specimens were dried and then re-weighed. Metallographic mounting and polishing of the specimens were carried out to reveal the original microstructures of materials investigated. Observations were done visually and under ACCUSCOPE Optical Microscope The anode efficiency (%) calculated followed the relationship:  108 L.E. Umoru and O.O. Ige Vol.7, No.2 100(%)x CC CC ETH A = (1) where CCA and CCTH are respectively the current capacity of the actual and theoretical anode. The current capacity was calculated using the formula: 100 )( x mm It CC fi − = (2) I is the current in ampere, t is the time in hours, mi and mf are the initial and final weight in grams respectively. 3. EXPERIMENTAL RESULTS The results of this study include visual observation, which gives an insight to the relationship between current density and calcareous deposit, gravimetric analysis and microstructural examination. It was observed that the anodes were subjected to general and localized attack of different degree. The localized attacks were crevice and pitting corrosions; but of this, pitting corrosion was prevalent. It was noted that the severity of the attack is irrespective of the tin concentration. The anode sample with 0.05% tin was found to be most susceptible to attack than others. It was followed by sample with 0.1% tin. It was also observed that the sample without tin showed the least susceptibility to the corrosion attack, followed by the alloy with 0.01% tin. The calcareous deposit was found to increase with increase in tin composition and exposure period. Table 2 shows the composite effects of tin addition on the anodic efficiency of the alloy. The alloy with the maximum concentration of 0.1% Sn gave the best result. Although at the initial stage of investigation it recorded the lowest value but as the period of exposure increased, the anode performance progressively improved, while the efficiency decreased as the tin content decreases and hence the alloy without tin has the lowest efficiency. Table 2. The effect of tin on anode efficiency of Al-Zn-Mg alloy as sacrificial anode E (%) Hours A B C D 48 98.90 98.65 98.59 93.58 96 98.46 98.51 99.28 97.01 144 98.16 98.53 98.64 98.83 192 98.42 98.64 98.71 99.07 240 98.13 98.68 98.80 99.21  Vol.7, No.2 The Effect of Tin on Aluminum-Zinc-Magnesium Alloys 109 288 98.19 98.50 98.80 99.01 336 98.32 98.47 98.47 99.53 Figures 1 to 3 represent the micrographs of some specimens prior to and after ten days exposure to the environment. The micrograph of Fig.1 represents the 0.01% Sn alloy before exposure, and it showed well-pronounced grain boundaries and segregation within the grains. Fig. 2a that exhibits the surface of 0.05% Sn prior to immersion showed well developed grain boundary, segregation along grain boundary, and irregular grain sizes. The effect of 0.05% Sn after exposure is contained in Fig. 2b. It is characterized by wide spread localized attack and the presence of whitish corrosion product. The micrograph of the sample with 0.1% Sn before exposure (Fig. 3a) reveals obscure grain boundary with precipitates evenly distributed within the grains that are irregular and almost hexagonal. Fig. 3b shows the surface of 0.1% Sn after exposure in seawater and the corrosion product is minimal but the attack seems to be along grain boundaries. Fig.1: Micrograph of Al-Zn-Mg alloy with 0.01% Sn without heat treatment, prior to exposure. 100x  110 L.E. Umoru and O.O. Ige Vol.7, No.2 a) before exposure b) after exposure Fig. 2: Micrograph of Al-Zn-Mg with 0.05% Sn prior and after exposure. 100x a) 0.1% Sn before exposure b) 0.1% Sn after exposure Fig. 3: Micrograph of Al-Zn-Mg-Sn prior to and after exposure. 100x 4. DISCUSSION The distribution of the modifiers, namely zinc and magnesium in the aluminum matrix must have been heterogeneous. This situation could have set up galvanic cells in some portions of the aluminum resulting in the pockets of localized attacks characteristic of pitting or crevice corrosion. This explanation is corroborated by the work of  Vol.7, No.2 The Effect of Tin on Aluminum-Zinc-Magnesium Alloys 111 Hollingsworth and Hunsicker (1987), which confirms that corrosion of aluminum alloys in the passive is localized, and showing manifestation of random formation of pits. From physical metallurgy and phase diagrams of aluminum alloys, it is clear that tin is negligibly soluble in aluminum. Tin has been observed to have a solubility of less than 0.01 wt% in the aluminum matrix at the melting point of approximately 231.2oC. Also it is known that the solubility of tin is approximately about 0.1% at temperature of 600oC and above (Polmear, 1995). This is probably why its globules were found (black dots) in the aluminum matrix. It is suspected that galvanic cells set up between the tin globules and the aluminum matrix results in dissolution of aluminum or zinc and magnesium in the vicinity of the tin when they are soaked in seawater. The consequence of this phenomenon is that the networks of the passive oxides of the aluminum alloy are broken down thus increasing the current output capacity and anode efficiency of the alloy. The sacrificial anode samples with 0.1% Sn suffered less localized attack because of the even distribution of the sufficient tin globules in the matrix of the anodes. The calculated Faradaic efficiencies of the aluminum anode alloys containing 0%, 0.01%, 0.05% and 0.1% tin used for this investigation are respectively 2713 A-hr/Kg, 2775 A-hr/Kg, 2684 A-hr/Kg and 2589 A-hr/Kg. NACE and DNV tests specify that aluminum anodes should have current capacity between 2300 and 2700 A-hr/Kg (Suarez et al, 1999). Only anodes with 0.05% Sn and 0.1% Sn have their current output capacity in this range. What this implies is that the localized attacks of the anode characteristic of the aluminum alloys with little or no tin is responsible for the lower anode efficiencies. With increased tin content the attacks on the anode tends towards general attack because of probably the even distribution of Sn globules which engenders uniform breakdown of the network of passive films on the aluminum anode surfaces. Callister (1997) stated that for many alloy systems and at some specific temperature there is a maximum concentration of solute atoms that may dissolve in the solvent to form a solid solution and this is called solubility limit. The addition of solute in excess of this solubility limit results in the formation of another solid solution or compound that has a distinctly different composition. It is found that no quaternary phase diagrams for Al-Zn- Mg-Sn are available in the literature. However phase diagrams for Al-Sn, Al-Mg, Al-Zn and Al-Fe do exist and have been reported. Also the ternary phase diagrams for Al-Zn- Mg are available and have been reported; these diagrams give some clues to the possible structure of the Al-Zn-Mg phase diagram. The Al-Zn and Al-Mg phase diagrams show that Zn and Mg are both soluble at high temperature and still very soluble (about 5% for Zn and 4% for Mg) at room temperature. Iron is also slightly soluble in aluminum and tends to form intermetallic compound Fe3Al (m.p 550oC), which are precipitated on the boundary.  112 L.E. Umoru and O.O. Ige Vol.7, No.2 Several researchers have concluded that in the as-cast condition there is existence of a microstructure consisting of α-Al solid solution with precipitation of the τ (Al-Zn-Mg) phase and an eutectic consisting of a fine dispersion of the α and τ segregates (α + τ) at grain boundaries [Kutznetsov et al, 1986; Kilmer & Stonere, 1991]. It is reported in the literature that alloying element distribution, whether as solid solution, second phase segregates; intermetallic compounds or inclusions affect the behaviour of the ternary aluminum anodes (Fagbayi, 2000). When precipitates are uniformly distributed throughout the whole grain they have higher efficiencies than those that accumulate along the grain boundaries perhaps because of greater breakdown of the passive oxide network. Grain growth occurs by the migration of grain boundaries. Therefore, as the tin concentration increases, the grain size becomes smaller; that is the directions of boundary movement and atomic motions are opposite to each other. Thus it means that as the tin concentration increases and it diffuses uniformly it leads to shrinkage of grain boundary. Gummow (2004) observed that fine structure with very fine precipitates distributed in the matrix produces more general corrosion as opposed to pitting corrosion. While Genesca and Juarez (2000) observed that the electrochemical performance of an aluminum sacrificial anode alloy is strongly dependent upon the formation of corrosion products on the aluminum surface. It is observed that the corrosion attack and corrosion product becomes minimal as the tin concentration increases. 5. CONCLUSION The result obtained has shown that by alloying Al-Zn-Mg anode with tin at various compositions, the anode efficiency increased with the increase of tin concentration. The sample with 0.1% Sn is advocated for use because of its high output current capacity and is enhanced by better microstructural features. REFERENCES Bennett, L.M. (1978): Economic Effects of Metallic Corrosion in the US, NBS Special Publication 511 – 1, Washington DC. Callister, W, D. Jr (1997): Materials Science and Engineering, John Wiley and Sons Inc., New York, P. 426 – 480. DNV Recommended Practice RP B401 (1993): “Cathodic Protection Design”, Det Norske Veritas Industry, AS, Hovik. Fagbayi, K.(2000): “Adverse Effect of Temperature on the Operating- Potential Behaviours of Al-Zn-In Anodes”, Ph D Thesis, UMIST. Gummow, R.A. (2004): Efficiency of High Potential Magnesium Anodes for Cathodically Protecting Iron Water Mains, Materials Performance, May, P. 27-33.  Vol.7, No.2 The Effect of Tin on Aluminum-Zinc-Magnesium Alloys 113 Genesca. J. and Juarez, J. (2000): Development and Testing of Galvanic Anodes for Cathodic Protection, CONTRIBUTIONS TO SCIENCE, 1 (3), P. 331 – 343. Hollingsworth, E. H and Hunsicker N. Y (1987): “Corrosion of Aluminum and Aluminum Alloys”, Metals Handbook, Vol 13, Corrosion, 9th Ed., ASM International, Metals Park, Ohio, p 583. Kilmer, R. J and Stonere, G. E (1991): ‘Light Weight Alloys for Aerospace Applications II, TMS, p 3. Kuznetsov, G. M., Barsukov, A. D, Krivosheeva, G. B and Dieva, E. G(1986): “ A Study of Phase Equilbrium in Al-Zn-Mg Alloys, Akad, Nayk, SSSR Met., 4, 198. Polmear, I.J. (1995): Light Alloys:Metallurgy of the Light Metals, 3rd Ed., Arnold Pub., London. Suarez, M., Rodriguez, F.J., Juarez, J. and Genesca, J. (1999): EIS Testing of an Indium Activated Aluminum Alloy Sacrificial Anode Using DNV RP B401, EUROCORR ’99 Symposium: Marine Corrosion, Dechema, Frankfurt, P. 1 – 9. |