Effect of the Pre-Treatment Severity on the Antioxidant Properties of Ethanol Organosolv Miscanthus x giganteus Lignin 33

Products

Coupling reactions

MeO

LO

2

H+

LO

2

OH

OMe

MeO OMe

O.

LO

2

+

LO

2

LO

2

+

Products

LOOH + LO

2

AIBN + LH + O

2

LO

2

+ LH + O

2

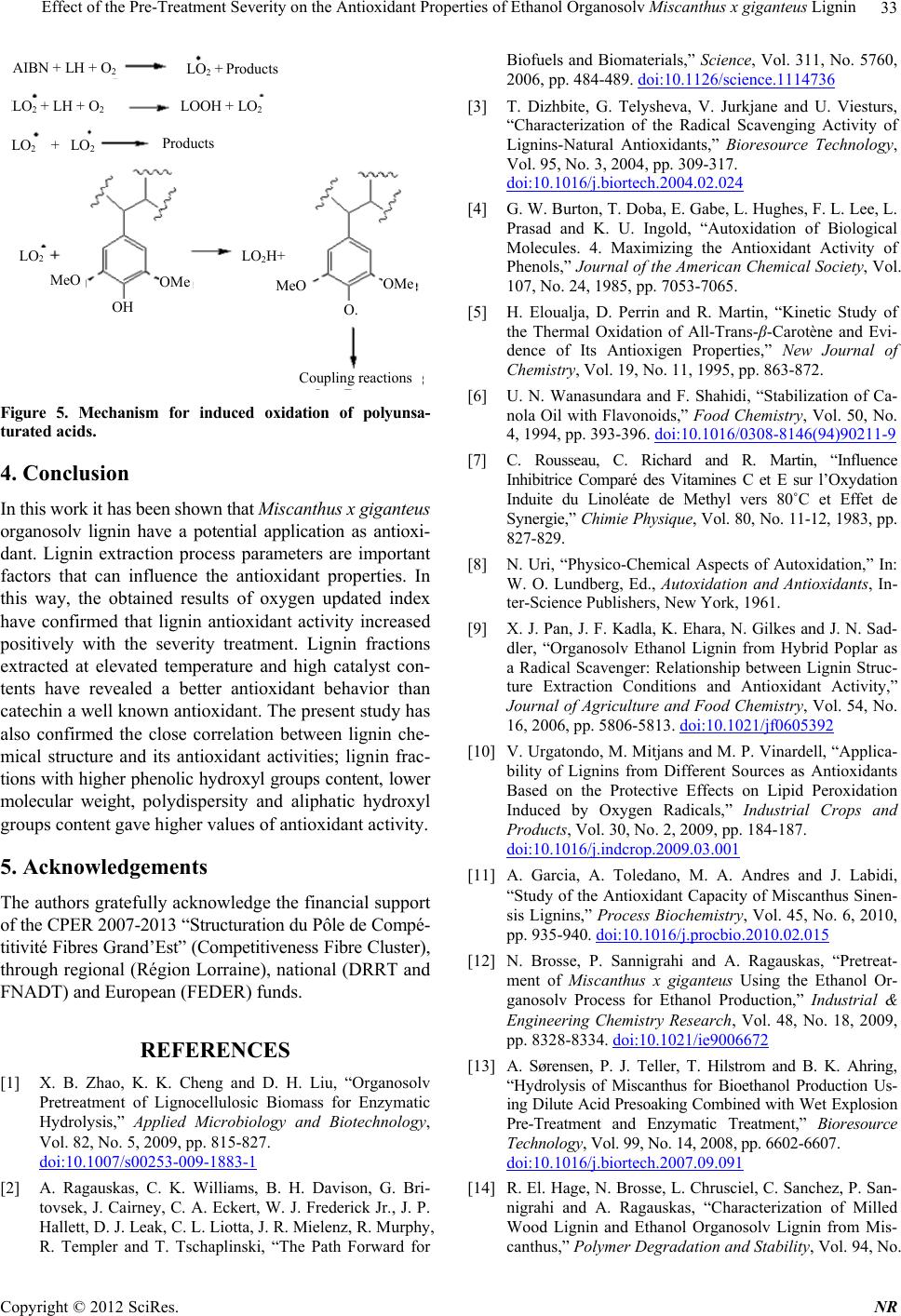

Figure 5. Mechanism for induced oxidation of polyunsa-

turated aci ds.

4. Conclusion

In this work it has been shown that Miscanthus x giganteus

organosolv lignin have a potential application as antioxi-

dant. Lignin extraction process parameters are important

factors that can influence the antioxidant properties. In

this way, the obtained results of oxygen updated index

have confirmed that lignin antioxidant activity increased

positively with the severity treatment. Lignin fractions

extracted at elevated temperature and high catalyst con-

tents have revealed a better antioxidant behavior than

catechin a well known antioxidant. The present study has

also confirmed the close correlation between lignin che-

mical structure and its antioxidant activities; lignin frac-

tions with higher phenolic hydroxyl groups content, lower

molecular weight, polydispersity and aliphatic hydroxyl

groups content gave higher values of antioxidant activity.

5. Acknowledgements

The authors gratefully acknowledge the financial support

of the CPER 2007-2013 “Structuration du Pôle de Compé-

titivité Fibres Grand’Est” (Competitiveness Fibre Cluster),

through regional (Région Lorraine), national (DRRT and

FNADT) and European (FEDER) funds.

REFERENCES

[1] X. B. Zhao, K. K. Cheng and D. H. Liu, “Organosolv

Pretreatment of Lignocellulosic Biomass for Enzymatic

Hydrolysis,” Applied Microbiology and Biotechnology,

Vol. 82, No. 5, 2009, pp. 815-827.

doi:10.1007/s00253-009-1883-1

[2] A. Ragauskas, C. K. Williams, B. H. Davison, G. Bri-

tovsek, J. Cairney, C. A. Eckert, W. J. Frederick Jr., J. P.

Hallett, D. J. Leak, C. L. Liotta, J. R. Mielenz, R. Murphy,

R. Templer and T. Tschaplinski, “The Path Forward for

Biofuels and Biomaterials,” Science, Vol. 311, No. 5760,

2006, pp. 484-489. doi:10.1126/science.1114736

[3] T. Dizhbite, G. Telysheva, V. Jurkjane and U. Viesturs,

“Characterization of the Radical Scavenging Activity of

Lignins-Natural Antioxidants,” Bioresource Technology,

Vol. 95, No. 3, 2004, pp. 309-317.

doi:10.1016/j.biortech.2004.02.024

[4] G. W. Burton, T. Doba, E. Gabe, L. Hughes, F. L. Lee, L.

Prasad and K. U. Ingold, “Autoxidation of Biological

Molecules. 4. Maximizing the Antioxidant Activity of

Phenols,” Journal of the American Chemical Society, Vol.

107, No. 24, 1985, pp. 7053-7065.

[5] H. Eloualja, D. Perrin and R. Martin, “Kinetic Study of

the Thermal Oxidation of All-Trans-β-Carotène and Evi-

dence of Its Antioxigen Properties,” New Journal of

Chemistry, Vol. 19, No. 11, 1995, pp. 863-872.

[6] U. N. Wanasundara and F. Shahidi, “Stabilization of Ca-

nola Oil with Flavonoids,” Food Chemistry, Vol. 50, No.

4, 1994, pp. 393-396. doi:10.1016/0308-8146(94)90211-9

[7] C. Rousseau, C. Richard and R. Martin, “Influence

Inhibitrice Comparé des Vitamines C et E sur l’Oxydation

Induite du Linoléate de Methyl vers 80˚C et Effet de

Synergie,” Chimie Physique, Vol. 80, No. 11-12, 1983, pp.

827-829.

[8] N. Uri, “Physico-Chemical Aspects of Autoxidation,” In:

W. O. Lundberg, Ed., Autoxidation and Antioxidants, In-

ter-Science Publishers, New York, 1961.

[9] X. J. Pan, J. F. Kadla, K. Ehara, N. Gilkes and J. N. Sad-

dler, “Organosolv Ethanol Lignin from Hybrid Poplar as

a Radical Scavenger: Relationship between Lignin Struc-

ture Extraction Conditions and Antioxidant Activity,”

Journal of Agriculture and Food Chemistry, Vol. 54, No.

16, 2006, pp. 5806-5813. doi:10.1021/jf0605392

[10] V. Urgatondo, M. Mitjans and M. P. Vinardell, “Applica-

bility of Lignins from Different Sources as Antioxidants

Based on the Protective Effects on Lipid Peroxidation

Induced by Oxygen Radicals,” Industrial Crops and

Products, Vol. 30, No. 2, 2009, pp. 184-187.

doi:10.1016/j.indcrop.2009.03.001

[11] A. Garcia, A. Toledano, M. A. Andres and J. Labidi,

“Study of the Antioxidant Capacity of Miscanthus Sinen-

sis Lignins,” Process Biochemistry, Vol. 45, No. 6, 2010,

pp. 935-940. doi:10.1016/j.procbio.2010.02.015

[12] N. Brosse, P. Sannigrahi and A. Ragauskas, “Pretreat-

ment of Miscanthus x giganteus Using the Ethanol Or-

ganosolv Process for Ethanol Production,” Industrial &

Engineering Chemistry Research, Vol. 48, No. 18, 2009,

pp. 8328-8334. doi:10.1021/ie9006672

[13] A. Sørensen, P. J. Teller, T. Hilstrom and B. K. Ahring,

“Hydrolysis of Miscanthus for Bioethanol Production Us-

ing Dilute Acid Presoaking Combined with Wet Explosion

Pre-Treatment and Enzymatic Treatment,” Bioresource

Technology, Vol. 99, No. 14, 2008, pp. 6602-6607.

doi:10.1016/j.biortech.2007.09.091

[14] R. El. Hage, N. Brosse, L. Chrusciel, C. Sanchez, P. San-

nigrahi and A. Ragauskas, “Characterization of Milled

Wood Lignin and Ethanol Organosolv Lignin from Mis-

canthus,” Polymer Degradation and Stability, Vol. 94, No.

Copyright © 2012 SciRes. NR