Experimental Study of a Solar Adsorption Refrigeration Unit, Factorial Analysis

Copyright © 2012 SciRes. SGRE

132

REFERENCES

[1] J. A. Edmonds, D. L. Wuebles and M. J. Scott, “Energy

and Radiative Precursor Emissions,” International Con-

ference on Alternative Energy Sources, Miami, 14-16 De-

cember 1987.

[2] F. Zigler, “Recent Development and Future Prospects of

Sorption Heat Pump Systems,” International Journal of

Thermals, Vol. 38, No. 3, 1999, pp. 191-208.

doi:10.1016/S1290-0729(99)80083-0

[3] E. B. Miller “The Development of Silica Gel Refrigera-

tion,” Refrigeration Engineering, Vol. 17, No. 4, 1929, pp.

103-108.

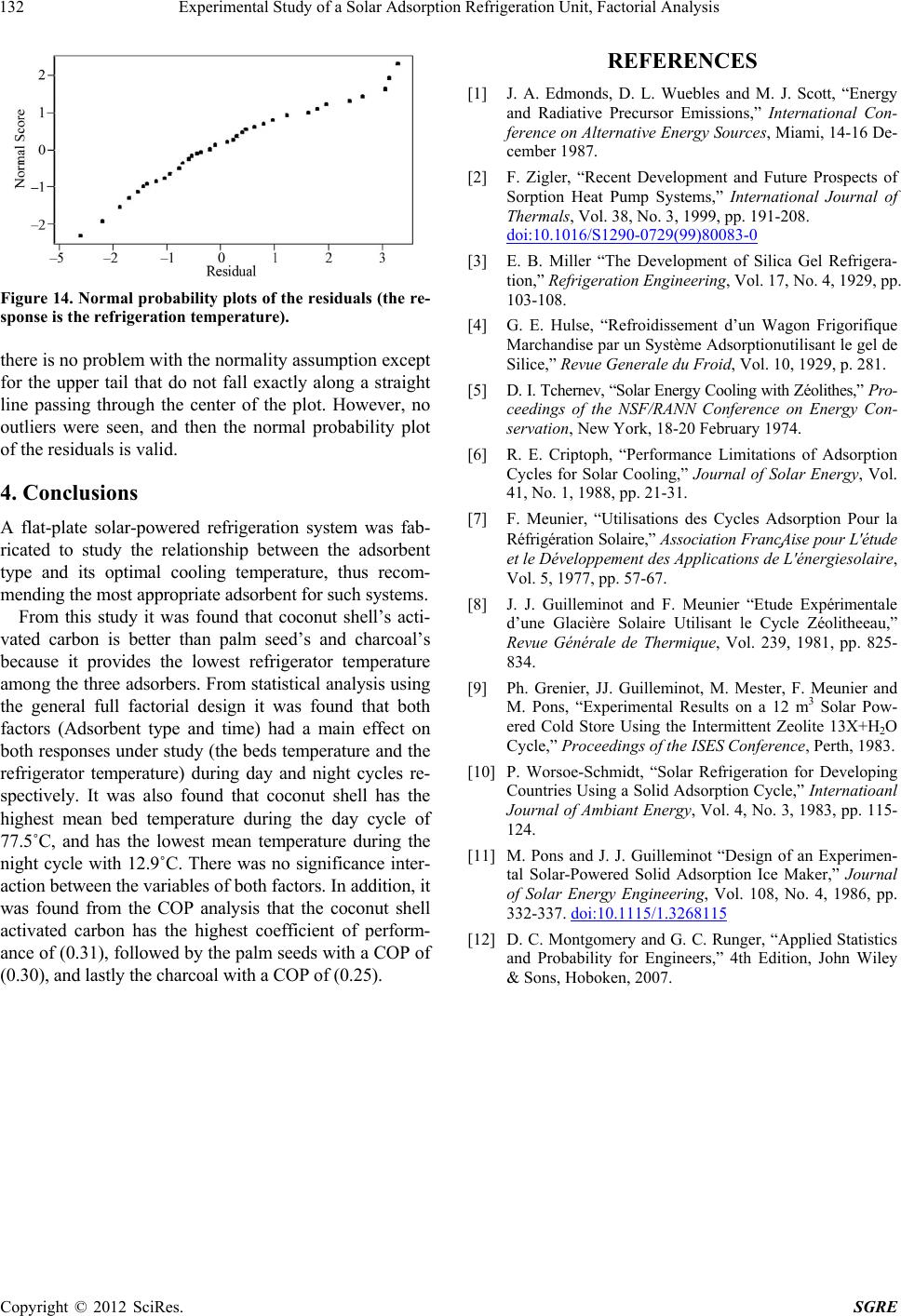

Figure 14. Normal probability plots of the residuals (the re-

sponse is the refrigeration temperature). [4] G. E. Hulse, “Refroidissement d’un Wagon Frigorifique

Marchandise par un Système Adsorptionutilisant le gel de

Silice,” Revue Generale du Froid, Vol. 10, 1929, p. 281.

there is no problem with the normality assumption except

for the upper tail that do not fall exactly along a straight

line passing through the center of the plot. However, no

outliers were seen, and then the normal probability plot

of the residuals is valid.

[5] D. I. Tchernev, “Solar Energy Cooling with Zéolithes,” Pro-

ceedings of the NSF/RANN Conference on Energy Con-

servation, New York, 18-20 February 1974.

[6] R. E. Criptoph, “Performance Limitations of Adsorption

Cycles for Solar Cooling,” Journal of Solar Energy, Vol.

41, No. 1, 1988, pp. 21-31.

4. Conclusions

[7] F. Meunier, “Utilisations des Cycles Adsorption Pour la

Réfrigération Solaire,” Association Franc

̧

Aise pour L'étude

et le Développement des Applications de L'énergiesolaire,

Vol. 5, 1977, pp. 57-67.

A flat-plate solar-powered refrigeration system was fab-

ricated to study the relationship between the adsorbent

type and its optimal cooling temperature, thus recom-

mending the most appropriate adsorbent for such systems. [8] J. J. Guilleminot and F. Meunier “Etude Expérimentale

d’une Glacière Solaire Utilisant le Cycle Zéolitheeau,”

Revue Générale de Thermique, Vol. 239, 1981, pp. 825-

834.

From this study it was found that coconut shell’s acti-

vated carbon is better than palm seed’s and charcoal’s

because it provides the lowest refrigerator temperature

among the three adsorbers. From statistical analysis using

the general full factorial design it was found that both

factors (Adsorbent type and time) had a main effect on

both responses under study (the beds temperature and the

refrigerator temperature) during day and night cycles re-

spectively. It was also found that coconut shell has the

highest mean bed temperature during the day cycle of

77.5˚C, and has the lowest mean temperature during the

night cycle with 12.9˚C. There was no significance inter-

action between the variables of both factors. In addition, it

was found from the COP analysis that the coconut shell

activated carbon has the highest coefficient of perform-

ance of (0.31), followed by the palm seeds with a COP of

[9] Ph. Grenier, JJ. Guilleminot, M. Mester, F. Meunier and

M. Pons, “Experimental Results on a 12 m3 Solar Pow-

ered Cold Store Using the Intermittent Zeolite 13X+H2O

Cycle,” Proceedings of the ISES Conference, Perth, 1983.

[10] P. Worsoe-Schmidt, “Solar Refrigeration for Developing

Countries Using a Solid Adsorption Cycle,” Internatioanl

Journal of Ambiant Energy, Vol. 4, No. 3, 1983, pp. 115-

124.

[11] M. Pons and J. J. Guilleminot “Design of an Experimen-

tal Solar-Powered Solid Adsorption Ice Maker,” Journal

of Solar Energy Engineering, Vol. 108, No. 4, 1986, pp.

332-337. doi:10.1115/1.3268115

[12] D. C. Montgomery and G. C. Runger, “Applied Statistics

and Probability for Engineers,” 4th Edition, John Wiley

& Sons, Hoboken, 2007.

(0.30), and lastly the charcoal with a COP of (0.25).