Paper Menu >>

Journal Menu >>

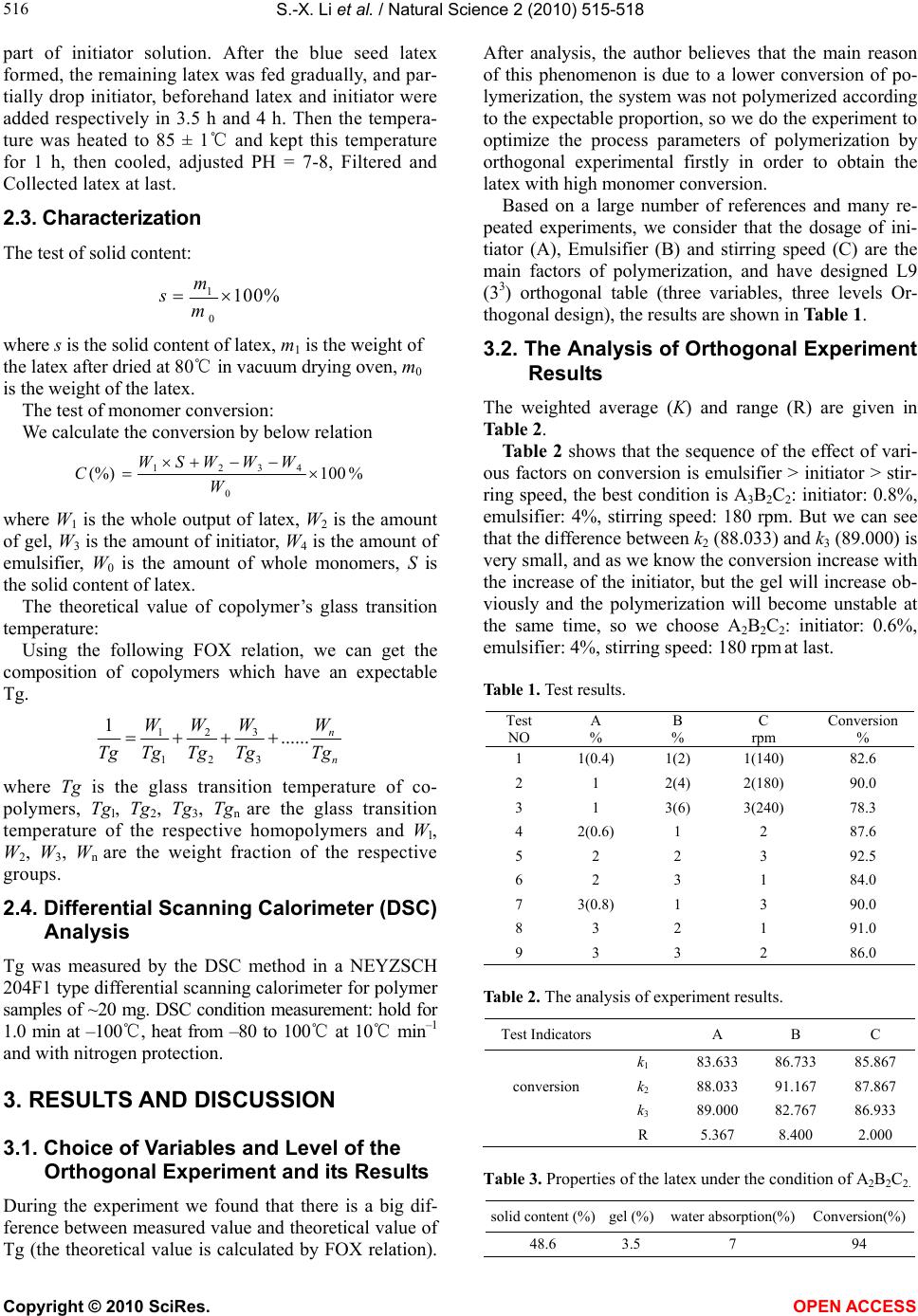

Vol.2, No.5, 515-518 (2010) Natural Science http://dx.doi.org/10.4236/ns.2010.25064 Copyright © 2010 SciRes. OPEN ACCESS Effect of latex conversion on glass transition temperature Shao-Xiang Li1, Ying-Dong Guan1*, Lu-Mei Liu2 1Department of Micropolymer Materials of Science and Engineering, Qingdao University of Science & Technology, Qingdao, China; *Corresponding Author: gyd821123@126.com 2Department of Materials Science and Engineering, Qingdao University of Science & Technology, Qingdao, China Received 29 January 2010; revised 1 March 2010; accepted 25 March 2010. ABSTRACT We have synthesized styrene-acrylic latex and investigated the effect of such reaction condi- tions as the dosage of initiator, surfactant and stirring speed on monomer conversion and glass transition temperature (Tg) of polymer by means of orthogonal experiment, then we get the best reaction conditions. Test results prove that the glass transition temperature of the polymer is directly related to the monomer con- version. The improvement of monomer conver- sion can make the glass transition temperature close to the theoretical value. In the case of high final conversion, we can predict the glass tran- sition temperature of the polymers of different composition according to the theoretical rela- tion effectively. Keywords: Monomer Conversion; Orthogonal Experiment; Glass Transition Temperature 1. INTRODUCTION Styrene-acrylic latex is made of styrene and acrylate monomers, which has many advantages. For example, it has wide source of raw materials, high function/price ratio, simple synthetic process and the latex has out- standing water resistance, alkali resistance, scrub re- sistance and also the paint film has good outdoor du- rable, adhesive attraction. So the styrene-acrylic latex has been widely used in building coating, metal sur- face coating and so on. Many researchers [1-5] have studied styrene-acrylic latex. Climates are usually di- verse across countries, even in one country. Therefore, a single recipe cannot satisfy different needs in the different climate. In order to adapt to different envi- ronment, especially the temperature environment, it requires the minimum film-forming temperature can not only has an unchangeable temperature. Scholars in this area had focused mostly on performance optimi- zation but ignored the investigation of minimum film- forming temperature. In fact, there is a big difference between actual minimum film-forming temperature and theoretical minimum film-forming temperature, which brings polymer designers difficulties in pre- dicting glass transition temperature and designing the hardness of the polymer, at the same time, brings users a lot of inconvenience in use. There are many reasons for the difference between actual minimum film- forming temperature and theoretical minimum film- forming temperature, one of the most important is the monomer conversion. Due to the minimum film- forming temperature has a good corresponding relation with the glass-transition temperature [6], so this paper mainly investigates the glass-transition temperature by means of optimizing the latex’s polymerization condi- tions. We obtain latex with high conversion, thus we can solve the above problems in polymerization tech- nology aspect and obtain the latex recipe of different glass transition temperature under the guidance of the theoretical relation. 2. EXPERIMENTAL 2.1. Materials Butyl acrylate (BA, 96%), Styrene (St, 97%), Methyl Methacrylate (MAA, 96%) and Diacetone acryl amide (DAAM) were purchased from Qingdao Reagent Com- pany. The anionic surfactant sodium dodecyl sulfate (SDS), nonionic surfactant nonylphenol polyoxyethyl- ene ether (OP-10) and ammonium persulfate (APS) were purchased from Qingdao Chemistry Reagent Company. All materials were used without further puri- fication. 2.2. Preparation of Styrene-Acrylic Latex All emulsifier and deionized water were feeded into four-necked flask and stirred at high speed first, then feed monomer mixtures slowly to obtain the before- hand latex. Take part of beforehand latex for seed latex, when temperature was wormed up to 75 ± 1℃, feed  S.-X. Li et al. / Natural Science 2 (2010) 515-518 Copyright © 2010 SciRes. OPEN ACCESS 516 part of initiator solution. After the blue seed latex formed, the remaining latex was fed gradually, and par- tially drop initiator, beforehand latex and initiator were added respectively in 3.5 h and 4 h. Then the tempera- ture was heated to 85 ± 1 a℃nd kept this temperature for 1 h, then cooled, adjusted PH = 7-8, Filtered and Collected latex at last. 2.3. Characterization The test of solid content: 1 0 100% m sm where s is the solid content of latex, m1 is the weight of the latex after dried at 80 in vacuum drying oven, ℃ m0 is the weight of the latex. The test of monomer conversion: We calculate the conversion by below relation %100(%) 0 4321 W WWWSW C where W1 is the whole output of latex, W2 is the amount of gel, W3 is the amount of initiator, W4 is the amount of emulsifier, W 0 is the amount of whole monomers, S is the solid content of latex. The theoretical value of copolymer’s glass transition temperature: Using the following FOX relation, we can get the composition of copolymers which have an expectable Tg. 3 12 123 1...... n n WW WW Tg TgTgTgTg where Tg is the glass transition temperature of co- polymers, Tgl, Tg2, Tg3, Tgn are the glass transition temperature of the respective homopolymers and Wl, W2, W3, Wn are the weight fraction of the respective groups. 2.4. Differential Scanning Calorimeter (DSC) Analysis Tg was measured by the DSC method in a NEYZSCH 204F1 type differential scanning calorimeter for polymer samples of ~20 mg. DSC condition measurement: hold for 1.0 min at –100, heat from ℃–80 to 100 at 10 min℃℃ –1 and with nitrogen protection. 3. RESULTS AND DISCUSSION 3.1. Choice of Variables and Level of the Orthogonal Experiment and its Results During the experiment we found that there is a big dif- ference between measured value and theoretical value of Tg (the theoretical value is calculated by FOX relation). After analysis, the author believes that the main reason of this phenomenon is due to a lower conversion of po- lymerization, the system was not polymerized according to the expectable proportion, so we do the experiment to optimize the process parameters of polymerization by orthogonal experimental firstly in order to obtain the latex with high monomer conversion. Based on a large number of references and many re- peated experiments, we consider that the dosage of ini- tiator (A), Emulsifier (B) and stirring speed (C) are the main factors of polymerization, and have designed L9 (33) orthogonal table (three variables, three levels Or- thogonal design), the results are shown in Table 1. 3.2. The Analysis of Orthogonal Experiment Results The weighted average (K) and range (R) are given in Table 2. Table 2 shows that the sequence of the effect of vari- ous factors on conversion is emulsifier > initiator > stir- ring speed, the best condition is A3B2C2: initiator: 0.8%, emulsifier: 4%, stirring speed: 180 rpm. But we can see that the difference between k2 (88.033) and k3 (89.000) is very small, and as we know the conversion increase with the increase of the initiator, but the gel will increase ob- viously and the polymerization will become unstable at the same time, so we choose A2B2C2: initiator: 0.6%, emulsifier: 4%, stirring speed: 180 rpm at last. Table 1. Test results. Test NO A % B % C rpm Conversion % 1 1(0.4) 1(2) 1(140) 82.6 2 1 2(4) 2(180) 90.0 3 1 3(6) 3(240) 78.3 4 2(0.6) 1 2 87.6 5 2 2 3 92.5 6 2 3 1 84.0 7 3(0.8) 1 3 90.0 8 3 2 1 91.0 9 3 3 2 86.0 Table 2. The analysis of experiment results. Test Indicators A B C k1 83.633 86.733 85.867 conversion k2 88.033 91.167 87.867 k3 89.000 82.767 86.933 R 5.367 8.400 2.000 Table 3. Properties of the latex under the condition of A2B2C2. solid content (%)gel (%)water absorption(%) Conversion(%) 48.6 3.5 7 94  S.-X. Li et al. / Natural Science 2 (2010) 515-518 Copyright © 2010 SciRes. OPEN ACCESS 517 517 As shown in Tables 1 an d 2, the final conversion can reach 94% under the condition of A2B2C2 and it is higher than the others, in addition, some other properties are ideal too. 3.3. DSC Test Analysis In this paper, the initial composition of monomer is BA: MMA:St = 33:19:18, the theoretical value of Tg which is calculated by FOX relation is 8. But when we adopt the ℃ flowing factor: initiator: 0.6%, emulsifier: 4%, speed: 180 rpm, the final conversion reaches 94% and the meas- ured value of Tg achieved by DSC test is 9.8℃ (Figure 1), the difference between them is small. That is to say at the condition of high conversion, the measured value of Tg is very close to its theoretical value and so we can design the hardness of copolymers according FOX relation. 3.4. The Relationship of Monomer Conversion and Glass Transition Temperature Figure 2 shows us the relation between Tg and mono- mer conversion (BA:MMA:St = 33:19:18) and we can -80-60-40-200 20406080100120 0.00 0.05 0.10 0.15 0.20 0.25 0.30 Glass Transition: Mid: 9.8℃ DSC /(mW/mg) Temperature /℃ Figure 1. DSC curve of Styrene-acrylic latex (BA:MMA:St = 33:19:18). 82 84 86 88 90 92 94 8 10 12 14 16 18 20 Tg /℃ Monomer conversion /% Figure 2. The relation between Tg and monomer conversion. see from it that with the increase of the monomer con- version, the glass transition temperature of the latex de- crease gradually, when the final conversion is over 90%, Tg reaches a plateau and the value is about 10.0. ℃ The mainly reason is that during the radical copolymerization, when the final conversion is low, the monomer with a strong conjugacy is easier to polymerize than the others, styrene is such a hard monomer and the glass transition temperature of its homopolymer is 105, so the Tg ℃of copolymer will be a little higher than usual; on the con- trary, when the final conversion is high, the system is able to polymerize according to the expectable propor- tion, the measured value and theoretical value of Tg match very well. However, the conversion of polymeri- zation can not reach 100%. In addition, Tg will increase because of the hydrogen bonds formed between the Components [7]. Some references [8-11] introduce that some additives and functional monomers will have a certain impact on glass transition temperature, therefore, there will be a difference between measured and ex- pected value of Tg inevitably. 3.5. The Latex Recipe of Different Tg In this paper, the total mass of the monomer is fixed at 70 g and the ratio of two hard monomer (St and MMA) will not change at about 1:1, we changes the proportion of soft and hard monomer only. Table 4 shows the latex recipe with different Tg which are obtained at the condi- tion of A2B2C2. Table 4 shows that when the final conversion is at a high level, the measured value and theoretical value of Tg matches very well, thus researcher can be able to forecast the Tg of polymer according to the proportion monomers. 4. CONCLUSIONS 1) The results of the orthogonal experimental shows that emulsifier > initiator > stirring speed in terms of their effects on conversion. And we get the best condition: emulsifier 4%, initiator 0.6%, stirring speed 180 rpm. Table 4. Latex recipe with different Tg. BA(g) MMA(g)St(g) theoretical value of Tg measured value of Tg 1# 48 11 11 –20.0℃ –18.3℃ 2# 43 14 13 –10.0℃ –9.3℃ 3# 38 16 16 –3.0℃ –2.2℃ 4# 33 19 18 7.8℃ 9.8℃ 5# 28 21 21 20.0℃ 20.4℃ 6# 26 22 22 24.0℃ 25.2℃ 7# 24 23 23 30.0℃ 32.7℃ 8# 20 25 25 40.0℃ 42.7℃ 9# 17 27 26 45.0℃ 46.9℃  S.-X. Li et al. / Natural Science 2 (2010) 515-518 Copyright © 2010 SciRes. OPEN ACCESS 518 2) There is a direct relationship between conversion and glass transition temperature, the improvement of the final conversion has made the measured value close to the theoretical value. 3) At the condition of high conversion, the measured value and theoretical value of Tg matches very well. REFERENCES [1] Yu, Y.B. and Zhang, Y.H. (1996) Studying progress on styrene-acrylate emulsion polymerization[J]. Chemical Industry and Engineering Progress, 2, 36-39. [2] Wang, W.F., Li, S.X. and Liu, L.M. (2007) Preparation of low VOC waterborne epoxy-acrylate hybrid emulsion for wood coating [J]. Coating Industry, 37(11), 30-33. [3] Pan, G.R., Wu, L.M. and Zhang, Z.Q. (2002) Synthesis and characterization of epoxy-acrylate composite latex [J]. Journal of Applied Polymer Science, 83(8), 1736-1743. [4] Chen, C.F., Lee, K.H. and Chiu, W.Y. (2007) Synthesis and characterization of poly (butyl acrylate-methyl me- thacrylate)/polyaniline core-shell latexes [J]. Journal of Applied Polymer Science, 104(2), 823-830. [5] Joensson, J.L., Hassander, H. and Jansson, L.H. (1991) Morphology of two-phase polystyrene/poly (methyl methacrylate) latex particles prepared under different polymerization conditions [J]. Macromolecules, 24(1), 126-131. [6] Chen, R. (2007) Minimum temperature and polymer glass-transition temperatures [J]. Chemical Industry of Acrylic and Application, 20(1), 17-19. [7] Gómez-Carracedo, A. and Alvarez-Lorenzo, C. (2003) Chemical structure and glass transition temperature of non-ionic cellulose ethers DSC, TMDSC [J]. Journal of Thermal Analysis and Calorimetry, 73(2), 587-596. [8] Luo, H. and Wei, Z.G. (1997) Study on Tg of acrylic emulsion copolymer [J]. Fine Chemicals, 69, 42-45. [9] Xu, J. and Chen, B. (2005) Prediction of glass transition temperatures of OLED materials using topological indi- ces [J]. Journal of Molecular Modeling, 12(1), 24-33. [10] An, J., Li, X.Y. and Zhu, X.W. (2007) Segment distribut- ing of copolymer form microemulsion copolymerization of styrene and butyl acrylate [J]. Chinese Journal of Colloid & Polymer, 25 (1), 1-2. [11] Wang, C.C. and Bao, Q.Y. (2005) Acrylate coatings [M]. Chemical and Industry Publishing Company, Beijing. |