Food and Nutrition Sciences

Vol. 3 No. 9 (2012) , Article ID: 22307 , 8 pages DOI:10.4236/fns.2012.39174

Chips Production from Jerusalem Artichoke (Helianthus tuberosus L.)

![]()

1Department of Food Engineering of Faculty of Engineering, Middle East Technical University, Ankara, Turkey; 2Department of Food Engineering, Faculty of Agriculture, Selcuk University, Konya, Turkey.

Email: *cembaltacioglu@gmail.com, *bcem@metu.edu.tr

Received July 27th, 2012; revised August 27th, 2012; accepted September 4th, 2012

Keywords: Jerusalem Artichoke; Chips; Frying; Microwave Cooking

ABSTRACT

Jerusalem artichoke has been cultivated in various regions without any special breeding technique. As a food, Jerusalem artichoke has a characteristic flavour and functional ingredients including inulin, other dietary fibers, minerals and traces of polyphenol. The production of chips from Jerusalem artichoke was examined in this study because it contains high amount of inulin. Inulin gives health promoting effects especially for the people suffering from diabetes. Firstly, chips production from Jerusalem artichoke was studied in the scope of properties like moisture, oil, color, texture, sensory. After cleaning, tubers prepared in specified size and slices were cooked in the deep fat fryer or microwave oven. The best results obtained for frying and microwave oven application of Jerusalem artichoke were obtained at 180˚C for 240 s treatment time and at 600 W for 105 s, respectively.

1. Introduction

The Jerusalem artichoke (Helianthus tuberosus L.) is raised irrespective of climate conditions, and its tubers can be produced in world-wide [1]. Jerusalem artichoke tubers contain little or no starch, virtually no fat, and have relatively low calorie. Regarding fat content of Jerusalem artichoke, it has been reported tubers has traces or no monounsaturated and polyunsaturated fatty acids, on the other hand no saturated fatty acids has been declared [2]. In addition to the utilization of tubers as a source of biomass, they are accepted to be a health-promoting food source, especially due in part to inulin content instead of starch [3]. Inulin, a fructose polymer, and its degraded product oligofructose are the major compounds of interest in the food industry owing to being functional food ingredients and low-calorie food materials. Health-promoting effects, such as the prevention of diabetes and anti-carcinoma activities, have been reported [4-6]. Distinctive properties and particular value of inulin is attributed to its nutritional contributions and low-calorie sweetener property [7,8]. This carbohydrate form is also included in diabetic foods, since inulin ingestion slightly influences blood sugar compared to other carbohydrates [4,7]. In the light of these facts, consumption of Jerusalem artichoke in daily diet may provide supportive actions for healthier life for consumers. As a raw material, its consumption is not preferable, and so it is required to be processed to alternative forms, especially similar to the potato products due to similarities in both plant materials. Except for the fact that fried potato products including chips, extruded products etc., have some potential hazards on health depending on the process conditions and materials and nutritional values of final products, these types of commercial items have attracted high interest of consumers. Jerusalem artichoke has the potential to overcome some of the negative aspects of these types of fried products by the advances as a conesquence of compositional and depending structural differences. Frying is a key process to produce fried foods and extra care is required for this kind of applications. Frying is a fast and convenient technique for the production of foods with unique sensory properties of color, flavour, texture, and palatability. Deep-fat frying can be defined as the process of drying and cooking through contact with hot oil [9]. Deep fat frying is a process of simultaneous heat and mass transfer. Heat is transferred from the oil to the food and oil penetrates the crust through the pores created by the evaporation of water from the food. So, fat uptake is largely determined by the moisture content of the food being processed [10-12]. Due to the evaporation, surface drying is observed. The evaporation also leads to shrinkage and crust formation [13]. Microwaves offer tremendous advantages, such as time and energy savings, in food processing operations. In addition, more nutritious products are formed because of shorter time in microwave processes. In microwave heating, the driving forces for heat and mass transfer differ from conventional methods. Absorption of energy from the microwave field results in internal heat generation within product [14]. Microwave heating is greatly affected by the presence of water in foods [15]. Water is the major absorber of microwave energy in the foods and consequently, the higher the moisture content, the faster the heating. The physical state of water in a food affects also microwave heating [16]. Since microwaves penetrate within a food and do not retain just at the surface, heating occurs more rapidly and efficiently. Microwave processing can also be helpful to control energy costs, since heating takes place only in the food material being processed but not in the surrounding medium [17].

In the present study, as a superior alternative of conventional snack food, Jerusalem artichoke was used for chips production owing to its advantages in manufacturing and consumption. Two cooking methods were used for chips production. One of them was the well-known method, frying having favorable influences on color, flavor, texture and palatability. Deep-fat frying is common process for foods, because it imparts a desirable deep-fried flavor that is not developed during other cooking methods. Microwave application was another cooking method for chips production. The main objective of this study was to present chips produced from Jerusalem artichoke tubers as an alternative to the snack foods and by this way, to compare two distinct cooking methods and to figure out the best production technique in terms of process advances and product quality. Meanwhile potential increase in consumption of this plant material might be achieved and utilization of functional properties of Jerusalem artichoke might be possible. It was worth to state that the present article was the first study focusing on the possible alternative usage of Jerusalem artichoke tubers.

2. Materials and Methods

2.1. Slice Preparation

Jerusalem artichoke tubers were provided from the local market and were kept in the refrigerator (4263TMB, Arcelik, Turkey) at +4˚C until experiments were carried out. Raw materials were peeled by a knife and washed under tap water. Washed raw tubers were sliced to get pieces having a thickness of 2 mm and then slices were cooked.

2.2. Frying

Jerusalem artichoke slices were fried in the bench top deep fat fryer (HMT872L, Bosch, Germany) at four temperature levels (160˚C, 170˚C, 180˚C and 190˚C) and three frying times (120 s, 180 s and 240 s). Fryer container was filled with 2.5l sunflower oil (Biryag, Turkey) and four slices were immersed into preheated oil at desired temperature. The oil was not used twice for avoiding possible alterations. Fried sample was taken out from fryer and remaining oil on slice surface was removed by tissue towel. Following the frying, proposed analysis were performed.

2.3. Microwave Cooking

Jerusalem artichoke slices were cooked in the microwave oven (TFB9730, Bosch, Germany) at two power levels, 600 W and 900 W for 60 s, 75 s, 90 s, 105 s, 120 s, 135 s and 150 s. Cooked samples were analyzed, after microwave process.

2.4. Determination of Moisture Content

For moisture content measurement, standard gravimetric method was used. For this purpose, samples were weighed by an electronic balance (EW-1500-2M, Kern, Germany) with a sensitivity of 1/100 g and placed in a Petri dish. The sample was placed in the oven (ST055, Simsek Laborteknik, Turkey) and held there until the constant weight was attained. Moisture content of the sample was calculated using the dry weight [18].

2.5. Determination of Oil Content

The oil content of the fried samples was determined by using Soxhlet extraction method with n-hexane for 6 hours after the Jerusalem artichoke product was dried in the conventional oven [19]. Results were presented in dry basis.

2.6. Measurement of Color

Color values of cooked samples were measured using a Minolta Color Reader (CR-10, Konica Minolta, Japan). The color readings were expressed by CIE (L*, a*, b*) color system. Color readings were carried out at room temperature on three different sections of each sample and the mean value was recorded. The L* value represents “lightness”, from zero (black) to 100 (white). The a* value represents “redness” or “greenness” ranging from +60 to –60 while b* value represents “yellowness” or “blueness” [20].

2.7. Measurement of Texture

Texture measurement of Jerusalem artichoke samples were performed in 60 min after frying, using a Texture Analyzer (TA-XT Plus, Stable Micro System, UK). Three point bend probe was attached to the instrument adjusted to; compression force mode, trigger force of 5.0 g, pre-test speed of 1.0 mm/s, test speed of 5.0 mm/s; post-test speed of 10.0 mm/s and rupture distance of 10 mm. Samples were placed horizontally on the base of the equipment. Hardness of the slices was quantified by measuring force (gforce) required for breaking of fried slices. Deformation distance at fracture (mm) was used to describe fracturability of slices. The final values were obtained by taking the arithmetic mean of three results per sample.

2.8. Sensory Evaluation

Panelists were given training for approximately one hour before the test in the Quantitative Descriptive Analysis [21] including descriptive terms, evaluation techniques, usage of sensory scales, scoring. When the evaluation of sensory tests was performed, roughness, char marks, whiteness and yellow color were studied under the “appearance” title. In the same manner, hardness, crunchiness, fracturability and crispness values fell under the “texture” part. In addition, the assessment of “flavor” was made by examining bitterness, oiliness and sweetness while that of “chewing characteristics” was made by moistness of the mass, roughness of mass and persistence of crisp examination. At last, oil/greasy film were evaluated as “oiliness”.

2.9. Statistical Analysis

All experiments were performed at least in triplicate at each condition, mean values were reported with standard error. Data obtained from the analysis were assessed by analysis of variance (ANOVA) to determine the significant differences between process parameters evaluated in defined ranges in both production methods using MINITAB software (p ≤ 0.05) (MINITAB for Windows, Version 15.0).

3. Results and Discussion

Chips production from Jerusalem artichoke was found to have high potential as an alternative to the current chips present in the food markets. Our results displayed that the Jerusalem artichoke chips produced using two methods, frying and microwave cooking have bright characteristics in terms of quality criteria defined by moisture content, oil, color, texture and sensory analysis.

3.1. Moisture Content

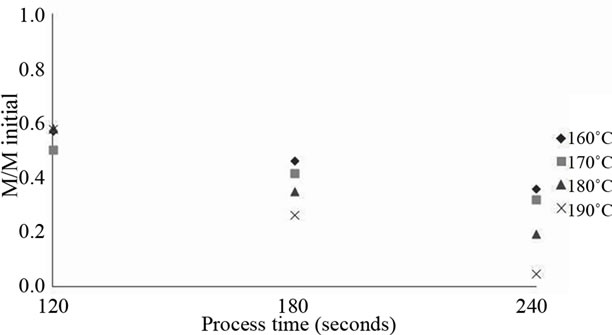

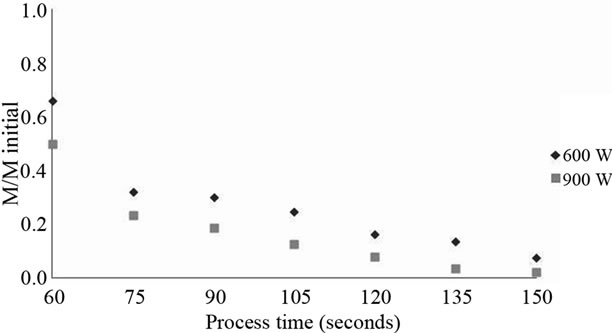

Moisture content of purchased samples was calculated as about 85% (wet basis) of the fresh weight. In the literature initial moisture content of raw Jerusalem artichoke tubers were reported in the range of 78% to 82% [7]. The change of moisture content of fried product was shown in Figure 1(a). Change in moisture content was given as moisture content of samples/initial moisture. During the frying, Jerusalem artichoke slices were immersed into the oil at high temperature values (180˚C - 190˚C) that led to intensive vaporization of the water in the food and transported out through the surface. As water moved out, some part of the pores in the fried material were occupied by the frying oil. Moisture content of slices significantly decreased with increasing of process time and temperature in the frying process (p ≤ 0.05). The slices showed that almost the same amount of moisture removal was achieved in microwave treatment operated at 900 W for 120 s and in frying process carried at 190˚C for 240 s (Figure 1(b)). Statistical analysis of microwave results pointed out power level and process time dependencies of remaining water in cooked slices (p ≤ 0.05). As a consequence, the rate of moisture removal in microwave cooking was higher than that in frying process due to the advance heat transfer in microwave ovens compared to process in frying.

3.2. Oil Content

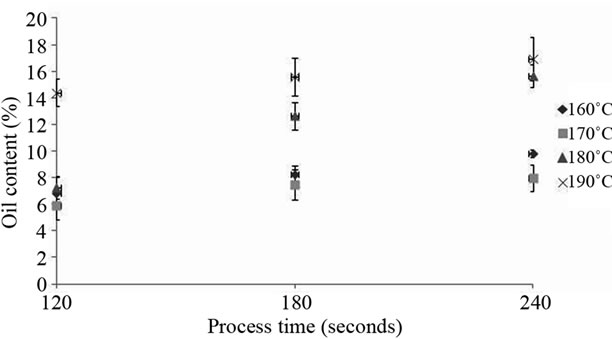

Oil content of Jerusalem artichoke slices were determined after frying process, oil intake of slices increased for the studied treatment at all temperature values, as can be seen from Figure 2. The weight percentages of oil absorbed by slices increased from 6.9% to 9.8% (w/w) within the frying times of 120s to 240s at 160˚C. The oil content of fried Jerusalem artichoke slices was strongly dependent on temperature (p ≤ 0.05), whereas frying time was not a statistically significant process variable (p > 0.05). Oil content is one of the most important quality attributes of a fried product. The texture of a low-oil-content product

(a)

(a) (b)

(b)

Figure 1. Variation of moisture content of Jerusalem artichoke chips ((a) Frying; (b) Microwave cooking).

Figure 2. Oil content of frying Jerusalem artichoke slices.

can be soft and unpleasant. However, the high oil content is not cost efficient for the processor and results in an oily product. After frying of food, a crispy porous structure in addition to flavor and other chemical changes that is desired by the consumer originates. Oil tends to replace water inside the product because the shrinkage of the product during frying is incomplete. In the previous study, [22] observed that an increase in temperature of frying process resulted in higher oil content for the identical process time of frying. [10] and [12] reported that internal oil content of the flat cut crisps increased as the moisture content of the sample decreased. Process temperature had a positive effect on oil content of the Jerusalem artichoke products.

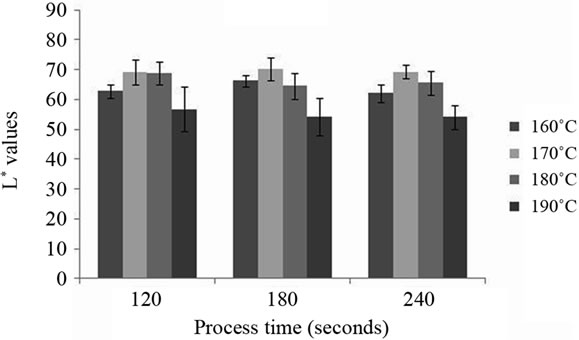

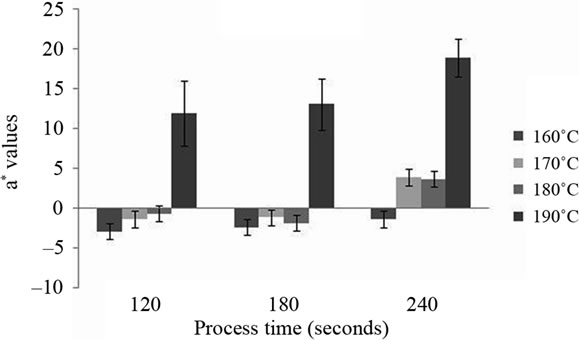

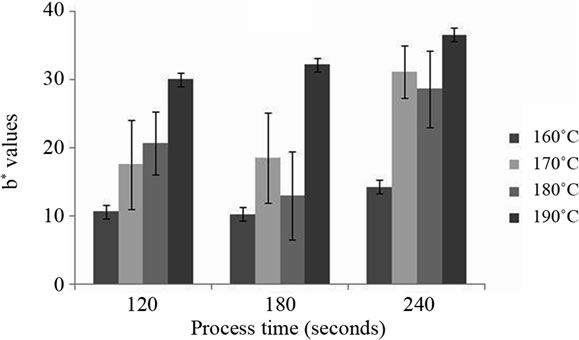

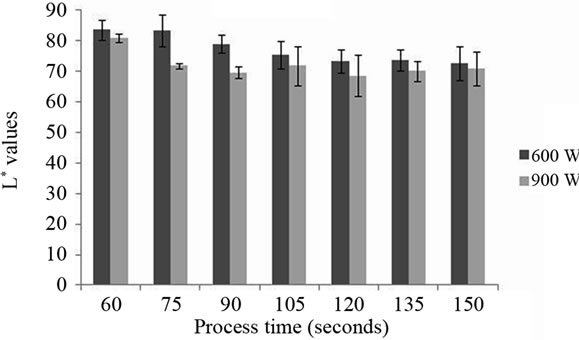

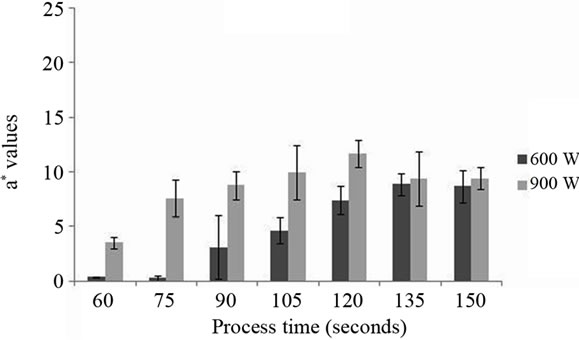

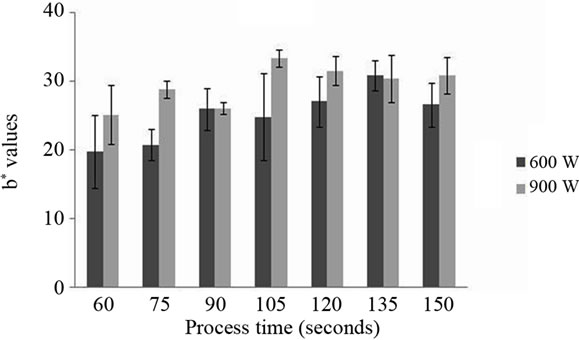

3.3. Color

Color change of the slices of Jerusalem artichoke was evaluated at different temperatures of frying process or power levels of microwave. The effects of time, temperature and power level on color of Jerusalem artichoke products were evaluated by measuring color of slices and results were given in terms of CIE L*, a*, b* values. Increase in temperature from 160˚C to 170˚C resulted in the highest L* values obtained at three different frying times whereas further increase in temperature from 170˚C to 190˚C caused a decrease in L* values (Figure 3(a)). Frying temperature and process time are obtained as significant parameters for L*, a*, b* color values (p ≤ 0.05). A reduction in L* and an increase in a* values of the fried Jerusalem artichoke slices with increasing frying time occurred due to the slices which became darker and redness on the surface enhanced, respectively (Figure 3(b)). Color is an important factor influencing consumer acceptance of a fried product. The producer generally uses the color of a product in order to determine the end of the frying process [23-25] declared that the effect of time and temperature on L* and a* values showed that color changes were confirmed by an increase in parameter a* and the reduction of L* during conventional deep frying. Changing the frying oil temperature from 160˚C to 190˚C resulted with an increase in b* values of the fried chips (Figure 3(c)). In addition, a* and b* values generally showed an increase as frying time increased in accordance with the results of [26]. As expected the lowest a* values were observed at 160˚C (Figure 3(b)). However, as can be seen after 180 s of frying time, a sharp increase in the values of a* seemed to be inevitable especially at temperature level exceeding 160˚C. In general, higher b* values of products give more yellowish color, which is desirable for the fried products. Changing the frying oil temperature from 160˚C to 190˚C resulted in an increase in b* values of the fried slices (Figure 3(c)), but frying at 160˚C and 180˚C for 180 sec caused decrease in b* values compared to processing for 120 s and 240 s. [26] reported that the change in b* values of fried potatoes significantly increased with increasing process temperature. Color values of the microwave treated samples were determined similar to the fried ones. The time of the treatment and power level were found to be significant (p ≤ 0.05) variables affecting the L*, a*, b* values of the slices in the studied time range of 60 s to 150 s. L* values of slices cooked in microwave oven were found to be slightly decreasing by a decrease in power level (Figure 3(d)). Also the trend showed that a* values increased with increasing cooking time up to 120 s after which it remained quite constant (Figure 3(e)). a* values of the microwave cooked samples were lower than that of the fried samples. Cooking time increasing from 60 s to 150 s resulted in an increase in b* values of cooked slices at both power levels (Figure 3(f)) as in deep fat frying. In a previous study, [27] declared a* and b* values of potatoes increased with time in microwave drying process in which is parallel with the results obtained in this study. b* values at 900 W were higher than those at 600 W power level, in addition, b* values of the microwave cooked Jerusalem artichoke slices were higher than those of the fried samples, so color of the microwave cooked samples were close to yellow.

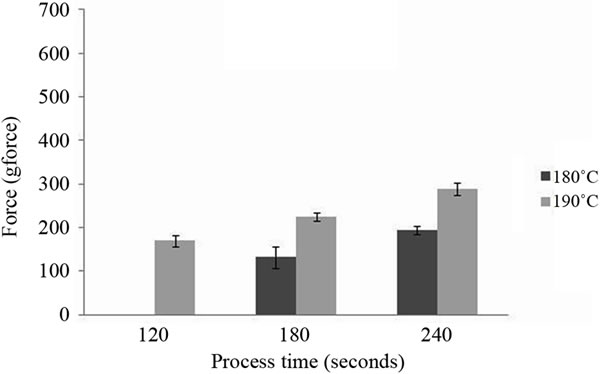

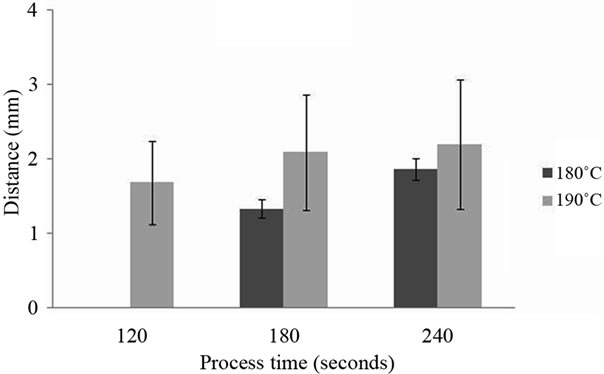

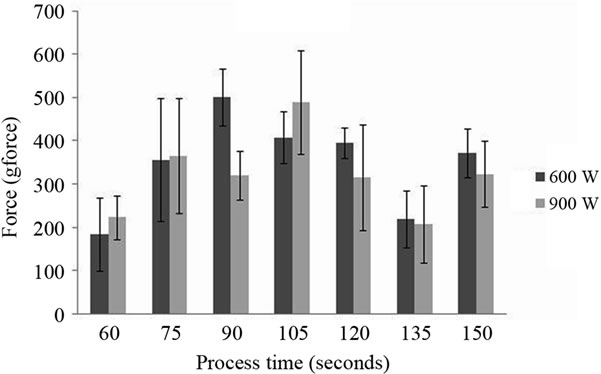

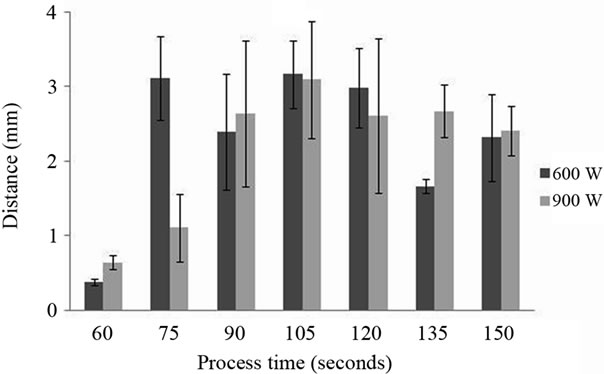

3.4. Texture

Hardness and fracturability of Jerusalem artichoke products were determined for the texture analysis which had an influence on consumer demand. Hardness of slice was quantified by measuring force (gforce) required for breaking the processed slices. Deformation distance at fracture (mm) was used to describe fracturability of the Jerusalem artichoke slices. Firstly, texture profiles of the fried products were evaluated. For fried products, there was no result at 160˚C, 170˚C and 180˚C for 120 s because product does not consist in the form of chips. Therefore, only the fried products at 180˚C and 190˚C could be tested and these tests indicated that at higher temperatures and long processing times, harder slices were produced (Figure 4(a)). Increase in the time of fry-

(a)

(a) (b)

(b) (c)

(c)

(d)

(d) (e)

(e) (f)

(f)

Figure 3. Color values of frying ((a) L* values; (b) a* values; (c) b* values) and microwave cooking ((d) L* values, (e) a* values; (f) b* values ) Jerusalem artichoke chips.

ing from 120 s to 240 s resulted in an increase in the distance values of fracture (Figure 4(b)). Prolonged operation of the cooking time leads to more rigid product. Treatment time and frying temperature were found to be significant (p ˂ 0.05) variables affecting fracturability and hardness of the fried Jerusalem artichoke slices. According to [28] showed frying time significantly affected hardness of potato chips which is parallel to results of fried Jerusalem artichoke slices. Hardness values of the microwave processed slices were given in Figure 4(c) for the products processed at different time-power combinations. The lowest hardness value was observed for the product cooked for 60 s at 600 W. The scatter in the data may be due to the non-uniform energy distribution in the oven. Furthermore, processing at 600 W or 900 W power levels seemed to have no appreciable effect on the hardness (p > 0.05). According to the statistical evaluation, processing time was significantly (p ≤ 0.05) important on the hardness values of the microwaved cooked Jerusalem artichoke slice but the power level was not statistically important (p > 0.05). Hardness values of the fried slices were lower than that of the microwaved cooked products. Low humidity values of the microwave cooked products may be associated with the low hardness values. Deformation distances at fracture of the microwave cooked samples were given in Figure 4(d). The least value of deformation distance was observed for the both power levels for the 60 s processed products. Despite the presence of scatter owing to the reason explained above, it can be said that the fracturability of the 600 W and the 900 W microwave cooked samples were of about the same magnitude and they attain a final value around 2.5 mm. The statistical findings also supported this conclusion.

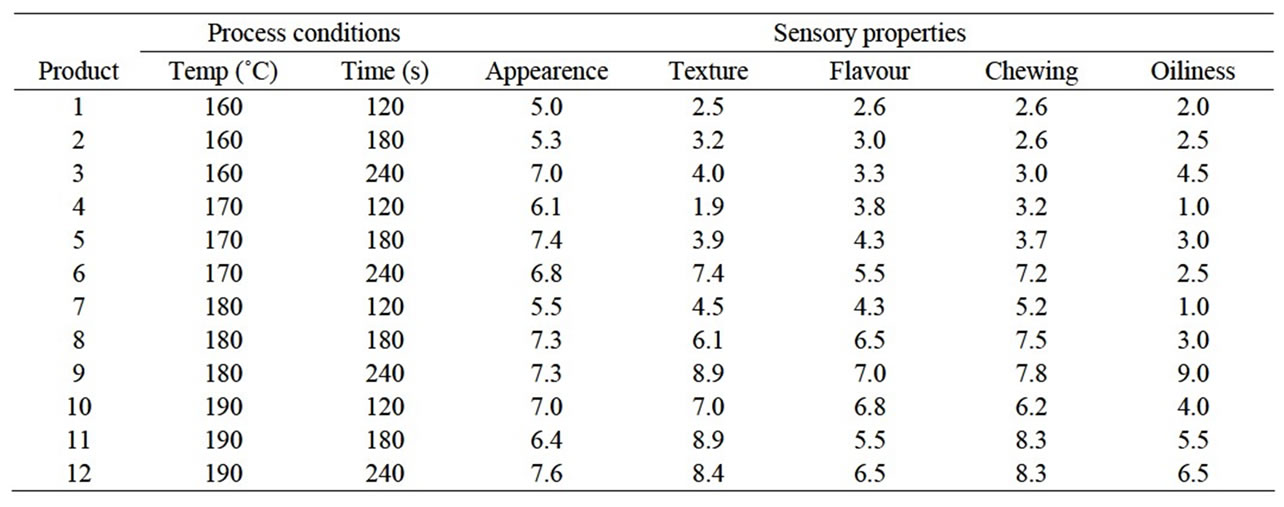

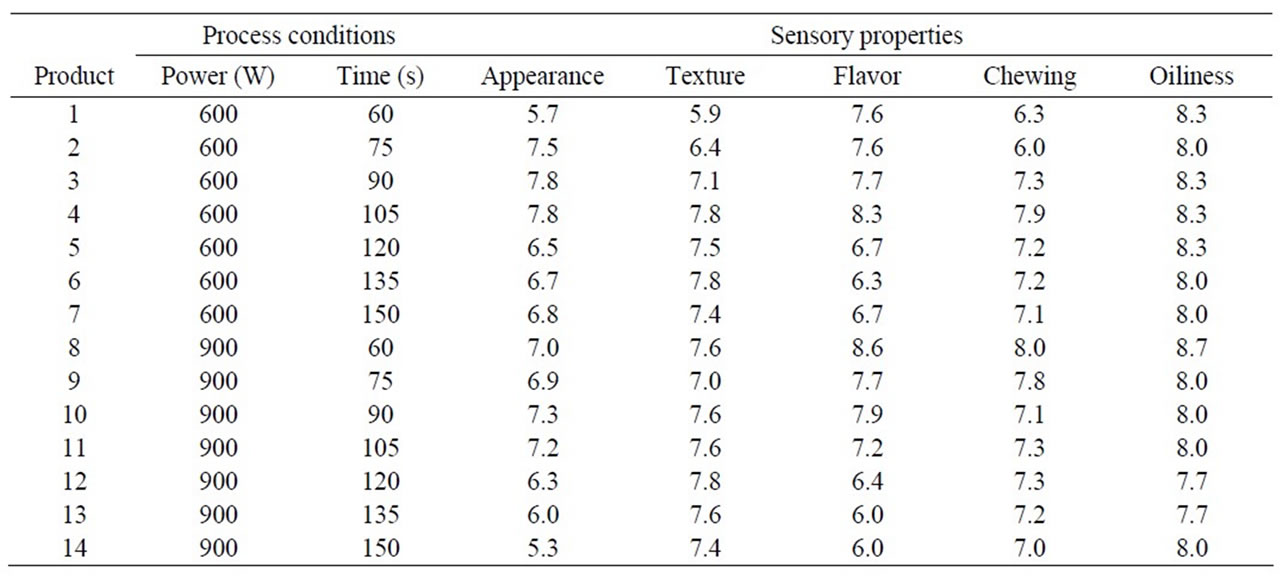

3.5. Sensory Analysis

A descriptive sensory analysis was applied by 15 trained panelists for all of the products. The sensory evaluations were performed according to the ranking test developed for measuring the food acceptability, in which higher score means higher acceptability. Scores of the fried samples were given in Table 1. On the basis of the scores obtained, the highest scores for the appearance and the chewing characteristics belonged to the product 12. On the other hand, product 9 favored (Table 1) in terms of the texture, flavor and oiliness. As an overall evaluation, the results indicated that the products of 9 and 12 ranked at the top of the panelists’ score, being the first and second, respectively (Table 1). Table 2 showed

(a)

(a) (b)

(b) (c)

(c) (d)

(d)

Figure 4. Variation of texture parameters of frying ((a) Hardness; (b) Fracturability) and microwave cooking ((c) Hardness; (d) Fracturability) Jerusalem artichoke chips.

Table 1. Scores for the sensory properties of the fried Jerusalem artichoke chips.

Table 2. Scores for the sensory properties of the microwave cooked Jerusalem artichoke chips.

the sensory properties of microwave cooked Jerusalem artichoke slices. The parameters for the highest scores achieved by the various products were for appearance products 3 and 4, for texture at products 6 and 12, for flavor, chewing characteristics and oiliness product 8 (Table 2). Overall evaluation indicated that product 8 is the most desired one (Table 2).

4. Conclusion

In this study, the use of Jerusalem artichoke for production of diabetic and/or dietary chips-like product was studied using the parameters of frying temperature or microwave power and time of treatment. In the light of the experimental results obtained and their discussion, it can be concluded that Jerusalem artichoke slices can be used to produce low or no calorie, no sugar chips. As future studies, development of new products by using Jerusalem artichoke flour and their shelf-lives is promising. In that respect, Jerusalem artichoke flour may be a healthy alternative or substitute for infant foods and baking products. The physical and chemical properties of this product may be investigated.

REFERENCES

- R. Slimestad, R. Seljasen, K. Meijer and S. L. Skar, “Norwegian-Grown Jerusalem Artichoke (Helianthus tuberosus L.): Morphology and Content of Sugars and Fructo-Oligosaccharides in Stems and Tubers,” Journal of the Science of Food and Agriculture, Vol. 90, 2010, pp. 956-964.

- E. N. Whitney and S. R. Rolfes, “Understanding Nutrition,” 8th Edition, West/Wadsworth, Belmont, 1999.

- S. P. Marx, J. Nosberger and M. Frehner, “Seasonal Variation of Fructan-Bfructosidase (FEH) Activity and Characterization of a b-(2:1)-Linkage Specific FEH from Tubers of Jerusalem Artichoke (Helianthus tuberosus)”, New Phytologist, Vol. 135, No. 2, 1997, pp. 267-277. doi:10.1046/j.1469-8137.1997.00641.x

- N. Kaur and A. K. Gupta, “Applications of Inulin and Oligofructose in Health and Nutrition,” Journal of Biosciences, Vol. 27, No. 7, 2002, pp. 703-714. doi:10.1007/BF02708379

- K. R. Niness, “Inulin and Oligofructose: What Are They?” Journal of Nutrition, Vol. 129, 1999, pp. 1402-1406.

- L. Pan, M. R. Sinden, A. H. Kennedy, H. Chai, L. E. Watson and T. L. Graham, “Bioactive Constituents of Helianthus tuberosus (Jerusalem Artichoke),” Phytochemistry Letters, Vol. 2, 2009, pp. 15-18. doi:10.1016/j.phytol.2008.10.003

- S. J. Kays and S. F. Nottingham, “Biology and Chemistry of Jeruslaem Artichoke (Helianthus tuberosus L.),” CRC Press Taylor and Francis Group, Boca Raton, London, 2008.

- B. C. Tungland and D. Meyer, “Non Digestible Oligoand Polysaccharides (Dietary Fiber): Their Physiology and Role in Human Health and Food,” Comprehensive Reviews in Food Science and Food Safety, Vol. 1, 2002, pp. 73-92. doi:10.1111/j.1541-4337.2002.tb00009.x

- S. Sahin, S. K. Sastry and L. Bayindirli, “Heat Transfer during Frying of Potato Slices,” Lebensmittel-Wissenschaft und Technologie, Vol. 32, 1999, pp. 19-24.

- M. H. Gamble, P. Rice and J. D. Selman, “Relationship between Oil Uptake and Moisture Loss during Frying Potato Slices from CV Record UK Tubers,” International Journal of Food Science and Technology, Vol. 22, No. 3, 1987, pp. 233-241. doi:10.1111/j.1365-2621.1987.tb00483.x

- I. S. Saguy and E. J. Pinthus, “Oil Uptake during DeepFat Frying-Factors and Mechanism,” Food Technology, Vol. 49, No. 4, 1995, pp. 142-145.

- C. R. Southern, X. D. Chen, M. M. Farid, B. Howard and L. Eyres, “Determining Internal Oil Uptake and Water Content of Fried Thin Potato Crisps,” Food and Bioproducts Processing, Vol. 78, No. C3, 2000, pp. 119-125. doi:10.1205/096030800532851

- M. Mellema, “Mechanism and Reduction of Fat Uptake in Deep-Fat Fried Foods,” Trends in Food Science and Technology, Vol. 14, No. 9, 2003, pp. 364-373. doi:10.1016/S0924-2244(03)00050-5

- P. O. Risman, “Terminology and Notation of Microwave Power and Electromagnetic Energy,” Journal of Microwave Power and Electromagnetic Energy, Vol. 26, 1991, pp. 243-250.

- S. O. Nelson and A. W. Kraszewski, “Grain Moisture Content Determination by Microwave Measurements,” Transactions of the ASAE, Vol. 33, 1990, pp. 1303-1307.

- R. E. Mudgett, “Microwave Food Processing,” Food Technology, Vol. 43, No. 1, 1989, p. 117.

- J. Giese, “Advances in Microwave Food Processing,” Food Technology, Vol. 46, 1992, pp. 118-123.

- AOAC, “Official Methods of Analysis,” 16th Edition, Association of Official Analytical Chemists, Washington DC, 1995.

- C. S. James, “Analytical Chemistry of Foods,” Blackie Academic and Professional, London, 1995. doi:10.1007/978-1-4615-2165-5

- R. G. McGuire, “Reporting of Objective Colour Measurements,” HortScience, Vol. 27, No. 12, 1992, pp. 1254- 1255.

- M. Meilgraad, G. V. Civille and B. T. Carr, “Sensory Evaluation Techniques,” 2nd Edition, CRC Press, Boca Raton, 1991.

- M. K. Krokida, V. Oreopoulou and Z. B. Maroulis, “Water Loss and Oil Uptake as a Function of Frying Time,” Journal of Food Engineering, Vol. 44, No. 1, 2000, pp. 39-46. doi:10.1016/S0260-8774(99)00163-6

- R. Baixauli, A. Salvador, S. M. Fiszman and C. Calvo, “Effect of Addition of Corn Flour and Colorants on the Color of Fried, Battered Squid Rings,” European Food Research and Technology, Vol. 215, 2002, pp. 457-461. doi:10.1007/s00217-002-0605-z

- B. Innawong, P. Mallikarjunan, J. Marcy and J. Cundiff, “Pressure Conditions and Quality of Chicken Nuggets Fried under Gaseous Nitrogen Atmosphere,” Journal of Food Processing and Preservation, Vol. 30, No. 2, 2006, pp. 231-245. doi:10.1111/j.1745-4549.2006.00061.x

- S. F. Dogan, S. Sahin and G. Sumnu, “Effects of Soy and Rice Flour Addition on Batter Rheology and Quality of Deep-Fat Fried Chicken Nuggets,” Journal of Food Engineering, Vol. 71, No. 1, 2005, pp. 127-132. doi:10.1016/j.jfoodeng.2004.10.028

- M. K. Krokida, V. Oreopoulou, Z. B. Maroulis and D. Marinos-Kouris, “Effect of Osmotic Dehydration Pretreatment on Quality of French Fries,” Journal of Food Engineering, Vol. 49, 2001, pp. 339-345.

- M. K. Krokida and Z. B. Maroulis, “Effect of Microwave Drying on Some Quality Properties of Dehydrated Products,” Drying Technology, Vol. 17, No. 3, 1999, pp. 449- 466. doi:10.1080/07373939908917545

- S. Segnini, P. Dejmek and R. Öste, “Reproducible Texture Analysis of Potato Chips,” Journal of Food Science, Vol. 64, No. 2, 1999, pp. 309-312. doi:10.1111/j.1365-2621.1999.tb15889.x

NOTES

*Corresponding author.