A Model for the Characterization and Selection of Beeswaxes for Use as Base Substitute Tissue in Photon Teletherapy

Copyright © 2012 SciRes. MSA

223

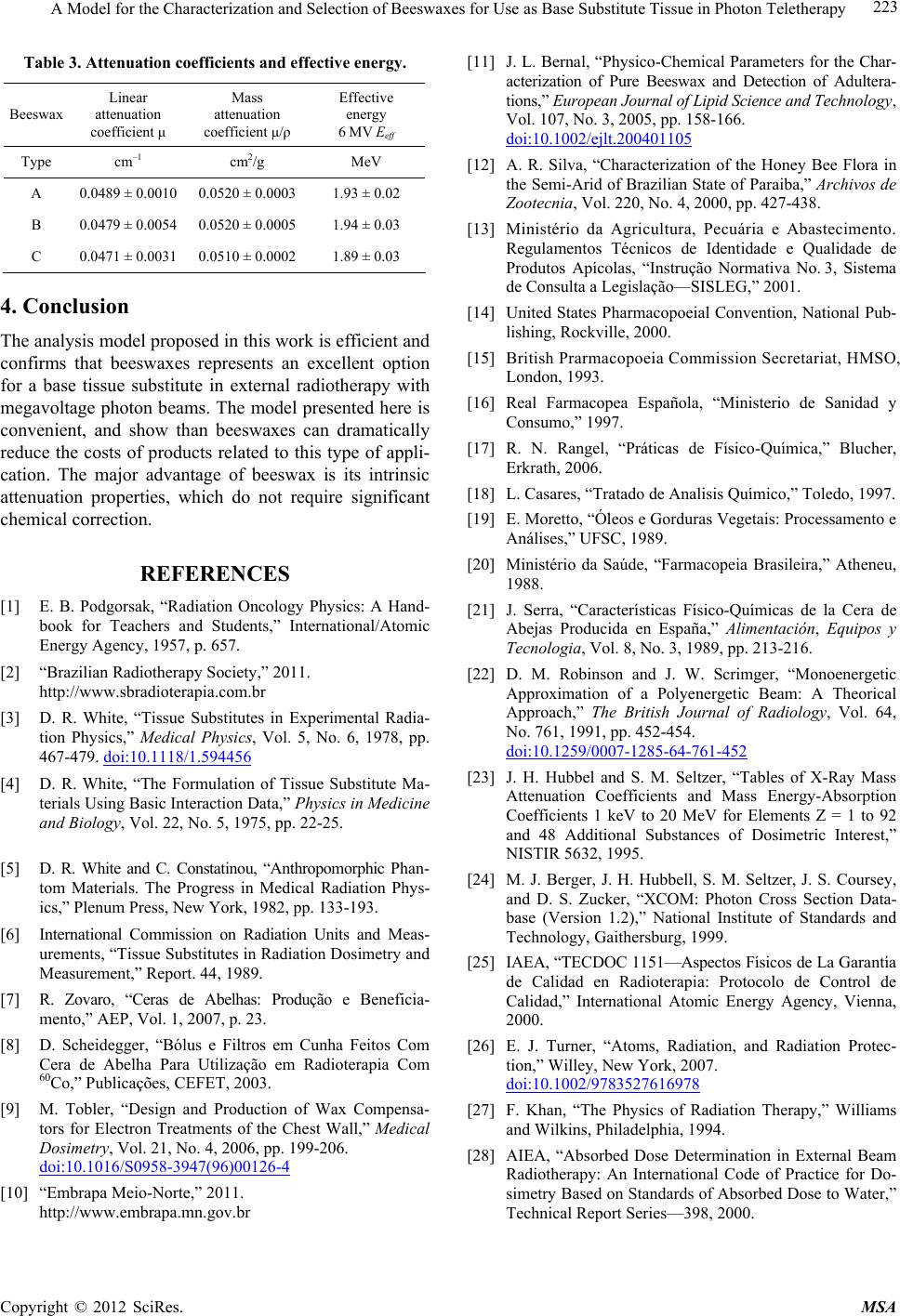

Table 3. Attenuation coefficients and effective energy.

Beeswax

Linear

attenuation

coefficient μ

Mass

attenuation

coefficient μ/ρ

Effective

energy

6 MV Eeff

Type cm–1 cm2/g MeV

A 0.0489 ± 0.0010 0.0520 ± 0.0003 1.93 ± 0.02

B 0.0479 ± 0.0054 0.0520 ± 0.0005 1.94 ± 0.03

C 0.0471 ± 0.0031 0.0510 ± 0.0002 1.89 ± 0.03

4. Conclusion

The analysis model proposed in this work is efficient and

confirms that beeswaxes represents an excellent option

for a base tissue substitute in external radiotherapy with

megavoltage photon beams. The model presented here is

convenient, and show than beeswaxes can dramatically

reduce the costs of products related to this type of appli-

cation. The major advantage of beeswax is its intrinsic

attenuation properties, which do not require significant

chemical correction.

REFERENCES

[1] E. B. Podgorsak, “Radiation Oncology Physics: A Hand-

book for Teachers and Students,” International/Atomic

Energy Agency, 1957, p. 657.

[2] “Brazilian Radiotherapy Society,” 2011.

http://www.sbradioterapia.com.br

[3] D. R. White, “Tissue Substitutes in Experimental Radia-

tion Physics,” Medical Physics, Vol. 5, No. 6, 1978, pp.

467-479. doi:10.1118/1.594456

[4] D. R. White, “The Formulation of Tissue Substitute Ma-

terials Using Basic Interaction Data,” Physics in Medicine

and Biology, Vol. 22, No. 5, 1975, pp. 22-25.

[5] D. R. White and C. Constatinou, “Anthropomorphic Phan-

tom Materials. The Progress in Medical Radiation Phys-

ics,” Plenum Press, New York, 1982, pp. 133-193.

[6] International Commission on Radiation Units and Meas-

urements, “Tissue Substitutes in Radiation Dosimetry and

Measurement,” Report. 44, 1989.

[7] R. Zovaro, “Ceras de Abelhas: Produção e Beneficia-

mento,” AEP, Vol. 1, 2007, p. 23.

[8] D. Scheidegger, “Bólus e Filtros em Cunha Feitos Com

Cera de Abelha Para Utilização em Radioterapia Com

60Co,” Publicações, CEFET, 2003.

[9] M. Tobler, “Design and Production of Wax Compensa-

tors for Electron Treatments of the Chest Wall,” Medical

Dosimetry, Vol. 21, No. 4, 2006, pp. 199-206.

doi:10.1016/S0958-3947(96)00126-4

[10] “Embrapa Meio-Norte,” 2011.

http://www.embrapa.mn.gov.br

[11] J. L. Bernal, “Physico-Chemical Parameters for the Char-

acterization of Pure Beeswax and Detection of Adultera-

tions,” European Journal of Lipid Science and Technology,

Vol. 107, No. 3, 2005, pp. 158-166.

doi:10.1002/ejlt.200401105

[12] A. R. Silva, “Characterization of the Honey Bee Flora in

the Semi-Arid of Brazilian State of Paraiba,” Archivos de

Zootecnia, Vol. 220, No. 4, 2000, pp. 427-438.

[13] Ministério da Agricultura, Pecuária e Abastecimento.

Regulamentos Técnicos de Identidade e Qualidade de

Produtos Apícolas, “Instrução Normativa No. 3, Sistema

de Consulta a Legislação—SISLEG,” 2001.

[14] United States Pharmacopoeial Convention, National Pub-

lishing, Rockville, 2000.

[15] British Prarmacopoeia Commission Secretariat, HMSO,

London, 1993.

[16] Real Farmacopea Española, “Ministerio de Sanidad y

Consumo,” 1997.

[17] R. N. Rangel, “Práticas de Físico-Química,” Blucher,

Erkrath, 2006.

[18] L. Casares, “Tratado de Analisis Químico,” Toledo, 1997.

[19] E. Moretto, “Óleos e Gorduras Vegetais: Processamento e

Análises,” UFSC, 1989.

[20] Ministério da Saúde, “Farmacopeia Brasileira,” Atheneu,

1988.

[21] J. Serra, “Características Físico-Químicas de la Cera de

Abejas Producida en España,” Alimentación, Equipos y

Tecnologia, Vol. 8, No. 3, 1989, pp. 213-216.

[22] D. M. Robinson and J. W. Scrimger, “Monoenergetic

Approximation of a Polyenergetic Beam: A Theorical

Approach,” The British Journal of Radiology, Vol. 64,

No. 761, 1991, pp. 452-454.

doi:10.1259/0007-1285-64-761-452

[23] J. H. Hubbel and S. M. Seltzer, “Tables of X-Ray Mass

Attenuation Coefficients and Mass Energy-Absorption

Coefficients 1 keV to 20 MeV for Elements Z = 1 to 92

and 48 Additional Substances of Dosimetric Interest,”

NISTIR 5632, 1995.

[24] M. J. Berger, J. H. Hubbell, S. M. Seltzer, J. S. Coursey,

and D. S. Zucker, “XCOM: Photon Cross Section Data-

base (Version 1.2),” National Institute of Standards and

Technology, Gaithersburg, 1999.

[25] IAEA, “TECDOC 1151—Aspectos Físicos de La Garantía

de Calidad en Radioterapia: Protocolo de Control de

Calidad,” International Atomic Energy Agency, Vienna,

2000.

[26] E. J. Turner, “Atoms, Radiation, and Radiation Protec-

tion,” Willey, New York, 2007.

doi:10.1002/9783527616978

[27] F. Khan, “The Physics of Radiation Therapy,” Williams

and Wilkins, Philadelphia, 1994.

[28] AIEA, “Absorbed Dose Determination in External Beam

Radiotherapy: An International Code of Practice for Do-

simetry Based on Standards of Absorbed Dose to Water,”

Technical Report Series—398, 2000.