H. K. CHITTE ET AL.

20

adopted was to coat the pre-formed Ag nanoparticles

with the polymers in suspension. The nanocomposites

thus formed were characterized using UV-Vis spectros-

copy (UV-Vis), X-ray diffraction (XRD) and Scanning

electron Microscopy (SEM). The advantages of these

nanocomposites over the control polymer and industrial

applications will be reported in a separate communica-

tion.

2. Experimental

2.1. Preparation of Silver Nanoparticles

AgNO3 was dissolved in double distilled water to give a

solution of 0.001 M solution. Trisodium citrate (0.02 M)

was used as reducing agent. To 100 ml of silver nitrate

solution was added to trisodium citrate solution drop by

drop, over a period of 30 min and maintained at 80˚C.

The stirring was continued for 1 hr. It was found that

solution turns yellow. The yellow colour confirms the

formation of silver nanoparticles [3]. A large quantity of

such solution was made and served as the stock solution

for other e xp erim en t s.

2.2. Coating of Ag Nanoparticles by Polymers

The coating of silver nanoparticle by polypyrrole was

performed by addition of 4 ml of pyrrole to 600 ml of

silver nanoparticle solution. The solution was stirred con-

tinuously during and after addition and it was observed

that the conversion of pyrrole to polypyrrole takes place

within 15 min. However the stirring was continued for

another 1 hr so that the pyrrole fully polymerizes and

coats the Ag nanoparticle evenly. The color of the solu-

tion changes from yellow to steel grey to black. The ob-

tained solution was left in the ambient condition for an-

other 24 hr before the precipitated material was filtered

out and washed.

Polymeric composites of Polyvinyl alcohol and Car-

boxymethyl cellulose were prepared by mixing the aque-

ous solutions of the respective polymers and the colloidal

suspension of pre-formed silver nanoparticles. The solu-

tions of PVA and CMC were made in water using 4% of

powders (w/w) and stirring for one hour at 80˚C. To

these solutions were added the solution of AgNP to get

various compositions containing 1% to 5% of Ag. Thin

films of these solutions were casted on glass plates for

further analysis.

The results described in this paper are for composi-

tions all containing 1% w/w of Ag nanoparticles.

2.3. Methods of Characterization

All the preparations i.e. pure silver nanoparticles and the

composites were characterized by UV-Vis, XRD, SEM

and TEM. For this purpose UV-Vis Spectrometer of Var-

ian make Cary 5000 which could scan from 175 nm to

3300 nm was used. Diluted solution of nanop articles was

filled into the quartz cuv ette to obtain the spectrum. PAN

analytical Xpert pro X-ray diffractometer with Cu tube

was used for recording the XRD pattern. The specimen

in the form of thin coating on glass plate or PET film was

prepa red an d used for s canni ng in th e range of 10˚ to 80˚.

Scanning electron micrographs were obtained using JEOL

SEM model JSM 5400. The samples were mounted on the

stub and coated with a thin film of gold before observa-

tions. Transmission electron micrographs were obtained

by using Philips TEM CM200 operating at voltage of

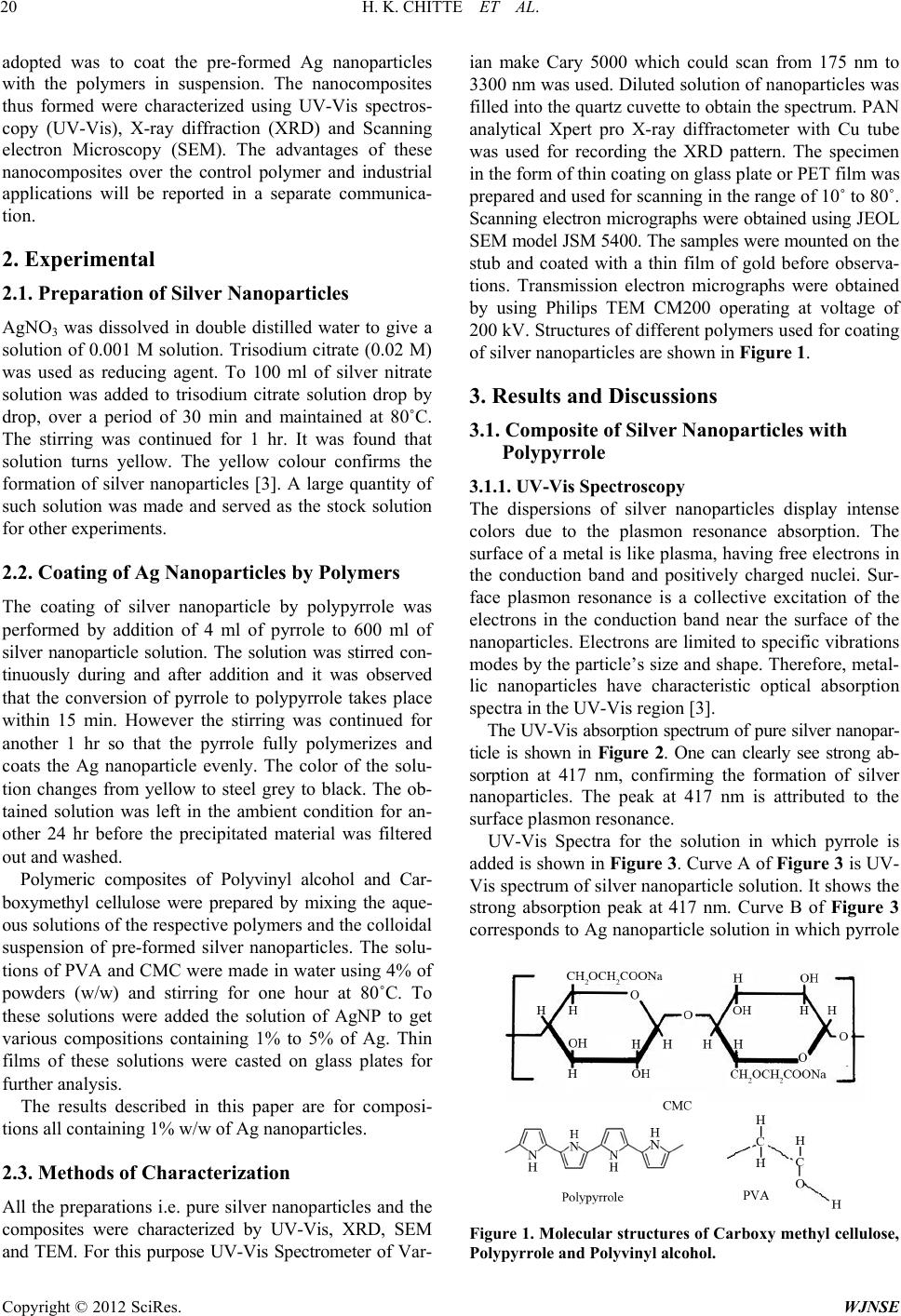

200 kV. Structures of different polymers used for coating

of silver nanoparticles are shown in Figure 1.

3. Results and Discussions

3.1. Composite of Silver Nanoparticles with

Polypyrrole

3.1.1. U V-Vis Spectroscopy

The dispersions of silver nanoparticles display intense

colors due to the plasmon resonance absorption. The

surface of a metal is like plasma, having free electrons in

the conduction band and positively charged nuclei. Sur-

face plasmon resonance is a collective excitation of the

electrons in the conduction band near the surface of the

nanoparticles. Electrons are limited to specific vibrations

modes by the particle’s size and shape. Therefor e, metal-

lic nanoparticles have characteristic optical absorption

spectra in the UV-Vis region [3].

The UV-Vis absorption spectrum of pure silver nanopar-

ticle is shown in Figure 2. One can clearly see strong ab-

sorption at 417 nm, confirming the formation of silver

nanoparticles. The peak at 417 nm is attributed to the

surface plasmon reso nance.

UV-Vis Spectra for the solution in which pyrrole is

added is shown in Figure 3. Curve A of Figure 3 is UV-

Vis spectrum of silver nanoparticle solu tion. It shows the

strong absorption peak at 417 nm. Curve B of Figure 3

corresponds to Ag nanoparticle solution in which pyrro le

Figure 1. Molecular structures of Carboxy methyl cellulose,

Polypyrr o le and Polyvi nyl alcohol.

Copyright © 2012 SciRes. WJNSE