Ferrofluid Actuated Thermal Overload Relay 65

The inertial force here is provided by the action of

gravity when the magnetic property is lost. The sudden

increase in weight causes the base plate to move down-

wards due to gravity. At this condition the weight of the

base plate is more than the restraining force of the spring

(Operating force > Restraining force). Hence, the base

plate pushes the movable contact downwards to short the

fixed contact following which the trip circuit is triggered.

The trip circuit eventually disconnects the motor from

the supply by opening the normally closed (NC) switches.

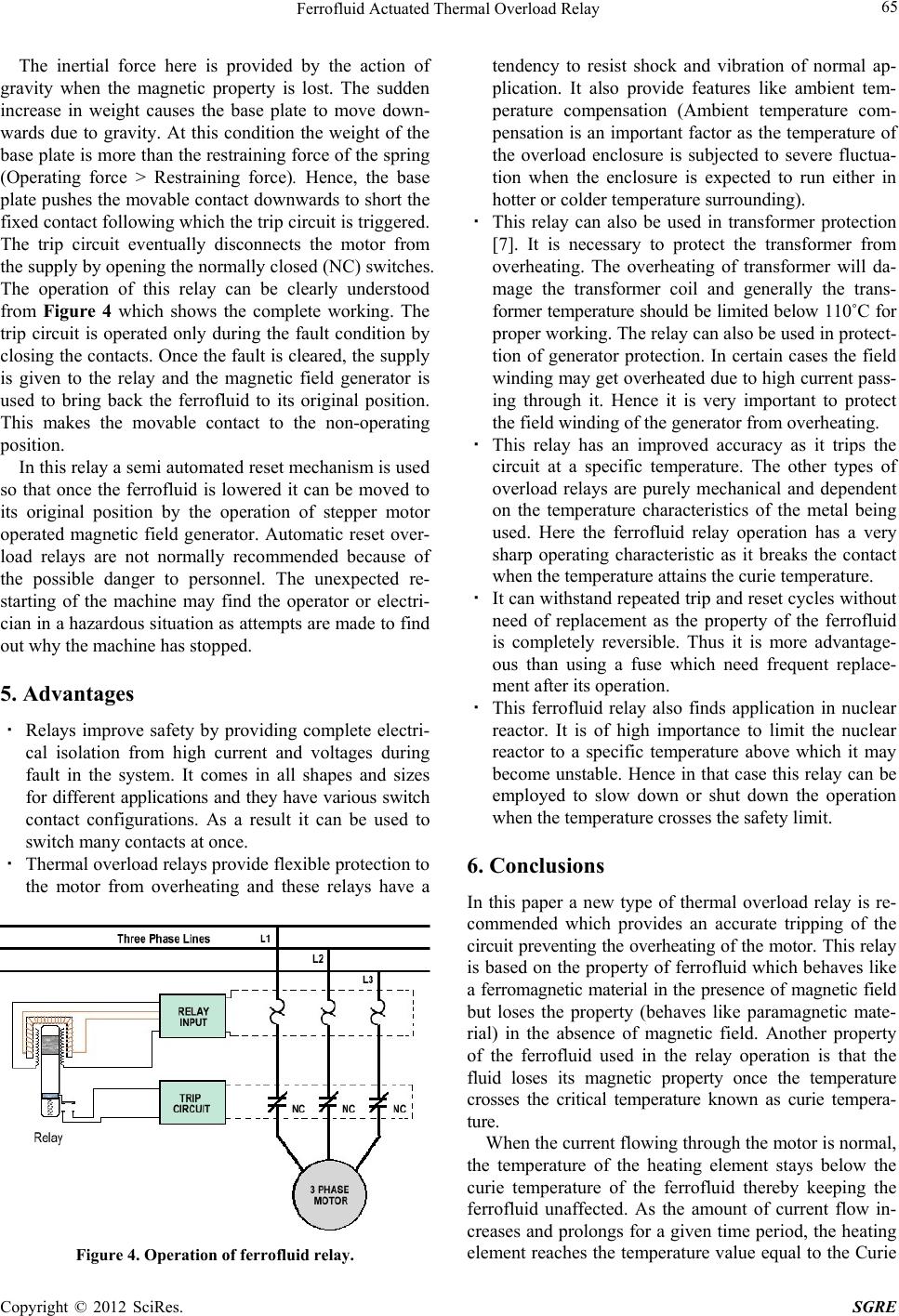

The operation of this relay can be clearly understood

from Figure 4 which shows the complete working. The

trip circuit is operated only during the fault condition by

closing the contacts. Once the fault is cleared, the supp ly

is given to the relay and the magnetic field generator is

used to bring back the ferrofluid to its original position.

This makes the movable contact to the non-operating

position.

In this relay a semi automated reset mechanism is used

so that once the ferrofluid is lowered it can be moved to

its original position by the operation of stepper motor

operated magnetic field generator. Automatic reset over-

load relays are not normally recommended because of

the possible danger to personnel. The unexpected re-

starting of the machine may find the operator or electri-

cian in a hazardous situation as attempts are made to find

out why the machine has stopped.

5. Advantages

· Relays improve safety by providing complete electri-

cal isolation from high current and voltages during

fault in the system. It comes in all shapes and sizes

for different applications and they have various switch

contact configurations. As a result it can be used to

switch many contacts at once.

· Thermal overload relays provide flexible protection to

the motor from overheating and these relays have a

Figure 4. Operation of ferrofluid relay.

tendency to resist shock and vibration of normal ap-

plication. It also provide features like ambient tem-

perature compensation (Ambient temperature com-

pensation is an important factor as the temperature of

the overload enclosure is subjected to severe fluctua-

tion when the enclosure is expected to run either in

hotter or colder temperature surrounding).

· This relay can also be used in transformer protection

[7]. It is necessary to protect the transformer from

overheating. The overheating of transformer will da-

mage the transformer coil and generally the trans-

former temperature should be limited below 110˚C for

proper working. The relay can also be used in protect-

tion of generator protection. In certain cases the field

winding may get overheated due to high current pass-

ing through it. Hence it is very important to protect

the field winding of the generator from overheating.

· This relay has an improved accuracy as it trips the

circuit at a specific temperature. The other types of

overload relays are purely mechanical and dependent

on the temperature characteristics of the metal being

used. Here the ferrofluid relay operation has a very

sharp operating characteristic as it breaks the contact

when the temperature attains the curie temperature.

· It can withstand repeated trip and reset cycles without

need of replacement as the property of the ferrofluid

is completely reversible. Thus it is more advantage-

ous than using a fuse which need frequent replace-

ment after its operation.

· This ferrofluid relay also finds application in nuclear

reactor. It is of high importance to limit the nuclear

reactor to a specific temperature above which it may

become unstable. Hence in that case this relay can be

employed to slow down or shut down the operation

when the temperature crosses the safety limit.

6. Conclusions

In this paper a new type of thermal overload relay is re-

commended which provides an accurate tripping of the

circuit preventing the overheating of the motor. This relay

is based on the property of ferrofluid which behaves like

a ferromagnetic material in the presence of magnetic field

but loses the property (behaves like paramagnetic mate-

rial) in the absence of magnetic field. Another property

of the ferrofluid used in the relay operation is that the

fluid loses its magnetic property once the temperature

crosses the critical temperature known as curie tempera-

ture.

When the current flowing thro ugh the motor is nor mal,

the temperature of the heating element stays below the

curie temperature of the ferrofluid thereby keeping the

ferrofluid unaffected. As the amount of current flow in-

creases and prolongs for a given time period, the heating

element reaches the temperature value equal to the Curie

Copyright © 2012 SciRes. SGRE