Paper Menu >>

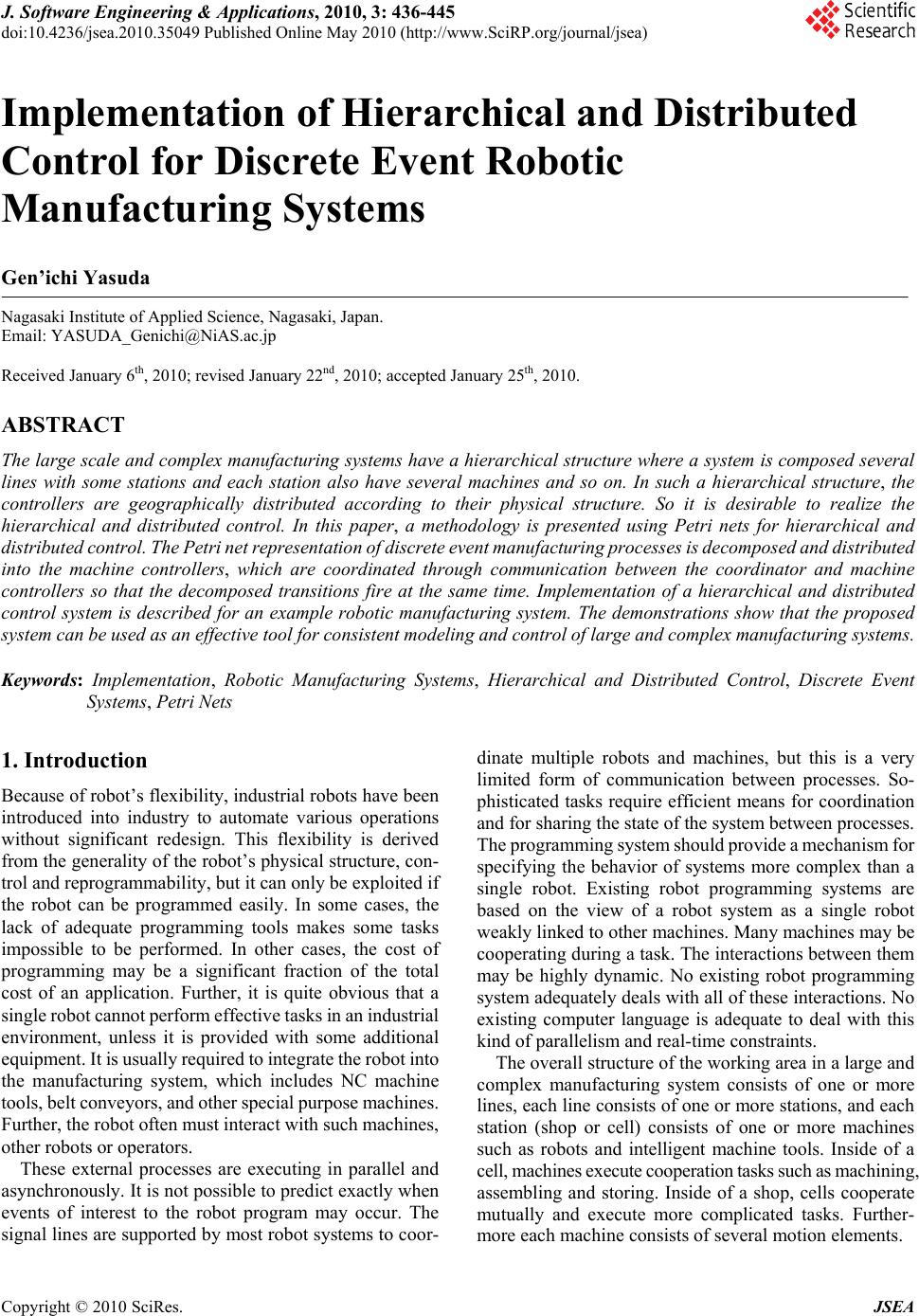

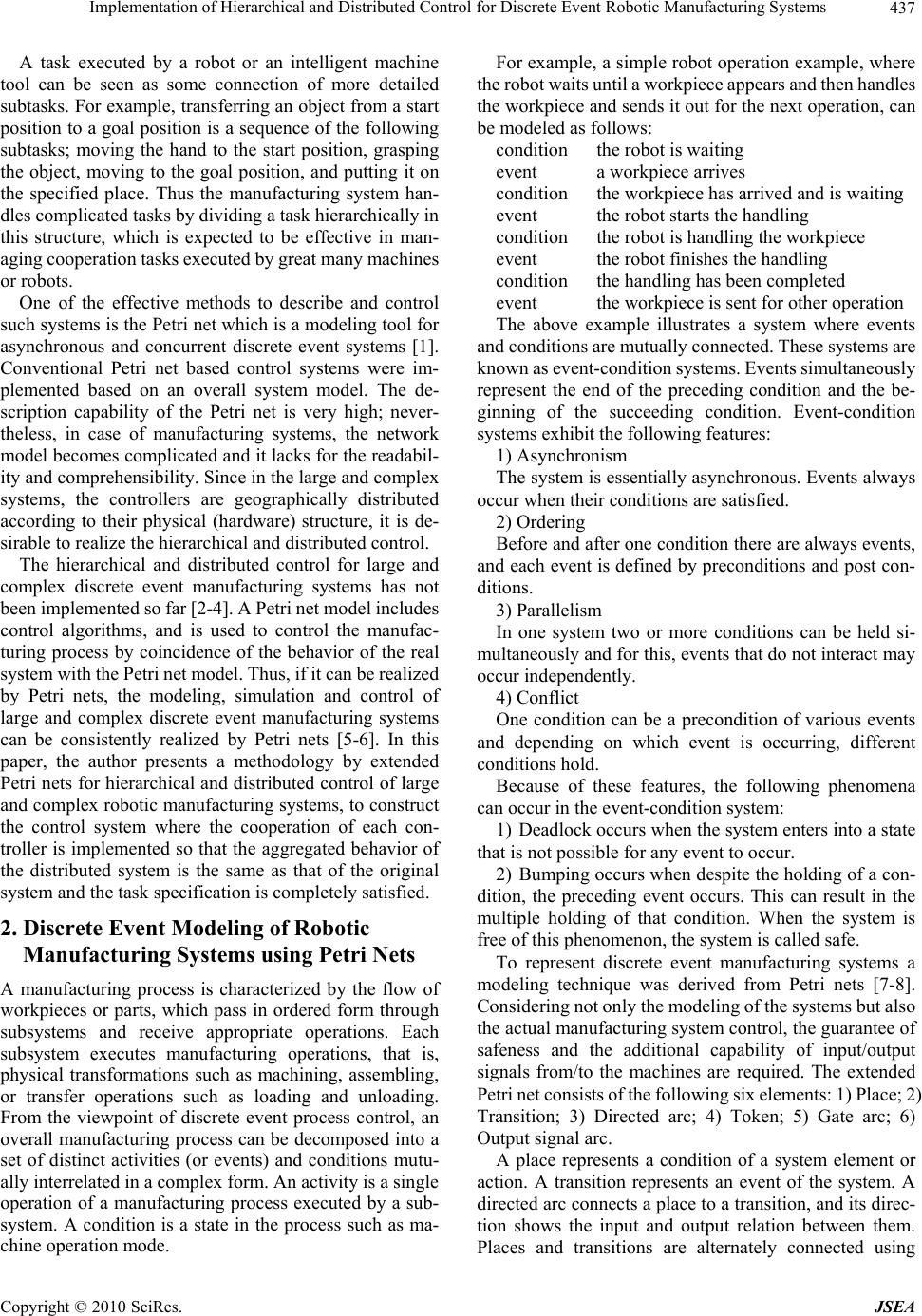

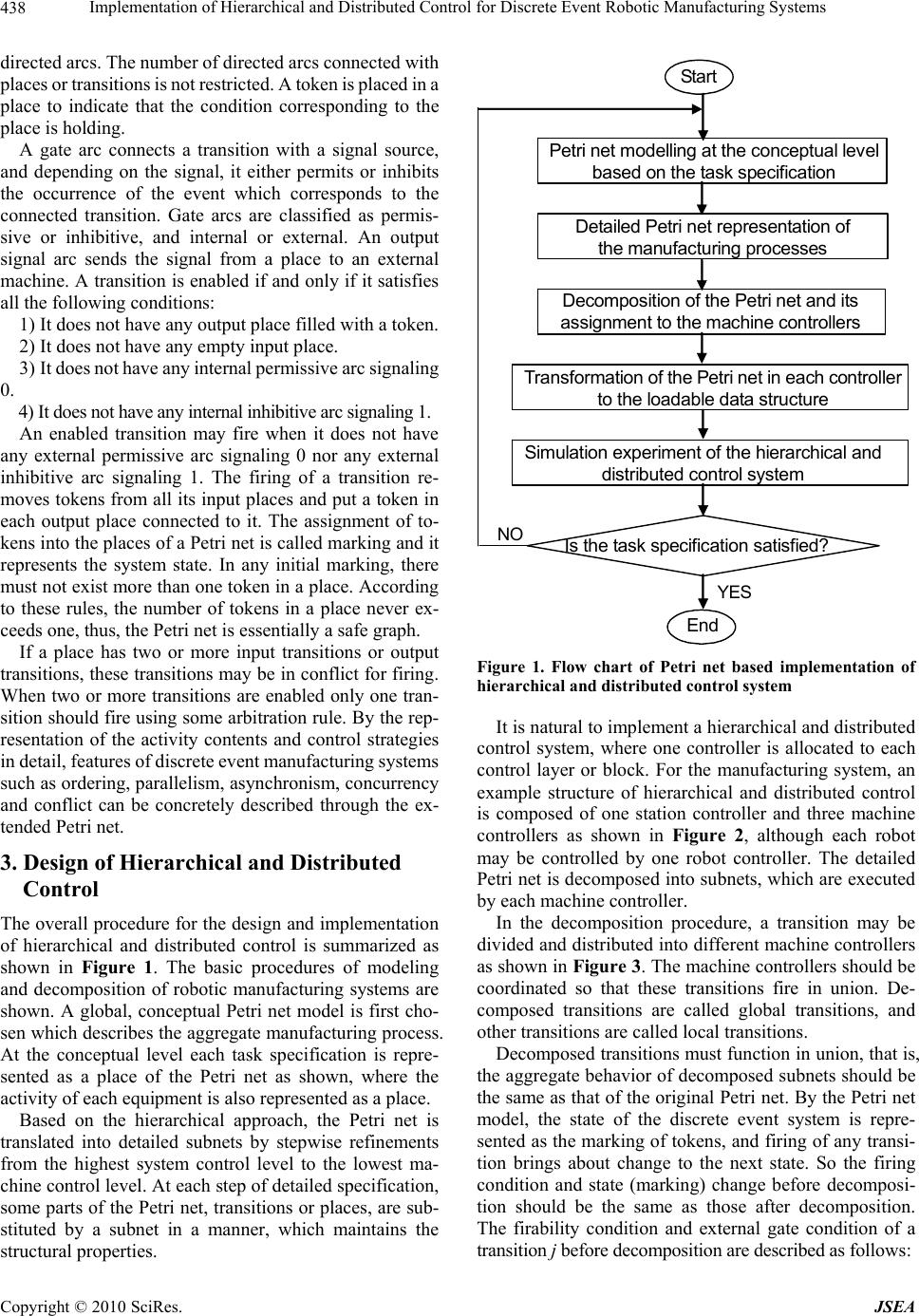

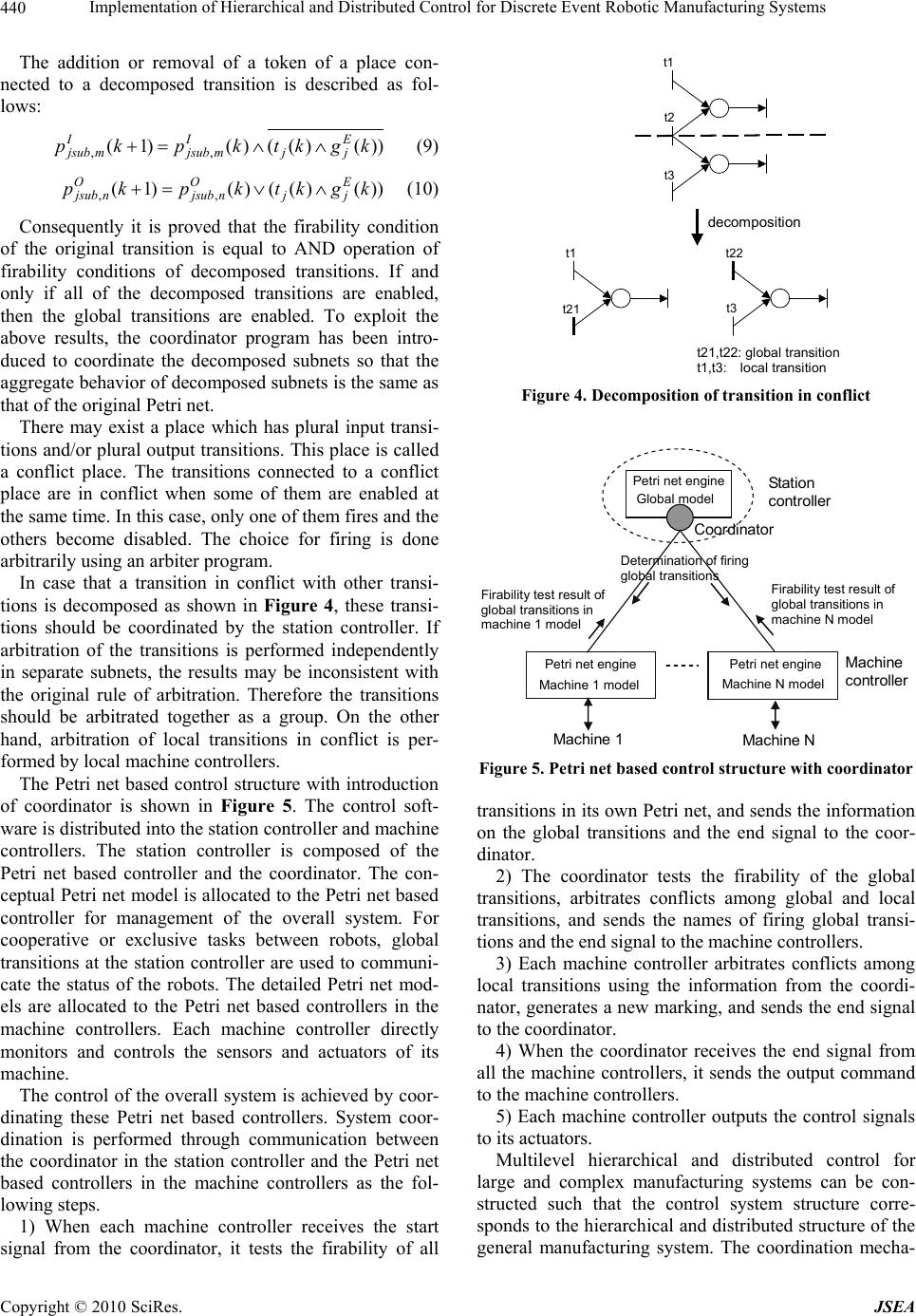

Journal Menu >>

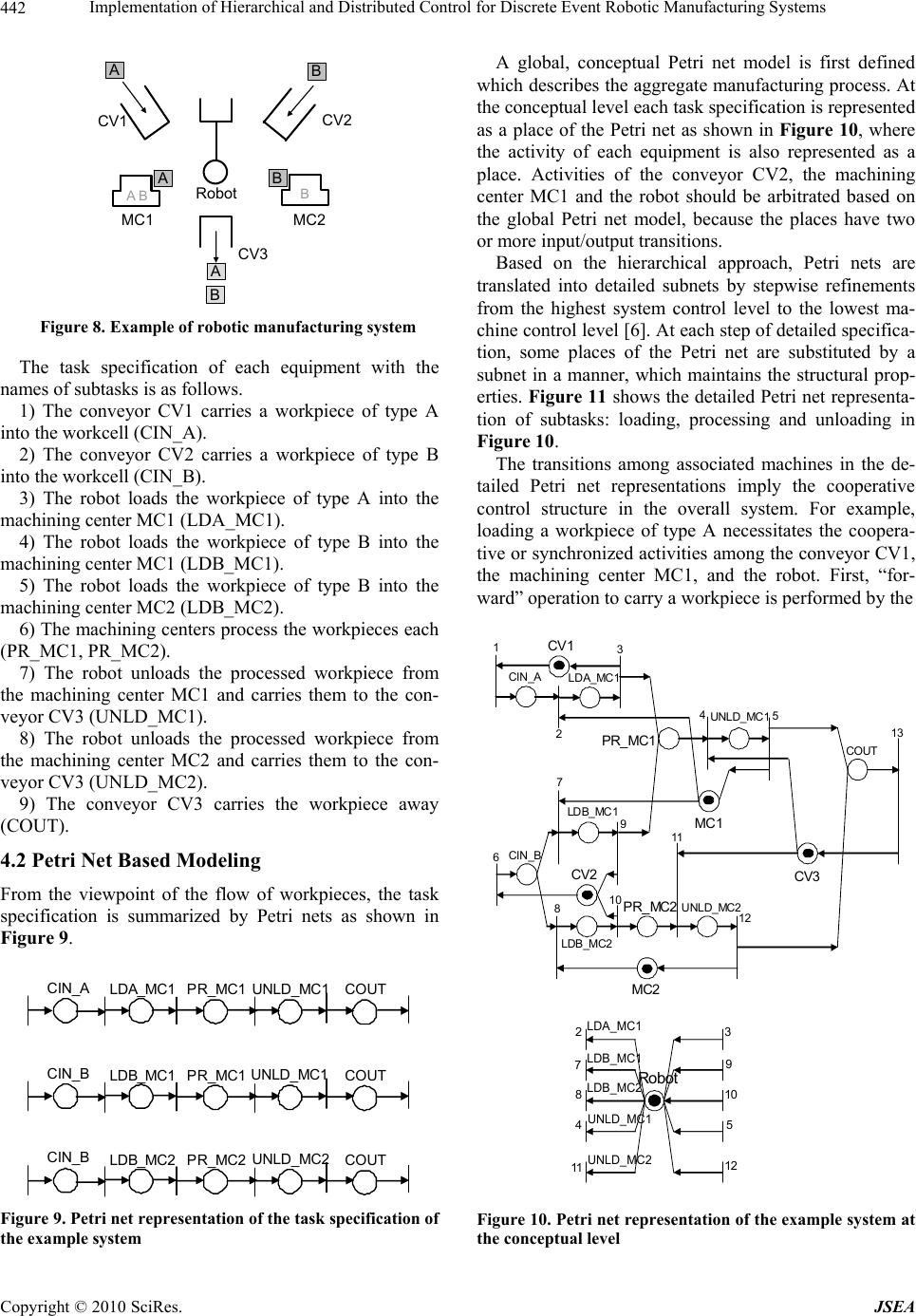

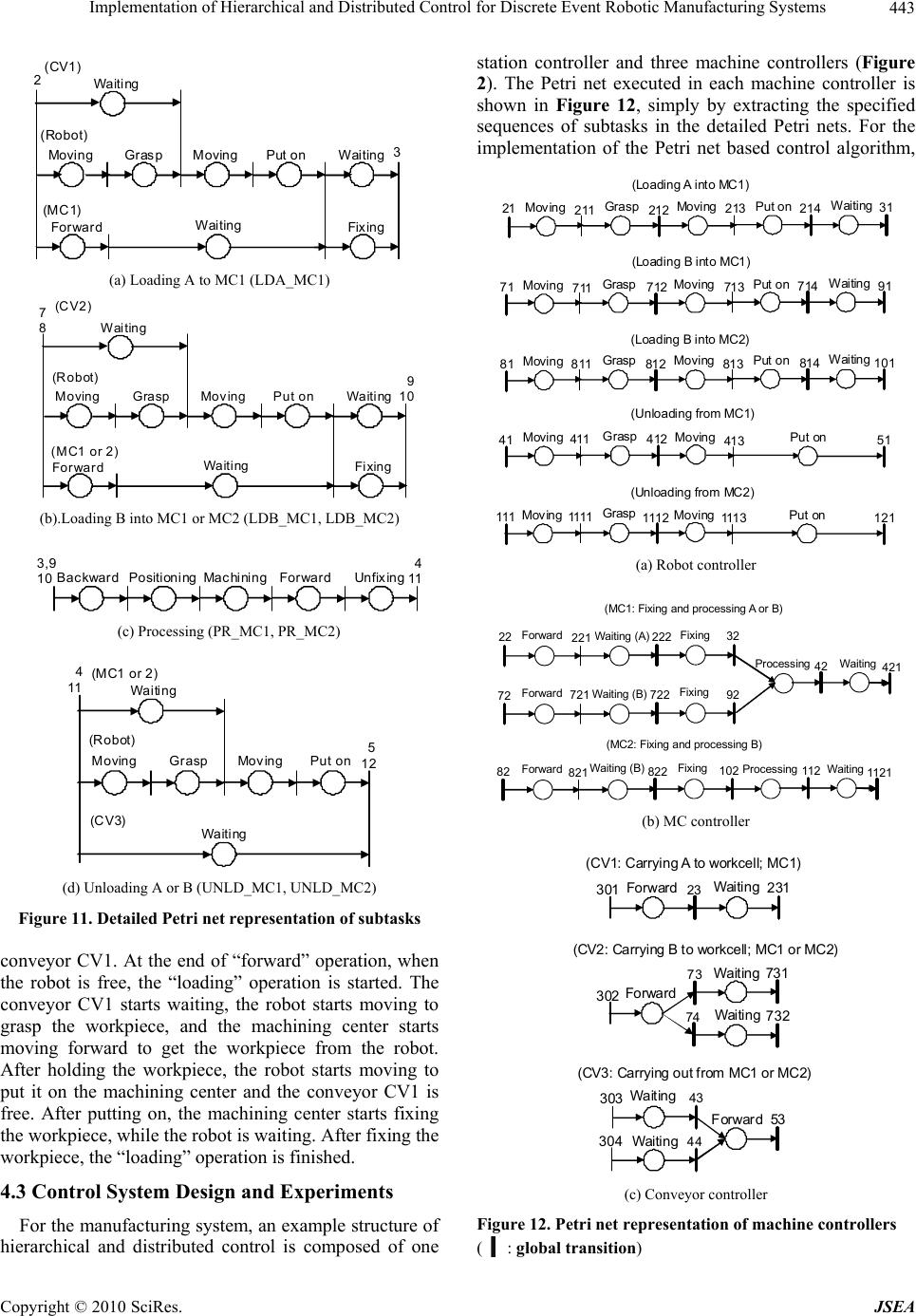

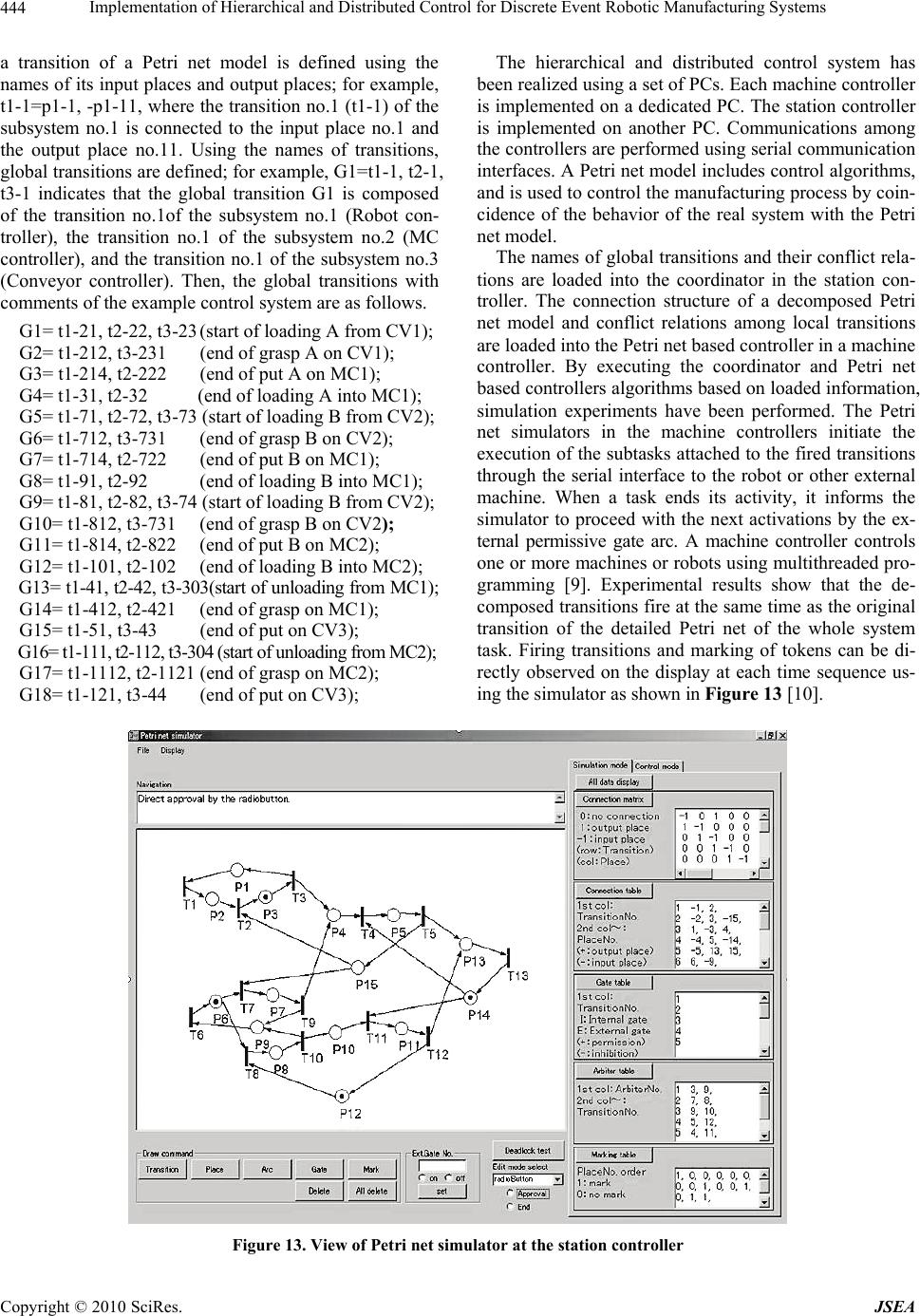

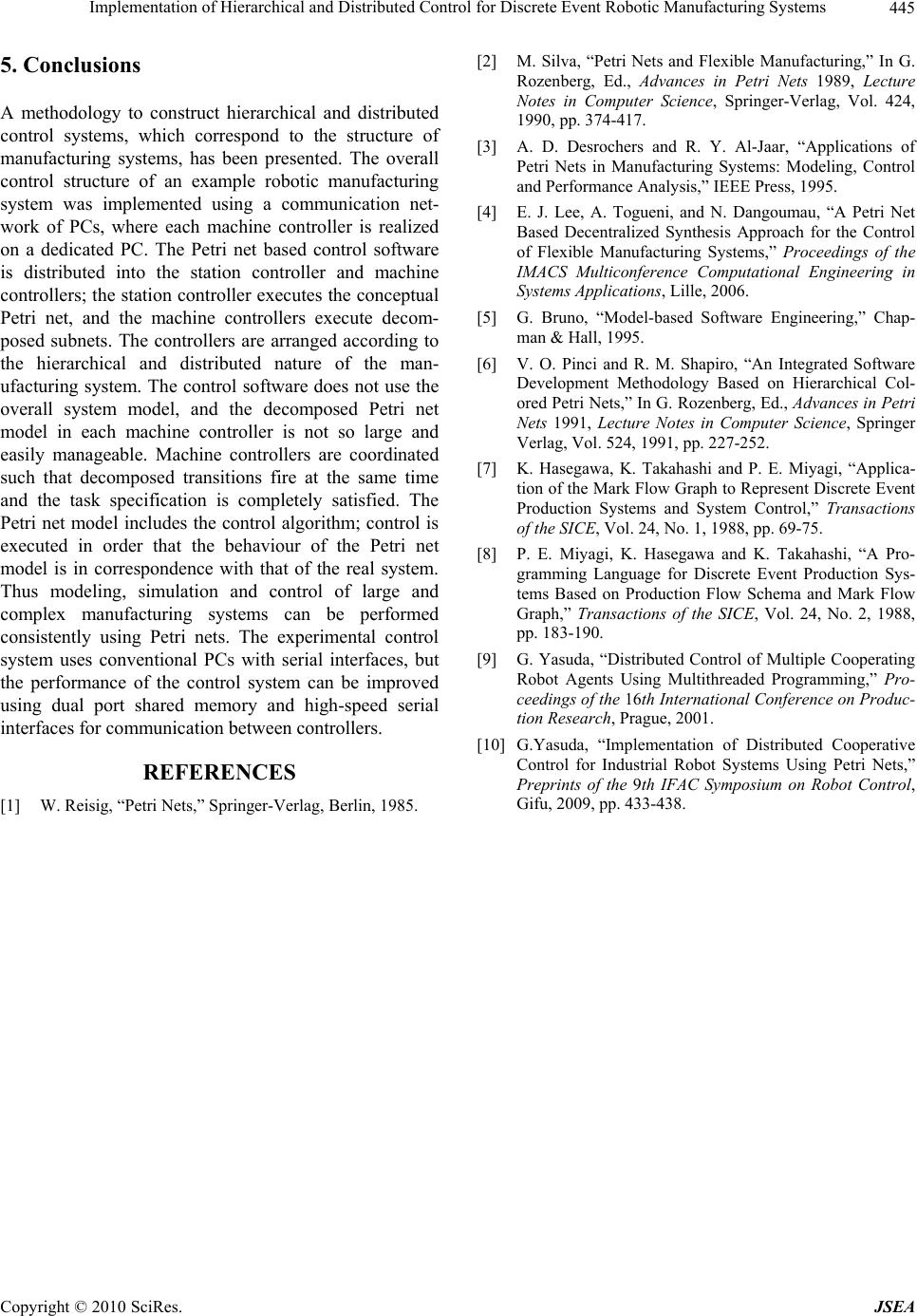

J. Software Engineering & Applications, 2010, 3: 436-445 doi:10.4236/jsea.2010.35049 Published Online May 2010 (http://www.SciRP.org/journal/jsea) Copyright © 2010 SciRes. JSEA Implementation of Hierarchical and Distributed Control for Discrete Event Robotic Manufacturing Systems Gen’ichi Yasuda Nagasaki Institute of Applied Science, Nagasaki, Japan. Email: YASUDA_Genichi@NiAS.ac.jp Received January 6th, 2010; revised January 22nd, 2010; accepted January 25th, 2010. ABSTRACT The large scale and complex manufacturing systems have a hierarchical structure where a system is composed several lines with some stations and each station also have several machines and so on. In such a hierarchical structure, the controllers are geographically distributed according to their physical structure. So it is desirable to realize the hierarchical and distributed control. In this paper, a methodology is presented using Petri nets for hierarchical and distributed control. The Petri net representation of discrete event manufacturing processes is decomposed and distributed into the machine controllers, which are coordinated through communication between the coordinator and machine controllers so that the decomposed transitions fire at the same time. Implementation of a hierarchical and distributed control system is described for an example robotic manufacturing system. The demonstrations show that the proposed system can be used as an effective tool for consistent modeling and control of large and complex manufacturing systems. Keywords: Implementation, Robotic Manufacturing Systems, Hierarchical and Distributed Control, Discrete Event Systems, Petri Nets 1. Introduction Because of robot’s flexibility, industrial robots have been introduced into industry to automate various operations without significant redesign. This flexibility is derived from the generality of the robot’s physical structure, con- trol and reprogrammability, but it can only be exploited if the robot can be programmed easily. In some cases, the lack of adequate programming tools makes some tasks impossible to be performed. In other cases, the cost of programming may be a significant fraction of the total cost of an application. Further, it is quite obvious that a single robot cannot perform effective tasks in an industrial environment, unless it is provided with some additional equipment. It is usually required to integrate the robot into the manufacturing system, which includes NC machine tools, belt conveyors, and other special purpose machines. Further, the robot often must interact with such machines, other robots or operators. These external processes are executing in parallel and asynchronously. It is not possible to predict exactly when events of interest to the robot program may occur. The signal lines are supported by most robot systems to coor- dinate multiple robots and machines, but this is a very limited form of communication between processes. So- phisticated tasks require efficient means for coordination and for sharing the state of the system between processes. The programming system should provide a mechanism for specifying the behavior of systems more complex than a single robot. Existing robot programming systems are based on the view of a robot system as a single robot weakly linked to other machines. Many machines may be cooperating during a task. The interactions between them may be highly dynamic. No existing robot programming system adequately deals with all of these interactions. No existing computer language is adequate to deal with this kind of parallelism and real-time constraints. The overall structure of the working area in a large and complex manufacturing system consists of one or more lines, each line consists of one or more stations, and each station (shop or cell) consists of one or more machines such as robots and intelligent machine tools. Inside of a cell, machines execute cooperation tasks such as machining, assembling and storing. Inside of a shop, cells cooperate mutually and execute more complicated tasks. Further- more each machine consists of several motion elements.  Implementation of Hierarchical and Distributed Control for Discrete Event Robotic Manufacturing Systems Copyright © 2010 SciRes. JSEA 437 A task executed by a robot or an intelligent machine tool can be seen as some connection of more detailed subtasks. For example, transferring an object from a start position to a goal position is a sequence of the following subtasks; moving the hand to the start position, grasping the object, moving to the goal position, and putting it on the specified place. Thus the manufacturing system han- dles complicated tasks by dividing a task hierarchically in this structure, which is expected to be effective in man- aging cooperation tasks executed by great many machines or robots. One of the effective methods to describe and control such systems is the Petri net which is a modeling tool for asynchronous and concurrent discrete event systems [1]. Conventional Petri net based control systems were im- plemented based on an overall system model. The de- scription capability of the Petri net is very high; never- theless, in case of manufacturing systems, the network model becomes complicated and it lacks for the readabil- ity and comprehensibility. Since in the large and complex systems, the controllers are geographically distributed according to their physical (hardware) structure, it is de- sirable to realize the hierarchical and distributed control. The hierarchical and distributed control for large and complex discrete event manufacturing systems has not been implemented so far [2-4]. A Petri net model includes control algorithms, and is used to control the manufac- turing process by coincidence of the behavior of the real system with the Petri net model. Thus, if it can be realized by Petri nets, the modeling, simulation and control of large and complex discrete event manufacturing systems can be consistently realized by Petri nets [5-6]. In this paper, the author presents a methodology by extended Petri nets for hierarchical and distributed control of large and complex robotic manufacturing systems, to construct the control system where the cooperation of each con- troller is implemented so that the aggregated behavior of the distributed system is the same as that of the original system and the task specification is completely satisfied. 2. Discrete Event Modeling of Robotic Manufacturing Systems using Petri Nets A manufacturing process is characterized by the flow of workpieces or parts, which pass in ordered form through subsystems and receive appropriate operations. Each subsystem executes manufacturing operations, that is, physical transformations such as machining, assembling, or transfer operations such as loading and unloading. From the viewpoint of discrete event process control, an overall manufacturing process can be decomposed into a set of distinct activities (or events) and conditions mutu- ally interrelated in a complex form. An activity is a single operation of a manufacturing process executed by a sub- system. A condition is a state in the process such as ma- chine operation mode. For example, a simple robot operation example, where the robot waits until a workpiece appears and then handles the workpiece and sends it out for the next operation, can be modeled as follows: condition the robot is waiting event a workpiece arrives condition the workpiece has arrived and is waiting event the robot starts the handling condition the robot is handling the workpiece event the robot finishes the handling condition the handling has been completed event the workpiece is sent for other operation The above example illustrates a system where events and conditions are mutually connected. These systems are known as event-condition systems. Events simultaneously represent the end of the preceding condition and the be- ginning of the succeeding condition. Event-condition systems exhibit the following features: 1) Asynchronism The system is essentially asynchronous. Events always occur when their conditions are satisfied. 2) Ordering Before and after one condition there are always events, and each event is defined by preconditions and post con- ditions. 3) Parallelism In one system two or more conditions can be held si- multaneously and for this, events that do not interact may occur independently. 4) Conflict One condition can be a precondition of various events and depending on which event is occurring, different conditions hold. Because of these features, the following phenomena can occur in the event-condition system: 1) Deadlock occurs when the system enters into a state that is not possible for any event to occur. 2) Bumping occurs when despite the holding of a con- dition, the preceding event occurs. This can result in the multiple holding of that condition. When the system is free of this phenomenon, the system is called safe. To represent discrete event manufacturing systems a modeling technique was derived from Petri nets [7-8]. Considering not only the modeling of the systems but also the actual manufacturing system control, the guarantee of safeness and the additional capability of input/output signals from/to the machines are required. The extended Petri net consists of the following six elements: 1) Place; 2) Transition; 3) Directed arc; 4) Token; 5) Gate arc; 6) Output signal arc. A place represents a condition of a system element or action. A transition represents an event of the system. A directed arc connects a place to a transition, and its direc- tion shows the input and output relation between them. Places and transitions are alternately connected using  Implementation of Hierarchical and Distributed Control for Discrete Event Robotic Manufacturing Systems Copyright © 2010 SciRes. JSEA 438 directed arcs. The number of directed arcs connected with places or transitions is not restricted. A token is placed in a place to indicate that the condition corresponding to the place is holding. A gate arc connects a transition with a signal source, and depending on the signal, it either permits or inhibits the occurrence of the event which corresponds to the connected transition. Gate arcs are classified as permis- sive or inhibitive, and internal or external. An output signal arc sends the signal from a place to an external machine. A transition is enabled if and only if it satisfies all the following conditions: 1) It does not have any output place filled with a token. 2) It does not have any empty input place. 3) It does not have any internal permissive arc signaling 0. 4) It does not have any internal inhibitive arc signaling 1. An enabled transition may fire when it does not have any external permissive arc signaling 0 nor any external inhibitive arc signaling 1. The firing of a transition re- moves tokens from all its input places and put a token in each output place connected to it. The assignment of to- kens into the places of a Petri net is called marking and it represents the system state. In any initial marking, there must not exist more than one token in a place. According to these rules, the number of tokens in a place never ex- ceeds one, thus, the Petri net is essentially a safe graph. If a place has two or more input transitions or output transitions, these transitions may be in conflict for firing. When two or more transitions are enabled only one tran- sition should fire using some arbitration rule. By the rep- resentation of the activity contents and control strategies in detail, features of discrete event manufacturing systems such as ordering, parallelism, asynchronism, concurrency and conflict can be concretely described through the ex- tended Petri net. 3. Design of Hierarchical and Distributed Control The overall procedure for the design and implementation of hierarchical and distributed control is summarized as shown in Figure 1. The basic procedures of modeling and decomposition of robotic manufacturing systems are shown. A global, conceptual Petri net model is first cho- sen which describes the aggregate manufacturing process. At the conceptual level each task specification is repre- sented as a place of the Petri net as shown, where the activity of each equipment is also represented as a place. Based on the hierarchical approach, the Petri net is translated into detailed subnets by stepwise refinements from the highest system control level to the lowest ma- chine control level. At each step of detailed specification, some parts of the Petri net, transitions or places, are sub- stituted by a subnet in a manner, which maintains the structural properties. Start Petri net modelling at the conceptual level based on the task specification Detailed Petri net representation of the manufacturing processes Decomposition of the Petri net and its assignment to the machine controllers Transformation of the Petri net in each controller to the loadable data structure Simulation experiment of the hierarchical and distributed control system Is the task specification satisfied? End YES NO Figure 1. Flow chart of Petri net based implementation of hierarchical and distributed control system It is natural to implement a hierarchical and distributed control system, where one controller is allocated to each control layer or block. For the manufacturing system, an example structure of hierarchical and distributed control is composed of one station controller and three machine controllers as shown in Figure 2, although each robot may be controlled by one robot controller. The detailed Petri net is decomposed into subnets, which are executed by each machine controller. In the decomposition procedure, a transition may be divided and distributed into different machine controllers as shown in Figure 3. The machine controllers should be coordinated so that these transitions fire in union. De- composed transitions are called global transitions, and other transitions are called local transitions. Decomposed transitions must function in union, that is, the aggregate behavior of decomposed subnets should be the same as that of the original Petri net. By the Petri net model, the state of the discrete event system is repre- sented as the marking of tokens, and firing of any transi- tion brings about change to the next state. So the firing condition and state (marking) change before decomposi- tion should be the same as those after decomposition. The firability condition and external gate condition of a transition j before decomposition are described as follows:  Implementation of Hierarchical and Distributed Control for Discrete Event Robotic Manufacturing Systems Copyright © 2010 SciRes. JSEA 439 R r II rj Q q IP qj N n O nj M m I mjj kgkg kpkpkt 1 , 1 , 1 , 1 , )()( )()()( (1) V v EI vj U u EP uj E jkgkgkg 1 , 1 ,)()()( (2) where, M : input place set of transition j ; )( ,kpI mj : state of input placemof transitionj at time sequence k; N: output place set of transitionj; )( ,kpO nj : state of output placenof transition j at time sequence k; Q: internal permissive gate signal set of transition j ; )( ,kg IP qj : internal permissive gate signal variableqof transition j at time sequence k; R : internal inhibitive gate signal set of transitionj; )( ,kg II rj : internal inhibitive gate signal variable r of transition j at time sequence k; U: external permissive gate signal set of transition j ; )( ,kg EP uj : external permissive gate signal variable u of transition j at time sequence k; V: external inhibitive gate signal set of transition j ; Station controller Robot controller MC controller Conveyor controller Machining Center1 Conveyor2 Robot Machining Center2 Conveyor1 Figure 2. Example structure of distributed control system t1 t2 t11 t21 t12 t22t3 t4 decomposition Station controller Machine controller t11,t21,t12,t22: global transition t3,t4: local transition Figure 3. Decomposition of transition )( ,kg EI vj : external inhibitive gate signal variablevof transition jat time sequence k; The state (marking) change, that is, the addition or removal of a token of a place, is described as follows: ))()(()()1( ,, kgktkpkpE jj I mj I mj (3) ))()(()()1(,, kgktkpkp E jj O nj O nj (4) If transition j is divided into s transitions 1j,2j, , ,s j , the firability condition of a transition after decomposition is described as follows: Rsub r II rjsub Qsub q IP qjsub Nsub n O njsub Msub m I mjsubjsub kgkg kpkpkt 1 , 1 , 1 , 1 , )()( )()()( (5) Vsub v EI vjsub Usub u EP ujsub E jsub kgkgkg 1 , 1 ,)()()( (6) From Equation (1) and Equation (5), S sub jsubjktkt 1 )()( (7) From Equation (2) and Equation (6), )()( 1 kgkg S sub E jsub E j (8) where, S: total number of subnets Msub : input place set of transitionjsub of subnet sub ; )( ,kpI mjsub : state of input placemof transitionjsubof subnet sub at time sequence k; Nsub : output place set of transitionjsub of subnet sub ; )( ,kpO njsub : state of output placenof transitionjsub of subnet subat time sequence k; Qsub : internal permissive gate signal set of transi- tion jsub of subnetsub ; Rsub : internal inhibitive gate signal set of transi- tion jsub of subnet sub ; Usub : external permissive gate signal set of transi- tion jsub of subnet sub ; Vsub : external permissive gate signal set of transi- tion jsub of subnet sub ;  Implementation of Hierarchical and Distributed Control for Discrete Event Robotic Manufacturing Systems Copyright © 2010 SciRes. JSEA 440 The addition or removal of a token of a place con- nected to a decomposed transition is described as fol- lows: ))()(()()1( ,, kgktkpkp E jj I mjsub I mjsub (9) ))()(()()1( ,, kgktkpkp E jj O njsub O njsub (10) Consequently it is proved that the firability condition of the original transition is equal to AND operation of firability conditions of decomposed transitions. If and only if all of the decomposed transitions are enabled, then the global transitions are enabled. To exploit the above results, the coordinator program has been intro- duced to coordinate the decomposed subnets so that the aggregate behavior of decomposed subnets is the same as that of the original Petri net. There may exist a place which has plural input transi- tions and/or plural output transitions. This place is called a conflict place. The transitions connected to a conflict place are in conflict when some of them are enabled at the same time. In this case, only one of them fires and the others become disabled. The choice for firing is done arbitrarily using an arbiter program. In case that a transition in conflict with other transi- tions is decomposed as shown in Figure 4, these transi- tions should be coordinated by the station controller. If arbitration of the transitions is performed independently in separate subnets, the results may be inconsistent with the original rule of arbitration. Therefore the transitions should be arbitrated together as a group. On the other hand, arbitration of local transitions in conflict is per- formed by local machine controllers. The Petri net based control structure with introduction of coordinator is shown in Figure 5. The control soft- ware is distributed into the station controller and machine controllers. The station controller is composed of the Petri net based controller and the coordinator. The con- ceptual Petri net model is allocated to the Petri net based controller for management of the overall system. For cooperative or exclusive tasks between robots, global transitions at the station controller are used to communi- cate the status of the robots. The detailed Petri net mod- els are allocated to the Petri net based controllers in the machine controllers. Each machine controller directly monitors and controls the sensors and actuators of its machine. The control of the overall system is achieved by coor- dinating these Petri net based controllers. System coor- dination is performed through communication between the coordinator in the station controller and the Petri net based controllers in the machine controllers as the fol- lowing steps. 1) When each machine controller receives the start signal from the coordinator, it tests the firability of all decomposition t1 t2 t3 t1 t21 t22 t3 t21,t22: global transition t1,t3: local transition Figure 4. Decomposition of transition in conflict Station controller Mac hi ne controller Global model Machine 1 model Machine 1 Machine N Machine N model Coordinator Petri net engine Petri net engine Petri net engine Firability test result of global transitions in machine 1 model Determination of firing global transitions Firability test result of global transitions in machine N model Figure 5. Petri net based control structure with coordinator transitions in its own Petri net, and sends the information on the global transitions and the end signal to the coor- dinator. 2) The coordinator tests the firability of the global transitions, arbitrates conflicts among global and local transitions, and sends the names of firing global transi- tions and the end signal to the machine controllers. 3) Each machine controller arbitrates conflicts among local transitions using the information from the coordi- nator, generates a new marking, and sends the end signal to the coordinator. 4) When the coordinator receives the end signal from all the machine controllers, it sends the output command to the machine controllers. 5) Each machine controller outputs the control signals to its actuators. Multilevel hierarchical and distributed control for large and complex manufacturing systems can be con- structed such that the control system structure corre- sponds to the hierarchical and distributed structure of the general manufacturing system. The coordination mecha-  Implementation of Hierarchical and Distributed Control for Discrete Event Robotic Manufacturing Systems Copyright © 2010 SciRes. JSEA 441 nism is implemented in each layer repeatedly as shown in Figure 6. The overall system is consistently controlled, such that a coordinator in a layer coordinates one-level lower Petri net based controllers and is coordinated by the one-level upper coordinator. The details of coordination in a two-level control sys- tem composed of a global controller and several local controllers have been implemented as shown in Figure 7. 4. Implementation of Control System 4.1 Example of Workstation Task The basic procedures of modeling and decomposition of robotic manufacturing systems are shown through a sim- ple example. The example robotic manufacturing system is composed of two input conveyors, two machining centers, one handling robot, and one output conveyor as shown in Figure 8. System controller Line controller Station controller Machine controll e r : Coordinator : Petri net based controller Figure 6. Hierarchical and distributed control structure for overall manufacturing system Holding of external gates Firability test of all transitions Firability test of global transitions Arbitration of conflicts concerning global transitions Determination of firing global transitions Arbitration of conflicts among local transitions Generation of a new marking Reception of end signal from its local controllers Output of control signals to its actuators Start Local coordinator Petri net based controller from coordinator to coordinator Holding of external gate s Firability test of all transition s Firability test of global transitions Arbitration of conflicts concerning global transitions Determination of firing global transitions Arbitration of conflicts among local transition s Generation of a new marking Reception of end signal from the global controller and all local coordinators End Sta r t Global coordinator Petri net based controller to subsystems from subsystems Figure 7. Flowchart of coordination in two-level control system  Implementation of Hierarchical and Distributed Control for Discrete Event Robotic Manufacturing Systems Copyright © 2010 SciRes. JSEA 442 CV2 CV1 MC1 MC2 CV3 Robot A B A B A B A B B Figure 8. Example of robotic manufacturing system The task specification of each equipment with the names of subtasks is as follows. 1) The conveyor CV1 carries a workpiece of type A into the workcell (CIN_A). 2) The conveyor CV2 carries a workpiece of type B into the workcell (CIN_B). 3) The robot loads the workpiece of type A into the machining center MC1 (LDA_MC1). 4) The robot loads the workpiece of type B into the machining center MC1 (LDB_MC1). 5) The robot loads the workpiece of type B into the machining center MC2 (LDB_MC2). 6) The machining centers process the workpieces each (PR_MC1, PR_MC2). 7) The robot unloads the processed workpiece from the machining center MC1 and carries them to the con- veyor CV3 (UNLD_MC1). 8) The robot unloads the processed workpiece from the machining center MC2 and carries them to the con- veyor CV3 (UNLD_MC2). 9) The conveyor CV3 carries the workpiece away (COUT). 4.2 Petri Net Based Modeling From the viewpoint of the flow of workpieces, the task specification is summarized by Petri nets as shown in Figure 9. LDA_MC1 PR_MC1 UNLD_MC1 CIN_A COUT LDB_MC1 PR_MC1 UNLD_MC1 CIN_B COUT LDB_MC2 PR_MC2 UNLD_MC2 CIN_B COUT Figure 9. Petri net representation of the task specification of the example system A global, conceptual Petri net model is first defined which describes the aggregate manufacturing process. At the conceptual level each task specification is represented as a place of the Petri net as shown in Figure 10, where the activity of each equipment is also represented as a place. Activities of the conveyor CV2, the machining center MC1 and the robot should be arbitrated based on the global Petri net model, because the places have two or more input/output transitions. Based on the hierarchical approach, Petri nets are translated into detailed subnets by stepwise refinements from the highest system control level to the lowest ma- chine control level [6]. At each step of detailed specifica- tion, some places of the Petri net are substituted by a subnet in a manner, which maintains the structural prop- erties. Figure 11 shows the detailed Petri net representa- tion of subtasks: loading, processing and unloading in Figure 10. The transitions among associated machines in the de- tailed Petri net representations imply the cooperative control structure in the overall system. For example, loading a workpiece of type A necessitates the coopera- tive or synchronized activities among the conveyor CV1, the machining center MC1, and the robot. First, “for- ward” operation to carry a workpiece is performed by the CV1 CV2 CV 3 MC2 MC1 LDB_MC1 LDA_MC1 PR_MC1 PR_MC2 UNLD_MC2 UNLD_MC1 LDB_MC2 CIN_A CIN_B COUT 1 2 3 4 5 6 7 8 9 10 11 12 13 LDA_MC1 LDB_MC1 LDB_MC2 UNLD_MC1 UNLD_MC2 Robot 2 3 7 9 8 10 4 5 11 12 Figure 10. Petri net representation of the example system at the conceptual level  Implementation of Hierarchical and Distributed Control for Discrete Event Robotic Manufacturing Systems Copyright © 2010 SciRes. JSEA 443 Forward Waiting Fixing Grasp Moving Waiting Put on Moving Waiting (CV1) (Robot) (MC1) 2 3 (a) Loading A to MC1 (LDA_MC1) Forward Waiting Fixing Grasp Moving Waiting Put on Moving Waiting (CV2) (Robot) (MC1 or 2) 7 8 9 10 (b).Loading B into MC1 or MC2 (LDB_MC1, LDB_MC2) Backward Positioning Machining Forward Unfix ing 3,9 10 4 11 (c) Processing (PR_MC1, PR_MC2) Waiting Grasp Moving Waiting Put on Moving (MC1 or 2) (Robot) (CV3) 4 11 5 12 (d) Unloading A or B (UNLD_MC1, UNLD_MC2) Figure 11. Detailed Petri net representation of subtasks conveyor CV1. At the end of “forward” operation, when the robot is free, the “loading” operation is started. The conveyor CV1 starts waiting, the robot starts moving to grasp the workpiece, and the machining center starts moving forward to get the workpiece from the robot. After holding the workpiece, the robot starts moving to put it on the machining center and the conveyor CV1 is free. After putting on, the machining center starts fixing the workpiece, while the robot is waiting. After fixing the workpiece, the “loading” operation is finished. 4.3 Control System Design and Experiments For the manufacturing system, an example structure of hierarchical and distributed control is composed of one station controller and three machine controllers (Figure 2). The Petri net executed in each machine controller is shown in Figure 12, simply by extracting the specified sequences of subtasks in the detailed Petri nets. For the implementation of the Petri net based control algorithm, Waiting Put on Put on Grasp Grasp (Loading A into MC1) (Unloading from MC1) Moving Moving Moving Moving Waiting Put on Grasp (Loading B into MC1) Moving Moving Waiting Put on Grasp (Loading B into MC2) Moving Moving Put on Grasp (Unloading from MC2) Moving Moving 21 211 212 213 214 31 71 711 712 713 714 91 81 811 812 813 814 101 41 111 411 1111 1112 1113 413 412 51 121 (a) Robot controller Processing Fixing Waiting Waiting (B) Forward (MC1: Fixing and processing A or B) (MC2: Fixing and processing B) Processing Fixing Waiting Waiting (A) Forward 22 82 221 222 32 42 421 821 822 102 112 1121 Fixing Waiting (B) Forward 72 92 721 722 (b) MC controller Forward Waiting Forward Waiting Forward (CV1: Carrying A to workcell; MC1) (CV2: Carrying B to workcell; MC1 or MC2) (CV3: Carrying out from MC1 or MC2) 23 73 231 731 43 53 301 302 303 Waiting Waiting Waiting 732 74 44 304 (c) Conveyor controller Figure 12. Petri net representation of machine controllers ( : global transition)  Implementation of Hierarchical and Distributed Control for Discrete Event Robotic Manufacturing Systems Copyright © 2010 SciRes. JSEA 444 a transition of a Petri net model is defined using the names of its input places and output places; for example, t1-1=p1-1, -p1-11, where the transition no.1 (t1-1) of the subsystem no.1 is connected to the input place no.1 and the output place no.11. Using the names of transitions, global transitions are defined; for example, G1=t1-1, t2-1, t3-1 indicates that the global transition G1 is composed of the transition no.1of the subsystem no.1 (Robot con- troller), the transition no.1 of the subsystem no.2 (MC controller), and the transition no.1 of the subsystem no.3 (Conveyor controller). Then, the global transitions with comments of the example control system are as follows. G1= t1-21, t2-22, t3-23 (start of loading A from CV1); G2= t1-212, t3-231 (end of grasp A on CV1); G3= t1-214, t2-222 (end of put A on MC1); G4= t1-31, t2-32 (end of loading A into MC1); G5= t1-71, t2-72, t3-73 (start of loading B from CV2); G6= t1-712, t3-731 (end of grasp B on CV2); G7= t1-714, t2-722 (end of put B on MC1); G8= t1-91, t2-92 (end of loading B into MC1); G9= t1-81, t2-82, t3-74 (start of loading B from CV2); G10= t1-812, t3-731 (end of grasp B on CV2); G11= t1-814, t2-822 (end of put B on MC2); G12= t1-101, t2-102 (end of loading B into MC2); G13= t1-41, t2-42, t3-303(start of unloading from MC1); G14= t1-412, t2-421 (end of grasp on MC1); G15= t1-51, t3-43 (end of put on CV3); G16= t1-111, t2-112, t3-304 (start of unloading from MC2); G17= t1-1112, t2-1121 (end of grasp on MC2); G18= t1-121, t3-44 (end of put on CV3); The hierarchical and distributed control system has been realized using a set of PCs. Each machine controller is implemented on a dedicated PC. The station controller is implemented on another PC. Communications among the controllers are performed using serial communication interfaces. A Petri net model includes control algorithms, and is used to control the manufacturing process by coin- cidence of the behavior of the real system with the Petri net model. The names of global transitions and their conflict rela- tions are loaded into the coordinator in the station con- troller. The connection structure of a decomposed Petri net model and conflict relations among local transitions are loaded into the Petri net based controller in a machine controller. By executing the coordinator and Petri net based controllers algorithms based on loaded information, simulation experiments have been performed. The Petri net simulators in the machine controllers initiate the execution of the subtasks attached to the fired transitions through the serial interface to the robot or other external machine. When a task ends its activity, it informs the simulator to proceed with the next activations by the ex- ternal permissive gate arc. A machine controller controls one or more machines or robots using multithreaded pro- gramming [9]. Experimental results show that the de- composed transitions fire at the same time as the original transition of the detailed Petri net of the whole system task. Firing transitions and marking of tokens can be di- rectly observed on the display at each time sequence us- ing the simulator as shown in Figure 13 [10]. Figure 13. View of Petri net simulator at the station controller  Implementation of Hierarchical and Distributed Control for Discrete Event Robotic Manufacturing Systems Copyright © 2010 SciRes. JSEA 445 5. Conclusions A methodology to construct hierarchical and distributed control systems, which correspond to the structure of manufacturing systems, has been presented. The overall control structure of an example robotic manufacturing system was implemented using a communication net- work of PCs, where each machine controller is realized on a dedicated PC. The Petri net based control software is distributed into the station controller and machine controllers; the station controller executes the conceptual Petri net, and the machine controllers execute decom- posed subnets. The controllers are arranged according to the hierarchical and distributed nature of the man- ufacturing system. The control software does not use the overall system model, and the decomposed Petri net model in each machine controller is not so large and easily manageable. Machine controllers are coordinated such that decomposed transitions fire at the same time and the task specification is completely satisfied. The Petri net model includes the control algorithm; control is executed in order that the behaviour of the Petri net model is in correspondence with that of the real system. Thus modeling, simulation and control of large and complex manufacturing systems can be performed consistently using Petri nets. The experimental control system uses conventional PCs with serial interfaces, but the performance of the control system can be improved using dual port shared memory and high-speed serial interfaces for communication between controllers. REFERENCES [1] W. Reisig, “Petri Nets,” Springer-Verlag, Berlin, 1985. [2] M. Silva, “Petri Nets and Flexible Manufacturing,” In G. Rozenberg, Ed., Advances in Petri Nets 1989, Lecture Notes in Computer Science, Springer-Verlag, Vol. 424, 1990, pp. 374-417. [3] A. D. Desrochers and R. Y. Al-Jaar, “Applications of Petri Nets in Manufacturing Systems: Modeling, Control and Performance Analysis,” IEEE Press, 1995. [4] E. J. Lee, A. Togueni, and N. Dangoumau, “A Petri Net Based Decentralized Synthesis Approach for the Control of Flexible Manufacturing Systems,” Proceedings of the IMACS Multiconference Computational Engineering in Systems Applications, Lille, 2006. [5] G. Bruno, “Model-based Software Engineering,” Chap- man & Hall, 1995. [6] V. O. Pinci and R. M. Shapiro, “An Integrated Software Development Methodology Based on Hierarchical Col- ored Petri Nets,” In G. Rozenberg, Ed., Advances in Petri Nets 1991, Lecture Notes in Computer Science, Springer Verlag, Vol. 524, 1991, pp. 227-252. [7] K. Hasegawa, K. Takahashi and P. E. Miyagi, “Applica- tion of the Mark Flow Graph to Represent Discrete Event Production Systems and System Control,” Transactions of the SICE, Vol. 24, No. 1, 1988, pp. 69-75. [8] P. E. Miyagi, K. Hasegawa and K. Takahashi, “A Pro- gramming Language for Discrete Event Production Sys- tems Based on Production Flow Schema and Mark Flow Graph,” Transactions of the SICE, Vol. 24, No. 2, 1988, pp. 183-190. [9] G. Yasuda, “Distributed Control of Multiple Cooperating Robot Agents Using Multithreaded Programming,” Pro- ceedings of the 16th International Conference on Produc- tion Research, Prague, 2001. [10] G.Yasuda, “Implementation of Distributed Cooperative Control for Industrial Robot Systems Using Petri Nets,” Preprints of the 9th IFAC Symposium on Robot Control, Gifu, 2009, pp. 433-438. |