R. ADARSHA ET AL.

Copyright © 2012 SciRes. JTTs

66

Figure 4. The task evaluation model.

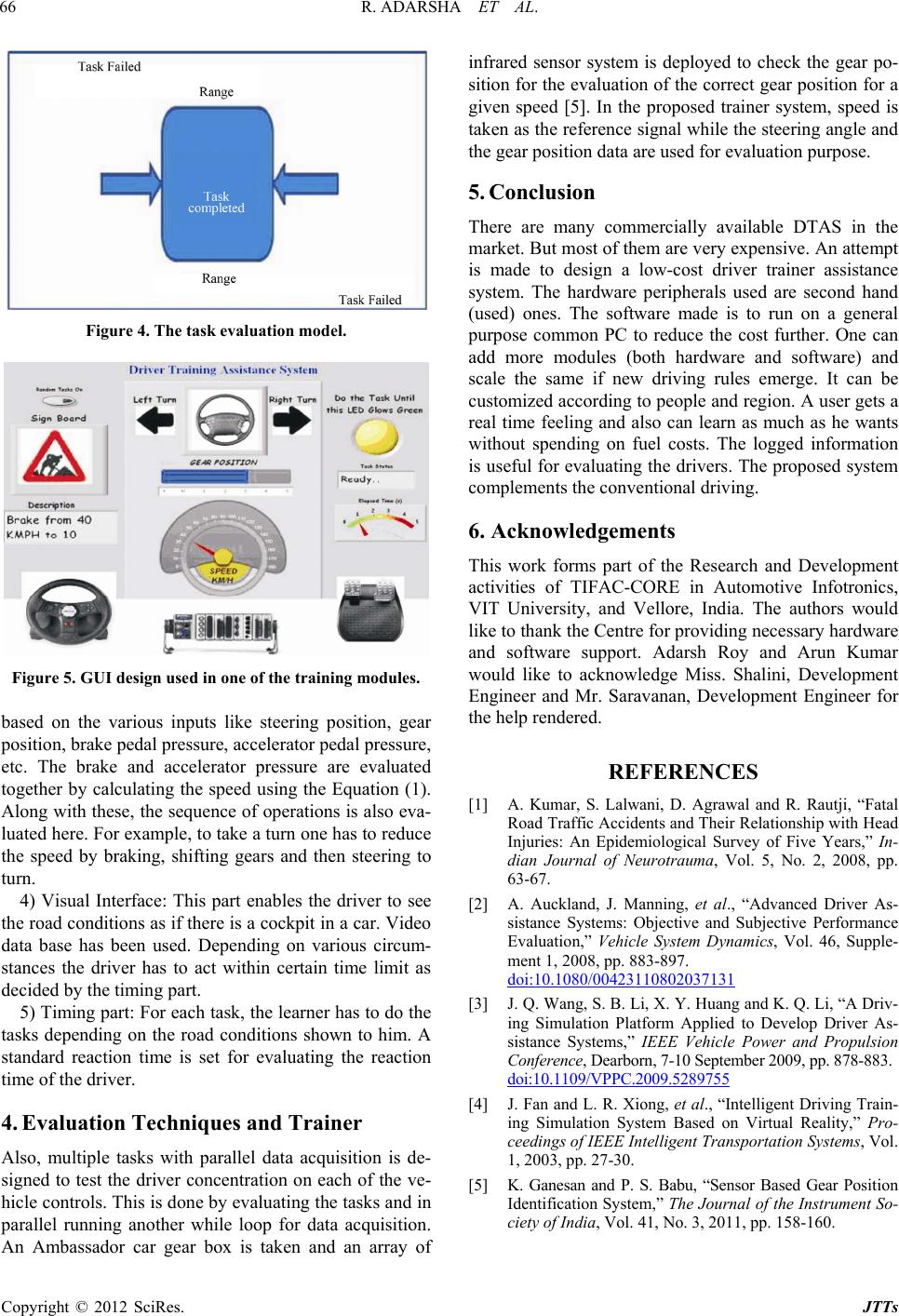

Figure 5. GUI design used in one of the training modules.

based on the various inputs like steering position, gear

position, brake pedal pressure, accelerator pedal pressure,

etc. The brake and accelerator pressure are evaluated

together by calculating the speed using the Equation (1).

Along with th ese, the sequen ce of operations is also eva-

luated here. For example, to take a turn one has to reduce

the speed by braking, shifting gears and then steering to

turn.

4) Visual Interface: This part enables the driver to see

the road condition s as if there is a cockpit in a car. Video

data base has been used. Depending on various circum-

stances the driver has to act within certain time limit as

decided by the timi ng pa rt .

5) Timing part: For each task, the learner has to do the

tasks depending on the road conditions shown to him. A

standard reaction time is set for evaluating the reaction

time of the driver.

4. Evaluation Techniques and Trainer

Also, multiple tasks with parallel data acquisition is de-

signed to test the driver concentration on each of the ve-

hicle controls. This is done by evaluating the tasks and in

parallel running another while loop for data acquisition.

n Ambassador car gear box is taken and an array of

infrared sensor system is deployed to check the gear po-

sition for the evalua tion of the correct gear position for a

given speed [5]. In the proposed trainer system, speed is

taken as the reference signal while th e steering angle and

the gear position data are used for evaluation purpose.

5. Conclusion

There are many commercially available DTAS in the

market. But most of them are very expensive. An attempt

is made to design a low-cost driver trainer assistance

system. The hardware peripherals used are second hand

(used) ones. The software made is to run on a general

purpose common PC to reduce the cost further. One can

add more modules (both hardware and software) and

scale the same if new driving rules emerge. It can be

customized according to people and region. A user gets a

real time feeling and also can learn as much as he wants

without spending on fuel costs. The logged information

is useful for evaluating the drivers. The proposed system

complements the conventional driving.

6. Acknowledgements

This work forms part of the Research and Development

activities of TIFAC-CORE in Automotive Infotronics,

VIT University, and Vellore, India. The authors would

like to thank the Centre for providing necessary hardware

and software support. Adarsh Roy and Arun Kumar

would like to acknowledge Miss. Shalini, Development

Engineer and Mr. Saravanan, Development Engineer for

the help rendered.

REFERENCES

[1] A. Kumar, S. Lalwani, D. Agrawal and R. Rautji, “Fatal

Road Traffic Accidents and Their Relationship with Head

Injuries: An Epidemiological Survey of Five Years,” In-

dian Journal of Neurotrauma, Vol. 5, No. 2, 2008, pp.

63-67.

[2] A. Auckland, J. Manning, et al., “Advanced Driver As-

sistance Systems: Objective and Subjective Performance

Evaluation,” Vehicle System Dynamics, Vol. 46, Supple-

ment 1, 2008, pp. 883-897.

doi:10.1080/00423110802037131

[3] J. Q. Wang, S. B. Li, X. Y. Huang and K. Q. Li, “A Driv-

ing Simulation Platform Applied to Develop Driver As-

sistance Systems,” IEEE Vehicle Power and Propulsion

Conference, Dearborn, 7-10 September 2009, pp. 878-883.

doi:10.1109/VPPC.2009.528975 5

[4] J. Fan and L. R. Xiong, et al., “Intelligent Driving Train-

ing Simulation System Based on Virtual Reality,” Pro-

ceedings of IEEE Intelligent Transportation Systems, Vol.

1, 2003, pp. 27-30.

[5] K. Ganesan and P. S. Babu, “Sensor Based Gear Position

Identification System,” The Journal of the Instrument So-

ciety of India, Vol. 41, No. 3, 2011, pp. 158-160.

A