Paper Menu >>

Journal Menu >>

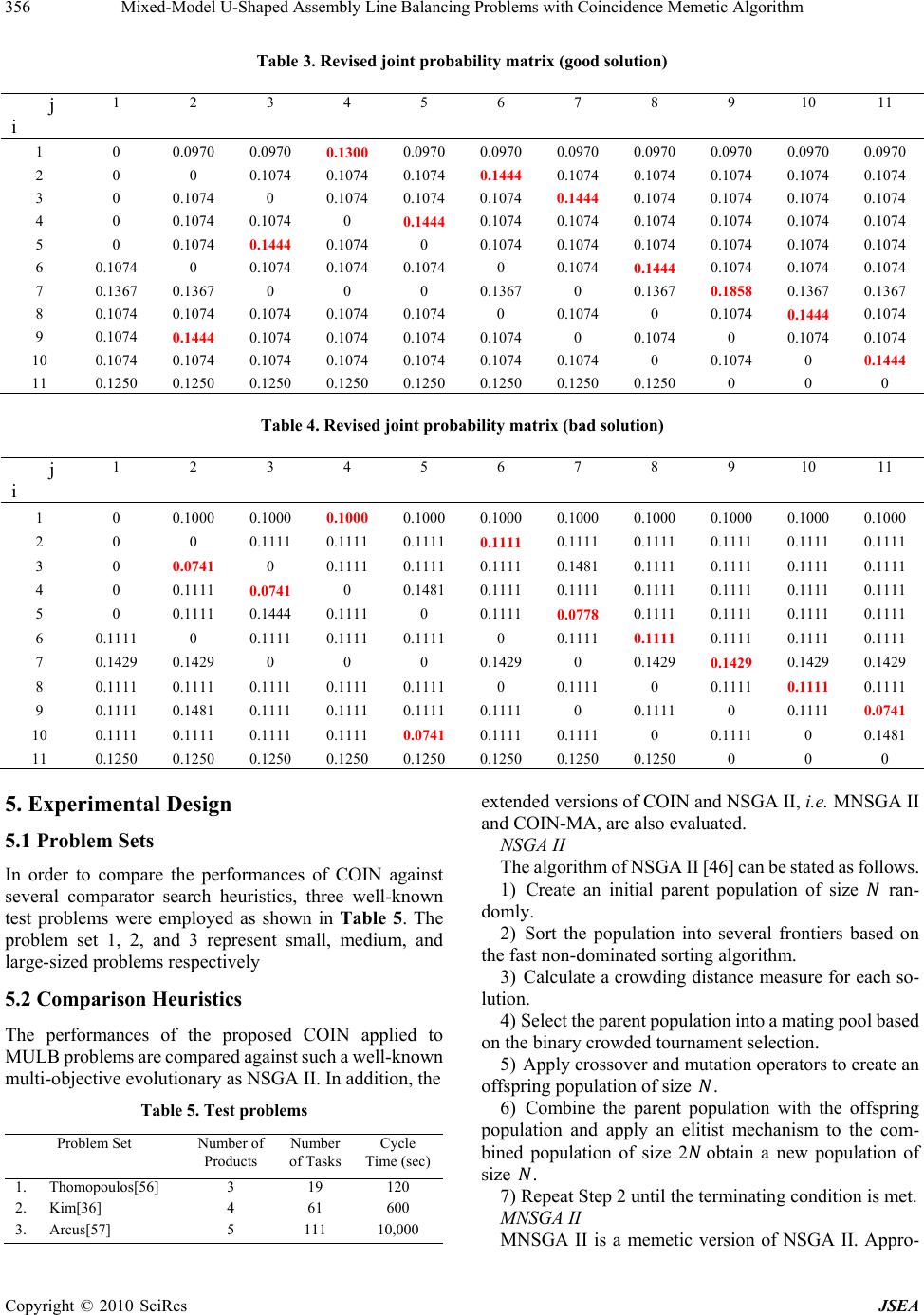

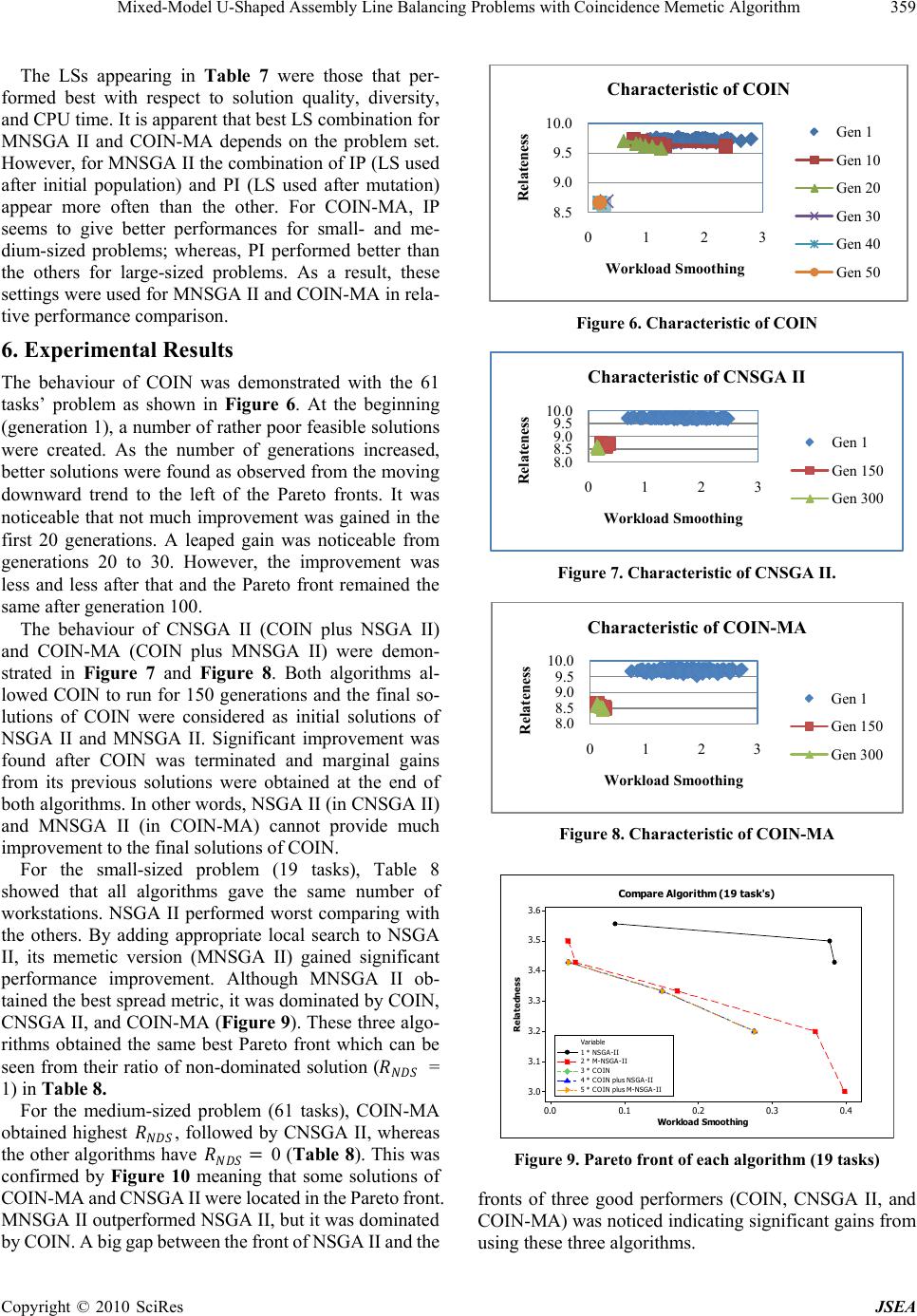

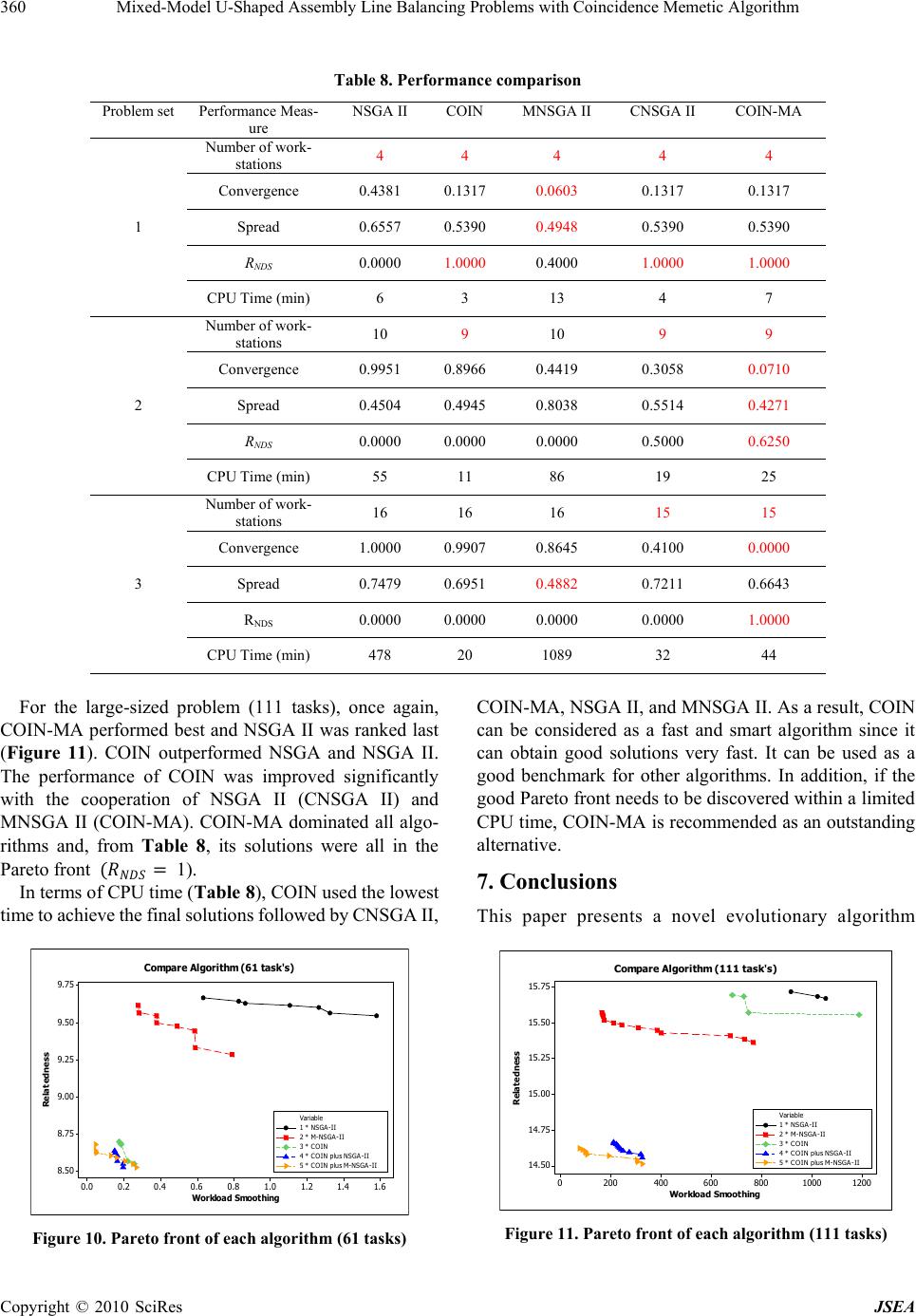

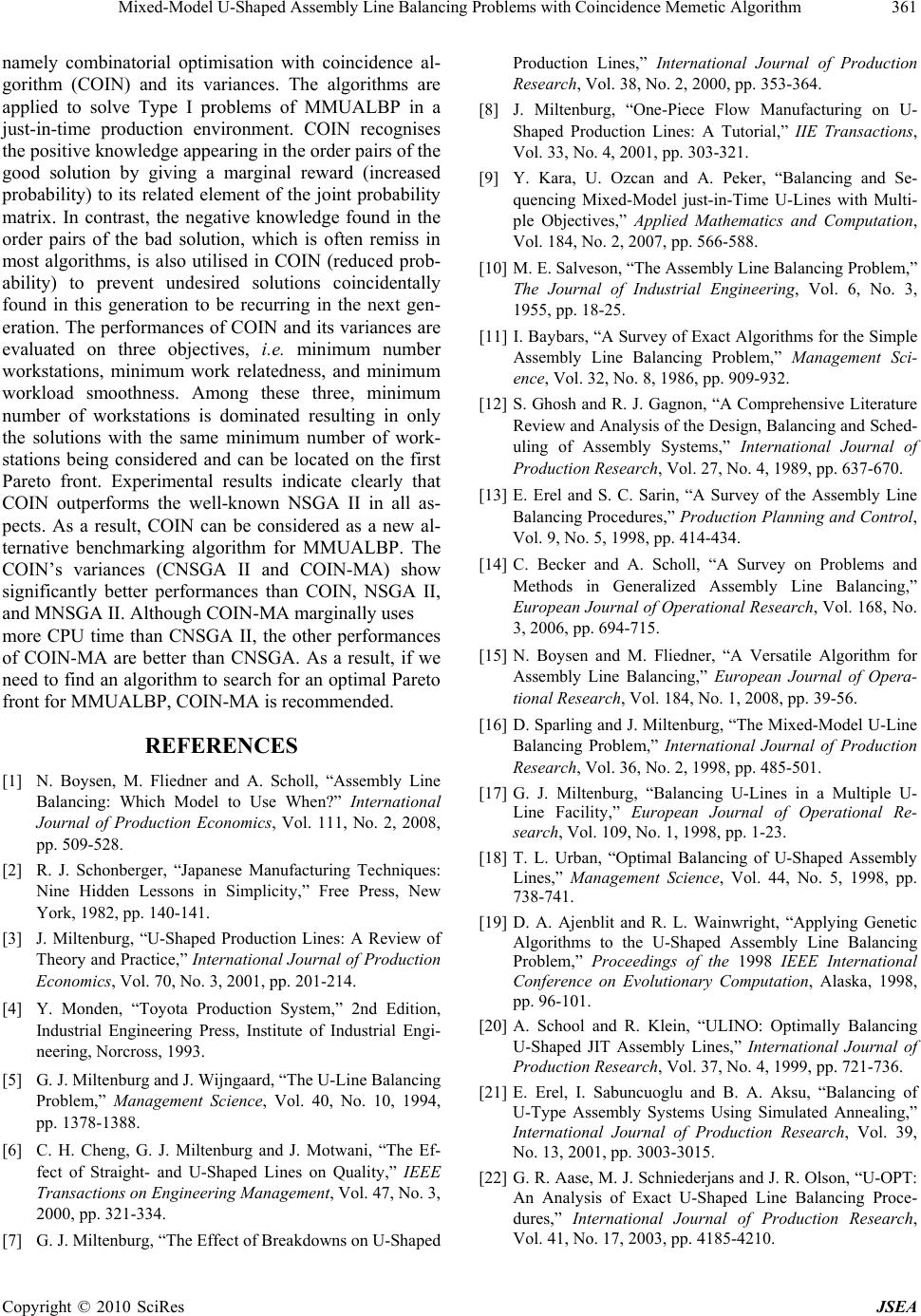

J. Software Engineering & Applications, 2010, 3: 347-363 doi:10.4236/jsea.2010.34040 Published Online April 2010 (http://www.SciRP.org/journal/jsea) Copyright © 2010 SciRes JSEA 347 Mixed-Model U-Shaped Assem bly Line Bal ancin g Problems with Coincidence Memetic Algorithm Parames Chutima, Panuwat Olanviwatchai Department of Industrial Engineering, Faculty of Engineering, Chulalongkorn University, Bangkok, Thailand Email: parames.c@chula.ac.th Received December 15th, 2009; revised January 8th, 2010; accepted January 25th, 20 10. ABSTRACT Mixed-model U-shaped assembly line balancing problems (MMUALBP ) is known to be NP-hard resulting in it being nearly impossible to obtain an optimal solution for practical problems with deterministic algorithms. This paper pre- sents a new evolutionary method called combinatorial optimisation with coincidence algorithm (COIN) being applied to Type I problems of MMUALBP in a just-in-time production system. Three objectives are simultaneously considered; minimum number workstations, minimum work relatedness, and minimum workload smoothness. The variances of COIN are also proposed, i.e. CNSGA II, and COIN-MA. COIN and its variances are tested against a well -known algo- rithm namely non-dominated sorting genetic algorithm II (NSGA II) and MNSGA II (a memetic version of NSGA II). Experimental results showed that COIN outperformed NSGA II. In addition, although COIN-MA uses a marginal CPU time than CNSGA II, its other performances are dominated. Keywords: Assembly Line Balancing, Mixed-Model U-Line, JIT, COIN 1. Introduction An assembly line comprises a sequence of workstations through which a predefined set of tasks are performed repeatedly on product units while they are moving along the line. It was originally developed to support mass production of single homogeneous standardised com- modity to gain a competitive unit cost. Fierce competi- tion in the current market as well as ever-changing cus- tomer requirements forces the mass production concept to become no longer attractive. Manufacturers need to redesign their production lines to accommodate mixed- model production known as mixed model assembly lines (MMALs). In MMALs, all models with the same stan- dardised platform but different customisable product attributes are classified in the same family [1]. Gen- eral-propose machines with automated tool changing equipment and highly flexible operators are necessary to realise an arbitrarily intermixed sequence of various models of a standardised product with similar process requirements to be assembled on the same line at negli- gible setup costs. Typically, workstations on the assembly line are aligned straight along a conveyer belt. Monotone and boring types of work in the straight line layout may not challenge the working enthusiasm of operators, as well as being inflexible to manage changes in external environ- ments. As a consequence of just-in-time (JIT) imple- mentation, manufacturers aim to achieve continuously improved productivity, cost, and product quality by eliminating all wastes in their production systems [2]. However, the straight line cannot fully support the adop- tion of JIT principles to manufacturing especially in the utilisation of multi-skilled operators. Hence, such com- panies as Allen-Bradley and GE have replaced their tra- ditional straight lines with U-shaped production lines, called U-lines hereafter [3]. Fig ure 1 shows the configu- ration of the U-line. In the U-line, the entrance and the exit are placed on the same position. A rather narrow U-shape is normally formed since both ends of the line are located closely S1 S2 S4 S3 1234 5 6 789 AC A B C Start of line End of line Front of the line Back of the line Side of the line Figure 1. Configuration of a U-shaped assembly line A C  Mixed-Model U-Shaped Assembly Line Balancing Problems with Coincidence Memetic Algorithm Copyright © 2010 SciRes JSEA 348 together. Tasks are arranged around the U-line and are organised into workstations. A part of the U-line com- prising a set of tasks w ith the same directional alignment as the entrance is called front zone. The opposite side of the front zone where the exit-side is located is called back zone. The set of tasks joining front and back zones and being the base of the U-line is located in side zone. Two kinds of workstations can be formed in the U-line. A regular workstation comprises tasks located sequen- tially along the front (S2), back (S4), or side (S3) of the U-line; whereas, a crossover workstation (S1) includes tasks located on both the front and back of the line. Multi-skilled operators are located inside of the line. Since some certain models have to visit a crossover workstation twice, the operator in charge of that cross- over workstation may have to process two different models in the same cycle. For example, operator S1 per- forms task 1 of model A on the front side of the line, travels to the back side of the line to perform task 9 of model C, and then returns to the front side of the line to begin the next cycle. The salient characteristic of cross- over workstations of the U-line poses additional chal- lenges for improved performances. Compared to the straight-line, the U-line gains popular- ity from its benefit offerings including improving visibil- ity and communication, operator flexibility, rotatable mul ti -skilled operators, know-how sharing, enhancing teamwork, better quality control, prompt problem solving, faster corrective action on rework, higher product quality, easily adjustable output rate, volume flexibility, eliminat- ing the need for special material handling equipment, fewer workstations, higher machine utilisation, and higher line effectiveness for breakdown prone systems [4-7]. The U-line is an inevitable element and becomes a cornerstone to obtain the main benefits of JIT production principles, i.e. one-piece flow manufacturing, smooth- ened workload, and multi-skilled workforce. The U-line is expected to gain much more popularity in industries in the future. The survey found that nearly 75% of available U-lines are configured to produce a product with differ- ent models or more than one type of product on the same line [8]. This type of production is called a mixed-model U-line (MUL). MUL has gradually superseded traditional mixed-model straight line due to its greater efficiency offerings, e.g. productivity, flexibility, cost, adaptability to demand changes, machine utilisation, and quality [9]. Successful utilisation of MUL needs effective solu- tions to mixed-model U-line balancing (MULB) and mixed-model U-line sequencing (MUS). MULB, a long to medium-term decision with a typical planning horizon of several months, is a problem of determining the num- ber and sequence of workstations on the line or the cycle time of the line to accommodate the different models of products; whereas MUS, a short-term decision normally revising on a daily basis, is a problem of determining a production sequence of mixed models introduced to the line to achieve given objectives. Although these two problems are heavily interrelated, they are normally ad- dressed independently and hierarchically due to their own computational complexities involved. This paper will focus on the MULB problem. A great deal of research has been conducted on the line balancing problem since it was first published in mathematical form by Salveson [10]. Comprehensive literature reviews presented by [3,11-14]. Boysen et al. [15] indicated that very little has been done concerning the U-line balancing problem. Since Monden [4] brought U-lines to the attention of research community, the first pioneer study of the U-line balancing problems was pub- lished by Miltenburg and Wijngaard [5]. They developed a dynamic programming (DP) procedure for a sin- gle-model U-line to determine the optimal balance for Type I of U-line balancing problems (minimum number of workstations) with up to 11 tasks. However, DP was reported impractical for obtaining optimal balances for large-sized problems. They then developed a single-pass heuristic namely U-line maximum ranked positional weight to use for larger problems (111 tasks) where the priority of each task is given to either the time required to complete both that task and all the tasks that must suc- ceed or must precede it, whichever is larger. The heuris- tics showed satisfactory performance for large-sized problems. Sparling and Miltenburg [16] proposed an approximate solution algorithm to solve the MMUALB problem up to 25 tasks. The algorithm transformed the mul ti-model problem into an equivalent single-model problem. The optimal balance was solved by branch and bound algorithm with exponential computational re- quirement to find minimum number of workstations. Smoothing algorithm was used to adjust the initial bal- ance to reduce the level of model imbalance. Miltenburg [17] presented a reaching dynamic algorithm to balance and rebalance a U-line facility that consists of numerous U-lines connected by multiline stations. The objective when balancing such a facility is to assign tasks to a minimum number of stations wh ile satisfying cycle time, precedence, location, and station-type constraints. A secondary objective is to concentrated idle time in a sin- gle station. The proposed algorithm can solve U-line balancing problem with no more than 22 tasks without wide, sparse precedence graphs. Urban [18] presented an integer programming formu- lation for determining the optimal balance for the U-line balancing (ULB) problem. By eliminating some variables through the use of bounds, the size of the model was re- duced. It was shown that the proposed formulation can optimally balance larger problems (21 to 45 tasks) than the DP procedure of Miltenburg and Wijngaard [5]. Ajenblit and W ainwritght [19] were the first who applied a genetic algorithm (GA) for Type I ULB problems with  Mixed-Model U-Shaped Assembly Line Balancing Problems with Coincidence Memetic Algorithm Copyright © 2010 SciRes JSEA 349 the objectives of minimising total idle time, balancing workload among stations, or a combination of both. Sev- eral algorithms for assigning tasks to workstations were proposed. The fitness value of a chromosome is deter- mined by applying all these algorithms to it and the one with lowest fitness value is selected. They found that these assignment algorithms proved to have merit and GA proved to be computationally efficient. Scholl and Klein [20] considered different types of the ULB prob- lem, i.e. Type I, Type II, and Type E. A new bra nch and bound procedure called ULINO (U-line optimiser) adapted from their previous algorithm developed for the straight-shaped problem called SALOME was proposed. Computational results of up to 297-task problems showed that the procedures yielded promising results in limited computation time. Erel et al. [21] proposed an algorithm with a coupling of a solution generator module and a simulated annealing (SA) module. The generator assigned tasks sequentially to separate stations and combines two adjacent stations with minimum total station time until infeasibility is found. Then, SA reconstructed feasibility for such solu- tions by reassigning the tasks in the combined station to other stations by minimizing the maximum station time. The algorithm was tested on a variety of d ata sets w ith up to 297 tasks and found quite effective. Aase et al. [22] proposed a branch-and-bound (B&B) solution procedure called U-OPT (U-line OPTimisation) for a ULB problem. Four design elements of the B&B procedure are investi- gated including branching strategies, fathoming criteria, heuristics to obtain upper bounds at each node, and iden- tification of initial setting solutions. Paired-task lower bound was largely responsible for the dominance in the efficacy of U-OPT over existing methods. Aase et al. [23] conducted empirical experiments to confirm that the U-shaped layout can significantly improve labour pro- ductivity over the traditional straight-line one. Interest- ingly, the improvement tends to be higher during high demand periods when operators are assigned three or fewer tasks on average, when the problem size is small, and when assembly sequence is fairly well structured. Martinez and Duff [24] applied heuristic rules adapted from the simple line balancing problem to the Type I UALB problems up to 21 tasks. Some heuristics were found to produce optimal results. To achieve improved solutions, each gene in a chromosome of GA represent- ing the heuristic rule was used to break ties during the task assignment process. Balakrishnan et al. [25] modi- fied 13 single-pass heuristics to balance U-lines with the existent of travelling time and investigated their effec- tiveness under various problem conditions. Gokcen and Agpak [26] developed a goal programming model for the ULB problems up to 30 tasks. This approach offers in- creased flexibility to the decision maker since conflicting goals can be dealt with at the same time. Urban and Chiang [27] considered the ULB problem with stochastic task times and developed a linear, integer program using a piecewise approximation for the chance constraints to find the optimal solution. The proposed method effec- tively solved practical -sized problems optimally u p to 28 tasks. Chiang and Urban [28] developed a hybrid heuris- tics comprising an initial feasible solution module and a solution improvement module for the stochastic ULB problem. The heuristic can identify optimal or near-op- timal solutions for up to 111-task problems. Kara et al. [29] developed a binary fuzzy goal programming for 8-task ULB with fuzzy goals that allow decision makers to consider the number of workstations and cycle time as imprecise values. Baykasoglu [30] proposed multi-objective SA for ULB problems with the aim of maximising smoothness index and minimising the number of workstations. Task assignment rules were used in constructing feasible solu- tions. The optimal solutions for each problem were found in short computation times. Hwang et al. [31] developed a priority-based genetic algorithm (PGA) for ULB prob- lems for up to 111 tasks. A weighted-sum objective func- tion comprising the number of workstations and the workload variation was considered. The proposed model obtained improved workload variation, especially for large size problems. Hwang and Katayama [32] proposed an extension version of PGA namely an amelioration structure with genetic algorithm (ASGA) to deal with workload balancing problems in mixed-model U-shaped lines for up to 111 tasks. ASGA was able to find better solutions than PGA in terms of workload variation. Boy- sen and Fliedner [33] proposed a general solution proce- dure for U-shaped assembly line balancing using an ant colony optimisation (ACO) approach. Their procedure was versatile in the sense that various line balancing fea- tures found in practice can be incorporated into the model. Baykasoglu and Dereli [33] proposed ACO that integrates COMSOAL and ranked positional weight heu- ristics for solving ULB problems. The proposed algo- rithm found optimum solutions in short computational time s. The existent of crossover workstations in MUL opens a chance for MUS, apart from MULB, to smoothen workload distribution among workstations since the crossover workstation allows a model mix to be proc- essed in a cycle. As a result, MULB and MUS can play significant roles in workload smoothening of MUL. Since these problems are highly correlated, especially when the workload smoothening objective needs to be achieved, several researchers have attempted to solve these two problems simultaneously in an aggregated manner. Miltenburg [34] modelled the joint problems of line balancing and model-sequencing for mixed-model U-lines operated under a JIT environment and proposed a solution algorithm for solving both problems simultane-  Mixed-Model U-Shaped Assembly Line Balancing Problems with Coincidence Memetic Algorithm Copyright © 2010 SciRes JSEA 350 ously. Kim et al. [35] developed a symbiotic evolution- ary algorithm called co-evolutionary algorithm (PCoA), which imitates the biological co-evolution process through symbiotic interaction, to handle the integration of balancing and sequencing problem in MUL for up to 111 tasks. Later, Kim et al. [36] proposed an endosymbi- otic evolutionary algorithm (EEA), an extended version of the symbiotic evolutionary algorithm, to simultane- ously solve line balancing and sequencing in MUL. The proposed algorithm obtained much better quality solu- tions than PCoA and a traditional hierarchical approach. Agrawal and Tiwari [37] demonstrated the superiority of the collaborative ant colony optimisation in simultane- ously tackling disassembly line balancing and sequenc- ing problem in MUL for up to 80 tasks. Sabuncuoglu et al. [38] developed a family of ant colony algorithms that make both sequencing and task assignment decisions simultane ous ly for ULB p roblems up to 111 tasks. Kara et al. [9] proposed SA to deal with a multi-ob- jective approach for balancing and sequencing MULs in JIT production systems for up to 30 tasks to simultane- ously minimise the weighted sum of the absolute devia- tions of workloads across workstations, part usage rate, and cost of setups. Kara et al. [39] proposed SA based heuristic approach for solving balancing and sequencing problems of mixed-model U-lines simultaneously for up to 30 tasks. SA was capable of minimising the number of workstations and minimising the absolute deviation of the workloads among workstations. Kara [40] presented a mixed, zero-one integer, nonlinear programming for mixed-model U-line balancing and sequencing problems for up to 111 tasks with the objective of minimising ab- solute deviation of workloads. An efficient SA was also proposed and its performance outperformed PCoA and EEA. Literature has demonstrated that the MULB is an im- portant problem for modern assembly systems operated under JIT environment. Although several exact methods for their solutions were proposed, only small sized prob- lems can be optimally solved due to the complexity of the problem. Hence, a computational more effective al- gorithm is needed for larger sized problem. Also, the algorithm has to be able to easily handle multiple objec- tives simultaneously. In this paper, such an algorithm that utilises the concept of evolutionary algorithm namely combinatorial optimization with coincidence algorithm (COIN) is proposed for multi-objectiv e MULB problems. Three objectives including minimum number workstations, minimum work relatedness, and minimum workload smoothness are considered simultaneously. The performances of COIN are compared with a well-known algorithm namely non-dominated sorting genetic algorithm II (NSGA II) and their memetic ver- sions The purpose of this study is to see the feasibility and effectiveness of the COIN approach which is one of the most recent meta-heuristics to solve this well-known problem and compare it against others in terms of quality of solutions and solution time. The organisation of this paper is as follows. In the next section, the detailed description of the multi-objective optimisation problem is presented, followed by an ex- planation of the multi-objective MULB problems. The proposed algorithm to solve MULB problems is elabo- rated next, and the experimental design and results are explained respectively. Finally, th e concluding remark of the research is given. 2. Multi-Objective Evolutionary Algorithms A multi-objective optimisation p roblem (MOP) is related to the problem where two or more objectives have to be optimised simultaneously. Generally, such objectives are conflicting and represented in different measurement units, preventing simultaneous optimisation s of each on e. MOP can be formulated, without loss of generality, as follows: Ω {1(),2(),…,()} (1) where solution is a vector of decision variables for the considered problem; Ω is the feasible solution space; and () is the ith objective function (=1, 2, … , ). Two approaches often employ to solve MOP. The first approach is to combine each objective function into a single composite function, e.g. weighted sum method, utility theory, etc. The advantage of this method is straightforward computation. However, two practical problems are often experienced with this approach: 1) selection of the suitable weights can be very difficult even for those who are unfamiliar with the problem and 2) small perturbations in the weights can sometimes lead to totally different solutions [41]. As a result, the second approach, e.g. multi-objective evolutionary algorithms (MOEAs), has come into play. This approach determines a set of alternative solutions for (1) rather than a single optimal solution. These solutions are optimal in the wider sense such that no other solutions in the search space are superior to them when all objectives are considered. A decision vector is said to dominate a decision vector (also written as ) if: ()(), for all {1, 2, … , } (2) and ()<(), for at least one {1, 2, … , } (3) All solutions that dominate the others but do not dominate themselves are called non-dominated (supe- rior) solutions. A Pareto-optimal solution is a global optimal solution which is not dominated by any other solutions in the feasible solution space. A set that con- tains all feasible Pareto-optimal solutions is called a Pareto-optimal set or efficient set. The collection of the points of the Pareto-optimal set (or the corresponding images of the Pareto-optimal set) along a curve in the  Mixed-Model U-Shaped Assembly Line Balancing Problems with Coincidence Memetic Algorithm Copyright © 2010 SciRes JSEA 351 objective space that has a set of attributes collectively dominating all other points not on the frontier are termed the Pareto-optimal frontier (front) or efficient frontier (front). An example of the Pareto-optimal solutions for a two-objective minimisation problem is illustrated in Figure 2. It is obvious that an amount of sacrifice in one objective is always incurred to achieve a certain amount of gain in the other (inverse relationship) while moving from one Pareto-optimal solution to another. Providing Pareto-optimal solutions to the decision maker is more preferable to a single solution since practically, when considering real-life problems, a final decision is always based on a trade-off between conflicting objective func- tions. MOEAs have recently become popular and have been applied to a wide range of problems from social to engi- neering problems [42]. In general, MOEAs are ideally suited to MOP because they are capable of searching a whole set of multiple Par eto-optimal solutions in a single run. In addition, the shape or continuity of the Pareto-optimal frontier has less effect to MOEAs than traditional mathematical programming. The approxima- tion of a true Pareto-optimal set involves two conflicting objectives: 1.) the distance to the tru e Pareto frontier is to be minimised, and 2.) the diversity of the evolved solu- tions is to be maxi mised [43]. To achieve the first objec- tive, a Pareto-based fitness assignment is normally de- signed to guide the search toward the true Pareto-optimal frontier [44, 45]. In the view of the second objective, some MOEAs successfully provide density estimation methods to pre- serve the population diversity. Although several versions of MOEAs have been developed [42], non-dominated sorting genetic algorithms-II (NSGA II) [46] is among the most promising one in terms of convergence speed to Pare to -optimal solutions and even distribution of the Figure 2. Pareto-optimal solutions Pareto frontier. NSGA II is an elitist multi-objective ge- netic algorithm being introduced by Deb et al. (2002). It uses a fixed population size of N for both parent and off- spring populations. Once a new offspring population is created, it is combined with its parent population. The size of the combined population becomes 2N. A non-dominated sorting method is used to identify Pareto frontiers (F1, F2, ..., Fk) in the combined population. The first frontier (F1) is the best in the combined population. The next population (archive) is created by selecting frontiers based on their rankings; the best Pareto frontier being selected first. If the number of members in the ar- chive is smaller than the population size (N), the next frontier will be selected and so on. If adding a frontier would increase the number of members in the archive to exceed the population size, a truncation operator is ap- plied to that frontier based on the crowded tournament selection by which the winner of two same rank solutions is the one that possesses the greater crowding distance (farther apart from its neighbours). This is to maintain a good spread of solutions in the obtained set of solutions. Memetic algorithms (MAs), a type of evolutionary al- gorithms (EAs), have been recognised as a powerful al- gorithmic paradigm on complex search spaces for evolu- tionary computing]47[ . MAs are inspired by models of adaptation in nature systems that combine evolutionary adaptation of populations of individuals with individual learning with a lifetime. A meme is a unit of information that reproduces itself while people exchange ideas. Memes are adapted by the people who transmit them before being passed on to the next generation. MAs use EAs to perform exploration and use local search to exer- cise exploitation. A separate local search algorithm can be applied to improve the fitness of individuals by spe- cial hill-climbing. Local search in MAs is similar to s im- ple hill-climbing with differences in that 1) the neigh- bourhood of the current solutions is searched systemati- cally instead of random searching in the space of all can- didate solutions, and 2) the neighborhood search is re- peated until a locally optimal solution is found. An ad- vantage of local search in MAs over other heuristics is that local exploitation around individual can be per- formed much more effectively; hence, good solutions in a small region of the search space can be found quickly. 3. Multi-Objective MULB Problem 3.1 MULB Problem To plan an assembly process for any product on an as- sembly line, its total amount of work is partitioned into a set of elementary op erations namely tasks. Assembly line balancing is the allocation of a set of tasks to worksta- tions without violating any constraints to optimize some measure of performance. Typical constraints include Pareto-optimal solutions Dominated solutions Minimize f 1 (x) Minimize f2(x) Pareto-optimal frontier  Mixed-Model U-Shaped Assembly Line Balancing Problems with Coincidence Memetic Algorithm Copyright © 2010 SciRes JSEA 352 each task is allocated to one and only one workstation, precedence relationship that reflects technological and organisational constraints among the tasks is not violated, and total task time of any workstation does not exceed the given cycle time [13]. To perform a task on a workstation, not only tools, equipment, machinery, and labour skills have to be se- lected properly, but also its precedence relationship has to be followed strictly. A precedence diagram is often used to visually demonstrate such relationship. Nodes, node weights, and arrows on the precedence diagram represent tasks, task times, and precedence constraints between tasks, respectively. For MMAL, a merged precedence diagram is needed which can be created as follows [16]. 1) Compute the weighted average task time for each task. Let M = t he number of models to be produce d during a planning horizon, = the demand of product model m (m=1,2,...,M) task i (i=1,2,...,N) of model has task time = , The weighted average task time is = {} =1 =1 (4) 2) Merge the precedence diagram of each model to form the merged precedence diagram. It is assumed that the precedence relationship is consistent from model to model. The merged precedence diagram (MPD) is cre- ated by adding a rrow to MPD if, for any model, task is an immediate predecessor of task . MULB is more complex than the traditional straight line since not only can the set of assignable tasks be con- sidered from the set of tasks whose predecessors have already been assigned (moving forward through MPD and allocating tasks on the front side of the U-line) as the straight line, but also from the set of tasks whose suc- cessors have already been assigned (moving backwards through allocating tasks on the back side of the U-line). This permission increases possibility on how to allocate tasks to workstations and often leads to a fewer number of workstations than the straight line. Based on MPD, literature always assumes that each task type is assigned to one and only one workstation regardless of the model [32]. 3.2 Objective Functions Although several measures can be used to evaluate the performance of line balancing in MUL, in this paper three main objectives that support JIT implementation to be simultaneously optimised are evaluated including number of workstations, variation of workload, and variation of work relatedness. Since the type I problem of MULB is considered, a fixed cycle time, assembly task time, and precedence relationship are given and our first objective is to minimize the number of workstations. Achieving this objective can result in low lab our co st and less space requirement. If is the number of work- station, the objective function is formulated as follows . 1()= (5) The second obje ctive is to smooth (minimize variation of) the workloads distributed across workstations. Sev- eral benefits can be gained when MUL is operated in this manner including increased production rate, reduced line congestion, but more importantly, mitigates the concerns of inequity in task assignments among workers [35]. Th e workload smoothness objective can be formulated as follows. 2()=( )2 =1 (6) where = total time of workstation , = maxi- mum total time of all workstations = (= 1, 2, … , ). The third objective is to minimize variation of work relate dness i n a w orksta tion. The purpos e of t his object ive is to allocate interrelated tasks to the same work station as many as possible. Not only can such an assignment im- prove work efficiency, but it is also useful to assembly line designers since they may have greater flexibility in locating facilities and workstations. The formulation of this objective is as follows. 3()={ =1 } (7) where = number of relatedness of tasks in work- station . Although three objectives are considered simultane- ously in this paper, for type I problem, the first objective dominates the others. As a result, if there are two candi- date solutions, the one with lower number of worksta- tions will always selected regardless of how good the other two objectives are. 4. Proposed Algorithm 4.1 COIN Wattanapornprom et al. [48] developed a new effective evolutionary algorithm called combinatorial optimisation with coincidence (COIN) originally aiming for solving travelling salesman problems. The idea is that most well-known algorithms such as GA search for good solu- tions by sampling through crossover and mutatio n opera- tions without much exploitation of the internal structure of good solution strings. This may not only generate large number of inefficient solutions dissipated over the solution space but also consuming long CPU time. In contrast, COIN considers the internal structure of good solution strings and memorises paths that could lead to good solutions. COIN replaces crossover and mutation operations of GA and employs joint probability matrix as a means to generate solutions. It prioritises the selection of the paths with higher chances of moving towards good solutions. Apart from traditional learning from good solutions,  Mixed-Model U-Shaped Assembly Line Balancing Problems with Coincidence Memetic Algorithm Copyright © 2010 SciRes JSEA 353 COIN allows learning from below average solutions as well. Any coincidence found in a situation can be statis- tically described whether the situation is good or bad. Most traditional algorithms always discard the bad solu- tions without utilising any information associated with them. In contrast, COIN learns from the coincidence found in the bad solutions and uses this information to avoid such situations to recurrent; meanwhile, experi- ences from good coincidences are also used to construct better solutions (Figure 3). Consequently, the chances that the paths always being parts of the bad solutions are used in the new generations are lessened. This lowers the number of solutions to be considered and hence increases the convergence speed. COIN uses a join probability matrix (generator) to create the population. The generator is initialised so that it can generate a random tree with equal probability for any configuration. The population is evaluated in the same way as traditional EAs. However, COIN uses both good and bad solutions to update the generator. Initially, COIN searches from a fully connected tree and then in- crementally strengthening or weakening the connections. As generations pass by, the probabilities of selection certain paths are increased or decreased depending on the incidences found in the good or bad solutions. The algo- rithm of COIN can be stated as follows. 1) Initialise the joint probability matrix (generator). 2) Generate the population using the generator. 3) Evaluate the population. 4) Diversity preserv ation . 5) Select the candidates according to two options: (a) good solution selection (select the solutions in the first rank of the current Pareto frontier), and (b) bad solution selection (select the solutions in the last rank of the current Pareto frontier). 6) For each joint probability matrix (/), adjust the generator according to the reward and punishment scheme as (4). Bad Solution )( 1 xf )( 2xf Good Solution General Solution Figure 3. Good and bad solutio ns ,(+ 1)=,()+ (1){,(+ 1),(+ 1)} + (1)2,(+1),(+ 1) =1 =1 (8) where , = the element (,) of joint probability matrix () , = the learning coefficient, , = the number of coincidences (, ) found in the good solu- tions, , = t he number of coincidences (, ) found in the bad sol utions, = generation numbe r, = the size of the proble m, and = number of the direct predecessors of task . 7) Apply a strategy to maintain elitist solutions in the population, and then repeat Step 2 until the terminating condition is met. 4.2 Numerical Example The 11-task problem originated by Jackson [49] and later extended to accommodate a product mix by Hwang and Katayama [31] is used to elaborate the algorithm of COIN. Three models (A, B, and C) of the product mix with an equal minimum part set (MPS = [1,1,1]) are produced on MUL with 10-minute cycle time. Their precedence diagrams are shown in Figure 4. Joint Probability Matrix Initializatio n The number of tasks to be considered is 11. Therefore, the dimension of from-to joint probability matrix (/) is (11 × 11). The value of each element (,) in the matrix is the probability of selecting product after product . In order to incorporate some precedence rela- tionship into the matrix, in each row, the element which belongs to the direct predecessor of the task is set to 0 to prohibi t pr o duc ing s uc h ta s k be fore i ts di rec t prede c es sor . For example, the direct predecessor of task 2 is task 1; hence, 2,1 = 0. Also, 2,2 = 0, since it cannot move within itself. Initially, the value of the remaining elements in the 2nd row of the matrix is e qual to 1 (12) = 1 (11 11) = 0.111. Continue this computation for all the remaining tasks (rows), the initial joint prob- ability matrix is shown in Table 1. Population Generation The order representation scheme is used to create chromosomes. The task order list in a chromosome is created by moving forward through MPD. If there is more than one task can be selected, the probability of selecting any task will depend on its value on the join probability matrix. For example, task 1 is selected for the first position since it is the only task to be considered. After selecting task 1, the set of eligible tasks comprises tasks 2, 3, 4 and 5. From row 1 of the joint probability matrix, a job is randomly selected according to its prob- ability of selection (1, = 0.1000, for = 2, …, 11). If the selected job is not in the set of eligible tasks, redo the  Mixed-Model U-Shaped Assembly Line Balancing Problems with Coincidence Memetic Algorithm Copyright © 2010 SciRes JSEA 354 1 2 3 5 7 8 9 10 11 1 2 3 4 5 7 8 9 10 11 6 (a) (b) 1 2 5 7 9 11 6 1 2 3 4 5 7 8 9 10 11 6 6 2 7 5 1 26 3 5 5 4 (c) (d) Figure 4. Precedence diagrams. (a) Precedence diagram of model A; (b) Precedence diagram of model B; (c) Precedence dia- gram of model C; (d) Merged precedence diagram of models A, B and C Table 1. Initial joint probability matrix j i 1 2 3 4 5 6 7 8 9 10 11 1 0 0.1000 0.1000 0.1000 0.1000 0.1000 0.1000 0.1000 0.1000 0.1000 0.1000 2 0 0 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 3 0 0.1111 0 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 4 0 0.1111 0.1111 0 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 5 0 0.1111 0.1111 0.1111 0 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 6 0.1111 0 0.1111 0.1111 0.1111 0 0.1111 0.1111 0.1111 0.1111 0.1111 7 0.1429 0.1429 0 0 0 0.1429 0 0.1429 0.1429 0.1429 0.1429 8 0.1111 0.1111 0.1111 0.1111 0.1111 0 0.1111 0 0.1111 0.1111 0.1111 9 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 0 0.1111 0 0.1111 0.1111 10 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 0 0.1111 0 0.1111 11 0.1250 0.1250 0.1250 0.1250 0.1250 0.1250 0.1250 0.1250 0 0 0 selection. Suppose we select task 5, the new set of eligi- ble tasks becomes tasks 2, 3 and 4. Continue this mecha- nism until all positions in the task order list are filled and we obtain the task order list of 1={1,5,3,4,7,2,6,9, 8,10,11}. Assume that the population size is 5 and the four remaining initial population consists of chromo- somes 2={1,4,5,3,7,9,2,6,8,10,11}; 3={1,3,2,6,8,5,10, 4,7,9,11}; 4={1,4,3,2,6,8,10,5,7,9,11}, and 5={1,5,4, 3,2,6,8,7,9,10,11}. Population Evaluation To find tentative tasks to be allocated on the U-line, we have to search through the task order list in both for- ward and backward directions. The tentative task on for- ward or backward searching is the first found task that has its task time less than or equal to the remaining work- station cycle time and does not violated MPR. If both forward and backward tentative tasks are found, either one is selected randomly. But if none is found and the task order list stil l has so me task no t yet bein g allo cated, a new workstation is opened. For example, for the task or- der list of 1={1,5,3,4,7,2,6,9,8,10,11} and cycle time = 10, the forward and backward tentative task s are tasks 1 and 11. If task 1 is randomly selected, the remaining cycle time is 10 – 6 = 4, the new forward and backward tenta- tive tasks are tasks 5 and 11 so on and so forth. Finally, a feasible line balance with = 7 workstations and work- station l oa d distribution given by 1= {1,5}, 2= {10,11} , 3= {8}, 4= {9}, 5= {3}, 6= {4,6,7}, 7= {2}. Re- peat this procedure for the remaining task order lists to obtain the number of workstations and workstation load distribution for each of them. Having obtained feasible line balances, three objectives have to be evaluated for each chromosome. Table 2 indicates that all chromo- somes give the same number of workstations; therefore, they are all eligible for Pareto ranking based on workload smoothness and work relatedness objectives. The Pareto ranking technique proposed by Goldberg [50] is used to classify the population into non-dominated frontiers and a dummy fitness va lue (lower value is better) is assig ned to each chromosom e (Figure 5).  Mixed-Model U-Shaped Assembly Line Balancing Problems with Coincidence Memetic Algorithm Copyright © 2010 SciRes JSEA 355 Diversity Preservation COIN employs a crowding distance approach [46] to generate a diversified population with uniformly spread over the Pareto frontier and avoid a genetic drift phe- nomenon (a few clusters of populations being formed in the solution space). The salient characteristic of this ap- proach is that there is no need to define any parameter in calculating a measure of population density around a solution. The crowding distances computed for all solu- tions are infinite since only one s olution is found fo r each frontier. Solution Selection Having defined the Pareto frontier, the good solutions are the chromosomes located on the first Pareto frontier (dummy fitness = 1), i.e. 2={1,4,5,3,7,9, 2,6,8,10,11}. The bad solutions are those located on the last Pareto fron- tier (dummy fitness = 5), i.e. 4={1,4,3,2,6,8,10,5,7,9,11}. Joint Probability Matrix Adjustme nt The adjustment of joint probability matrix is crucial to the per formance o f COIN. Reward wil l be give n to , if the order pair (,) is in the good solution to increase the chance of selection in the next round. For example, an order pai r (1,4) i s in the g ood soluti on 2={1,4,5,3,7,9,2,6, 8,10,11}. Assume that = 0.3, hence the value of , where = 1 and = 4 is increased by (1 1) = 0.3/( 11 – 1 – 0) = 0.03. The up date d val ue of , of the order pair (1,4) becomes 0.1 + 0.03 = 0.13. The values of the other order pairs located in the same row of the order pair (1,4) is reduced by (11)2 = 0.3/100 = 0.003. For example, the va l ue , where = 1 and = 4 is 0.1 – 0.003 = 0.0970. Continue this procedure to all order pairs located in the good solution; the revised joint probability matrix is obtained (Table 3). In contrast, if the order pair (,) is in the bad solution, , will be penalised to reduce the chan ce of selection in the next round. For example, an order pair (1,4) is in the bad solution 4={1,4,3,2,6,8, 10,5,7,9,11}. Therefore, the value of , where = 1 and = 4 is decreased by (11) = 0.3/10 = 0.03. The updated value of , of the or der pa ir (1, 4) be comes 0.130 – 0.030 = 0. 100 . The values of the other order pai rs loca ted i n the sam e row of the order pair (1, 4) is increa s e d by (11)2 = 0.3/100 = 0.003. For example, the value , where = 1 and = 2 is 0.097 + 0.003 = 0.100. Continue this pro- cedure to all order pairs located in the bad solution; the revised joint probabil ity matrix i s obtained (Table 4). Elitism To keep t he best sol utions f ound so far t o be survi ved in the next generation, COIN uses an external list with the same size as the population size to store elitist solutions. All non-dominated solutions created in the current popu- lation are combined with the current elitist solutions. Goldberg’s Pareto ranking technique is used to classify the combined population into several non-dominated frontiers. Only the solutions in the first non-dominated frontier are filled in the new elitist list. If the number of solutions in the first non-dominated frontier is less than or equal to the size of the elitist list, the new elitist list will contain all solutions of the first non-dominated frontier. Otherwise, Pareto domination tournament selection [51] is exercised. Two solutions from the first non-dominated solutions are randomly selected and then the solution with larger crowding distance measure and not being selected before is added to the new elitist list. This approach not only ensures that all solutions in the elitist list are non-dominated solutions but also promoting diversity of the sol utions. Accordi ng to our e xam ple, the current eliti st list is empty and the solutions in the current first non-dominated frontier is 2={1,4,5,3,7,9,2,6,8,10, 11}. When both sets are combined the non-dominate d frontier is still the same. Also, the number of the com- bined solutions is less than the size of the elitist list; hence, both solutions are added to the new elitist. Figure 5. Pareto frontier of each chromosome Table 2. Objective functions of each chromosome Chromosome Nu mb e r Number of Workstations Workload Smoothness Work Relatedness Pareto Frontier Crowding Distance 2 4 1.4142 4.4444 1 Infinite 3 4 2.0817 5.2500 2 Infinite 5 4 2.9439 5.3333 3 Infinite 1 4 4.2088 6.1250 4 Infinite 4 4 4.3425 6.2222 5 Infinite  Mixed-Model U-Shaped Assembly Line Balancing Problems with Coincidence Memetic Algorithm Copyright © 2010 SciRes JSEA 356 Table 3. Revised joint probability matrix (good solution) j i 1 2 3 4 5 6 7 8 9 10 11 1 0 0.0970 0.0970 0.1300 0.0970 0.0970 0.0970 0.0970 0.0970 0.0970 0.0970 2 0 0 0.1074 0.1074 0.1074 0.1444 0.1074 0.1074 0.1074 0.1074 0.1074 3 0 0.1074 0 0.1074 0.1074 0.1074 0.1444 0.1074 0.1074 0.1074 0.1074 4 0 0.1074 0.1074 0 0.1444 0.1074 0.1074 0.1074 0.1074 0.1074 0.1074 5 0 0.1074 0.1444 0.1074 0 0.1074 0.1074 0.1074 0.1074 0.1074 0.1074 6 0.1074 0 0.1074 0.1074 0.1074 0 0.1074 0.1444 0.1074 0.1074 0.1074 7 0.1367 0.1367 0 0 0 0.1367 0 0.1367 0.1858 0.1367 0.1367 8 0.1074 0.1074 0.1074 0.1074 0.1074 0 0.1074 0 0.1074 0.1444 0.1074 9 0.1074 0.1444 0.1074 0.1074 0.1074 0.1074 0 0.1074 0 0.1074 0.1074 10 0.1074 0.1074 0.1074 0.1074 0.1074 0.1074 0.1074 0 0.1074 0 0.1444 11 0.1250 0.1250 0.1250 0.1250 0.1250 0.1250 0.1250 0.1250 0 0 0 Table 4. Revised joint probability matrix (bad solution) j i 1 2 3 4 5 6 7 8 9 10 11 1 0 0.1000 0.1000 0.1000 0.1000 0.1000 0.1000 0.1000 0.1000 0.1000 0.1000 2 0 0 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 3 0 0.0741 0 0.1111 0.1111 0.1111 0.1481 0.1111 0.1111 0.1111 0.1111 4 0 0.1111 0.0741 0 0.1481 0.1111 0.1111 0.1111 0.1111 0.1111 0.1111 5 0 0.1111 0.1444 0.1111 0 0.1111 0.0778 0.1111 0.1111 0.1111 0.1111 6 0.1111 0 0.1111 0.1111 0.1111 0 0.1111 0.1111 0.1111 0.1111 0.1111 7 0.1429 0.1429 0 0 0 0.1429 0 0.1429 0.1429 0.1429 0.1429 8 0.1111 0.1111 0.1111 0.1111 0.1111 0 0.1111 0 0.1111 0.1111 0.1111 9 0.1111 0.1481 0.1111 0.1111 0.1111 0.1111 0 0.1111 0 0.1111 0.0741 10 0.1111 0.1111 0.1111 0.1111 0.0741 0.1111 0.1111 0 0.1111 0 0.1481 11 0.1250 0.1250 0.1250 0.1250 0.1250 0.1250 0.1250 0.1250 0 0 0 5. Experimental Design 5.1 Problem Sets In order to compare the performances of COIN against several comparator search heuristics, three well-known test problems were employed as shown in Table 5. The problem set 1, 2, and 3 represent small, medium, and large-sized problems respectively 5.2 Comparison Heuristics The performances of the proposed COIN applied to MULB problems are compared against such a well-known mul ti-objective evolutionary as NSGA II. In addition, the Table 5. Test problems Problem Set Number of Products Number of Tasks Cycle Time (sec) 1. Thomopoulos[56] 3 19 120 2. Kim[36] 4 61 600 3. Arcus[57] 5 111 10,000 extende d versions of COIN and NSGA II, i.e. MNSGA II and COIN-MA, are also evaluated. NSGA II The algorithm of NSGA II [46] can be stated as follo ws. 1) Create an initial parent population of size ran- domly. 2) Sort the population into several frontiers based on the fast non-dominated sorting algorithm. 3) Calculate a crowding distance measure for each so- lution. 4) Select the parent population into a mating pool based on the binary crowded tournament selection. 5) Apply crossover and mutation operators to create an offspring popula tion of size . 6) Combine the parent population with the offspring population and apply an elitist mechanism to the com- bined population of size 2 obtain a new population of size . 7) Repeat Step 2 until the terminating condition is met. MNSGA II MNSGA II is a memetic version of NSGA II. Appro-  Mixed-Model U-Shaped Assembly Line Balancing Problems with Coincidence Memetic Algorithm Copyright © 2010 SciRes JSEA 357 priate local searches can additionally embed into several positions of the NSGA II’s algorithm, i.e. after initial population, after crossover, and after mutation [52]. The number of places to apply local search has a direct effect on the qua li t y of s ol ut io n a nd computati on ti m e. Henc e , if computation time needs to be saved, local search should be taken only at some specific steps in the algorithm of MA rather than at all possible steps. In this research, we choose to take local search after obtaining initial solution and after mutation since pilot experiments and our pre- vious research [53] indicated that these two points were enough to find significantly improved solutions, pull the solutions out of the local optimal, and reduce computa- tional time. The algorithm of MNSGA II can be stated as follows. 1) Create an initial parent population of size ran- domly. 2) Apply a local search to the initial parent popu latio n. 3) Sort the population into several frontiers based on the fast non-dominated sorting algorithm. 4) Calculate a crowding distance measure for each so- lution. 5) Select the parent population into a mating pool based on the binary crowded tournament selection. 6) Apply crossover and mutation operators to create an offspring popula tion of size . 7) Apply a local search to the offspring population. 8) Combine the parent population with the offspring population and apply an elitist mechanism to the com- bined population of size 2 obtain a new population of size . 9) Repeat Step 3 until the terminating condition is met. Four local searches modified from Kumar and Singh [54] originally developed to solve travelling salesman problem s by repeate dly exc hangi ng ed ges of the tou r until no improvement is attained are examined including Pairwise Interchange (PI), Insertion Procedures (IP), 2-Opt, and 3-Opt. Three criteria are used to test whether to accept a move that a local search heuristic creates a neighbo ur soluti on from the current s olution a s follows: ( 1) accept the new solution if 1() is descendent, (2) accept the new solution if 1() is the same and 2() is de- scendent ; ( 2) a c ce pt t he ne w s ol ut io n if 1() is the same and 3() is de s c e ndent; or (3) accept t he new solution if it dominates the current solution (1() is the same, and both 2() and 3() are descendent). CNSGA II In this heuristic, COIN is run for a certain number of generations. NSGA II then accepts the final solutions of COIN as its initial populatio n and proceeds with its alg o- rithm. COIN-MA In this heuristic, COIN is activated first for a certain number of generations. The final solutions obtained from COIN are then fed into MNSGA II as an initial population. 5.3 Comparison Metrics Three metrics are measured to evaluate the achievement of two common goals for comparison of multi-objective optimisation methods as recommended by Kumar and Singh [54]: 1) convergence to the Pareto-optimal set, and 2) maintenance of diversity in the solutions of Pareto- optimal set. In addition, CPU time of each heuristic for achieving the final solutions is measured. The convergence of the obtained Pareto-optimal solu- tion towards a true Pareto-set () is the difference be- tween the obtained solution set and the true-Pareto set. Mathematically, it is defined as (9) and (10) ()= || =1 || (9) = =1 ||()() 2 2 =1 (10) where || is the number of elements in set A , is the Euclidean distance between non-dominated solution in the true-Pareto frontier () and the obtained so- lution (), and are maximum and mini- mum values of objective functions in the true- Pareto set respectively. For metric , lower value indi- cates superiority of the solution set. When all solutions converge to Pareto-optimal frontier, this metric is zero indicating that the obtained solution set has all solutions in the true Pareto set. Since the true Pareto frontier is unknown, its approximation is needed. The approximated true Pareto-optimal frontier is the result of combining all final non-dominated solutions obtained from of all algo- rithms, applying Goldberg’s Pareto ranking technique to the combined solutions, and the first frontier of the com- bined solutions is the approximated true Pareto-optimal frontier. The second measure is a spread metric. This measure computes the distribution of the obtained Pareto-solu- tions by calculating a relative distance between consecu- tive solutions as shown in (11) and (12). ()= ++ ||1 =1 ++(||1) (11) = ()(+1) 2 2 =1 (12) where and are the Euclidean distances be- tween the extreme solutions and boundary solutions of the obtained Pareto-optimal, || is the number of ele- ments in the obtained-Pareto solutions, is the Euclidian distance of between consecutive solutions in the obtained-Pareto solutions for =1, 2, … , ||1,  Mixed-Model U-Shaped Assembly Line Balancing Problems with Coincidence Memetic Algorithm Copyright © 2010 SciRes JSEA 358 is the average Euclidean distance of , and the operator “|| ||” means an absolute value. The value of this measure is zero for a uniform distribution, but it can be more tha n 1 when bad dist ribution is found. The third measure is the ratio of non-dominated solu- tions which indicates the coverage of one set over another. Let be a solution sets (=1, 2, … , ). For comparing each solution set (=12… ) the ratio of non-dominated measure of the solution set to the solution sets is the ratio of solutions in that are not dominated by any other solution in , which is defined as (13), where means the ob- tained solution is dominated by the true-Pareto solu- tion . The higher ratio indicates superiority of one solu- tion set o ve r a n other. = | : (13) All algorithms are coded in Mathlab 7.0. The test platform is on Intel Core2 Duo 2.00 GHz under Win- dows XP with 1.99 GB RAM. The CPU time of each heuristic is kept after the program is terminated. 5.4 Parameter Settings To tune MOEA for the MULB problems, an experimental design [55] was employed to systematically conduct and investigate the effect of each parameter to the responses of each heuristic. Recommendations from the past re- searches, e.g. Kim et al. [36], Chutima and Pinkoompee [53], etc. were used as a starting point for parameter set- tings. Extensive pilot runs were conducted around the vicinities of the starting point. The selection for each pa- rameter setting was based on quality and diversity of so- lutions. If neither quality nor diversity of solutions was significantly d if f eren t for several setting s of the parameter, the one with lowest CP U time was selected. Having don e that, Table 6 shows the parameter settings found to be effective for each problem. The process of finding appropriate local searches (LSs) for MNSGA II and COIN-MA for each problem set is worth mentioning. Four local searches that gave good performances from previous research [53] were investi- gated, i.e. Pairwise Interchange (PI), Insertion Proce- dures (IP), 2-Opt, and 3-Opt. Although LS can be located on 3 different places in MA, pilot runs indicated that pu t- ting LS after crossover did not help MA improve its per- formances. Therefore, LSs were placed only after initial population and after mutation for MNSGA II and after mutation for COIN-MA. Full factorial experiments were conducted to test the performances of LSs on each problem with 2 replicates. The number of experiment runs for each problem of MNSGA II and COIN-MA is 4*4*2 = 32 and 4*2 = 8 respectively. In total the number of runs is 120. ANOVA and Tukey’s multiple range test were conducted to test significant different at 0.05 level. Table 6. Parameter settings for each heuristic Parameter settings COIN NSGA II MNSGA II CNSGA II COIN-MA Population size 100 100 100 100 100 Number of genera- tions Small = 100 Medium = 150 Large = 300 Small = 100 Medium = 150 Large = 300 Small = 100 Medium = 150 Large = 300 Small = 100 Medium = 150 Large = 300 Small = 100 Medium = 150 Large = 300 Crossover - Weight mapping crossover Weight mapping crossover Weight mapping crossover Weight mapping crossover Mutation - Reciprocal exchange Reciprocal exchange Reciprocal exchange Reciprocal exchange Probability of cross- over - 0.7 0.7 0.7 0.7 Probability of muta- tion - 0.1 0.1 0.1 0.1 Learning coefficient (k) Small = 0.1 Medium = 0.2 Large = 0.2 - - Small = 0.1 Medium = 0.2 Large = 0.2 Small = 0.1 Medium = 0.2 Large = 0.2 Percentage of gen- erations of COIN to NSGA II - - - Small = 80:20 Medium = 60:40 Large = 60:40 Small = 80:20 Medium = 60:40 Large = 60:40 Table 7. Appropriate local searches Problem set MNSGA II COIN-MA LS after initial population LS after mutation LS after mutation 1 IP PI IP 2 PI 3-Opt IP 3 IP PI PI  Mixed-Model U-Shaped Assembly Line Balancing Problems with Coincidence Memetic Algorithm Copyright © 2010 SciRes JSEA 359 The LSs appearing in Table 7 were those that per- formed best with respect to solution quality, diversity, and CPU time. It is apparent that b es t LS combination for MNSGA II and COIN-MA depends on the problem set. However, for MNSGA II the combination of IP (LS used after initial population) and PI (LS used after mutation) appear more often than the other. For COIN-MA, IP seems to give better performances for small- and me- dium-sized problems; whereas, PI performed better than the others for large-sized problems. As a result, these settings were used for MNSGA II and COIN-MA in rela- tive performance comparison. 6. Experimental Results The behaviour of COIN was demonstrated with the 61 tasks’ problem as shown in Figure 6. At the beginning (generation 1), a number of rather poor feasible solutions were created. As the number of generations increased, better solutions were found as observed from the moving downward trend to the left of the Pareto fronts. It was noticeable that not much improvement was gained in the first 20 generations. A leaped gain was noticeable from generations 20 to 30. However, the improvement was less and less after that and the Pareto front remained the same after generation 100. The behaviour of CNSGA II (COIN plus NSGA II) and COIN-MA (COIN plus MNSGA II) were demo n- strated in Figure 7 and Figure 8. Both algorithms al- lowed COIN to run for 150 generations and the final so- lutions of COIN were considered as initial solutions of NSGA II and MNSGA II. Significant improvement was found after COIN was terminated and marginal gains from its previous solutions were obtained at the end of both algorithms. In other words, NSGA II (in CNSGA II) and MNSGA II (in COIN-MA) cannot provide much improvement to the final solutions of COIN. For the small-sized problem (19 tasks), Table 8 showed that all algorithms gave the same number of workstations. NSGA II performed worst comparing with the others. By adding appropriate local search to NSGA II, its memetic version (MNSGA II) gained significant performance improvement. Although MNSGA II ob- tained the best spread metric, it was do minated by COIN, CNSGA II, and CO IN-MA (Figure 9). These three algo- rithms obtained the same best Pareto front which can be seen from their ratio of non-dominated solution ( = 1) in Tab l e 8. For the medium-sized problem (61 tasks), COIN-MA obtained highest , followed by CNSGA II, whereas the other algorithms have = 0 (Table 8). This was confirmed by Figure 10 meaning that some solutions of COIN-MA and CNSGA II were located in the Pareto front. MNSGA II outperf ormed NSGA II, bu t it was domina ted by COIN . A big gap between the front of NSGA I I and the Figure 6. Characteristic of COIN Figure 7. Characteristic of CNSGA II. Figure 8. Characteristic of COIN-MA Workload Smoothing Relatedness 0.40.30.20.10.0 3.6 3.5 3.4 3.3 3.2 3.1 3.0 Variable 3 * COIN 4 * COIN plus NSGA-II 5 * COIN plus M-NSGA-II 1 * NSGA-II 2 * M-NSGA-II Compare Algorithm (19 task's) Figure 9. Pareto front of each algorithm (19 tasks) fronts of three good performers (COIN, CNSGA II, and COIN-MA) was noticed indicating s ignificant gains from using these three algorithms. 8.5 9.0 9.5 10.0 0 1 2 3 Relateness Workload Smoothing Characteristic of COIN Gen 1 Gen 10 Gen 20 Gen 30 Gen 40 Gen 50 8.0 8.5 9.0 9.5 10.0 0123 Relateness Workload Smoothing Characteristic of CNSGA II Gen 1 Gen 150 Gen 300 8.0 8.5 9.0 9.5 10.0 0123 Relateness Workload Smoothing Characteristic of COIN-MA Gen 1 Gen 150 Gen 300  Mixed-Model U-Shaped Assembly Line Balancing Problems with Coincidence Memetic Algorithm Copyright © 2010 SciRes JSEA 360 Table 8. Performance comparison Problem set Performance Meas- ure NSGA II COIN MNSGA II CNSGA II COIN-MA 1 Number of wor k- stations 4 4 4 4 4 Convergence 0.4381 0.1317 0.0603 0.1317 0.1317 Spread 0.6557 0.5390 0.4948 0.5390 0.5390 RNDS 0.0000 1.0000 0.4000 1.0000 1.0000 CPU Time (min) 6 3 13 4 7 2 Number of wor k- stations 10 9 10 9 9 Convergence 0.9951 0.8966 0.4419 0.3058 0.0710 Spread 0.4504 0.4945 0.8038 0.5514 0.4271 RNDS 0.0000 0.0000 0.0000 0.5000 0.6250 CPU Time (min) 55 11 86 19 25 3 Number of wor k- stations 16 16 16 15 15 Convergence 1.0000 0.9907 0.8645 0.4100 0.0000 Spread 0.7479 0.6951 0.4882 0.7211 0.6643 RNDS 0.0000 0.0000 0.0000 0.0000 1.0000 CPU Time (min) 478 20 1089 32 44 For the large-sized problem (111 tasks), once again, COIN-MA performed best and NSGA II was ranked last (Figure 11). COIN outperformed NSGA and NSGA II. The performance of COIN was improved significantly with the cooperation of NSGA II (CNSGA II) and MNSGA II (COIN-MA). COIN-MA dominated all algo- rithms and, from Table 8, its solutions were all in the Pareto front (= 1). In terms of CPU time (Table 8), CO IN used the lowest time to achie ve the final s oluti ons foll owed b y CNSGA II, Workload Smoothing Relatedness 1.61.41.21.00.80.60.40.20.0 9.75 9.50 9.25 9.00 8.75 8.50 Variable 3 * COIN 4 * COIN plus NSGA-II 5 * COIN plus M-NSGA-II 1 * NSGA-II 2 * M-NSGA-II Compare Algorithm (61 task's) Figure 10. Pareto front of each algorithm (61 tasks) COIN-MA, NSGA II, and MNSGA II. As a result, COIN can be considered as a fast and smart algorithm since it can obtain good solutions very fast. It can be used as a good benchmark for other algorithms. In addition, if the good Pareto front needs to be discovered within a limited CPU time, COIN-MA is recommended as an outstanding alternative. 7. Conclusions This paper presents a novel evolutionary algorithm Workload Smoothing Relatedness 120010008006004002000 15.75 15.50 15.25 15.00 14.75 14.50 Variable 3 * COIN 4 * COIN plus NSGA-II 5 * COIN plus M-NSGA-II 1 * NSGA-II 2 * M-NSGA-II Compare Algorithm (111 task's) Figure 11. Pareto front of each algorithm (111 tasks)  Mixed-Model U-Shaped Assembly Line Balancing Problems with Coincidence Memetic Algorithm Copyright © 2010 SciRes JSEA 361 namely combinatorial optimisation with coincidence al- gorithm (COIN) and its variances. The algorithms are applied to solve Type I problems of MMUALBP in a just-in-time production environment. COIN recognises the positive knowledge appearing in the order pairs of the good solution by giving a marginal reward (increased probability) to its related element of the joint probability matrix. In contrast, the negative knowledge found in the order pairs of the bad solution, which is often remiss in most algorithms, is also utilised in COIN (reduced prob- ability) to prevent undesired solutions coincidentally found in this generation to be recurring in the next gen- eration. The performances of COIN and its variances are evaluated on three objectives, i.e. minimum number workstations, minimum work relatedness, and minimum workload smoothness. Among these three, minimum number of workstations is dominated resulting in only the solutions with the same minimum number of work- stations being considered and can be located on the first Pareto front. Experimental results indicate clearly that COIN outperforms the well-known NSGA II in all as- pects. As a result, COIN can be considered as a new al- ternative benchmarking algorithm for MMUALBP. The COIN’s variances (CNSGA II and COIN-MA) show significantly better performances than COIN, NSGA II, and MNSGA I I. Although COIN-MA marginally uses more CPU time than CNSGA II, the other performances of COIN-MA are better than CNSGA. As a result, if we need to find an algorithm to search for an optimal Pareto front for MMUALBP, COIN-MA is recommended. REFERENCES [1] N. Boysen, M. Fliedner and A. Scholl, “Assembly Line Balancing: Which Model to Use When?” International Journal of Production Economics, Vol. 111, No. 2, 2008, pp. 509-528. [2] R. J. Schonberger, “Japanese Manufacturing Techniques: Nine Hidden Lessons in Simplicity,” Free Press, New York, 1982, pp. 140-141. [3] J. Miltenburg, “U-Shaped Production Lines: A Review of Theory and Practice,” International Journal of Production Economics, Vol. 70, No. 3, 2001, pp. 201-214. [4] Y. Monden, “Toyota Production System,” 2nd Edition, Industrial Engineering Press, Institute of Industrial Engi- neering, Norcross, 1993. [5] G. J. Miltenburg and J. Wijngaard, “The U-Line Balancing Problem,” Management Science, Vol. 40, No. 10, 1994, pp. 1378-1388. [6] C. H. Cheng, G. J. Miltenburg and J. Motwani, “The Ef- fect of Straight- and U-Shaped Lines on Quality,” IEEE Transactions on Engineering Management, Vol. 47, No. 3, 2000, pp. 321-334. [7] G. J. Miltenburg, “The Effect of Breakdowns on U-Shaped Production Lines,” International Journal of Production Research, Vol. 38, No. 2, 2000, pp. 353-364. [8] J. Miltenburg, “One-Piece Flow Manufacturing on U- Shaped Production Lines: A Tutorial,” IIE Transactions, Vol. 33, No. 4, 2001, pp. 303-321. [9] Y. Kara, U. Ozcan and A. Peker, “Balancing and Se- quencing Mixed-Model just-in-Time U-Lines with Multi- ple Objectives,” Applied Mathematics and Computation, Vol. 184, No. 2, 2007, pp. 566-588. [10] M. E. Salveson, “The Assembly Line Ba l a nc ing Problem,” The Journal of Industrial Engineering, Vol. 6, No. 3, 1955, pp. 18-25. [11] I. Baybars, “A Survey of Exact Algorithms for the Simple Assembly Line Balancing Problem,” Management Sci- ence, Vol. 32, No. 8, 1986, pp. 909-932. [12] S. Ghosh and R. J. Gagnon, “A Comprehensive Li terature Review and Analysis of the Design, Balanci ng and Sched- uling of Assembly Systems,” International Journal of Production Research, Vol. 27, No. 4, 1989, pp. 637-670. [13] E. Erel and S. C. Sarin, “A Survey of the Assembly Line Balancing Procedures,” Production Planning and Control, Vol. 9, No. 5, 1998, pp. 414-434. [14] C. Becker and A. Scholl, “A Survey on Problems and Methods in Generalized Assembly Line Balancing,” European Journal of Operational Research, Vol. 168, No. 3, 2006, pp. 694-715. [15] N. Boysen and M. Fliedner, “A Versatile Algorithm for Assembly Line Balancing,” European Journal of Opera- tional Research, Vol. 184, No. 1, 2008, pp. 39-56. [16] D. Sparling and J. Miltenburg, “The Mixed-Model U-Line Balancing Problem,” International Journal of Production Research, Vol. 36, No. 2, 1998, pp. 485-501. [17] G. J. Miltenburg, “Balancing U-Lines in a Multiple U- Line Facility,” European Journal of Operational Re- search, Vol. 109, No. 1, 1998, pp. 1-23. [18] T. L. Urban, “Optimal Balancing of U-Shaped Assembly Lines,” Management Science, Vol. 44, No. 5, 1998, pp. 738-741. [19] D. A. Ajenblit and R. L. Wainwright, “Applying Genetic Algorithms to the U-Shaped Assembly Line Balancing Problem,” Proceedings of the 1998 IEEE International Conference on Evolutionary Computation, Alaska, 1998, pp. 96-101. [20] A. School and R. Klein, “ULINO: Optimally Balancing U-Shaped JIT Assembly Lines,” International Journal of Production Research, Vol. 37, No. 4, 1999, pp. 721-736. [21] E. Erel, I. Sabuncuoglu and B. A. Aksu, “Balancing of U-Type Assembly Systems Using Simulated Annealing,” International Journal of Production Research, Vol. 39, No. 13, 2001, pp. 3003-3015. [22] G. R. Aa se, M. J. Schniederjans and J. R. Olson, “U-OPT: An Analysis of Exact U-Shaped Line Balancing Proce- dures,” International Journal of Production Research, Vol. 41, No. 17, 2003, pp. 4185-4210.  Mixed-Model U-Shaped Assembly Line Balancing Problems with Coincidence Memetic Algorithm Copyright © 2010 SciRes JSEA 362 [23] G. R. Aase, J. R. Olson and M. J. Schniederjans, “U- Shaped Assembly Line Layouts and t heir Impact on Labor Productivity: An Experimental Study,” European Journal of Operational Research, Vol. 156, No. 3, 2004, pp. 698- 711. [24] U. Martinez and W. S. Duff, “Heuristic Approaches to Solve the U-Shaped Line Balancing Problem Augmented by Geneti c Algorithms,” Proc eedings of the 2004 Systems and Information Engineering Design Symposium, Char- lottesville, 16 April 2004, pp. 287-293. [25] J. Balakrishnan, C.-H. Cheng, K.-C. Ho and K. K. Yang, “The Application of Single-Pass Heuristics for U-Lines,” Journal of Manufacturing Systems, Vol. 28, No. 1, 2009, pp. 28-40. [26] H. Gokcen and K. Agpak, “A Goal Programming Ap- proach to Simple U-Line Balancing Problem,” European Journal of Operational Research, Vol. 171, No. 2, 2006, pp. 577-585. [27] T. L. Urban and W.-C. Chiang, “An Optimal Piece- wise-Linear Program for the U-Line Balancing Problem with Stochastic Task Times,” European Journal of Opera- tional Research, Vol. 168, No. 3, 2006, pp. 771-782. [28] W.-C. Chiang and T. L. Urban, “The Stochastic U-Line Balancing Problem: A Heuristic Procedure,” European Journal of Operational Research, Vol. 175, No. 3, 2006, pp. 1767-1781. [29] Y. Kara, T. Paksoy and C. T. Chang, “Binary Fuzzy Goal Programming Approach to Single Model Straight and U-Shaped Assembly Line Balancing,” European Journal of Operational Research, Vol. 195, No. 2, 2009, pp. 335- 347. A. L. Arcus, “COMSOAL: A Computer Method of Sequencing Operations for Assembly Lines,” Interna- tional Journal of Production Research, Vol. 4, No. 4, 1965, pp. 259-277. [30] A. Baykasoglu, “Multi-Rule Multi-Objective Simulated Annealing Algorithm for Straight and U Type Assembly Line Balancing Problems,” Journal of Intelligent Manu- facturing, Vol. 17, No. 2, 2006, pp. 217-232. [31] R. K. Hwang, H. Katayama and M. Gen, “U-Shaped As- sembly Line Balancing Problem with Genetic Algorithm,” International Journal of Production Research, Vol. 46, No. 16, 2008, pp. 4637-4649. [32] R. K. Hwang and H. Katayama, “A Multi-Decision Ge- netic Approach for Workload Balancing of Mixed-Model U-Shaped Assembly Line Systems,” International Journal of Production Research, Vol. 47, No. 14, 2009, pp. 3797- 3822. [33] A. Baykasoglu and T. Dereli, “Simple and U-Type As- sembly Line Balancing by Using an Ant Colony Based Algorithm,” Mathematical and Computational Applica- tions, Vol. 14, No. 1, 2009, pp. 1-12. [34] G. J. Miltenburg, “Balancing and Scheduling Mixed-Model U-Shaped Production Lines,” International Journal of Flexible Manufacturing Systems, Vol. 14, No. 2, 2002, pp. 119-151. [35] Y. K. Kim, S. J. Kim and J. Y. Kim, “Balancing and Se- quencing Mixed-Model U-Lines with a Co-Evolutionary Algorithm,” Production Planning and Control, Vol. 11, No. 8, 2000, pp. 754-764. [36] Y. K. Kim, J. Y. Kim and Y. Kim, “An Endosymbiotic Evolutionary Algorithm for the Integration of Balancing and Sequencing in Mixed-Model U-Lines,” European Journal of Operational Research, Vol. 168, No. 3, 2006, pp. 838-852. [37] S. Agrawal and M. K. Tiwari, “A Collaborative Ant Col- ony Algorithm to Stochastic Mixed-Mode l U-Shaped Dis- assembly Line Balancing and Sequencing Problem,” In- ternational Journal of Production Research, Vol. 46, No. 6, 2008, pp. 1405-1429. [38] I. Sabuncuoglu, E. Erel and A. Alp, “Ant Colony Optimi- zation for the Single Model U-Type Assembly Line Bal- ancing Problem,” International Journal of Production Economics, Vol. 120, No. 2, 2009, pp. 287-300. [39] Y. Kara, U. Ozcan and A. Peker, “An Approach for Bal- ancing and Sequencing Mixed-Model JIT U-Lines,” In- ternational Journal of Advanced Manufacturing Technol- ogy, Vol. 32, No. 11-12, 2007, pp. 1218-1231. [40] Y. Kara, “Line Balancing and Model Sequencing to Re- duce Work Overload in Mixed-Model U-Line Production Environments,” Engineering Optimization, Vol. 40, No. 7, 2008, pp. 669-684. [41] A. Konak, D. W. Coit and A. E. Smith, “Multi-Objective Optimization Using Genetic Algorithms: A Tutorial,” Re- liability Engineering & System Safety, Vol. 91, No. 9, 2006, pp. 992-1007. [42] C. A. C. Coello, D. A. Veldhuizen and G. B. Lamont, “Evolutionary Algorithms for Solving Multi-Objective Problems,” Kluwer A cad emic Publishers, Dordrecht, 2002. [43] E. Zitzler and L. Thiele, “Multiobjective Evolutionary Algorithms: A Comparative Case Study and the Strength Pareto Approach,” IEEE Transactions on Evolutionary Computation, Vol. 3, No. 4, 1999, pp. 257-271. [44] C. M. Fonseca and P. J. Fleming, “Genetic Algorithms for Multiobjective Optimization: Formulation, Discussion and Generalization,” Proceedings of 5th International Confer- ence on Genetic Algorithm, Urbana, June 1993, pp. 416- 423. [45] C. M. Fonseca a nd P. J. Fleming, “An overview of Evolu- tionary Algorithms in Multiobjective Optimization,” Evo- lutionary Computation, Vol. 3, No. 1, 1995, pp. 1-16. [46] K. Deb, A. Pratap, S. Agarwal and T. Meyarivan, “A Fast and Elitist Multiobjective Genetic Algorithm: NSGA II,” IEEE Transactions on Evolutionary Computation, Vol. 6, No. 2, 2002, pp. 182-197. [47] D. Corne, M. Dorigo and F. Glover, “New Ideas in Opti- mization,” McGraw-Hill, London, 1999. [48] W. Wattanapornprom, P. Olanviwitchai, P. Chutima and P. Chongsatitvatana, “Multi-Objective Combinatorial Op-  Mixed-Model U-Shaped Assembly Line Balancing Problems with Coincidence Memetic Algorithm Copyright © 2010 SciRes JSEA 363 timisation with Coincidence Algorithm,” Proceedings of IEEE Congress on Evolutionary Computation, Norway, 11 February 2009, pp. 1675-1682. [49] J. R. Jackson, “A Computing Procedure for a Line Bal- ancing Problem,” Management Science, Vol. 2, No. 3, 1956, pp. 261-271. [50] D. E. Goldberg, “Genetic Algorithms in Search, Optimiza- tion, and Machine Learning,” Addison-Wesley, Boston, 1989. [51] J. Horn, N. Nafpliotis and D. E. Goldberg, “A Niched Pareto Genetic Algorithm for Multiobjective Optimiza- tion,” Proceedings of the First IEEE Conference on Evo- lutionary Computation, IEEE World Congress on Compu- tational Intelligence, Orla ndo, 27-29 June 1994. [52] P. Lacomme, C. Prins and M. Sevaux, “A Genetic Algo- rithm for a Bi-Objective Capacitated ARC Routing Prob- lem,” Computer & Operations Research, Vol. 33, No. 12, 2006, pp. 3473-3493. [53] P. Chutima and P. Pinkoompee, “An Investigation of Lo- cal Searches in Memetic Algorithms for Multi-Objective Sequencing Problems on Mixed-Model Assembly Lines,” Proceedings of Computers and Industrial Engineering, Beijing, 31 October-2 November 2008. [54] R. Kumar and P. K. Singh, “Pareto Evolutionary Algo- rithm Hybridized with Local Search for Bi-Objective TSP,” Studies in Computational Intelligence (Hybrid Evo- lutionary Algorithms), Springer, Berlin/Heidelberg, Vol. 75, 2007, pp. 361-398. [55] D. C. Montomery, “Design and Analysis of Experiments,” John Wiley & Sons, Inc., Hoboken, 2009. [56] N. T. Thomopoulos, “Mixed Model Line Balancing with Smoothed Station Assignment,” Management Science, Vol. 14, No. 2, 1970, pp. B59-B75. [57] A. L. Arcus, “COMSOAL: A Computer Method of Se- quencing Operations for Assembly Lines,” International Journal of Production Research, Vol. 4, No. 4, 1965, pp. 259-277. |