A. R. F. Nahrekhalaji ET AL.

142

formed components. Y. Xu and S. H. Zhang [4] simu-

lated distributions of stress and strain rate of the defor-

mation by 3D rigid-plastic finite element method. Chang

and Wang [5] designed a new thermo mechanical treat-

ment process in the tube spinning for fabricating 2024

aluminum tubes. The designed process can be outlined in

sequential order as annealing, first spinning, solution

treatment, second spinning and aging. They indicated

that annealing and solution treatment can effectively re-

cover the ductility of the spun tube.

In this research, the influences of perform's thickness,

percentage of thickness reduction, mandrel rotational

speed, feed rate, solution and aging treatment time on

process time and wall thickness changes for fabricating

2024 aluminum tubes using DOE has been studied.

It is desirable to know the effects of the major pa-

rameters and interactive influences among the process

parameters on process time and wall thickness changes

and relationship between process time, wall thickness

changes and process parameters to obtain the best condi-

tions of parameters for optimum production.

For modeling and determining the influences of main

parameters and interaction effects among parameters of

the process on time of process and wall thickness chan-

ges, DOE method has been employed. The DOE is a stat-

istical method which is used to find the significance of

interactive effects among variables and relations among

process parameters using variance analysis. Finally, us-

ing this model and suitable time of process, input pa-

rameters has been achieved for optimum production.

2. Description of Material and

Thermo-Mechanical Process

All ductile metals are suitable for tube spinning. We have

chosen 2024 aluminum as experimental sample, because

it is suitable for tube spinning. The chemical composition

of this alloy (work metal) is presented in Table 1.

During fabrication, the property of 2024 aluminum

tubes must satisfy the spinning operation. Therefore, the

preform property requires appropriate heat treatment to

increase spin ability or to relieve residual stresses. In this

research the thermo mechanical treatment process de-

signed by S. C. Chang and C. C. Wang [5] has been em-

ployed.

Five processes of thermo-mechanical treatments which

are used in this study are as follows:

1) The original preform is annealed completely in order

to unify the microstructure and accomplish the mechani-

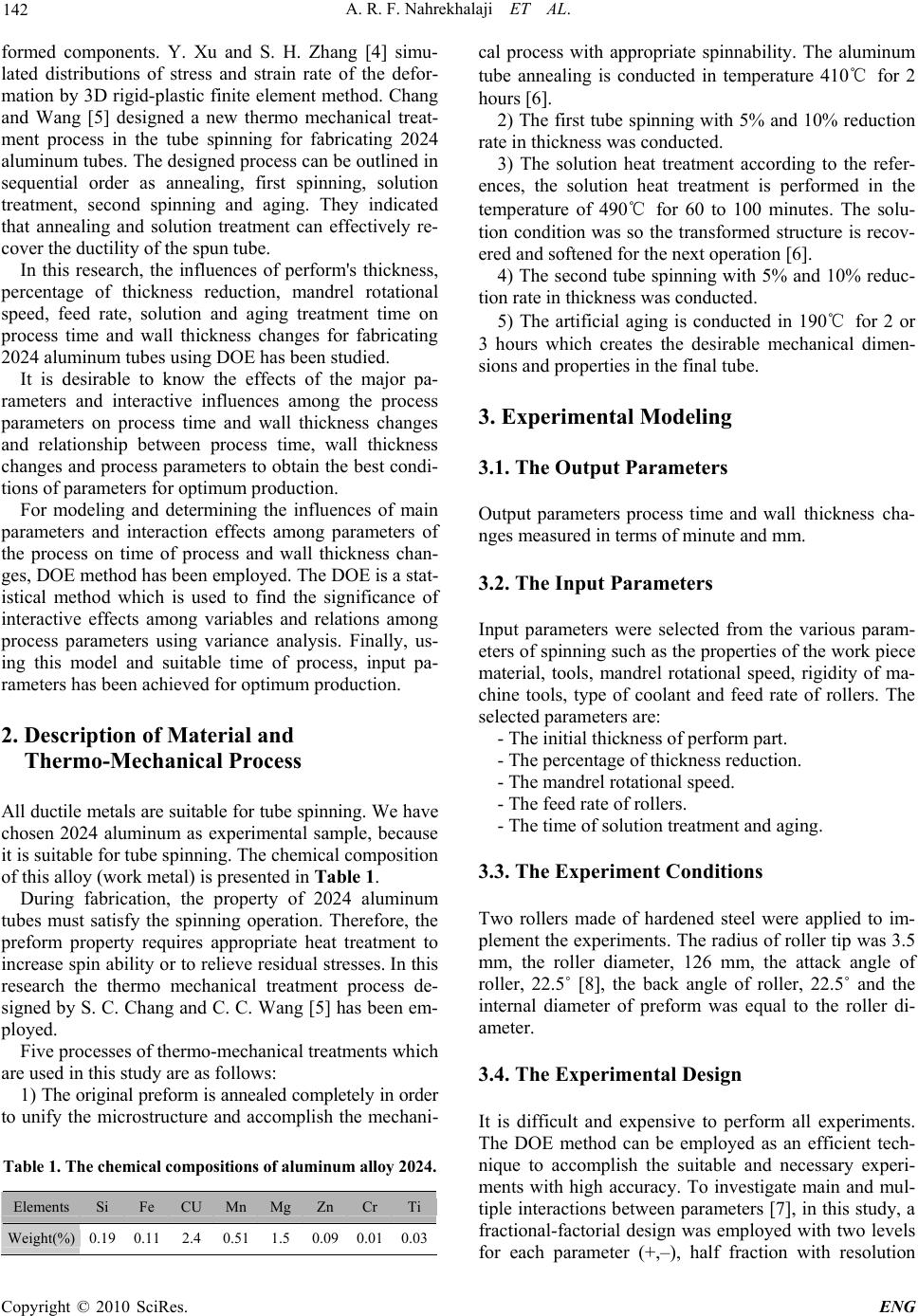

Table 1. The chemical compositions of aluminum alloy 2024.

Elements Si Fe CU Mn Mg Zn Cr Ti

Weight(%) 0.19 0.11 2.4 0.51 1.5 0.09 0.010.03

cal process with appropriate spinnability. The aluminum

tube annealing is conducted in temperature 410℃ for 2

hours [6].

2) The first tube spinning with 5% and 10% reduction

rate in thickness was conducted.

3) The solution heat treatment according to the refer-

ences, the solution heat treatment is performed in the

temperature of 490℃ for 60 to 100 minutes. The solu-

tion condition was so the transformed structure is recov-

ered and softened for the next operation [6].

4) The second tube spinning with 5% and 10% reduc-

tion rate in thickness was conducted.

5) The artificial aging is conducted in 190℃ for 2 or

3 hours which creates the desirable mechanical dimen-

sions and properties in the final tube.

3. Experimental Modeling

3.1. The Output Parameters

Output parameters process time and wall thickness cha-

nges measured in terms of minute and mm.

3.2. The Input Parameters

Input parameters were selected from the various param-

eters of spinning such as the properties of the work piece

material, tools, mandrel rotational speed, rigidity of ma-

chine tools, type of coolant and feed rate of rollers. The

selected parameters are:

- The initial thickness of perform part.

- The percentage of thickness reduction.

- The mandrel rotational speed.

- The feed rate of rollers.

- The time of solution treatment and aging.

3.3. The Experiment Conditions

Two rollers made of hardened steel were applied to im-

plement the experiments. The radius of roller tip was 3.5

mm, the roller diameter, 126 mm, the attack angle of

roller, 22.5˚ [8], the back angle of roller, 22.5˚ and the

internal diameter of preform was equal to the roller di-

ameter.

3.4. The Experimental Design

It is difficult and expensive to perform all experiments.

The DOE method can be employed as an efficient tech-

nique to accomplish the suitable and necessary experi-

ments with high accuracy. To investigate main and mul-

tiple interactions between parameters [7], in this study, a

fractional-factorial design was employed with two levels

for each parameter (+,–), half fraction with resolution

Copyright © 2010 SciRes. ENG