Journal of Minerals and Materials Characterization and Engineering

Vol. 1 No. 6 (2013) , Article ID: 40062 , 5 pages DOI:10.4236/jmmce.2013.16055

Predictability of Hardness of the Heat Affect Zone in Aluminum Weldments Cooled in Palm Oil Based on Hardness of Similarly Cooled Mild Steel and Cast Iron Weldments

1Department of Metallurgical and Materials Engineering, Nnamdi Azikiwe University, Awka, Nigeria

2Department of Metallurgical and Materials Engineering, Enugu State University of Science & Technology, Enugu, Nigeria

3Department of Mechanical Engineering, Abia Polythecnic Aba, Nigeria

Email: *chikeyn@yahoo.com

Copyright © 2013 Chukwuka Nwoye et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Received September 8, 2013; revised October 18, 2013; accepted October 30, 2013

Keywords: Model; Hardness; Heat Affected Zone; Aluminum Weldments; Mild Steel; Cast Iron

ABSTRACT

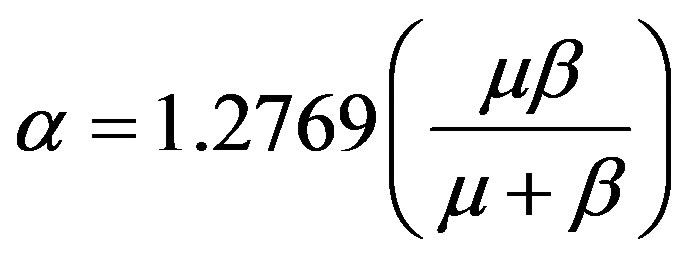

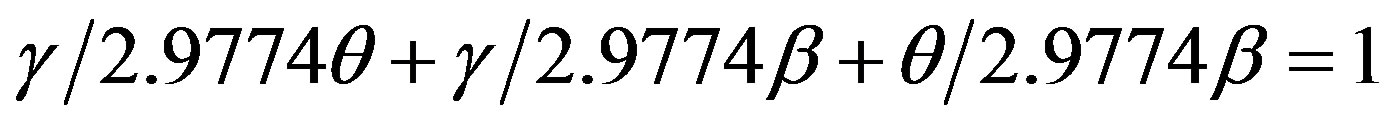

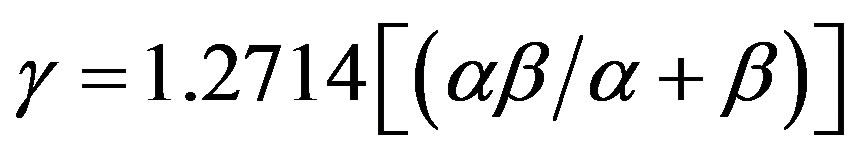

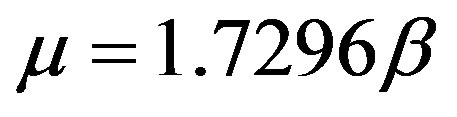

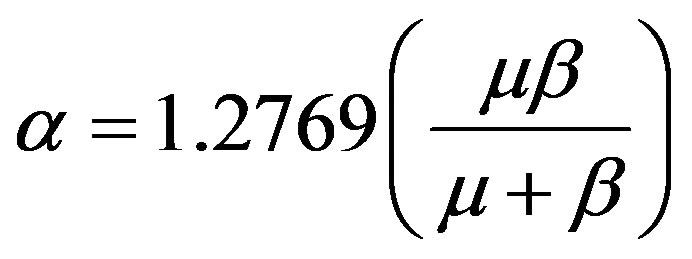

The predictability of hardness of the heat affected zone (HAZ) in aluminum weldments cooled in palm oil, based on hardness of similarly cooled mild steel and cast iron weldments has been ascertained. The general model:  indicates that HAZ hardness of aluminium weldment is dependant on the ratio of product to sum of HAZ hardness of mild steel and cast iron weldments cooled in palm oil under the same conditions. The maximum deviations of the model-predicted HAZ hardness values α, μ and β from the corresponding experimental values αexp, μexp and βexp were less than 0.04% indicating the reliability and validity of the model.

indicates that HAZ hardness of aluminium weldment is dependant on the ratio of product to sum of HAZ hardness of mild steel and cast iron weldments cooled in palm oil under the same conditions. The maximum deviations of the model-predicted HAZ hardness values α, μ and β from the corresponding experimental values αexp, μexp and βexp were less than 0.04% indicating the reliability and validity of the model.

1. Introduction

In recent times, great importance has been placed on the weldability of some alloys as a way of repairing structural components damaged in service. The application of fusion welding and other conventional welding processes in the repair and fabrication of nickel based superalloy such as RR1000 has been seriously restricted. This is because these alloys especially those containing significant amount of Al and Ti (>3 wt%), have been considered highly susceptible to heat affected zone (HAZ) cracking during welding and post weld heat treatment strain age cracking [1].

Welding cracks of superalloys have been reportedly attributed to large shrinkage stress occurring as a result of rapid precipitation of particles during cooling from the welding temperature [2].

Heat affected zone microfissuring susceptibility has been traced to depend on the composition and microstructure of a material [2]. It has been discovered that liquation which could occur by different mechanisms, is the primary cause of low HAZ crack resistance in most austenitic alloys including precipitation hardened Ni base superalloys [3]. Based on the foregoing, the synergetic effect of thermally induced welding strain and very low ductility in the alloy due to localized melting at the grain boundaries results in HAZ liquation cracking.

Result of previous study [4] shows that pre weld heat treatment operation has resulted in considerably minimized HAZ cracking in some superalloy weldments. Reports [5] have shown that weldment cracking is one of the reasons for low mechanical properties such as hardness and impact strength in welded parts. HAZ is the area adjacent to the immediate welded area or fusion zone. The formation of hard and brittle martensite in all the sub zones of the HAZ or increase in the martensite region in size is relative to the other regions results from too rapid cooling. The presence of martensite in the HAZ results in a very high hardness value for the heat affected zone. Slow cooling favours a better microstructure needed for engineering applications. Also, increased rapidity of the quenching rate, results to greater HAZ hardness.

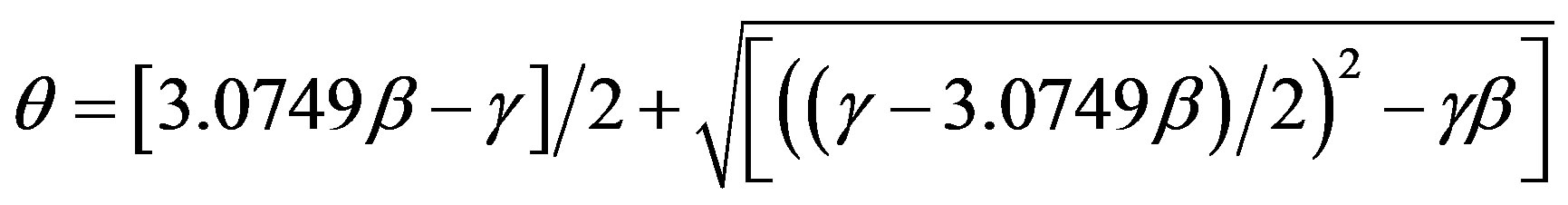

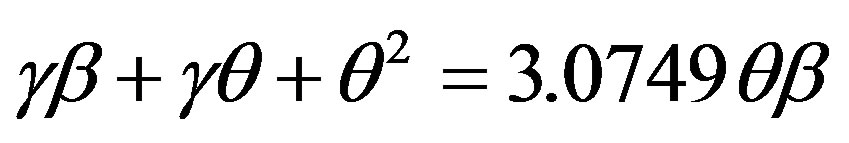

Quadratic and linear models have been derived [6] for predicting the heat-affected zone (HAZ) hardness of water cooled cast iron weldment in relation to the combined and respective values of the heat-affected zone hardness of aluminum and mild steel welded and cooled under the same conditions. The model:

(1)

(1)

was found to be the solution to a quadratic equation:

(2)

(2)

where: γ = Model-predicted hardness of HAZ in aluminum weldment cooled in water (VPN); β = Model-predicted hardness of HAZ in mild steel weldment cooled in water (VPN); θ = Model-predicted hardness of HAZ in cast iron weldment cooled in water (VPN).

It was found that the validity of the model is rooted on the fractional expression:

.

.

The respective deviations of the model-predicted heataffected zone hardness values of aluminum, cast iron and mild steel from the corresponding experimental values were less than 0.01% which is quite insignificant, indicating reliability of the model.

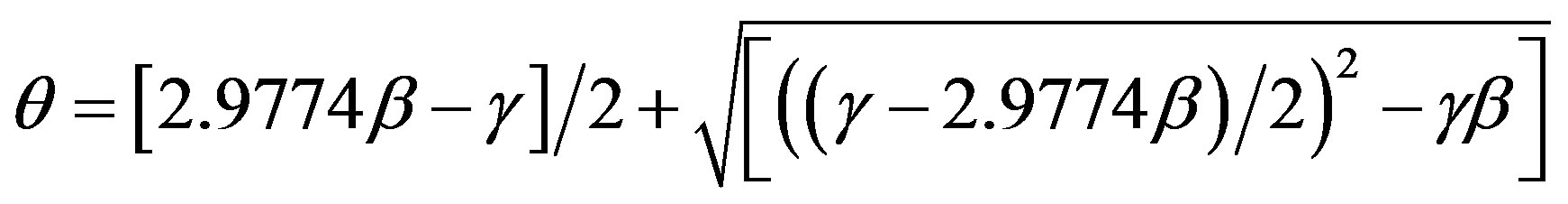

Successful attempt has also been made [7] to derive quadratic and linear models for predicting the HAZ hardness of air cooled cast iron weldment in relation to the combined and respective values of HAZ hardness of aluminum and mild steel welded and cooled under the same conditions. It was discovered that the general model:

(3)

(3)

predicts the HAZ hardness of cast iron weldment cooled in air as a function of the HAZ hardness of both aluminum and mild steel welded and cooled under the same conditions. The linear models; θ = 2.2391γ and θ = 1.7495β on the other hand predict the HAZ hardness of cast iron weldment cooled in air as a function of the HAZ hardness of aluminum or mild steel welded and cooled under the same conditions. Re-arrangement of the general model also resulted to the evaluation of the corresponding HAZ hardness in aluminum and mild steel weldments. It was found that the validity of the model is rooted on the fractional expression:

since the actual computational analysis of the expression was also equal to 1, apart from the fact that the expression comprised the three metallic materials. The respective deviations of the model-predicted HAZ hardness values θ, γ, and β from the corresponding experimental values θexp, γexp, and βexp was less than 0.003% indicating the validity and reliability of the model.

The hardness of the heat affected zone in aluminium weldments has been evaluated using computational models [8]. The general model:

(4)

(4)

was found to predict the HAZ hardness of aluminum weldment cooled in water as a function of the HAZ hardness of both mild steel and cast iron welded and cooled under the same conditions. The maximum deviations of the model-predicted HAZ hardness values γ, α and β from the corresponding experimental values γexp, αexp and βexp were less than 0.02% respectively.

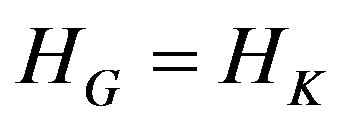

The hardness of HAZ in aluminum, cast iron and mild steel cooled in kerosine was found to be exactly the same as the hardness value of the same materials cooled in groundnut oil [9]. This implies that

(5)

(5)

Where: HG = Hardness of HAZ cooled in groundnut oil; HK = Hardness of HAZ cooled kerosene.

Nwoye [9] reported that 8% - 10% less hardness than that from water occurs when kerosine or groundnut oil is used as quenchant for HAZ. It was discovered that quenching the HAZ with kerosine or groundnut oil gives approximately 8% - 10.7% more hardness than that from quenching with air. The researcher found that palm oil gave the lowest hardness and cooling rate on the HAZ.

Recent research [10] focused on the hardening characteristics of medium carbon steel and ductile cast iron in SAE engine oil, neem oil and water as quenching media. The samples were quenched to room temperature in Neem oil, water and SAE engine oil for a clear comparison of the associated microstructures and mechanical properties of the quenched samples. The result shows that hardness value of the medium carbon steel increased from 18.30 HVN in the as-cast condition to 21.60, 20.30 and 20.70 HVN while that of ductile cast iron samples increased from 18.90 HVN in the as-cast condition to 22.65, 20.30 and 21.30 HVN for water, neem oil and SAE40 engine oil respectively. The as-received steel sample gave the highest impact strength value and water quenched sample gave the least impact strength. The impact strength of the medium carbon steel samples are 50.84, 41.35, 30.50 and 45.15 Joule and that of ductile iron are 2.71, 1.02, 0.68 and 1.70 Joule for as-cast condition, neem oil, water and SAE 40 engine oil quenched respectively. The microstructure of the samples quenched in the Neem oil revealed the formation of martensite. Hence, neem oil can be used where cooling severity less than that of water but greater than SAE 40 engine oil is required for hardening of plain carbon steels and ductile cast iron.

The present study aims at ascertaining the predictability of the hardness of the heat affected zone (HAZ) in aluminum weldment cooled in palm oil, as a function of the respective and combined values of HAZ hardness of mild steel and cast iron welded and cooled under the same conditions.

2. Materials and Methods

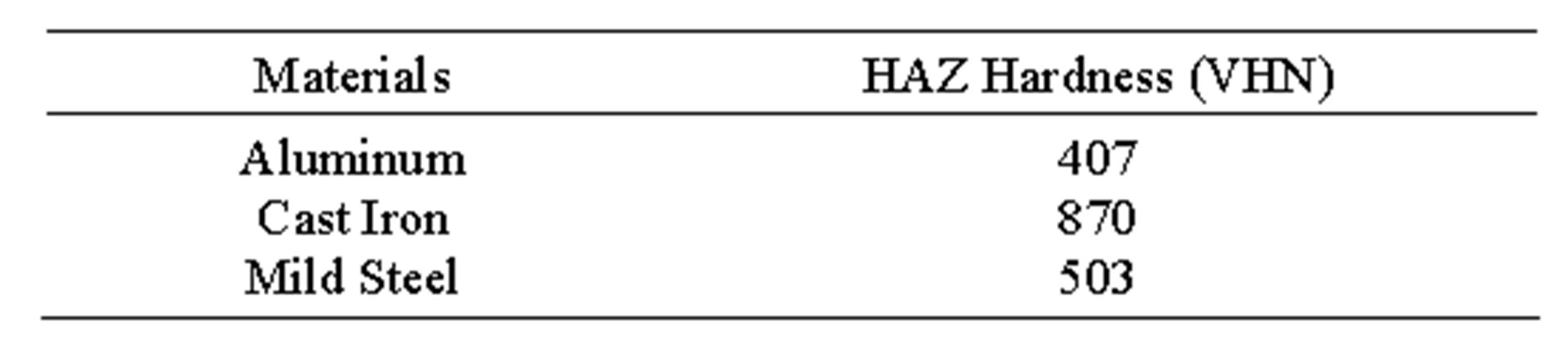

Aluminum, mild steel and cast iron were cut and welded using the shielded metal arc welding technique and the hardness of the HAZ (cooled in palm oil maintained at room temperature) tested. The hardness of the HAZ is as presented in Table 1. The full details of the experimental procedures and equipment used are presented in the previous report [9]. Table 2 shows the welding current and voltage used.

Where: Ctype = Current type; WCt = Welding current (A); WVe = Welding voltage (V); DC = Direct current (A); AC = Alternating current (A).

2.1. Model Formulation

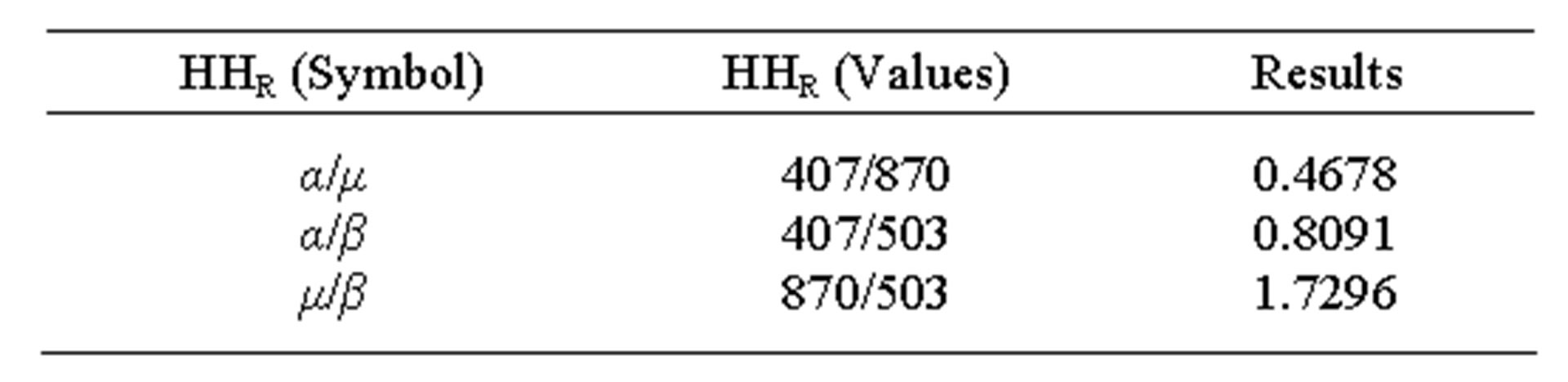

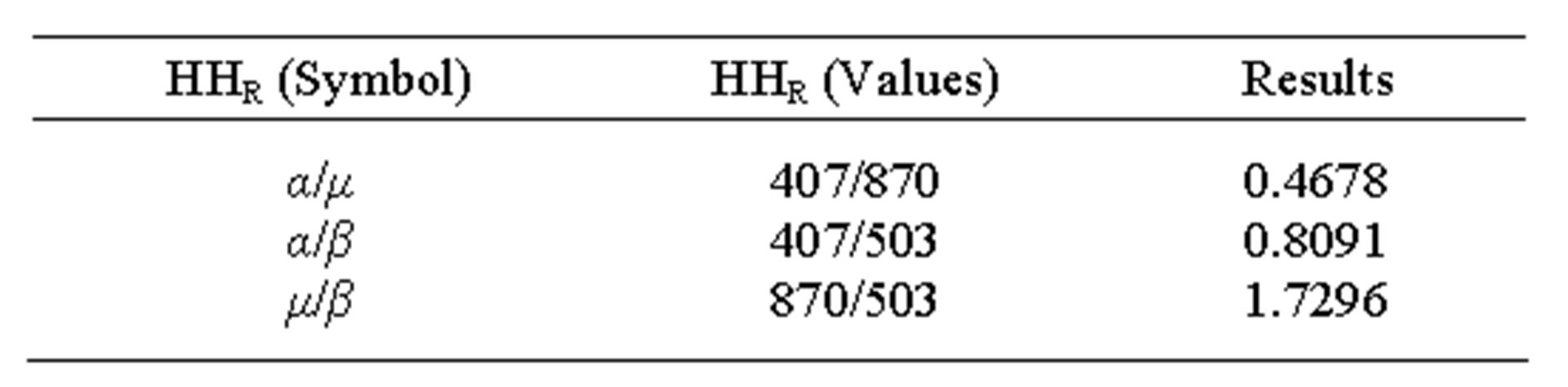

Experimental data obtained from research work [9] carried out at Metallurgical and Materials Engineering Department of Federal University of Technology, Owerri was used for this work. Results of the experiment as presented in the report [9] and used for the model formulation are as shown in Table 1. Computational analysis of the experimental data [9] is shown in Table 1 resulted in Table 3.

Where: HHR (Symbol) = Ratio of HAZ Hardness (Symbol); HHR (Values) = Ratio of HAZ Hardness (Values).

Table 1. Hardness of HAZ in weldments [9].

Table 2. Variation of materials with welding current and voltage [9].

Table 3. HAZ Hardness ratio between aluminum, mild steel, and cast iron weldments cooled in palm oil.

Table 3 shows that the hardness of HAZ in aluminum weldment cooled in palm oil is a function of the hardness of HAZ in cast iron and mild steel weldment also cooled in palm oil. Therefore,

(6)

(6)

(7)

(7)

(8)

(8)

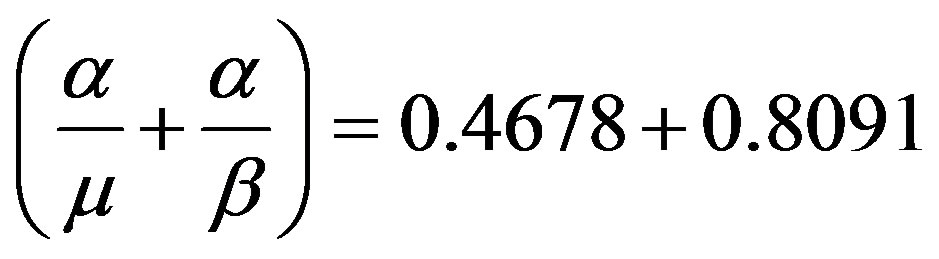

Adding equations (6) and (7) as arranged in Table 1:

(9)

(9)

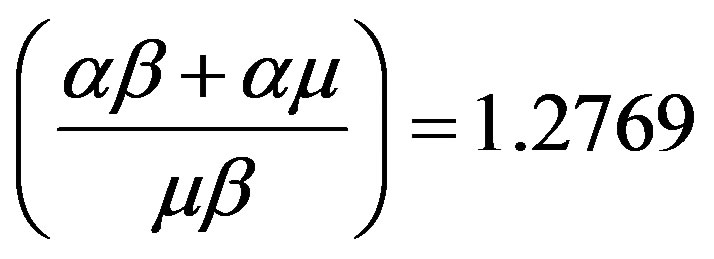

(10)

(10)

(11)

(11)

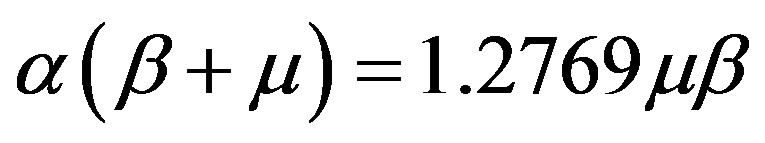

(12)

(12)

(13)

(13)

The derived model (general model) is equation (13).

Where: α = Model-predicted hardness of HAZ in aluminum; weldment cooled in palm oil (VPN); β = Modelpredicted hardness of HAZ in mild steel; weldment cooled in palm oil (VPN); μ = Model-predicted hardness of HAZ in cast iron weldment cooled in palm oil (VPN).

2.2. Boundary and Initial Conditions

The welding operation was carried out under atmospheric condition. After welding, weldments were also maintained under atmospheric condition. Welding current and voltage used are 180 A and 220 V respectively. SiO2- coated electrodes were used to avoid oxidation of weld spots. The coolants used were maintained at 25˚C (room temperature). Volume of coolants used; 1000 cm3. No pressure was applied to the HAZ during or after the welding process. No force due to compression or tension was applied in any way to the HAZ during or after the welding process. The sides and shapes of the samples are symmetries.

3. Results and Discussions

The derived model is equation (13). The computational analysis of Table 1 gave rise to Table 3.

A comparison of the HAZ hardness values from experiment and those of the model show model values very much within the range of the experimental values. The HAZ hardness of aluminium weldment was found to be dependant on the ratio of product to sum of HAZ hardness of mild steel and cast iron weldments. Results of this comparison are presented in Tables 4 and 5. Model values of α evaluated from equations (6) and (7) and tabulated in Table 4 show that all the equations are valid since all of them gave almost the same corresponding experimental values αexp. The value of μ in equation (8) was evaluated to establish the validity of the model. It was found that the model-predicted μ value was also almost the same as the corresponding experimental value μexp. This is a clear indication that the HAZ hardness of any of aluminum, mild steel and cast iron weldments cooled in palm oil can be predicted as a function of the HAZ hardness of any of the other two materials, providing each pair was cooled in palm oil. Table 5 also indicates that the model-predicted value of α is approximately the same as the corresponding experimental value αexp.

3.1. Model Validation

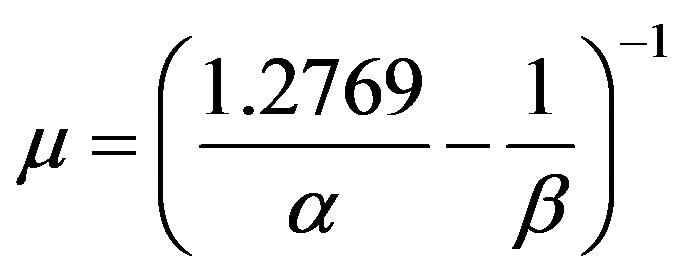

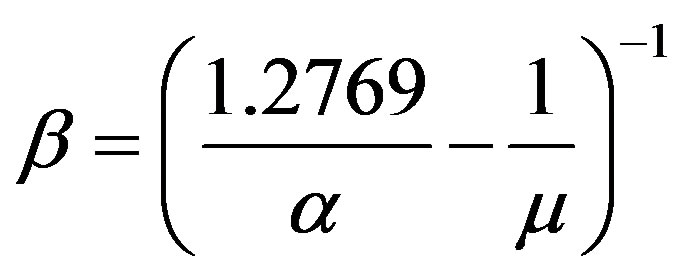

The derived model was validated by evaluating the model-predicted values of HAZ hardness in aluminum weldment cooled in palm oil α and comparing them with the corresponding values obtained from the experiment αexp [9]. Following re-arrangement of the model equation (13), the values of μ and β were also evaluated as:

(14)

(14)

(15)

(15)

and compared with their respective corresponding experimental values μexp and βexp to further establish the validity of the model. The model-predicted values of α, μ and β are shown in Table 5.

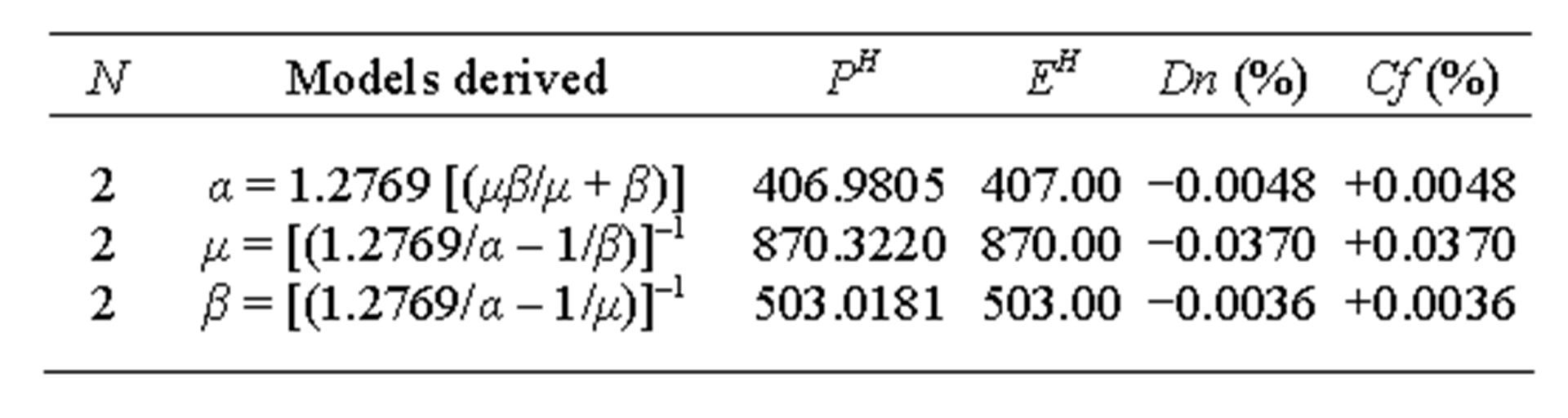

Table 4. Comparison of the hardness of HAZ in aluminum, mild steel and cast iron weldments cooled in palm oil as obtained from experiment [9] and as predicted by derived model (each material as a function of 1-material).

Table 5. Comparison of the hardness of HAZ in aluminum, mild steel and cast iron weldments cooled in palm oil as obtained from experiment [9] and as predicted by derived model (each material as a function of 2-materials).

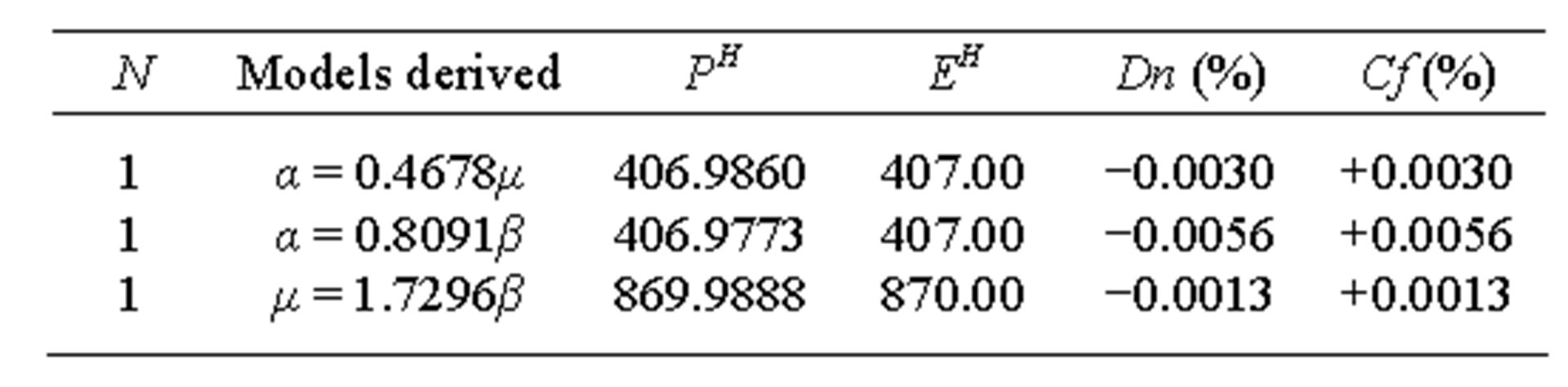

3.2. Deviational Analysis

Analysis and comparison between the model-predicted values α, μ, β and the respective corresponding experimental values αexp, μexp and βexp reveal deviations of model data from the experimental data. This is attributed to the non-consideration of the chemical properties of the coolant and the physiochemical interactions between the materials (aluminum, mild steel and cast iron) and the coolant which is believed to have played vital roles in modifying the microstructure of the HAZ during the cooling process. These deviations necessitated the introduction of correction factor to bring the model-predicted values to exactly that of the corresponding experimental values.

Deviation (Dn) of model-predicted HAZ hardness from that of the experiment [9] is given by

(16)

(16)

Correction factor (Cf) is the negative of the deviation i.e.

(17)

(17)

therefore

(18)

(18)

EH. where: PH = Model-predicted HAZ hardness (VHN); EH = HAZ hardness from experiment (VHN); Cf = Correction factor (%); Dn = Deviation (%).

Where: N = No. of materials constituting the corresponding model as independent variable.

Introduction of the value of Cf from equation (18) into the models give exactly the corresponding experimental values αexp, μexp and βexp [9].

It can also be seen from Table 5 that the model-predicted values of μ and β are also almost the same as the corresponding experimental values of μexp and βexp respectively. Tables 4 and 5 indicate that the respective deviations of the model-predicted HAZ hardness values α, μ and β from those of the corresponding experimental values αexp, μexp and βexp are all less than 0.04% which is quite negligible and within the acceptable model deviation range from experimental results. Furthermore, the values of μ and β (from equations (14) and (15) respectively) evaluated to be approximately equal to the respective corresponding experimental values μexp and βexp confirm the validity of the model. This also implies that the general model; equation (13) can predict the HAZ hardness of any of aluminum, mild steel and cast iron weldments cooled in palm oil as a function of the HAZ hardness of the other two materials, providing the three materials constituting the model (aluminum, mild steel and cast iron) were cooled in palm oil. Equation (13) is regarded as the general model equation because it comprises of the HAZ hardness of all the materials considered for the model formulation. Based on the foregoing, the models in equations (6), (7) and (13) are valid and very useful for predicting HAZ hardness of aluminum, mild steel and cast iron weldments cooled in palm oil depending on the material of interest and the given HAZ hardness values for the other materials.

4. Conclusion

The derived models: α = 0.4678μ, α = 0.8091β, and μ = 1.7296β, can predict the HAZ hardness of aluminum weldment cooled in palm oil as a function of the HAZ hardness of mild steel or cast iron welded and cooled under the same conditions. Similarly, the general model:

can predict the HAZ hardness of aluminum weldment cooled in palm oil as a function of the HAZ hardness of both mild steel and cast iron welded and cooled under the same conditions. Furthermore, re-arrangement of these models could be done to evaluate the HAZ hardness of mild steel or cast iron respectively as in the case of aluminum. The respective deviations of the model-predicted HAZ hardness values α, μ and β from the corresponding experimental values αexp, μexp and βexp were less than 0.04% indicating the reliability and validity of the model.

REFERENCES

- M. Prager and C. S. Shira, “Welding of Precipitation Hardening Nickel-Base Alloys,” Weld Research Council Bulletin, Vol. 6, 1968, pp. 128-155.

- M. H. Haasken and G. H. Matthey, “New Approach to Weldability of Nickel-Base As-Cast and Powder Metallurgy Superalloys,” Weld Journal, Vol. 61, 1982, pp. 25- 30.

- W. A. Owczarski, D. S. Duvall and C. P. Sullivan, “Model for Heat Affected Zone Cracking in Nicke-Base Superalloy,” Weld Journal, Vol. 45, 1966, pp. 145-155.

- A. Thakur, N. L. Richards and M. C. Chaturvedi, “On Crack-Free Welding of Cast Inconel 738,” International Journal of Joining Materials, Vol. 15, 2003, pp. 21-25.

- E. E. Nnuka, F. A. Ovat and M. I. Oseni, “Effect of Electrode Types on the Mechanical Properties and Structure of Welded Steel Joints,” Journal of Metallurgical and Materials Engineering, Vol. 3, No. 1, 2008, pp. 7-13.

- C. I. Nwoye, “Quadratic Model for Predicting the Hardness of Heat Affected Zone in Water Cooled Cast Iron Weldment in Relation to Similarly Cooled Aluminum and Mild Steel Weldments,” Journal of Minerals & Materials Characterization & Engineering, Vol. 8, No. 10, 2009, pp. 765-773.

- C. I. Nwoye, “Quadratic and Linear Models for Predicting the Hardness of Heat Affected Zone in Air Cooled Cast Iron Weldment in Relation to the HAZ Hardness of Aluminum and Mild Steel Weldments Cooled in Same Media,” Researcher, Vol. 1, No. 4, 2009, pp. 1-6.

- C. I. Nwoye, C. N. Anyakwo, E. Obidiegwu and N. E. Nwankwo, “Models for Assessment and Computational Analysis of Hardness of the Heat Affected Zone in Water Cooled Aluminum Weldment,” Journal of Minerals & Materials Characterization & Engineering, Vol. 10, No. 8, 2011, pp. 707-715.

- C. I. Nwoye, “Comparative Studies of the Cooling Ability of Hydrocarbon Based Media and their Effects on the Hardness of the Heat Affected Zone (HAZ) in Weldments,” Journal of Metallurgical and Materials Engineering, Vol. 3, No. 1, 2008, pp. 35-37.

- S. B. Hassan, J. B. Agboola. V. S. Aigbodion and E. J. Williams, “Hardening Characteristics of Plain Carbon Steel and Ductile Cast Iron Using Neem Oil as Quenchant,” Journal of Minerals & Materials Characterization & Engineering, Vol. 10, No. 2, 2011, pp. 161-172.

NOTES

*Corresponding author.