Paper Menu >>

Journal Menu >>

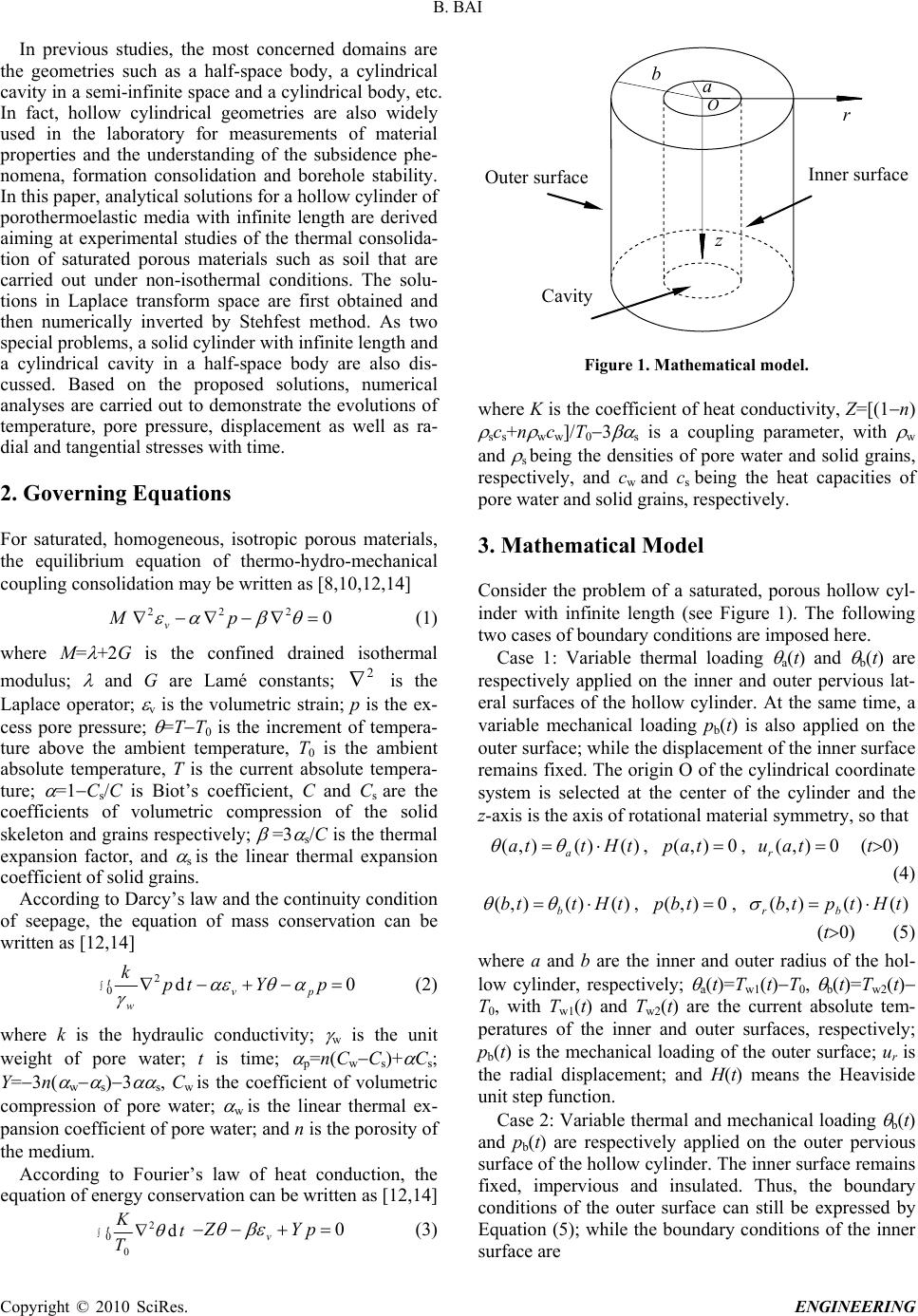

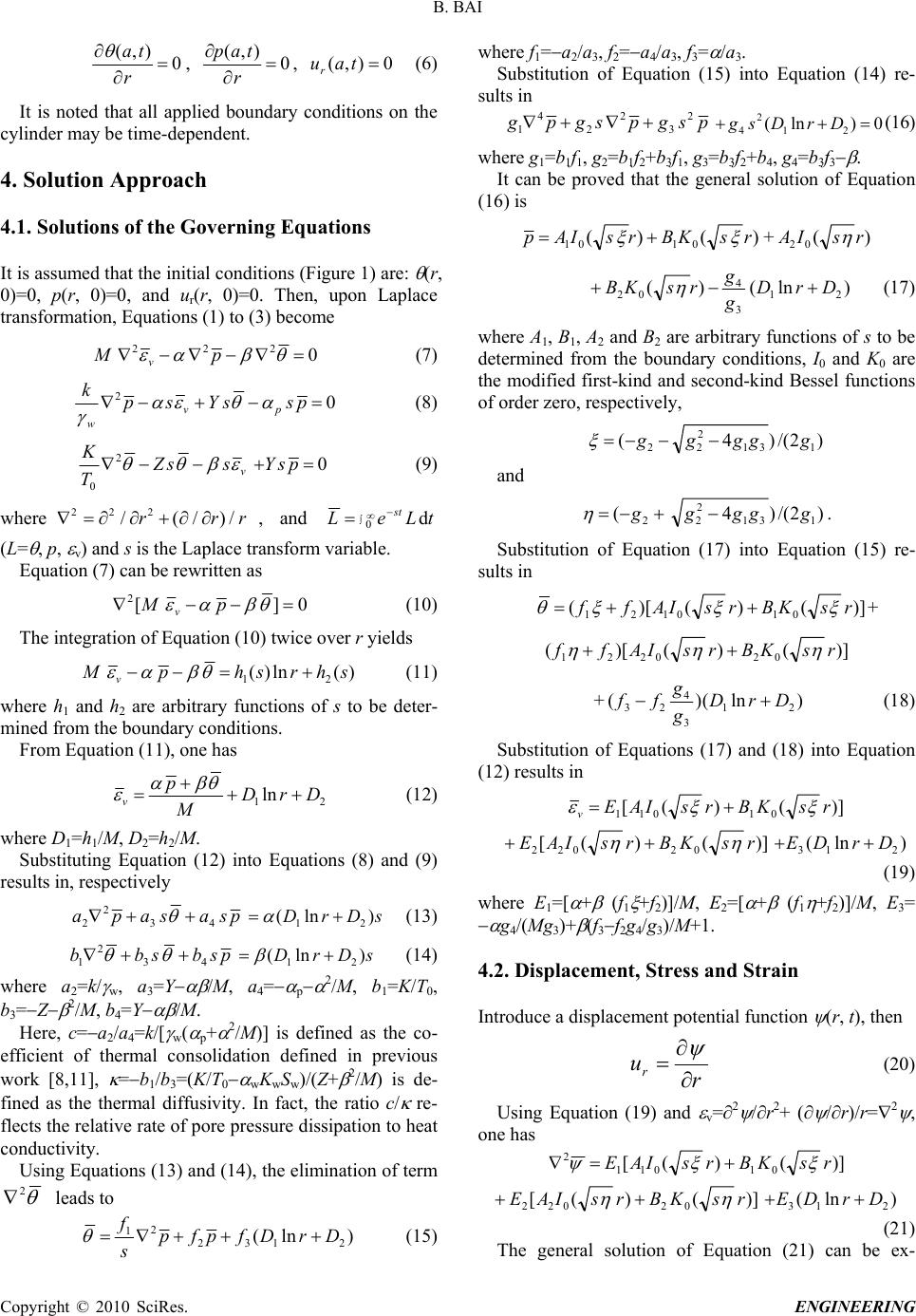

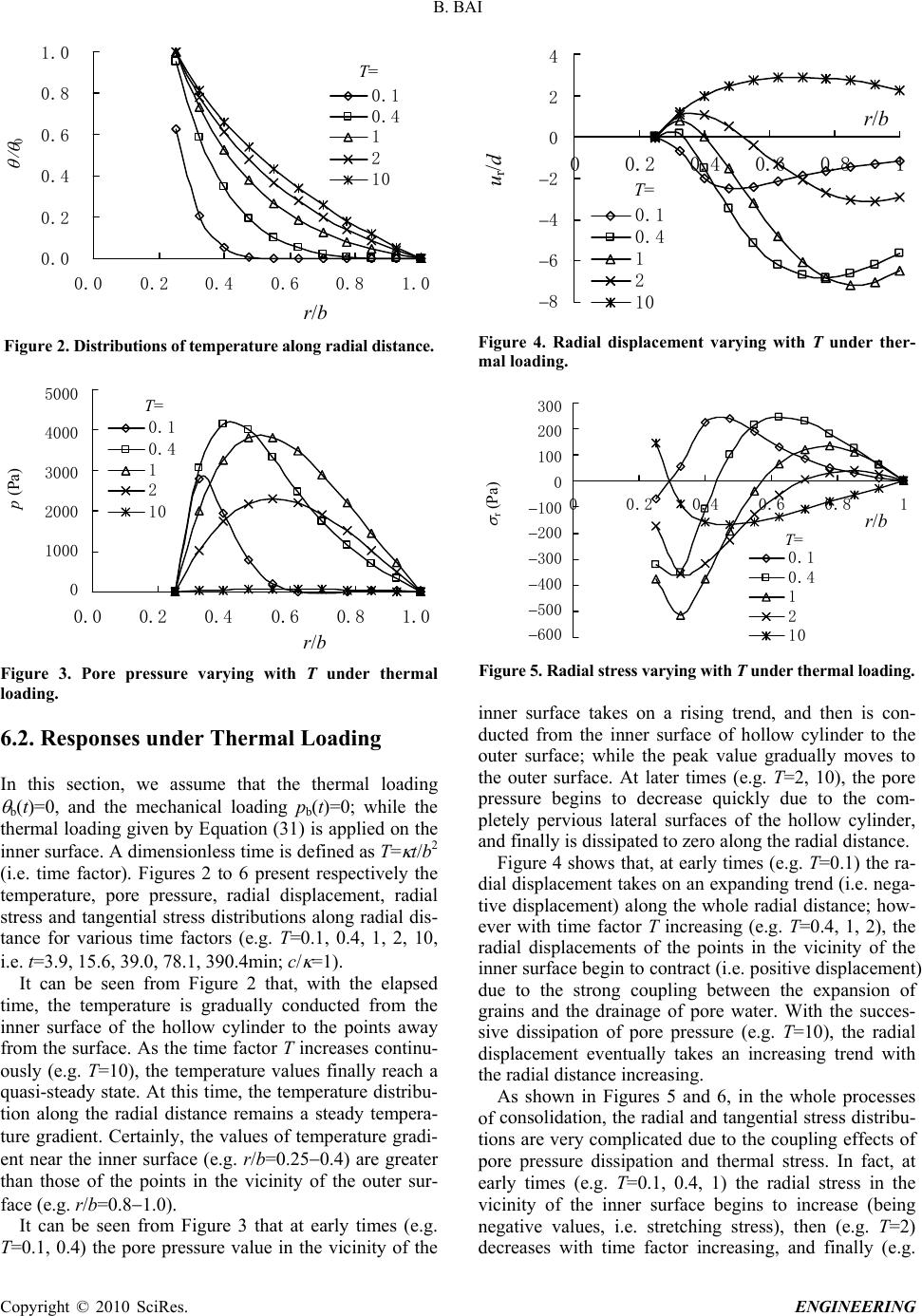

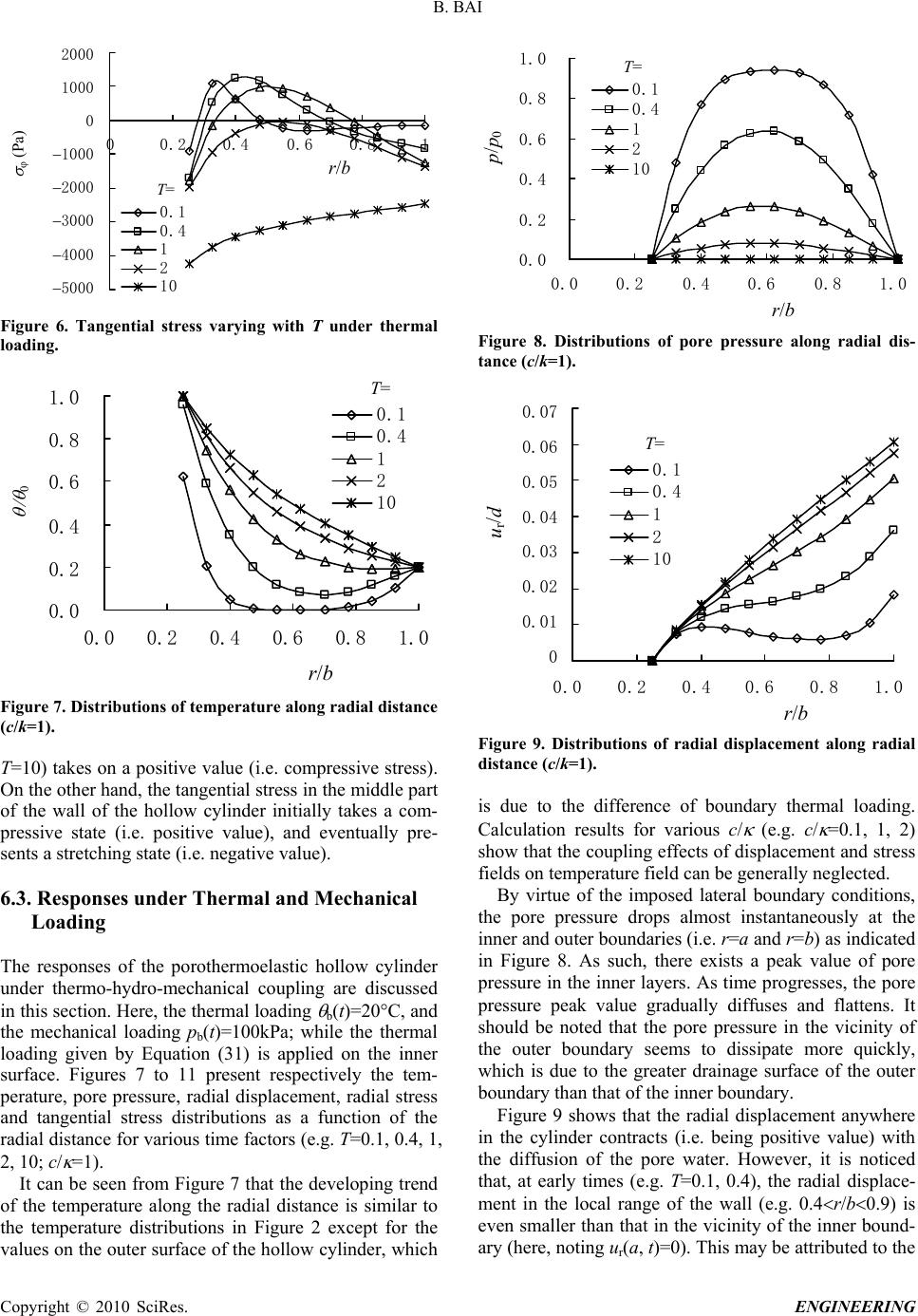

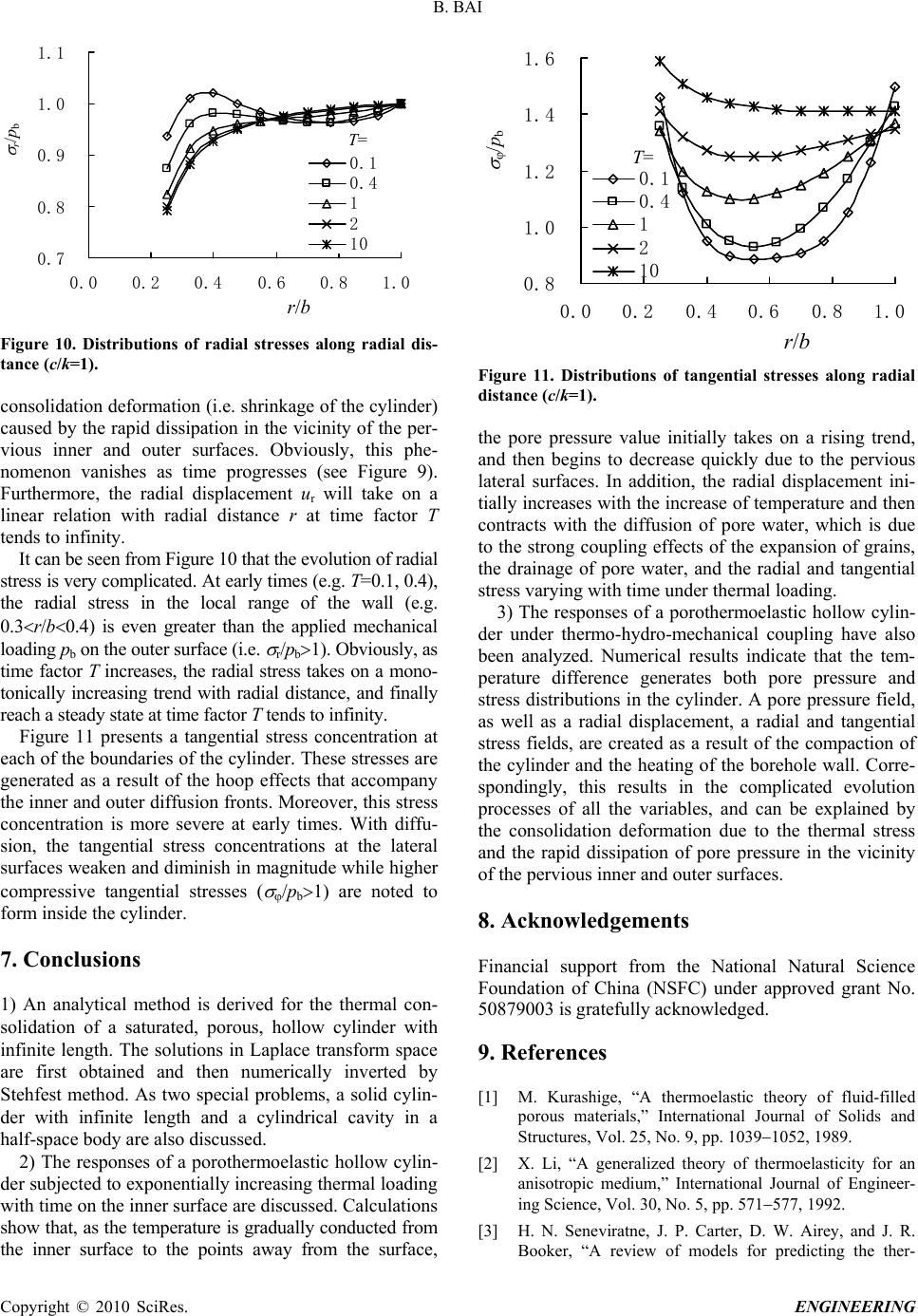

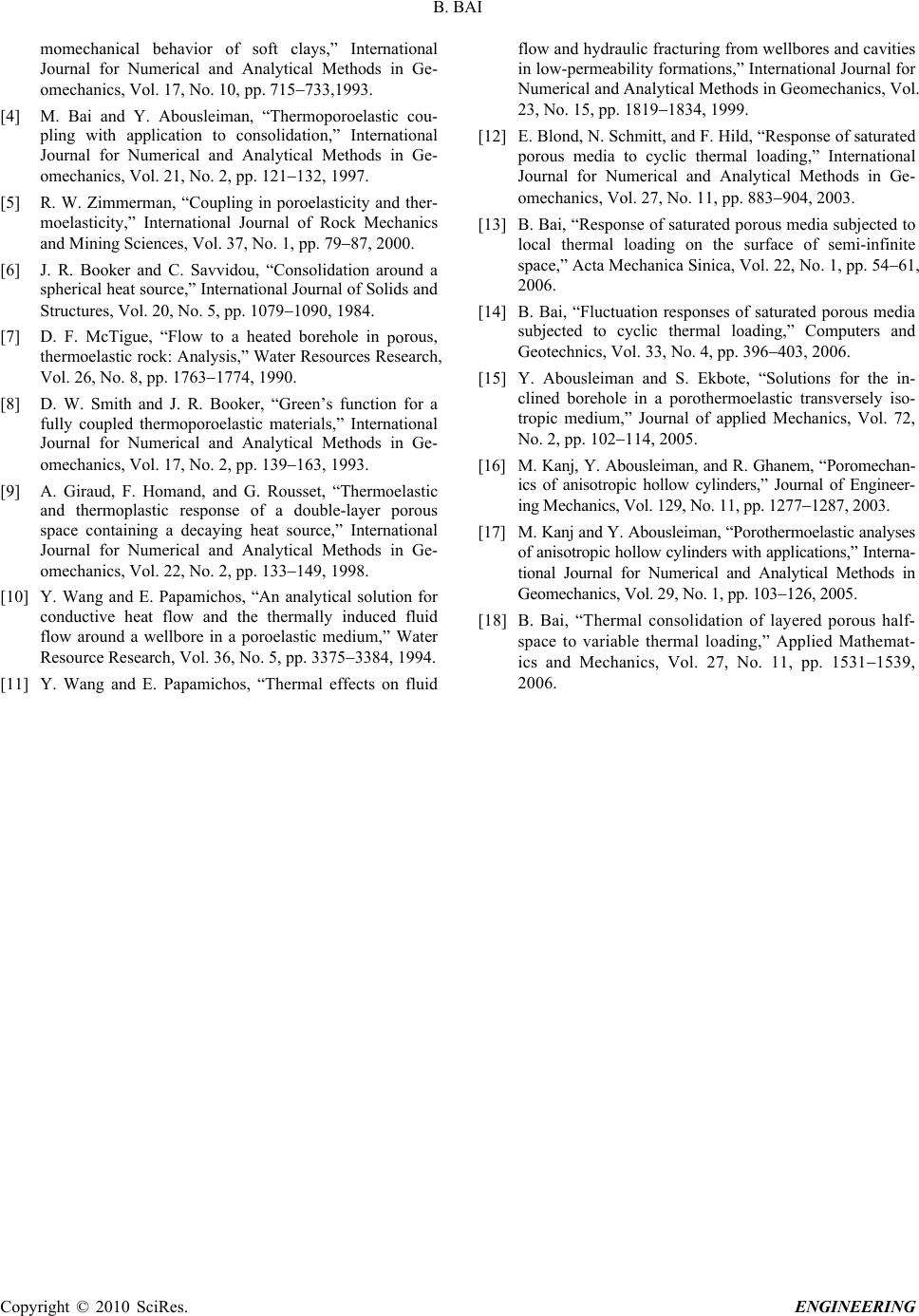

Engineering, 2010, 2, **-** doi:10.4236/eng.2010.21005 Published Online January 2010 (http://www.scirp.org/journal/eng/). Copyright © 2010 SciRes. ENGINEERING Consolidation Solutions of a Saturated Porothermoelastic Hollow Cylinder with Infinite Length Consolidation Solutions of Porothermoelastic Media Bing BAI School of Civil Engineering, Beijing Jiaotong University, Beijing, China Email: Baibing66@263.net Received June 4, 2009; revised July 28, 2009; accepted August 10, 2009 Abstract An analytical method is derived for the thermal consolidation of a saturated, porous, hollow cylinder with infinite length. The solutions in Laplace transform space are first obtained and then numerically inverted by Stehfest method. Two cases of boundary conditions are considered. First, variable thermal loadings are ap- plied on the inner and outer pervious lateral surfaces of the hollow cylinder, and a variable mechanical load- ing with time is applied on the outer surface; while the displacement of the inner surface remains fixed. Sec- ondly, variable thermal and mechanical loading are applied on the outer pervious surface, and the inner sur- face remains fixed, impervious and insulated. As two special problems, a solid cylinder with infinite length and a cylindrical cavity in a half-space body are also discussed. Finally, the evolutions of temperature, pore pressure and displacement with time along radial direction are analyzed by a numerical example. Keywords: Porothermoelastic Media, Hollow Cylinder, Variable Thermal Loading, Consolidation Solutions, Stehfest Method 1. Introduction The studies on the thermo-hydro-mechanical responses of saturated porous materials are widely used in various engineering fields such as the disposal of high-level nu- clear waste, extraction of geothermal energy, storage of hot fluids, biomechanics to materials sciences, concrete resistance against fire, reliability of airfield. There exists a substantial and growing literature to account for non-isothermal consolidation behavior of fluid-saturated porous materials [15]. Up to now, some analytical solutions to boundary and initial value prob- lems have been developed under various scenarios. Booker and Savvidou [6] have presented solutions for the temperature, pressure and stress fields arising from a spherical heat source buried in a thermally consolidating material of infinite extent. McTigue [7] presented resolu- tion methods and established exact solutions for a semi- infinite porous medium subjected to a constant surface temperature or heat flux with either drained or undrained boundary conditions. Smith and Booker [8] presented the Green’s functions for a system of fully coupled linear equations governing thermal consolidation in a homoge- neous isotropic material, and later gave a boundary inte- gral method of numerical analysis. Giraud et al. [9] ana- lyzed the case of a heat source that decreases exponen- tially with time by considering a low-permeability clay for nuclear waste disposal. Wang and Papamichos [10,11] discussed solutions for a cylindrical wellbore and a spherical cavity subjected to a constant temperature change and heat flow rate. Blond et al. [12] developed a closed-form solution for a porothermoelastic half-space submitted to a cyclic thermal loading, and a pressure- diffusion equation that governs the fluctuation of the interstitial pressure was established. Bai [13] developed a solution approach for a planar thermal loading with variable intensity with time on the surface of a semi- infinite space. Bai [14] later derived an analytical method for the responses of saturated porous media subjected to cyclic thermal loading by using the Laplace transform and the Gauss-Legendre method of Laplace transform inversion. Abousleiman and Ekbote [15] presented the analytical solutions for an inclined hollow cylinder in a transversely isotropic material subjected to thermal and stress perturbations. Kanj et al. [16,17] applied an ani- sotropic porothermoelastic solution to an unjacketed hollow cylinder in a triaxial set-up. Bai [18] derived an analytical method for the thermal consolidation of lay- ered, saturated porous half-space to variable thermal loading with time.  B. BAI In previous studies, the most concerned domains are the geometries such as a half-space body, a cylindrical cavity in a semi-infinite space and a cylindrical body, etc. In fact, hollow cylindrical geometries are also widely used in the laboratory for measurements of material properties and the understanding of the subsidence phe- nomena, formation consolidation and borehole stability. In this paper, analytical solutions for a hollow cylinder of porothermoelastic media with infinite length are derived aiming at experimental studies of the thermal consolida- tion of saturated porous materials such as soil that are carried out under non-isothermal conditions. The solu- tions in Laplace transform space are first obtained and then numerically inverted by Stehfest method. As two special problems, a solid cylinder with infinite length and a cylindrical cavity in a half-space body are also dis- cussed. Based on the proposed solutions, numerical analyses are carried out to demonstrate the evolutions of temperature, pore pressure, displacement as well as ra- dial and tangential stresses with time. 2. Governing Equations For saturated, homogeneous, isotropic porous materials, the equilibrium equation of thermo-hydro-mechanical coupling consolidation may be written as [8,10,12,14] 0 222 pM v (1) where M= +2G is the confined drained isothermal modulus; and G are Lamé constants; is the Laplace operator; v is the volumetric strain; p is the ex- cess pore pressure; =TT0 is the increment of tempera- ture above the ambient temperature, T0 is the ambient absolute temperature, T is the current absolute tempera- ture; =1Cs/C is Biot’s coefficient, C and Cs are the coefficients of volumetric compression of the solid skeleton and grains respectively; =3 s/C is the thermal expansion factor, and s is the linear thermal expansion coefficient of solid grains. 2 According to Darcy’s law and the continuity condition of seepage, the equation of mass conservation can be written as [12,14] 0d 0 2 pYtp k pv t w (2) where k is the hydraulic conductivity; w is the unit weight of pore water; t is time; p=n(CwCs)+ Cs; Y=3n( w s)3 s, Cw is the coefficient of volumetric compression of pore water; w is the linear thermal ex- pansion coefficient of pore water; and n is the porosity of the medium. According to Fourier’s law of heat conduction, the equation of energy conservation can be written as [12,14] tt T K 0 2 0 d 0 pYZ v (3) z r a O Outer surface b Cavity Inner surface Figure 1. Mathematical model. where K is the coefficient of heat conductivity, Z=[(1n) scs+n wcw]/T03 s is a coupling parameter, with w and s being the densities of pore water and solid grains, respectively, and cw and cs being the heat capacities of pore water and solid grains, respectively. 3. Mathematical Model Consider the problem of a saturated, porous hollow cyl- inder with infinite length (see Figure 1). The following two cases of boundary conditions are imposed here. Case 1: Variable thermal loading a(t) and b(t) are respectively applied on the inner and outer pervious lat- eral surfaces of the hollow cylinder. At the same time, a variable mechanical loading pb(t) is also applied on the outer surface; while the displacement of the inner surface remains fixed. The origin O of the cylindrical coordinate system is selected at the center of the cylinder and the z-axis is the axis of rotational material symmetry, so that )()(),( tHtta a , , (t0) 0),( tap 0),( taur (4) )()(),(tHttb b , , 0),(tbp )()(),( tHtptb br (t0) (5) where a and b are the inner and outer radius of the hol- low cylinder, respectively; a(t)=Tw1(t)T0, b(t)=Tw2(t) T0, with Tw1(t) and Tw2(t) are the current absolute tem- peratures of the inner and outer surfaces, respectively; pb(t) is the mechanical loading of the outer surface; ur is the radial displacement; and H(t) means the Heaviside unit step function. Case 2: Variable thermal and mechanical loading b(t) and pb(t) are respectively applied on the outer pervious surface of the hollow cylinder. The inner surface remains fixed, impervious and insulated. Thus, the boundary conditions of the outer surface can still be expressed by Equation (5); while the boundary conditions of the inner surface are Copyright © 2010 SciRes. ENGINEERING  B. BAI 0 ),( r ta , 0 ),( r tap , 0),( taur (6) It is noted that all applied boundary conditions on the cylinder may be time-dependent. 4. Solution Approach 4.1. Solutions of the Governing Equations It is assumed that the initial conditions (Figure 1) are: (r, 0)=0, p(r, 0)=0, and ur(r, 0)=0. Then, upon Laplace transformation, Equations (1) to (3) become 0 222 pM v (7) 0 2 pssYsp k pv w (8) v ssZ T K 2 0 0 psY (9) where , and 222 /(/)/rr r 0dtLeL st (L= , p, v) and s is the Laplace transform variable. Equation (7) can be rewritten as 0][ 2 pM v (10) The integration of Equation (10) twice over r yields )(ln)( 21 shrshpM v (11) where h1 and h2 are arbitrary functions of s to be deter- mined from the boundary conditions. From Equation (11), one has 21ln DrD M p v (12) where D1=h1/M, D2=h2/M. Substituting Equation (12) into Equations (8) and (9) results in, respectively psasapa43 2 2 sDrD )ln(21 (13) psbsbb 43 2 1 sDrD )ln( 21 (14) where a2=k/ w, a3=Y /M, a4= p 2/M, b1=K/T0, b3=Z 2/M, b4=Y /M. Here, c=a2/a4=k/[ w( p+ 2/M)] is defined as the co- efficient of thermal consolidation defined in previous work [8,11], =b1/b3=(K/T0 wKwSw)/(Z+ 2/M) is de- fined as the thermal diffusivity. In fact, the ratio c/ re- flects the relative rate of pore pressure dissipation to heat conductivity. Using Equations (13) and (14), the elimination of term 2 leads to )ln( 2132 2 1DrDfpfp s f (15) where f1=a2/a3, f2=a4/a3, f3= /a3. Substitution of Equation (15) into Equation (14) re- sults in psgpsgpg 2 3 2 2 4 1 0)ln(21 2 4 DrDsg (16) where g1=b1f1, g2=b1f2+b3f1, g3=b3f2+b4, g4=b3f3 . It can be proved that the general solution of Equation (16) is )()(0101rsKBrsIAp +)( 02 rsIA )ln()(21 3 4 02 DrD g g rsKB (17) where A1, B1, A2 and B2 are arbitrary functions of s to be determined from the boundary conditions, I0 and K0 are the modified first-kind and second-kind Bessel functions of order zero, respectively, )2/()4( 131 2 22 ggggg and 2 (g )2/()4 131 2 2gggg . Substitution of Equation (17) into Equation (15) re- sults in )]()()[( 010121 rsKBrsIAff + )]()()[( 020221 rsKBrsIAff +)ln()(21 3 4 23 DrD g g ff (18) Substitution of Equations (17) and (18) into Equation (12) results in )]()([ 01011rsKBrsIAE v )]()([02022 rsKBrsIAE )ln( 213 DrDE (19) where E1=[ + (f1 +f2)]/M, E2=[ + (f1 +f2)]/M, E3= g4/(Mg3)+ (f3f2g4/g3)/M+1. 4.2. Displacement, Stress and Strain Introduce a displacement potential function (r, t), then r ur (20) Using Equation (19) and v=2 /r2+ ( /r)/r=2 , one has )]()([01011 2rsKBrsIAE )]()([02022 rsKBrsIAE )ln( 213 DrDE (21) The general solution of Equation (21) can be ex- Copyright © 2010 SciRes. ENGINEERING  B. BAI pressed as )]()([ 0101 1rsKBrsIA s E )]()([ 0202 2rsKBrsIA s E ])1(ln[ 4 2 2 2 1 3rDrrD E )ln(43 DrD (22) where D3 and D4 are arbitrary functions of s to be deter- mined from the boundary conditions. Using Equations (20) and (22) results in )]()([ 1111 1rsKBrsIA s E ur )]()([ 1212 2rsKBrsIA s E ]2)1ln2([ 421 3rDrrD E r D3 (23) where ur is radial displacement, I1 and K1 are the modi- fied first-kind and second-kind Bessel functions of order one, respectively. Using Equation (23) and generalized Hooke’s law, ra- dial stress r and tangential stress can be obtained: )]()([{2 1111 1rsKBrsIA rs E G r )]()([ 1212 2rsKBrsIA rs E + ]2)1ln2([ 421 3DrD E 2 3 r D } (24) 21ln MDrMD )]( 1 )([{2 1011 rsI rs rsIAEG + )]( 1 )([ 1011 rsK rs rsKBE )]( 1 )([1022 rsI rs rsIAE + )]( 1 )([ 1022rsK s rsKBE + ]2)1ln2([ 421 3DrD E 2 3 r D } (25) 21ln MDrMD 4.3. Inversion of the Laplace Transform Equations (17) to (19), (23) to (25) constitute the solu- tions in the Laplace transform domain. In reality, solu- tions in the real domain can all be obtained by inverting inversion schemes reported in literatures [10,17]. The Stehfest method has been extensively used, due to its accuracy, efficiency and stability. This method is based on sampling inversion data according to a delta series. The present study uses the Stehfest method. the above solutions. There are many numerical Laplace . Determination of the Integration Functions a cylindrical coordinate system, the following equilib- 5 In rium is also used to determine the unknown coefficients in addition to the boundary conditions: 0 r rr r (26) Substitution of Equations (24) and (25) into Equation (2 cylinder with in . Numerical Examples .1. Material Properties and Loading he material properties used in the analysis are given as ner radius a= (31) where 0=100C, = 6) results in D1=0. The remaining six arbitrary coeffi- cients (A1, B1, A2, B2, D2 and D3) can be determined by solving Equation (A9) (see Appendix A). For the special case of a0 (i.e. a solid finite length), there are three arbitrary coefficients (A1, A2 and D 2), which can be determined by solving Equa- tion (A10) (see Appendix B). For the special case of b (i.e. a cylindrical cavity in a half-space body), there are also three arbitrary coefficients (B1, B2 and D3), which can be determined by solving Equation (A11) (see Appendix C). 6 6 T follows: the elastic modulus E=6.0105 Pa, the Poisson ratio =0.3, the bulk modulus of solid grains Ks=21010 Pa, the bulk modulus of pore water Kw=5109 Pa, the thermal expansion coefficient of solid grains s= 1.5105/C, the thermal expansion coefficient of pore water w=2.0104/C, the porosity n=0.4, the heat ca- pacity of solid grains cs=800 J/(kg C), the heat capacity of pore water cw=4200 J/(kg C), the density of pore wa- ter w=1.0103 kg/m3, the density of solid grains s =2.6103 kg/m3, the coefficient of heat conductivity K=0.5 W/(m C) and Biot’s coefficient =1.0. Geometrically, the hollow cylinder has an in 0.02m; and an outer radius b=0.08m (see Figure 1). As such, the thickness of the cylinder wall d=0.06m. For convenience, the following problem is discussed (i.e. Case 1): the thermal loading b(t) and mechanical load- ing pb(t) on the outer surface remain both constant; while an exponentially increasing temperature variation a(t) is applied on the inner surface. It can be written as a(t)= 0 [1exp( t)] 0.00384s1. Copyright © 2010 SciRes. ENGINEERING  B. BAI 0.0 0.2 0.4 0.6 0.8 1.0 0.0 0.20.4 0.60.8 1.0 0.1 0.4 1 2 10 r /b 0 T= Figure 2. Distributions of temperature along radial distance. -5000 -4000 -3000 -2000 -1000 0 0.0 0.2 0.40.6 0.8 1.0 0.1 0.4 1 2 10 5000 4000 3000 2000 1000 0 r /b p (Pa) T= Figure 3. Pore pressure varying with T under therma .2. Responses under Thermal Loading this section, we assume that the thermal loading t he elapsed tim igure 3 that at early times (e.g. T= l loading. 6 In b(t)=0, and the mechanical loading p b(t)=0; while the hermal loading given by Equation (31) is applied on the inner surface. A dimensionless time is defined as T= t/b2 (i.e. time factor). Figures 2 to 6 present respectively the temperature, pore pressure, radial displacement, radial stress and tangential stress distributions along radial dis- tance for various time factors (e.g. T=0.1, 0.4, 1, 2, 10, i.e. t=3.9, 15.6, 39.0, 78.1, 390.4min; c/ =1). It can be seen from Figure 2 that, with t e, the temperature is gradually conducted from the inner surface of the hollow cylinder to the points away from the surface. As the time factor T increases continu- ously (e.g. T=10), the temperature values finally reach a quasi-steady state. At this time, the temperature distribu- tion along the radial distance remains a steady tempera- ture gradient. Certainly, the values of temperature gradi- ent near the inner surface (e.g. r/b=0.250.4) are greater than those of the points in the vicinity of the outer sur- face (e.g. r/b=0.81.0). It can be seen from F 0.1, 0.4) the pore pressure value in the vicinity of the 0 .00008 0 .00006 0 .00004 0 .00002 0 .00000 0 .00002 0 .00004 4 2 0 2 4 6 8 00.2 0.4 0.6 0.81 0.1 0.4 1 2 10 r /b u r /d T = Figure 4. Radial displacement varying with T under ther- mal loading. -600 -500 -400 -300 -200 -100 0 100 200 300 00.2 0.4 0.6 0.81 0.1 0.4 1 2 10 300 200 100 0 100 200 300 400 500 600 r /b r (Pa) T = Figure 5. Radial stress varying with T under thermal loading inner surface takes on a rising trend, and then is con- di 6, in the whole processes of . ducted from the inner surface of hollow cylinder to the outer surface; while the peak value gradually moves to the outer surface. At later times (e.g. T=2, 10), the pore pressure begins to decrease quickly due to the com- pletely pervious lateral surfaces of the hollow cylinder, and finally is dissipated to zero along the radial distance. Figure 4 shows that, at early times (e.g. T=0.1) the ra- al displacement takes on an expanding trend (i.e. nega- tive displacement) along the whole radial distance; how- ever with time factor T increasing (e.g. T=0.4, 1, 2), the radial displacements of the points in the vicinity of the inner surface begin to contract (i.e. positive displacement) due to the strong coupling between the expansion of grains and the drainage of pore water. With the succes- sive dissipation of pore pressure (e.g. T=10), the radial displacement eventually takes an increasing trend with the radial distance increasing. As shown in Figures 5 and consolidation, the radial and tangential stress distribu- tions are very complicated due to the coupling effects of pore pressure dissipation and thermal stress. In fact, at early times (e.g. T=0.1, 0.4, 1) the radial stress in the vicinity of the inner surface begins to increase (being negative values, i.e. stretching stress), then (e.g. T=2) decreases with time factor increasing, and finally (e.g. Copyright © 2010 SciRes. ENGINEERING  B. BAI -5000 -4000 -3000 -2000 -1000 0 1000 2000 2000 00.2 0.40.6 0.81 0.1 0.4 1 2 10 1000 0 1000 2000 3000 4000 5000 r /b (Pa) T= Figure 6. Tangential stress varying with T under thermal loading. 0.0 0.2 0.4 0.6 0.8 1.0 0.0 0.2 0.4 0.6 0.8 1.0 0.1 0.4 1 2 10 r /b 0 T = Figure 7. Distributions of temperature along radial distanc =10) takes on a positive value (i.e. compressive stress). .3. Responses under Thermal and Mechanical he responses of the porothermoelastic hollow cylinder n from Figure 7 that the developing trend of e (c/k=1). T On the other hand, the tangential stress in the middle part of the wall of the hollow cylinder initially takes a com- pressive state (i.e. positive value), and eventually pre- sents a stretching state (i.e. negative value). 6 Loading T under thermo-hydro-mechanical coupling are discussed in this section. Here, the thermal loading b(t)=20C, and the mechanical loading pb(t)=100kPa; while the thermal loading given by Equation (31) is applied on the inner surface. Figures 7 to 11 present respectively the tem- perature, pore pressure, radial displacement, radial stress and tangential stress distributions as a function of the radial distance for various time factors (e.g. T=0.1, 0.4, 1, 2, 10; c/ =1). It can be see the temperature along the radial distance is similar to the temperature distributions in Figure 2 except for the values on the outer surface of the hollow cylinder, which 0.0 0.2 0.4 0.6 0.8 1.0 T 0.1 0.4 1 0.0 0.20.4 0.60.8 1.0 2 / p 0 p 10 r /b = Figure 8. Distributions of pore pressure along radial dis- tance (c/k=1). -0.07 -0.06 -0.05 -0.04 -0.03 -0.02 -0.01 0.00 0.0 0.2 0.40.60.8 1.0 0.07 0.06 0.05 0.04 0.03 0.02 0.01 0 0.1 0.4 1 2 10 r /b T= u r /d Figure 9. Distributions of radial displacement along radia is due to the difference of boundary thermal loading. , th ent anywhere in l distance (c/k=1). Calculation results for various c/ (e.g. c/ =0.1, 1, 2) show that the coupling effects of displacement and stress fields on temperature field can be generally neglected. By virtue of the imposed lateral boundary conditions e pore pressure drops almost instantaneously at the inner and outer boundaries (i.e. r=a and r=b) as indicated in Figure 8. As such, there exists a peak value of pore pressure in the inner layers. As time progresses, the pore pressure peak value gradually diffuses and flattens. It should be noted that the pore pressure in the vicinity of the outer boundary seems to dissipate more quickly, which is due to the greater drainage surface of the outer boundary than that of the inner boundary. Figure 9 shows that the radial displacem the cylinder contracts (i.e. being positive value) with the diffusion of the pore water. However, it is noticed that, at early times (e.g. T=0.1, 0.4), the radial displace- ment in the local range of the wall (e.g. 0.4r/b0.9) is even smaller than that in the vicinity of the inner bound- ary (here, noting ur(a, t)=0). This may be attributed to the Copyright © 2010 SciRes. ENGINEERING  B. BAI 0.7 0.8 0.9 1.0 1.1 0.0 0.2 0.40.6 0.8 1.0 0.1 0.4 1 2 10 r /b r /p b T = Figure 10. Distributions of radial stresses along radial dis- consolidation deformation (i.e. shrinkage of the cylinder) om Figure 10 that the evolution of radial st n at ea . Conclusions ) An analytical method is derived for the thermal con- elastic hollow cylin- de tance (c/k=1). caused by the rapid dissipation in the vicinity of the per- vious inner and outer surfaces. Obviously, this phe- nomenon vanishes as time progresses (see Figure 9). Furthermore, the radial displacement ur will take on a linear relation with radial distance r at time factor T tends to infinity. It can be seen fr ress is very complicated. At early times (e.g. T=0.1, 0.4), the radial stress in the local range of the wall (e.g. 0.3r/b0.4) is even greater than the applied mechanical loading pb on the outer surface (i.e. r/pb1). Obviously, as time factor T increases, the radial stress takes on a mono- tonically increasing trend with radial distance, and finally reach a steady state at time factor T tends to infinity. Figure 11 presents a tangential stress concentratio ch of the boundaries of the cylinder. These stresses are generated as a result of the hoop effects that accompany the inner and outer diffusion fronts. Moreover, this stress concentration is more severe at early times. With diffu- sion, the tangential stress concentrations at the lateral surfaces weaken and diminish in magnitude while higher compressive tangential stresses ( /pb1) are noted to form inside the cylinder. 7 1 solidation of a saturated, porous, hollow cylinder with infinite length. The solutions in Laplace transform space are first obtained and then numerically inverted by Stehfest method. As two special problems, a solid cylin- der with infinite length and a cylindrical cavity in a half-space body are also discussed. 2) The responses of a porothermo r subjected to exponentially increasing thermal loading with time on the inner surface are discussed. Calculations show that, as the temperature is gradually conducted from the inner surface to the points away from the surface, 0.8 1.0 1.2 1.4 1.6 /p b 0.1 T 0.4 1 2 10 0.0 0.20.4 0.60.8 1.0 r /b = Figure 11. Distributions of tangential stresses along radial the pore pressure value initially takes on a rising trend, cylin- de . Acknowledgements inancial support from the National Natural Science . References ] M. Kurashige, “A thermoelastic theory of fluid-filled for an nd J. R. distance (c/k=1). and then begins to decrease quickly due to the pervious lateral surfaces. In addition, the radial displacement ini- tially increases with the increase of temperature and then contracts with the diffusion of pore water, which is due to the strong coupling effects of the expansion of grains, the drainage of pore water, and the radial and tangential stress varying with time under thermal loading. 3) The responses of a porothermoelastic hollow r under thermo-hydro-mechanical coupling have also been analyzed. Numerical results indicate that the tem- perature difference generates both pore pressure and stress distributions in the cylinder. A pore pressure field, as well as a radial displacement, a radial and tangential stress fields, are created as a result of the compaction of the cylinder and the heating of the borehole wall. Corre- spondingly, this results in the complicated evolution processes of all the variables, and can be explained by the consolidation deformation due to the thermal stress and the rapid dissipation of pore pressure in the vicinity of the pervious inner and outer surfaces. 8 F Foundation of China (NSFC) under approved grant No. 50879003 is gratefully acknowledged. 9 [1 porous materials,” International Journal of Solids and Structures, Vol. 25, No. 9, pp. 10391052, 1989. [2] X. Li, “A generalized theory of thermoelasticity anisotropic medium,” International Journal of Engineer- ing Science, Vol. 30, No. 5, pp. 571577, 1992. [3] H. N. Seneviratne, J. P. Carter, D. W. Airey, a Booker, “A review of models for predicting the ther- Copyright © 2010 SciRes. ENGINEERING  B. BAI Copyright © 2010 SciRes. ENGINEERING tic cou- nd ther- po n’s function for a oelastic ternational Journal for ational al loading on the surface of semi-infinite s media hermoelastic transversely iso- n- nterna- o variable thermal loading,” Applied Mathemat- ics and Mechanics, Vol. 27, No. 11, pp. 15311539, 2006. momechanical behavior of soft clays,” International Journal for Numerical and Analytical Methods in Ge- omechanics, Vol. 17, No. 10, pp. 715733,1993. [4] M. Bai and Y. Abousleiman, “Thermoporoelas pling with application to consolidation,” International Journal for Numerical and Analytical Methods in Ge- omechanics, Vol. 21, No. 2, pp. 121132, 1997. [5] R. W. Zimmerman, “Coupling in poroelasticity a moelasticity,” International Journal of Rock Mechanics and Mining Sciences, Vol. 37, No. 1, pp. 7987, 2000. [6] J. R. Booker and C. Savvidou, “Consolidation around a sp spherical heat source,” International Journal of Solids and Structures, Vol. 20, No. 5, pp. 10791090, 1984. [7] D. F. McTigue, “Flow to a heated borehole in rous, subjected to cyclic thermal loading,” Computers and Geotechnics, Vol. 33, No. 4, pp. 396403, 2006. [15] Y. Abousleiman and S. Ekbote, “Solutions for the in- clined borehole in a porot thermoelastic rock: Analysis,” Water Resources Research, Vol. 26, No. 8, pp. 17631774, 1990. [8] D. W. Smith and J. R. Booker, “Gree fully coupled thermoporoelastic materials,” International Journal for Numerical and Analytical Methods in Ge- omechanics, Vol. 17, No. 2, pp. 139163, 1993. [9] A. Giraud, F. Homand, and G. Rousset, “Therm ics o and thermoplastic response of a double-layer porous space containing a decaying heat source,” International Journal for Numerical and Analytical Methods in Ge- omechanics, Vol. 22, No. 2, pp. 133149, 1998. [10] Y. Wang and E. Papamichos, “An analytical solution for tional Journal for Numerical and Analytical Methods in Geomechanics, Vol. 29, No. 1, pp. 103126, 2005. [18] B. Bai, “Thermal consolidation of layered porous half- space t conductive heat flow and the thermally induced fluid flow around a wellbore in a poroelastic medium,” Water Resource Research, Vol. 36, No. 5, pp. 33753384, 1994. [11] Y. Wang and E. Papamichos, “Thermal effects on fluid flow and hydraulic fracturing from wellbores and cavities in low-permeability formations,” In Numerical and Analytical Methods in Geomechanics, Vol. 23, No. 15, pp. 18191834, 1999. [12] E. Blond, N. Schmitt, and F. Hild, “Response of saturated porous media to cyclic thermal loading,” Intern Journal for Numerical and Analytical Methods in Ge- omechanics, Vol. 27, No. 11, pp. 883904, 2003. [13] B. Bai, “Response of saturated porous media subjected to local therm ace,” Acta Mechanica Sinica, Vol. 22, No. 1, pp. 5461, 2006. [14] B. Bai, “Fluctuation responses of saturated porou tropic medium,” Journal of applied Mechanics, Vol. 72, No. 2, pp. 102114, 2005. [16] M. Kanj, Y. Abousleiman, and R. Ghanem, “Poromecha f anisotropic hollow cylinders,” Journal of Engineer- ing Mechanics, Vol. 129, No. 11, pp. 12771287, 2003. [17] M. Kanj and Y. Abousleiman, “Porothermoelastic analyses of anisotropic hollow cylinders with applications,” I  B. BAI Appendix A For the first case of boundary conditions (i.e. Case 1), from Equations (4) and (5), when t0, a ta ),( , 0),( tap,0),( taur, b tb ),( , 0),( tbp and br ptb ),( , which yields )()()(020101asIqAasKrBasIrA a vDasKqB 202 )( (A1) )()()( 020101asIAasKBasIA 0)( 202 uDasKB (A2) )()(1 1 11 1 1asK s E BasI s E A )()( 1 2 21 2 2asK s E BasI s E A 0 2 33 2a DaE D (A3) )()()( 020101 bsIqAbsKrBbsIrA b vDbsKqB 202)( (A4) )()()( 020101 bsIAbsKBbsIA 0)( 202 uDbsKB (A5) )( 2 )( 2 1 1 11 1 1bsK bs EG BbsI bs EG A )( 2 )( 2 1 2 21 2 2bsK bs EG BbsI bs EG A b p b G DwD 2 32 2 (A6) where 21 ffr , 21ffq , , , . 34 /ggu 342/ggfw 3 fv3 EGM For the second case of boundary conditions (i.e. Case 2), from 0),( taur and Equation (5), the Equations (A3) to (A6) can be obtained easily; while using Equation (6), when t0, 0/),( rta and 0/),( rtap, which yields )( )( )( 12 11 11 asIsqA asKsrB asIsrA 0)( 12 asKsqB (A7) )()()( 121111asIsAasKsBasIsA 0)( 12 asKsB (A8) Hence, the following equation is obtained: b b a p D D B A B A dddddd dddddd dddddd dddddd dddddd dddddd 0 0 0 0or 3 2 2 2 1 1 666564636261 565554535251 464544434241 363534333231 262524232221 161514131211 (A9) where the coefficients d11, d12, …, d65 and d66 can be given correspondingly by Equations (A1) to (A6) (for Case 1) or Equations (A7), (A8) and (A3) to (A6) (for Case 2). Appendix B Due to )( 1asK =, )( 1asK = and 1/a= at a0 in Equations (A7), (A8) and (A3), one has B1=0, B2=0 and D3=0. This implies that all variables must be finite. Hence, Equations (A7), (A8) and (A3) are satis- fied automatically (noting I1(0)=0). The remaining three arbitrary coefficients (A1, A2 and D2) can be determined by solving Equtions (A4) to (A6) simultaneously. At this time, Equation (A9) reduces to the following ex- pression: b b p D A A ddd ddd ddd 0 2 2 1 656361 555351 454341 (A10) where the coefficients d41, d43, …, d63 and d65 can be given correspondingly by Equations (A4) to (A6). Appendix C Due to )( 0bsI = and )( 0bsI = at b in Equations (A4) to (A6), one has A1=0 and A2=0. Noting K0()=0 and K 1()=0, for the satisfaction of Equations (A4) to (A6), one must let D2=0. The remaining three arbitrary coefficients (B1, B2 and D3) can be determined by solving Equations (A1) to (A3) simultaneously. At this time, Equation (A9) reduces to the following expres- sion: 0 0 3 2 1 363432 262422 161412 a D B B ddd ddd ddd (A11) where the coefficients d12, d14, …, d34 and d36 can be given correspondingly by Equations (A1) to (A3). Copyright © 2010 SciRes. ENGINEERING |