Paper Menu >>

Journal Menu >>

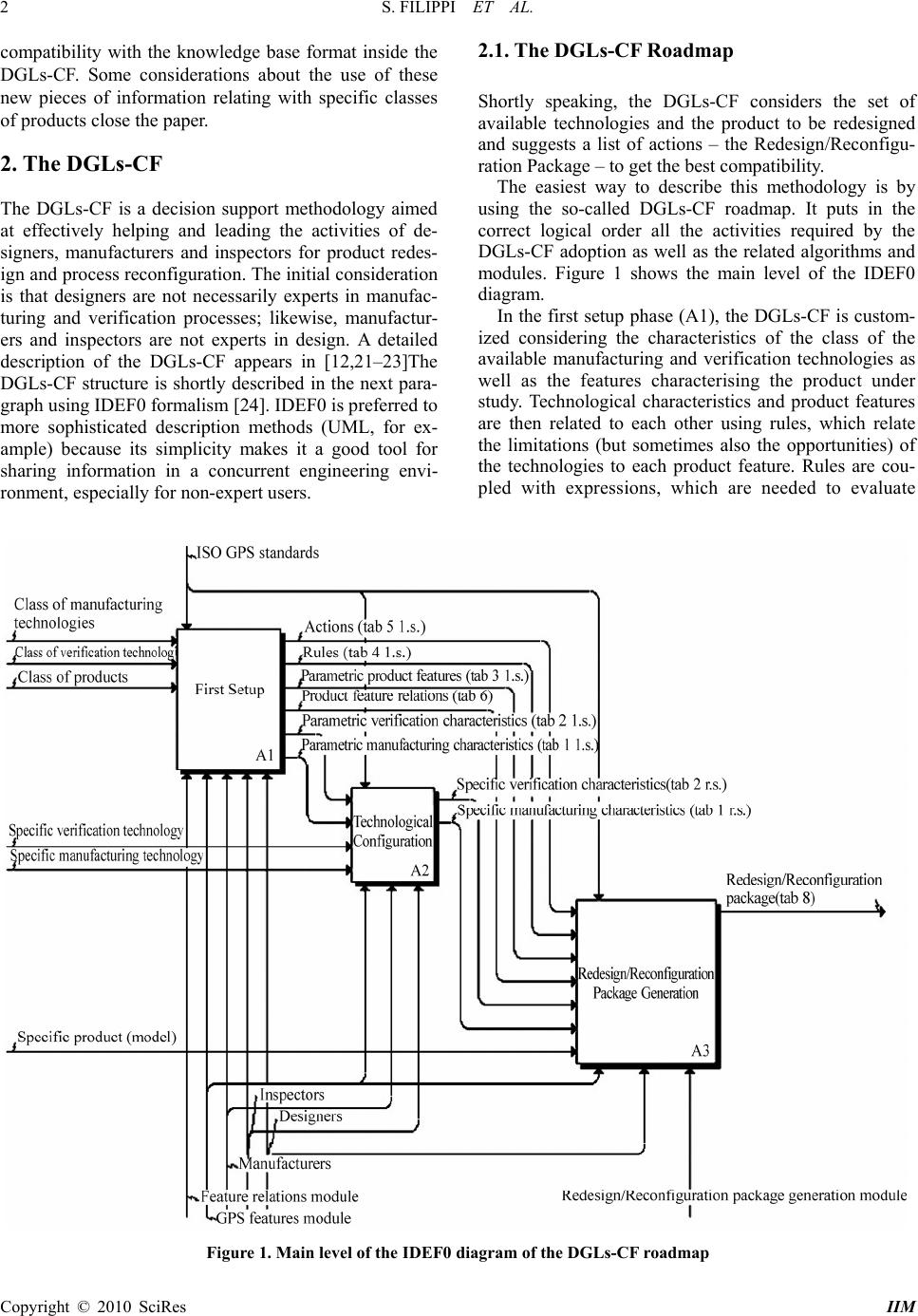

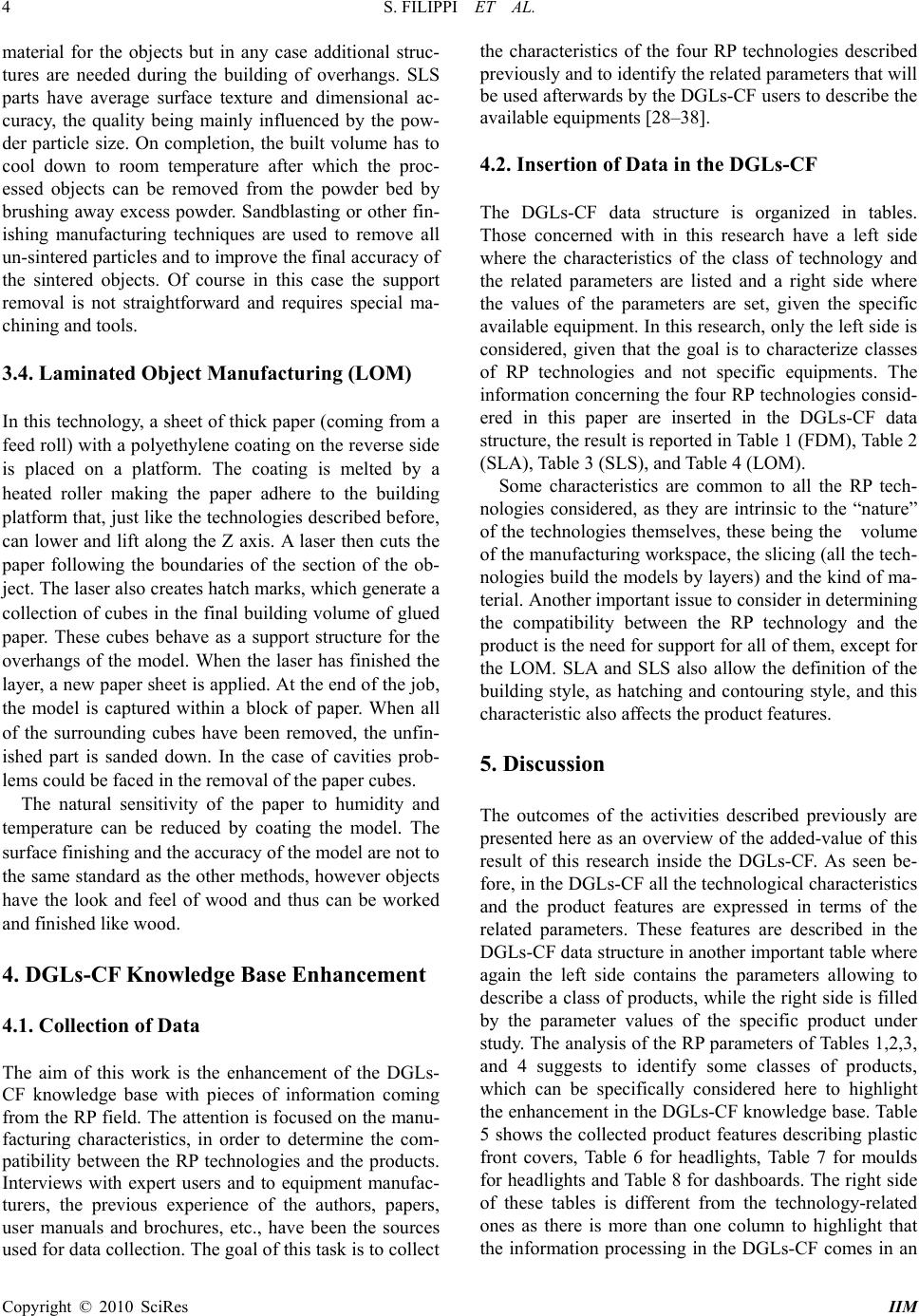

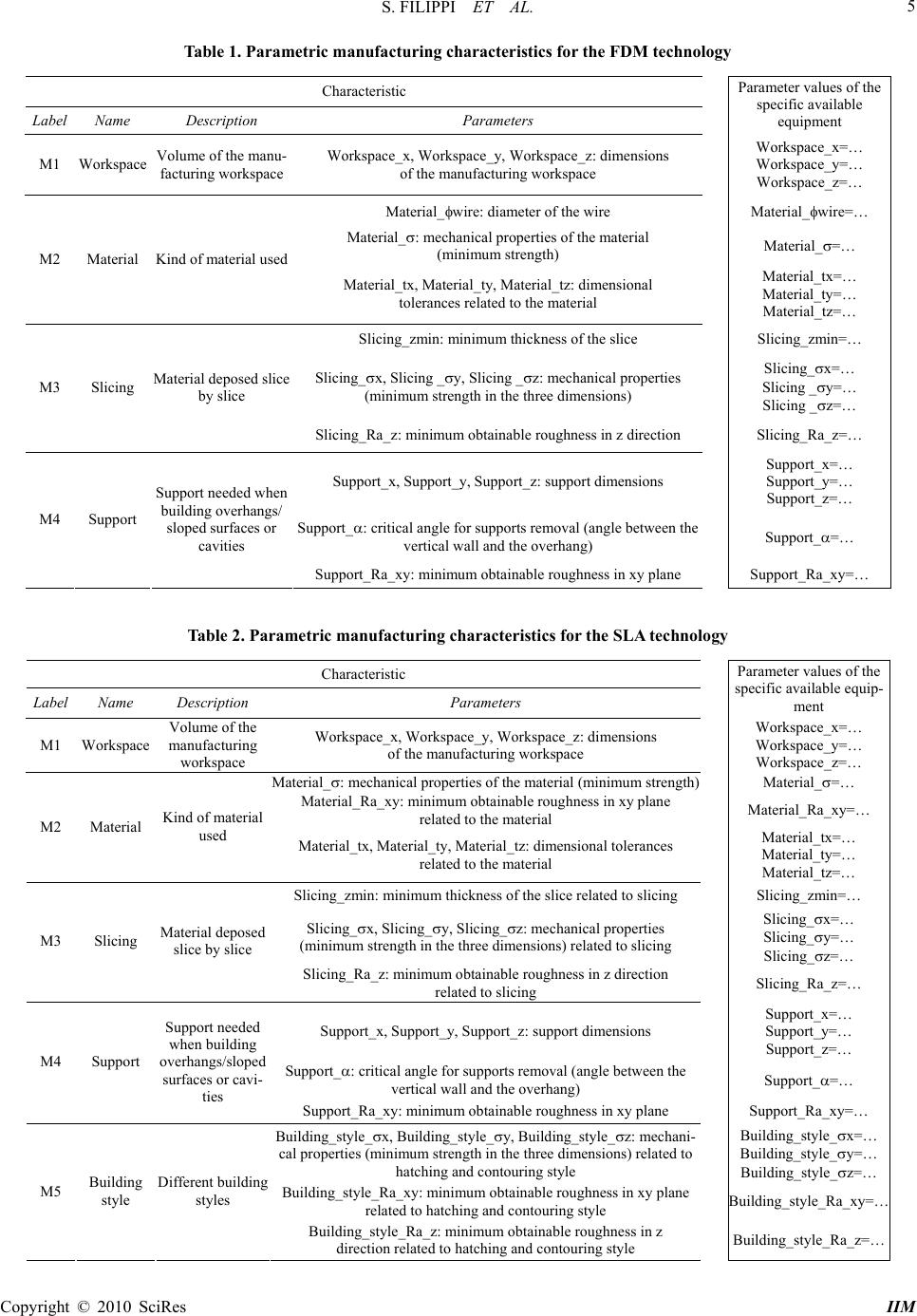

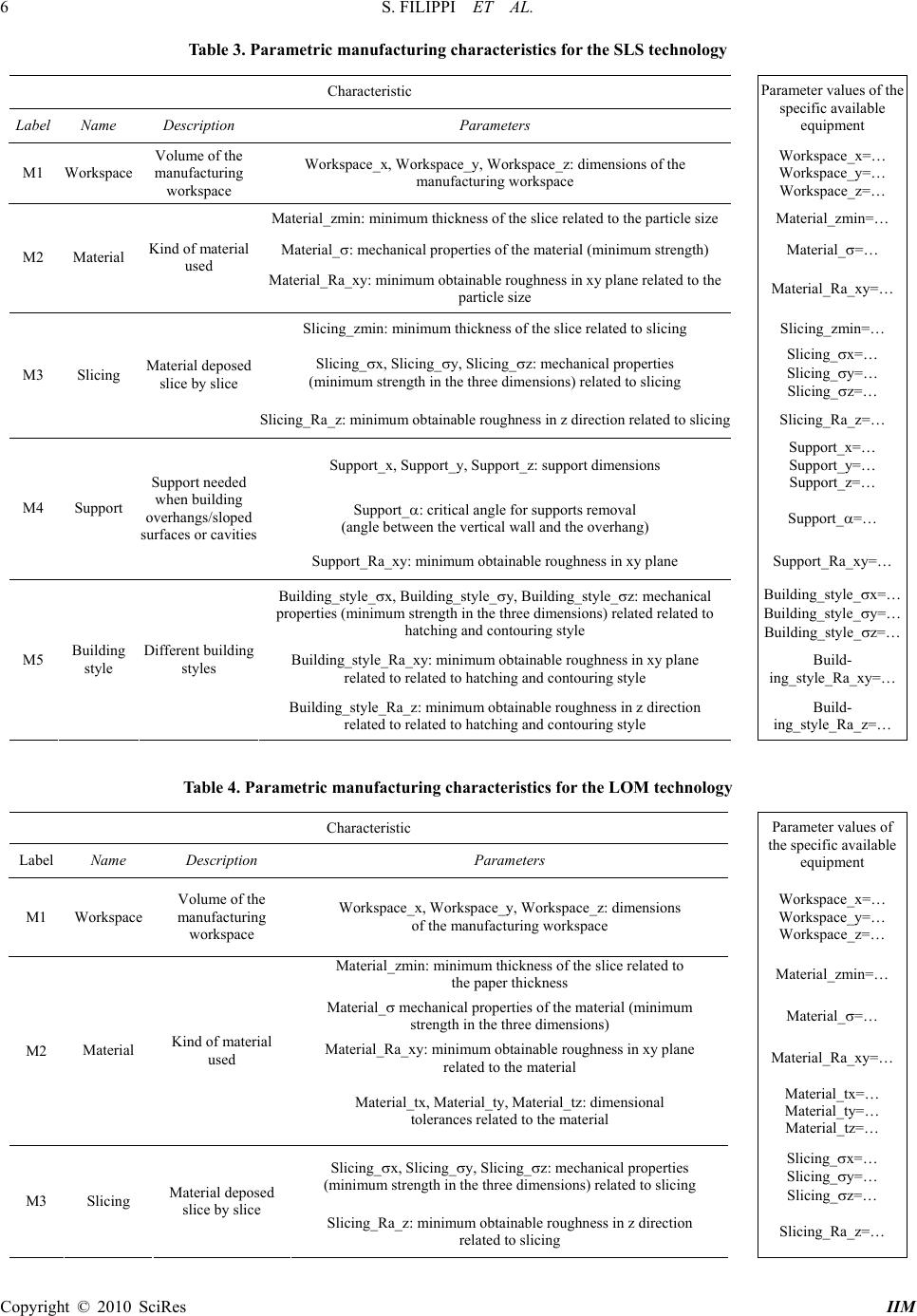

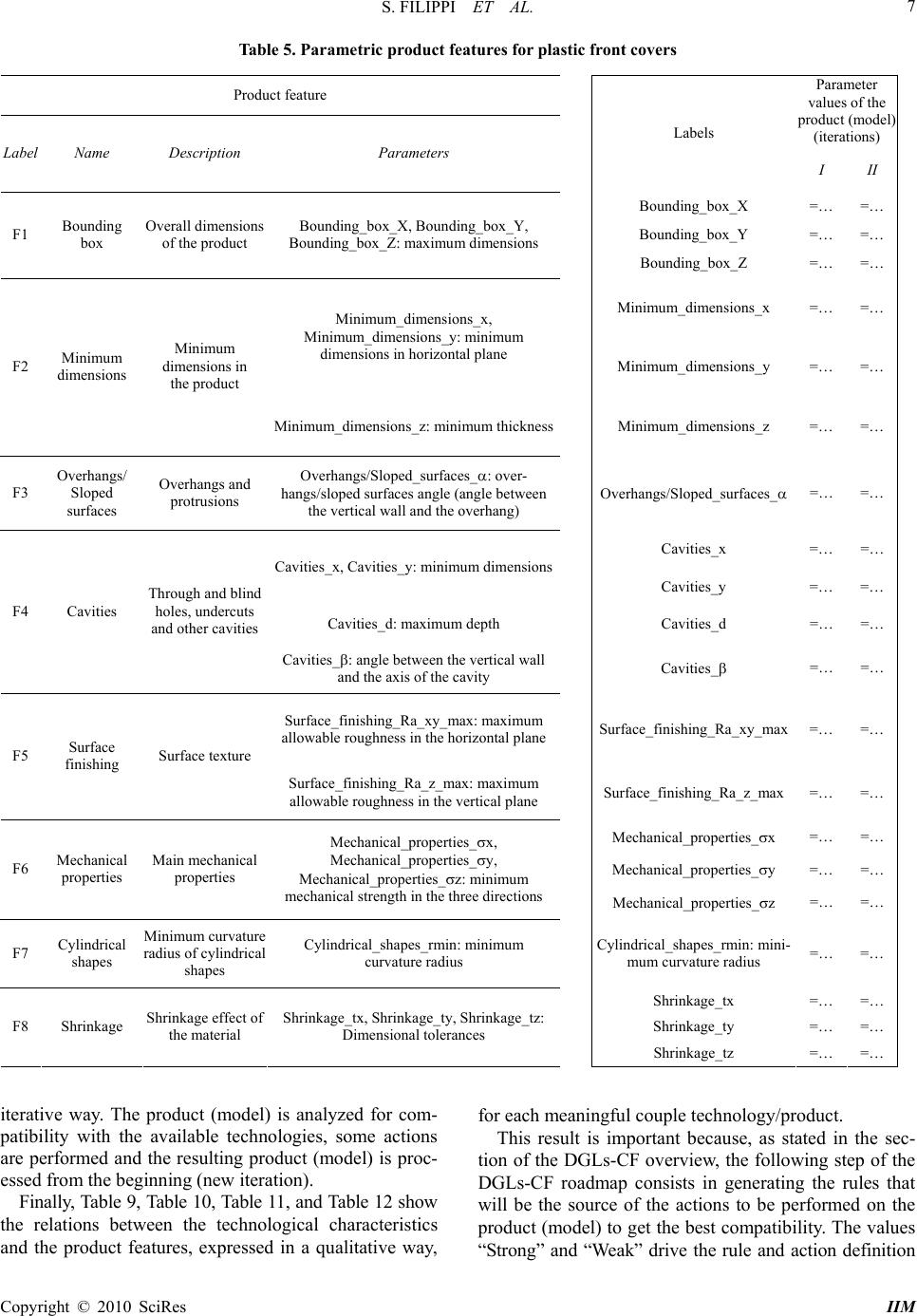

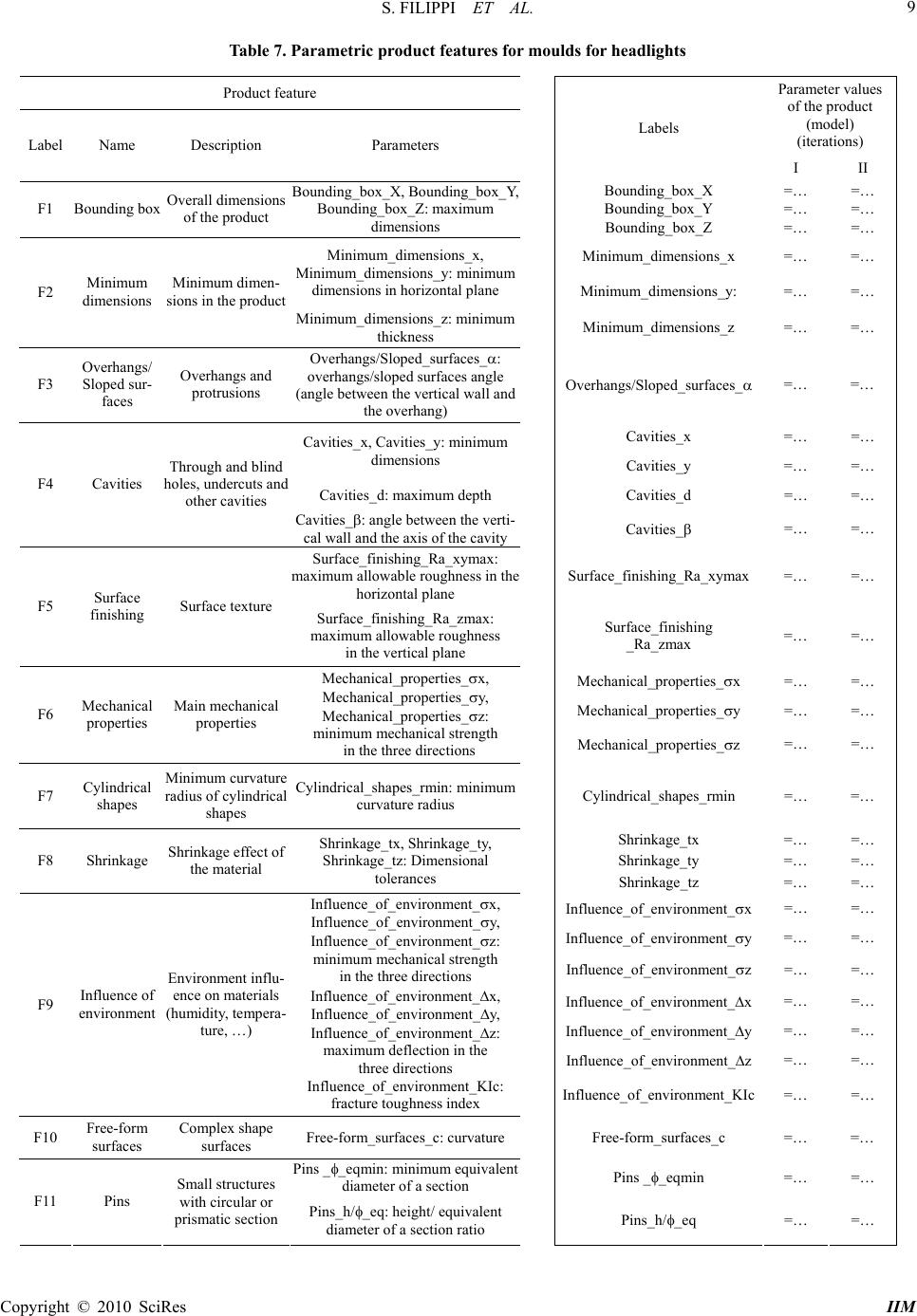

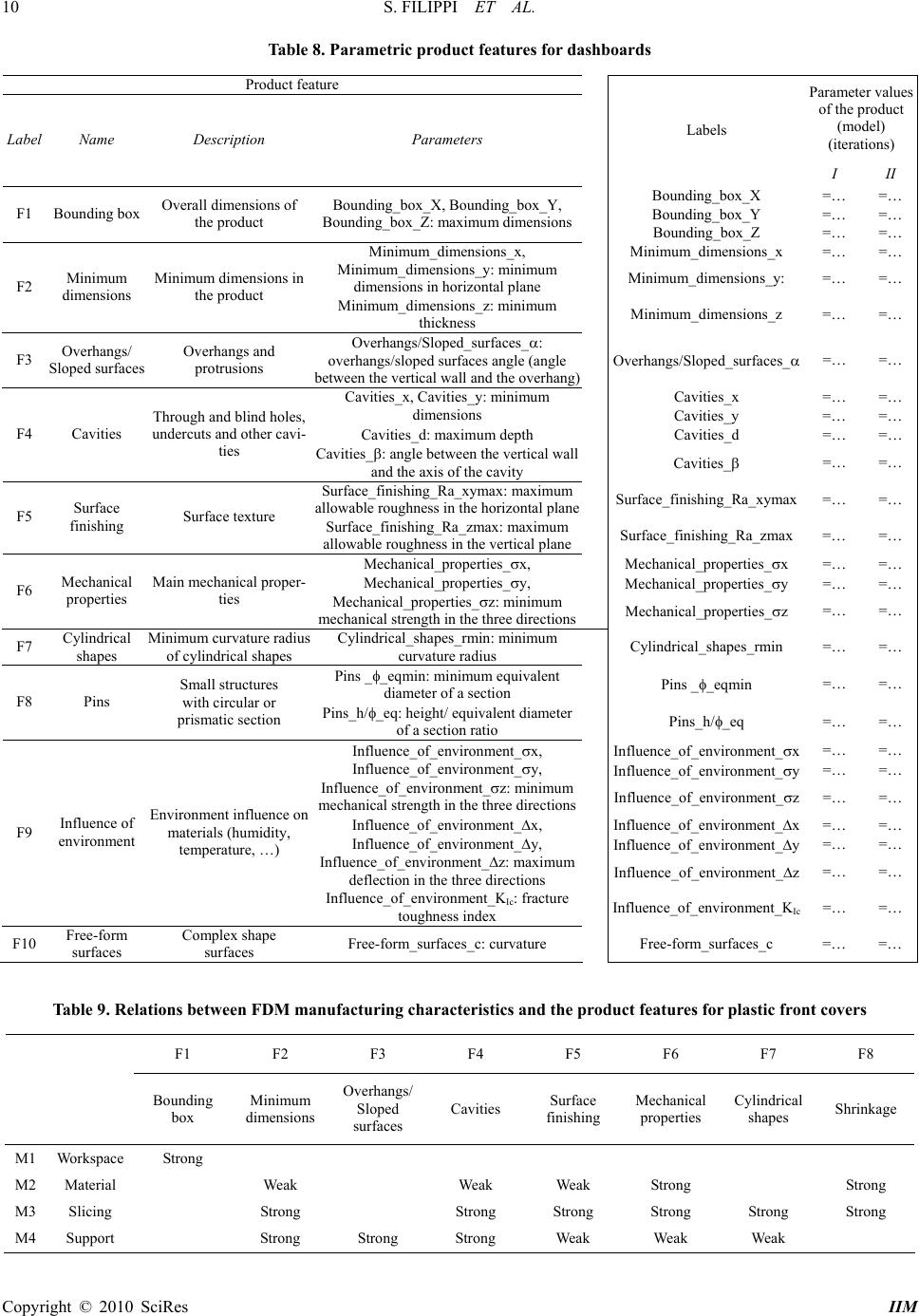

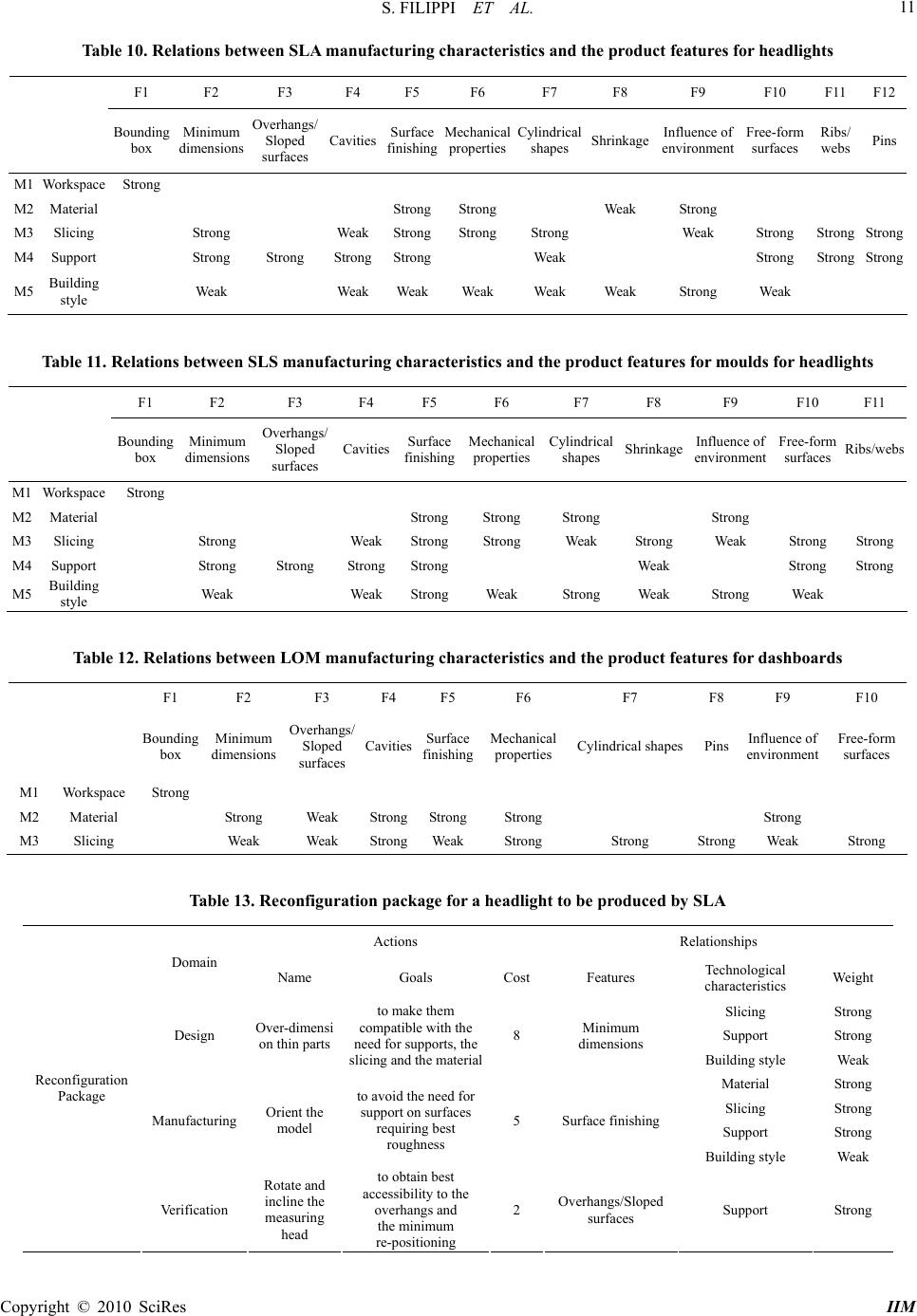

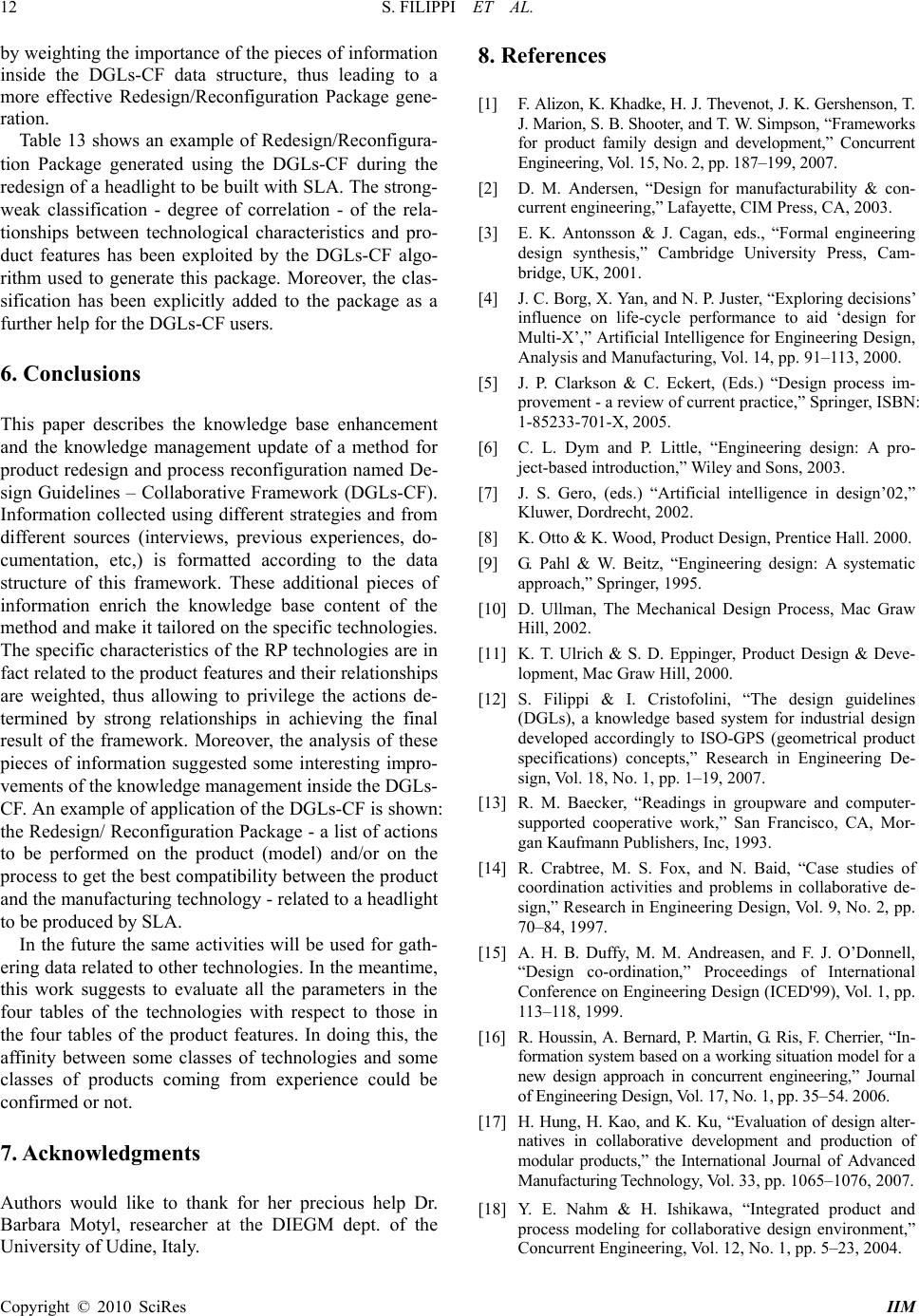

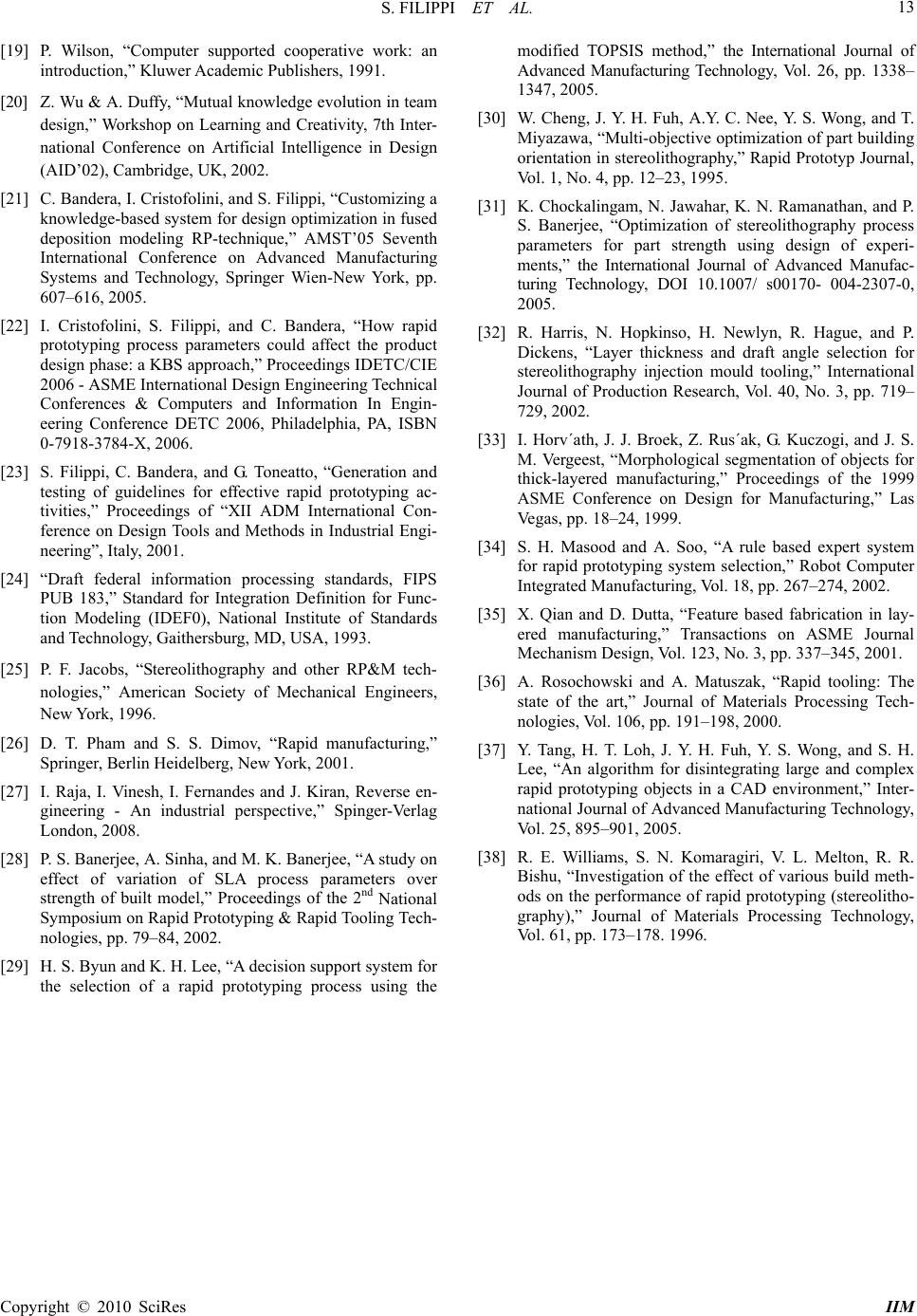

Intelligent Information Management, 2010, 2, 1-13 doi:10.4236/iim.2010.21001 Published Online January 2010 (http://www.scirp.org/journal/iim) Copyright © 2010 SciRes IIM Using Rapid Prototyping Data to Enhance a Knowledge-Based Framework for Product Redesign Stefano FILIPPI1, Ilaria CRISTOFOLINI2 1DIEGM Department, University of Udine, Viale delle Scienze Udine, Italy 2DIMS Department, University of Trento, Via Mesiano Trento, Italy Email: filippi@uniud.it, Ilaria.Cristofolini@ing.unitn.it Abstract The particular characteristics of Rapid Prototyping technologies, both in terms of constrains and opportuni- ties, often require the reconfiguration of the product model to obtain the best compliance with the product functionalities and performances. Within this field of research, a knowledge-based tool named Design GuideLines Collaborative Framework (DGLs-CF) was developed to support both the designers defining the product consistently with the manufacturing technologies and the manufacturers defining the building setup consistently with the product requirements. Present work is focused on enhancing the DGLs-CF knowledge base and on updating the DGLs-CF knowledge management by using the information gathered on some RP technologies. The added-value of this research is represented by an improvement in the Redesign/Reconfig- uration Package, the final result of the DGLs-CF adoption. This is a list of actions to be performed on the product model and on the process parameters to avoid the limitations of the technology and to exploit at best its opportunities. Keywords: rapid prototyping, knowledge-based engineering, product redesign, collaborative engineering 1. Introduction The increasing complexity of design tasks and continu- ous developments in technology require the improve- ment of designers’ problem-solving capabilities, through the development of Design for X (DfX) methods and tools accordingly. Moreover, they must be flexible enou- gh to allow an easy customization according to the evo- lution of the technologies that they address. Up to now, several examples of DfX appeared in the research land- scape, as described in [1–11] The next research step was to investigate the possibility of merging several DfXs together in an integrated framework able to generate de- sign guidelines related to more than one phase of the product lifecycle. In this context, the Design GuideLines Collaborative Framework (DGLs-CF) was developed as a knowledge-based tool to help designers defining the product consistently with manufacturing and verification technologies. The aim of the DGLs-CF is to evaluate the feasibility of the product (model) with available manu- facturing technologies, to exploit the particular charac- teristics of them and to measure the conformity of the product to the requirements with specific verification technologies [12]. Purpose of this work is enhancing the DGLs-CF knowledge base and updating the DGLs-CF knowledge management by exploiting the information related to several Rapid Prototyping (RP) technologies. The goal is to generate richer and more effective guidelines informa- tion for the designers. RP technologies build physical models starting directly from their CAD representations, as this way costs and times are drastically reduced. They are a very powerful tool in product development. New products normally develop in Concurrent Engineering environments where many actors play different roles; in these scenarios it is of great help having a physical pro- totype of the product, something tangible, which may help communicating different skills and developing new ideas [2,13–20]. The specific characteristics of the RP technologies, however, are not so widely known in depth and thus it is worthwhile customizing the DGLs-CF for them. This may be a good way of helping non-expert designers in exploiting the opportunities of RP technolo- gies. The paper opens with a short description of the DGLs- CF and then goes on to describe the four RP technologies selected for this research. The core section of the paper concerns the data collection and their elaboration to get  S. FILIPPI ET AL. 2 compatibility with the knowledge base format inside the DGLs-CF. Some considerations about the use of these new pieces of information relating with specific classes of products close the paper. 2. The DGLs-CF The DGLs-CF is a decision support methodology aimed at effectively helping and leading the activities of de- signers, manufacturers and inspectors for product redes- ign and process reconfiguration. The initial consideration is that designers are not necessarily experts in manufac- turing and verification processes; likewise, manufactur- ers and inspectors are not experts in design. A detailed description of the DGLs-CF appears in [12,21–23]The DGLs-CF structure is shortly described in the next para- graph using IDEF0 formalism [24]. IDEF0 is preferred to more sophisticated description methods (UML, for ex- ample) because its simplicity makes it a good tool for sharing information in a concurrent engineering envi- ronment, especially for non-expert users. 2.1. The DGLs-CF Roadmap Shortly speaking, the DGLs-CF considers the set of available technologies and the product to be redesigned and suggests a list of actions – the Redesign/Reconfigu- ration Package – to get the best compatibility. The easiest way to describe this methodology is by using the so-called DGLs-CF roadmap. It puts in the correct logical order all the activities required by the DGLs-CF adoption as well as the related algorithms and modules. Figure 1 shows the main level of the IDEF0 diagram. In the first setup phase (A1), the DGLs-CF is custom- ized considering the characteristics of the class of the available manufacturing and verification technologies as well as the features characterising the product under study. Technological characteristics and product features are then related to each other using rules, which relate the limitations (but sometimes also the opportunities) of the technologies to each product feature. Rules are cou- pled with expressions, which are needed to evaluate Figure 1. Main level of the IDEF0 diagram of the DGLs-CF roadmap Copyright © 2010 SciRes IIM  S. FILIPPI ET AL. 3 quantitatively the compatibility of the existing version of the product (model) with the available technologies. When the compatibility is not present, the rules suggest actions to be executed to overcome the limitations of the technologies and to exploit their opportunities. It must be noted that some actions may also affect different features when they are performed on a single feature to gain its compatibility. A “dynamic coefficient” is thus associated to the actions, with its value determined by the amount of features the action may affect. This value is decisive in defining the sequence of actions during the generation of the Redesign/Reconfiguration Package. The Technological Configuration phase (A2) allows to set the parameter values of the manufacturing and veri- fication characteristics, given the specific brands/models of the available equipments. Finally, the Redesign/Reconfiguration Package Gen- eration phase (A3) generates the list of actions (the Re- design/Reconfiguration Package) to be applied to the product (model) and to the technological process pa- rameters by means of a recursive algorithm that evalu- ates time by time different product (model) configura- tions. In this work the DGLs-CF knowledge base is en- hanced with information related to some RP technologies; for this reason the main characteristics of the RP tech- nologies considered here are described in the following. 3. RP Technologies The RP technologies considered here are Fused Deposi- tion Modelling (FDM), Stereolithography (SLA), Selec- tive Laser Sintering (SLS), and Laminated Object Manu- facturing (LOM). All of these systems build parts in mul- tiple thin layers and their main characteristics, which are used in the DGLs-CF customisation, are summarised hereafter [25–27]. 3.1. Fused Deposition Modelling (FDM) This technology extrudes a molten thermoplastic fila- ment (ABS, polyolefin, polyamide...) through a nozzle in the form of a thin ribbon and delivers it in computer- controlled locations appropriate for the object geometry, thus building the sections of the part. No high powered lasers are used. Typically, the delivery head moves in the horizontal plane while the support plane, where the part is built, moves vertically, so that each section is built over the previous one. The application temperature is such that the applied material bonds firmly with the pre- vious layer. Some support material may be necessary to build the model, depending on the geometrical complex- ity of the part and on its orientation inside the workspace. The quantity and the shape of the support, which has to be removed from the final part, are calculated automati- cally. The first section is always built on a support plane, which section is slightly larger than the model to allow an easy removal of the part from the building platform. Precision and surface finishing of the parts are affected by the so-called”slicing” (the layering), which depends on the kind of equipment used, and can vary typically from 0.17 mm to 0.33 mm. The final parts do not need post-processing, except for support removal and some grinding for a better surface finishing. 3.2. Stereolithography (SLA) A platform that can be lowered and elevated is usually located the thickness of a layer below the surface of a liquid photosensitive polymer contained in a tank. Each slice is etched onto the surface of the photosensitive pol- ymer that solidifies when exposed to the laser beam. Once the laser has covered the whole surface of the layer, the platform lowers to a depth of another layer thickness, allowing the liquid resin to flow over the previously cur- ed layer. A re-coating blade passes over the surface to ensure that a consistent layer thickness is present before the beginning of the next layer. Different building styles for the prototypes can be used with a SLA system. Nor- mal style involves building full resin prototypes while other styles leaves some resin in the liquid state for dif- ferent purposes (stresses minimization, generation of models for investment casting, etc.). Supports are re- quired when islands (portion of a layer that is discon- nected from any other portion of the same layer), over- hangs, or cantilevered sections exist in the part being built. SLA parts have good surface texture and dimensional accuracy, however the orientation of the model in the workspace (due to the staircase effect) and the presence of support can influence the surface finishing. At the end of the building phase the model is carefully removed from the platform and a post-curing phase is performed, in a UV-beam oven, to completely solidify the part. 3.3. Selective Laser Sintering (SLS) Here the object is built over a platform, where a layer of plastic, metal or ceramic powder (particle size approxi- mately 50μm) is spread and kept heated. A laser beam melts the powder particles selectively. As the layer is finished, the platform moves down by the thickness of one layer (approximately 0.10–0.15 mm), and a new layer of powder is spread on the previous one. When the laser exposes the new layer, it melts and bonds to the previous one. The process repeats until the part is com- plete. Surrounding powder particles act as supporting Copyright © 2010 SciRes IIM  S. FILIPPI ET AL. 4 material for the objects but in any case additional struc- tures are needed during the building of overhangs. SLS parts have average surface texture and dimensional ac- curacy, the quality being mainly influenced by the pow- der particle size. On completion, the built volume has to cool down to room temperature after which the proc- essed objects can be removed from the powder bed by brushing away excess powder. Sandblasting or other fin- ishing manufacturing techniques are used to remove all un-sintered particles and to improve the final accuracy of the sintered objects. Of course in this case the support removal is not straightforward and requires special ma- chining and tools. 3.4. Laminated Object Manufacturing (LOM) In this technology, a sheet of thick paper (coming from a feed roll) with a polyethylene coating on the reverse side is placed on a platform. The coating is melted by a heated roller making the paper adhere to the building platform that, just like the technologies described before, can lower and lift along the Z axis. A laser then cuts the paper following the boundaries of the section of the ob- ject. The laser also creates hatch marks, which generate a collection of cubes in the final building volume of glued paper. These cubes behave as a support structure for the overhangs of the model. When the laser has finished the layer, a new paper sheet is applied. At the end of the job, the model is captured within a block of paper. When all of the surrounding cubes have been removed, the unfin- ished part is sanded down. In the case of cavities prob- lems could be faced in the removal of the paper cubes. The natural sensitivity of the paper to humidity and temperature can be reduced by coating the model. The surface finishing and the accuracy of the model are not to the same standard as the other methods, however objects have the look and feel of wood and thus can be worked and finished like wood. 4. DGLs-CF Knowledge Base Enhancement 4.1. Collection of Data The aim of this work is the enhancement of the DGLs- CF knowledge base with pieces of information coming from the RP field. The attention is focused on the manu- facturing characteristics, in order to determine the com- patibility between the RP technologies and the products. Interviews with expert users and to equipment manufac- turers, the previous experience of the authors, papers, user manuals and brochures, etc., have been the sources used for data collection. The goal of this task is to collect the characteristics of the four RP technologies described previously and to identify the related parameters that will be used afterwards by the DGLs-CF users to describe the available equipments [28–38]. 4.2. Insertion of Data in the DGLs-CF The DGLs-CF data structure is organized in tables. Those concerned with in this research have a left side where the characteristics of the class of technology and the related parameters are listed and a right side where the values of the parameters are set, given the specific available equipment. In this research, only the left side is considered, given that the goal is to characterize classes of RP technologies and not specific equipments. The information concerning the four RP technologies consid- ered in this paper are inserted in the DGLs-CF data structure, the result is reported in Table 1 (FDM), Table 2 (SLA), Table 3 (SLS), and Table 4 (LOM). Some characteristics are common to all the RP tech- nologies considered, as they are intrinsic to the “nature” of the technologies themselves, these being the volume of the manufacturing workspace, the slicing (all the tech- nologies build the models by layers) and the kind of ma- terial. Another important issue to consider in determining the compatibility between the RP technology and the product is the need for support for all of them, except for the LOM. SLA and SLS also allow the definition of the building style, as hatching and contouring style, and this characteristic also affects the product features. 5. Discussion The outcomes of the activities described previously are presented here as an overview of the added-value of this result of this research inside the DGLs-CF. As seen be- fore, in the DGLs-CF all the technological characteristics and the product features are expressed in terms of the related parameters. These features are described in the DGLs-CF data structure in another important table where again the left side contains the parameters allowing to describe a class of products, while the right side is filled by the parameter values of the specific product under study. The analysis of the RP parameters of Tables 1,2,3, and 4 suggests to identify some classes of products, which can be specifically considered here to highlight the enhancement in the DGLs-CF knowledge base. Table 5 shows the collected product features describing plastic front covers, Table 6 for headlights, Table 7 for moulds for headlights and Table 8 for dashboards. The right side of these tables is different from the technology-related ones as there is more than one column to highlight that the information processing in the DGLs-CF comes in an Copyright © 2010 SciRes IIM  S. FILIPPI ET AL. Copyright © 2010 SciRes IIM 5 Table 1. Parametric manufacturing characteristics for the FDM technology Characteristic Label Name Description Parameters Parameter values of the specific available equipment M1 Workspace Volume of the manu- facturing workspace Workspace_x, Workspace_y, Workspace_z: dimensions of the manufacturing workspace Workspace_x=… Workspace_y=… Workspace_z=… Material_wire: diameter of the wire Material_wire=… Material_: mechanical properties of the material (minimum strength) Material_=… M2 Material Kind of material used Material_tx, Material_ty, Material_tz: dimensional tolerances related to the material Material_tx=… Material_ty=… Material_tz=… Slicing_zmin: minimum thickness of the slice Slicing_zmin=… Slicing_x, Slicing _y, Slicing _z: mechanical properties (minimum strength in the three dimensions) Slicing_x=… Slicing _y=… Slicing _z=… M3 Slicing Material deposed slice by slice Slicing_Ra_z: minimum obtainable roughness in z direction Slicing_Ra_z=… Support_x, Support_y, Support_z: support dimensions Support_x=… Support_y=… Support_z=… Support_: critical angle for supports removal (angle between the vertical wall and the overhang) Support_=… M4 Support Support needed when building overhangs/ sloped surfaces or cavities Support_Ra_xy: minimum obtainable roughness in xy plane Support_Ra_xy=… Table 2. Parametric manufacturing characteristics for the SLA technology Characteristic Label Name Description Parameters Parameter values of the specific available equip- ment M1 Workspace Volume of the manufacturing workspace Workspace_x, Workspace_y, Workspace_z: dimensions of the manufacturing workspace Workspace_x=… Workspace_y=… Workspace_z=… Material_: mechanical properties of the material (minimum strength) Material_=… Material_Ra_xy: minimum obtainable roughness in xy plane related to the material Material_Ra_xy=… M2 Material Kind of material used Material_tx, Material_ty, Material_tz: dimensional tolerances related to the material Material_tx=… Material_ty=… Material_tz=… Slicing_zmin: minimum thickness of the slice related to slicing Slicing_zmin=… Slicing_x, Slicing_y, Slicing_z: mechanical properties (minimum strength in the three dimensions) related to slicing Slicing_x=… Slicing_y=… Slicing_z=… M3 Slicing Material deposed slice by slice Slicing_Ra_z: minimum obtainable roughness in z direction related to slicing Slicing_Ra_z=… Support_x, Support_y, Support_z: support dimensions Support_x=… Support_y=… Support_z=… Support_: critical angle for supports removal (angle between the vertical wall and the overhang) Support_=… M4 Support Support needed when building overhangs/sloped surfaces or cavi- ties Support_Ra_xy: minimum obtainable roughness in xy plane Support_Ra_xy=… Building_style_x, Building_style_y, Building_style_z: mechani- cal properties (minimum strength in the three dimensions) related to hatching and contouring style Building_style_x=… Building_style_y=… Building_style_z=… Building_style_Ra_xy: minimum obtainable roughness in xy plane related to hatching and contouring style Building_style_Ra_xy=… M5 Building style Different building styles Building_style_Ra_z: minimum obtainable roughness in z direction related to hatching and contouring style Building_style_Ra_z=…  S. FILIPPI ET AL. 6 Table 3. Parametric manufacturing characteristics for the SLS technology Characteristic Label Name Description Parameters Parameter values of the specific available equipment M1 Workspace Volume of the manufacturing workspace Workspace_x, Workspace_y, Workspace_z: dimensions of the manufacturing workspace Workspace_x=… Workspace_y=… Workspace_z=… Material_zmin: minimum thickness of the slice related to the particle size Material_zmin=… Material_: mechanical properties of the material (minimum strength) Material_=… M2 Material Kind of material used Material_Ra_xy: minimum obtainable roughness in xy plane related to the particle size Material_Ra_xy=… Slicing_zmin: minimum thickness of the slice related to slicing Slicing_zmin=… Slicing_x, Slicing_y, Slicing_z: mechanical properties (minimum strength in the three dimensions) related to slicing Slicing_x=… Slicing_y=… Slicing_z=… M3 Slicing Material deposed slice by slice Slicing_Ra_z: minimum obtainable roughness in z direction related to slicing Slicing_Ra_z=… Support_x, Support_y, Support_z: support dimensions Support_x=… Support_y=… Support_z=… Support_: critical angle for supports removal (angle between the vertical wall and the overhang) Support_=… M4 Support Support needed when building overhangs/sloped surfaces or cavities Support_Ra_xy: minimum obtainable roughness in xy plane Support_Ra_xy=… Building_style_x, Building_style_y, Building_style_z: mechanical properties (minimum strength in the three dimensions) related related to hatching and contouring style Building_style_x=… Building_style_y=… Building_style_z=… Building_style_Ra_xy: minimum obtainable roughness in xy plane related to related to hatching and contouring style Build- ing_style_Ra_xy=… M5 Building style Different building styles Building_style_Ra_z: minimum obtainable roughness in z direction related to related to hatching and contouring style Build- ing_style_Ra_z=… Table 4. Parametric manufacturing characteristics for the LOM technology Characteristic Label Name Description Parameters Parameter values of the specific available equipment M1 Workspace Volume of the manufacturing workspace Workspace_x, Workspace_y, Workspace_z: dimensions of the manufacturing workspace Workspace_x=… Workspace_y=… Workspace_z=… Material_zmin: minimum thickness of the slice related to the paper thickness Material_zmin=… Material_ mechanical properties of the material (minimum strength in the three dimensions) Material_=… Material_Ra_xy: minimum obtainable roughness in xy plane related to the material Material_Ra_xy=… M2 Material Kind of material used Material_tx, Material_ty, Material_tz: dimensional tolerances related to the material Material_tx=… Material_ty=… Material_tz=… Slicing_x, Slicing_y, Slicing_z: mechanical properties (minimum strength in the three dimensions) related to slicing Slicing_x=… Slicing_y=… Slicing_z=… M3 Slicing Material deposed slice by slice Slicing_Ra_z: minimum obtainable roughness in z direction related to slicing Slicing_Ra_z=… Copyright © 2010 SciRes IIM  S. FILIPPI ET AL. Copyright © 2010 SciRes IIM 7 Table 5. Parametric product features for plastic front covers Product feature Parameter values of the product (model) (iterations) Label Name Description Parameters Labels I II Bounding_box_X =…=… Bounding_box_Y =…=… F1 Bounding box Overall dimensions of the product Bounding_box_X, Bounding_box_Y, Bounding_box_Z: maximum dimensions Bounding_box_Z =…=… Minimum_dimensions_x =…=… Minimum_dimensions_x, Minimum_dimensions_y: minimum dimensions in horizontal plane Minimum_dimensions_y =…=… F2 Minimum dimensions Minimum dimensions in the product Minimum_dimensions_z: minimum thickness Minimum_dimensions_z =…=… F3 Overhangs/ Sloped surfaces Overhangs and protrusions Overhangs/Sloped_surfaces_: over- hangs/sloped surfaces angle (angle between the vertical wall and the overhang) Overhangs/Sloped_surfaces_ =… =… Cavities_x =…=… Cavities_x, Cavities_y: minimum dimensions Cavities_y =…=… Cavities_d: maximum depth Cavities_d =…=… F4 Cavities Through and blind holes, undercuts and other cavities Cavities_: angle between the vertical wall and the axis of the cavity Cavities_ =… =… Surface_finishing_Ra_xy_max: maximum allowable roughness in the horizontal plane Surface_finishing_Ra_xy_max =…=… F5 Surface finishing Surface texture Surface_finishing_Ra_z_max: maximum allowable roughness in the vertical plane Surface_finishing_Ra_z_max =…=… Mechanical_properties_x =… =… Mechanical_properties_y =… =… F6 Mechanical properties Main mechanical properties Mechanical_properties_x, Mechanical_properties_y, Mechanical_properties_z: minimum mechanical strength in the three directions Mechanical_properties_z =… =… F7 Cylindrical shapes Minimum curvature radius of cylindrical shapes Cylindrical_shapes_rmin: minimum curvature radius Cylindrical_shapes_rmin: mini- mum curvature radius =… =… Shrinkage_tx =…=… Shrinkage_ty =…=… F8 Shrinkage Shrinkage effect of the material Shrinkage_tx, Shrinkage_ty, Shrinkage_tz: Dimensional tolerances Shrinkage_tz =…=… iterative way. The product (model) is analyzed for com- patibility with the available technologies, some actions are performed and the resulting product (model) is proc- essed from the beginning (new iteration). Finally, Table 9, Table 10, Table 11, and Table 12 show the relations between the technological characteristics and the product features, expressed in a qualitative way, for each meaningful couple technology/product. This result is important because, as stated in the sec- tion of the DGLs-CF overview, the following step of the DGLs-CF roadmap consists in generating the rules that will be the source of the actions to be performed on the product (model) to get the best compatibility. The values “Strong” and “Weak” drive the rule and action definition  S. FILIPPI ET AL. 8 Table 6. Parametric product features for headlights Product feature Parameter values of the product (model) (iterations) Label Name Description Parameters Labels I II Bounding_box_X =… =… Bounding_box_Y =… =… F1 Bounding box Overall dimensions of the product Bounding_box_X, Bounding_box_Y, Bounding_box_Z: maximum dimensions Bounding_box_Z =… =… Minimum_dimensions_x =… =… Minimum_dimensions_x, Minimum_dimensions_y: minimum dimensions in horizontal plane Minimum_dimensions_y =… =… F2 Minimum dimensions Minimum dimensions in the product Minimum_dimensions_z: minimum thickness Minimum_dimensions_z =… =… F3 Overhangs/ Sloped surfaces Overhangs and protrusions Overhangs /Sloped _surfaces_ : overhangs/sloped surfaces angle (angle between the vertical wall and the overhang) Overhangs/ Sloped_s urfaces_ =… =… Cavities_x =… =… Cavities_x, Cavities_y: minimum dimensions Cavities_y =… =… Cavities_d: maximum depth Cavities_d =… =… F4 Cavities Through and blind holes, undercuts and other cavities Cavities_: angle between the vertical wall and the axis of the cavity Cavities_ =… =… Surface_finishing_Ra_xy_max: maximum allowable roughness in the horizontal plane Surface_finishing_ Ra_xy_max =… =… F5 Surface finishing Surface texture Surface_finishing_Ra_z_max: maximum allowable roughness in the vertical plane Surface_finishing_ Ra_z_max =… =… Mechanical_properties_x =… =… Mechanical_ prop erties_y =… =… F6 Mechanical properties Main mechanical properties Mechanical_ prop erties_x, Mechanical_properties_y, Mechanical_ prop erties_z: minimum mechanical strength in the three directions Mechanical_ prop erties_z =… =… F7 Cylindrical shapes Minimum curvature radius of cylindrical shapes Cylindrical_shapes_rmin: minimum curvature radiusCylindrical_shapes_rmin: minimum curvature radius =… =… Shrinkage_tx =… =… Shrinkage_ty =… =… F8 Shrinkage Shrinkage effect of the material Shrinkage_tx, Shrinkage_ty, Shrinkage_tz: Dimensional tolerances Shrinkage_tz =… =… Influence_of_environment_x =… =… Influence_of_environment_y =… =… Influence_of_environment_x, Influ- ence_of_environment_y, Influ- ence_of_environment_z: minimum mechanical strength in the three directions Influence_of_environment_z =… =… Influence_of_environment_x =… =… Influence_of_environment_y =… =… Influence_of_environment_x, Influ- ence_of_environment_y, Influ- ence_of_environment_z: maximum deflection in the three directions Influence_of_environment_z =… =… F9 Influence of environment Environment influ- ence on materials (humidity, tempera- ture, …) Influence_of_environment_KIc: fracture toughness indexInfluence_of_environment_KIc =… =… F10 Free-form surfaces Complex shape surfaces Free-form_surfaces_c: curvature Free-form_surfaces_c =… =… Ribs/webs_zmin:_minimum rib thickness Ribs/webs_zmin =… =… F11 Ribs/webs Supports or net of supports Rib s/webs_ : angle between the vertical wall and the rib inclination Ribs/web s_ =… =… Pins__eqmin: minimum equivalent diameter of a section Pins__eqmin =… =… F12 Pins Small structures with circular or prismatic section Pins_h/ _eq: height/ equivalent diameter of a section ratio Pins_h/ _eq =… =… Copyright © 2010 SciRes IIM  S. FILIPPI ET AL. 9 Table 7. Parametric product features for moulds for headlights Product feature Parameter values of the product (model) (iterations) Label Name Description Parameters Labels I II Bounding_box_X =… =… Bounding_box_Y =… =… F1 Bounding box Overall dimensions of the product Bounding_box_X, Bounding_box_Y, Bounding_box_Z: maximum dimensions Bounding_box_Z =… =… Minimum_dimensions_x =… =… Minimum_dimensions_x, Minimum_dimensions_y: minimum dimensions in horizontal plane Minimum_dimensions_y: =… =… F2 Minimum dimensions Minimum dimen- sions in the product Minimum_dimensions_z: minimum thickness Minimum_dimensions_z =… =… F3 Overhangs/ Sloped sur- faces Overhangs and protrusions Overhangs/Sloped_surfaces_: overhangs/sloped surfaces angle (angle between the vertical wall and the overhang) Overhangs/Sloped_surfaces_ =… =… Cavities_x =… =… Cavities_x, Cavities_y: minimum dimensions Cavities_y =… =… Cavities_d: maximum depth Cavities_d =… =… F4 Cavities Through and blind holes, undercuts and other cavities Cavities_: angle between the verti- cal wall and the axis of the cavity Cavities_ =… =… Surface_finishing_Ra_xymax: maximum allowable roughness in the horizontal plane Surface_finishing_Ra_xymax =… =… F5 Surface finishing Surface texture Surface_finishing_Ra_zmax: maximum allowable roughness in the vertical plane Surface_finishing _Ra_zmax =… =… Mechanical_properties_x =… =… Mechanical_properties_y =… =… F6 Mechanical properties Main mechanical properties Mechanical_properties_x, Mechanical_properties_y, Mechanical_properties_z: minimum mechanical strength in the three directions Mechanical_properties_z =… =… F7 Cylindrical shapes Minimum curvature radius of cylindrical shapes Cylindrical_shapes_rmin: minimum curvature radius Cylindrical_shapes_rmin =… =… Shrinkage_tx =… =… Shrinkage_ty =… =… F8 Shrinkage Shrinkage effect of the material Shrinkage_tx, Shrinkage_ty, Shrinkage_tz: Dimensional tolerances Shrinkage_tz =… =… Influence_of_environment_x =… =… Influence_of_environment_y =… =… Influence_of_environment_x, Influence_of_environment_y, Influence_of_environment_z: minimum mechanical strength in the three directions Influence_of_environment_z =… =… Influence_of_environment_x =… =… Influence_of_environment_y =… =… Influence_of_environment_ x, Influence_of_environment_y, Influence_of_environment_z: maximum deflection in the three directions Influence_of_environment_z =… =… F9 Influence of environment Environment influ- ence on materials (humidity, tempera- ture, …) Influence_of_environment_KIc: fracture toughness index Influence_of_environment_KIc =… =… F10 Free-form surfaces Complex shape surfaces Free-form_surfaces_c: curvature Free-form_surfaces_c =… =… Pins _ _ eqmin: minimum equivalent diameter of a section Pins __eqmin =… =… F11 Pins Small structures with circular or prismatic section Pins_h/_eq: height/ equivalent diameter of a section ratio Pins_h/_eq =… =… Copyright © 2010 SciRes IIM  S. FILIPPI ET AL. 10 Table 8. Parametric product features for dashboards Product feature Parameter values of the product (model) (iterations) Label Name Description Parameters Labels I II Bounding_box_X =… =… Bounding_box_Y =… =… F1 Bounding box Overall dimensions of the product Bounding_box_X, Bounding_box_Y, Bounding_box_Z: maximum dimensionsBounding_box_Z =… =… Minimum_dimensions_x =… =…Minimum_dimensions_x, Minimum_dimensions_y: minimum dimensions in horizontal plane Minimum_dimensions_y: =… =… F2 Minimum dimensions Minimum dimensions in the product Minimum_dimensions_z: minimum thickness Minimum_dimensions_z =… =… F3 Overhangs/ Sloped surfaces Overhangs and protrusions Overhangs/Sloped_surfaces_: overhangs/sloped surfaces angle (angle between the vertical wall and the overhang) Overhangs/Sloped_surfaces_ =… =… Cavities_x =… =…Cavities_x, Cavities_y: minimum dimensions Cavities_y =… =… Cavities_d: maximum depth Cavities_d =… =… F4 Cavities Through and blind holes, undercuts and other cavi- ties Cavities_: angle between the vertical wall and the axis of the cavity Cavities_ =… =… Surface_finishing_Ra_xymax: maximum allowable roughness in the horizontal planeSurface_finishing_Ra_xymax =… =… F5 Surface finishing Surface texture Surface_finishing_Ra_zmax: maximum allowable roughness in the vertical planeSurface_finishing_Ra_zmax =… =… Mechanical_properties_x =… =… Mechanical_properties_y =… =… F6 Mechanical properties Main mechanical proper- ties Mechanical_properties_x, Mechanical_properties_y, Mechanical_properties_z: minimum mechanical strength in the three directionsMechanical_properties_z =… =… F7 Cylindrical shapes Minimum curvature radius of cylindrical shapes Cylindrical_shapes_rmin: minimum curvature radius Cylindrical_shapes_rmin =… =… Pins __eqmin: minimum equivalent diameter of a section Pins __eqmin =… =… F8 Pins Small structures with circular or prismatic section Pins_h/_eq: height/ equivalent diameter of a section ratio Pins_h/_eq =… =… Influence_of_environment_x =… =… Influence_of_environment_y =… =… Influence_of_environment_x, Influence_of_environment_y, Influence_of_environment_z: minimum mechanical strength in the three directionsInfluence_of_environment_z =… =… Influence_of_environment_x =… =… Influence_of_environment_y =… =… Influence_of_environment_x, Influence_of_environment_y, Influence_of_environment_z: maximum deflection in the three directions Influence_of_environment_z =… =… F9 Influence of environment Environment influence on materials (humidity, temperature, …) Influence_of_environment_KIc: fracture toughness index Influence_of_environment_KIc =… =… F10 Free-form surfaces Complex shape surfaces Free-form_surfaces_c: curvature Free-form_surfaces_c =… =… Table 9. Relations between FDM manufacturing characteristics and the product features for plastic front covers F1 F2 F3 F4 F5 F6 F7 F8 Bounding box Minimum dimensions Overhangs/ Sloped surfaces Cavities Surface finishing Mechanical properties Cylindrical shapes Shrinkage M1 Workspace Strong M2 Material Weak Weak Weak Strong Strong M3 Slicing Strong Strong Strong Strong Strong Strong M4 Support Strong Strong Strong Weak Weak Weak Copyright © 2010 SciRes IIM  S. FILIPPI ET AL. 11 Table 10. Relations between SLA manufacturing characteristics and the product features for headlights F1 F2 F3 F4 F5 F6 F7 F8 F9 F10 F11 F12 Bounding box Minimum dimensions Overhangs/ Sloped surfaces Cavities Surface finishing Mechanical properties Cylindrical shapes Shrinkage Influence of environment Free-form surfaces Ribs/ webs Pins M1 Workspace Strong M2 Material StrongStrong Weak Strong M3 Slicing Strong Weak StrongStrong Strong Weak Strong StrongStrong M4 Support Strong Strong StrongStrong Weak Strong StrongStrong M5 Building style Weak Weak WeakWeak Weak Weak Strong Weak Table 11. Relations between SLS manufacturing characteristics and the product features for moulds for headlights F1 F2 F3 F4 F5 F6 F7 F8 F9 F10 F11 Bounding box Minimum dimensions Overhangs/ Sloped surfaces Cavities Surface finishing Mechanical properties Cylindrical shapes Shrinkage Influence of environment Free-form surfaces Rib s/webs M1 Workspace Strong M2 Material StrongStrong Strong Strong M3 Slicing Strong Weak StrongStrong Weak Strong Weak Strong Strong M4 Support Strong Strong StrongStrong Weak Strong Strong M5 Building style Weak Weak StrongWeak Strong Weak Strong Weak Table 12. Relations between LOM manufacturing characteristics and the product features for dashboards F1 F2 F3 F4 F5 F6 F7 F8 F9 F10 Bounding box Minimum dimensions Overhangs/ Sloped surfaces Cavities Surface finishing Mechanical properties Cylindrical shapesPins Influence of environment Free-form surfaces M1 Workspace Strong M2 Material Strong Weak StrongStrongStrong Strong M3 Slicing Weak Weak StrongWeak Strong Strong Strong Weak Strong Table 13. Reconfiguration package for a headlight to be produced by SLA Actions Relationships Domain Name Goals CostFeatures Technological characteristics Weight Slicing Strong Support Strong Design Over-dimensi on thin parts to make them compatible with the need for supports, the slicing and the material 8 Minimum dimensions Building style Weak Material Strong Slicing Strong Support Strong Manufacturing Orient the model to avoid the need for support on surfaces requiring best roughness 5 Surface finishing Building style Weak Reconfiguration Package Verification Rotate and incline the measuring head to obtain best accessibility to the overhangs and the minimum re-positioning 2 Overhangs/Sloped surfaces Support Strong Copyright © 2010 SciRes IIM  S. FILIPPI ET AL. Copyright © 2010 SciRes IIM 12 by weighting the importance of the pieces of information inside the DGLs-CF data structure, thus leading to a more effective Redesign/Reconfiguration Package gene- ration. Table 13 shows an example of Redesign/Reconfigura- tion Package generated using the DGLs-CF during the redesign of a headlight to be built with SLA. The strong- weak classification - degree of correlation - of the rela- tionships between technological characteristics and pro- duct features has been exploited by the DGLs-CF algo- rithm used to generate this package. Moreover, the clas- sification has been explicitly added to the package as a further help for the DGLs-CF users. 6. Conclusions This paper describes the knowledge base enhancement and the knowledge management update of a method for product redesign and process reconfiguration named De- sign Guidelines – Collaborative Framework (DGLs-CF). Information collected using different strategies and from different sources (interviews, previous experiences, do- cumentation, etc,) is formatted according to the data structure of this framework. These additional pieces of information enrich the knowledge base content of the method and make it tailored on the specific technologies. The specific characteristics of the RP technologies are in fact related to the product features and their relationships are weighted, thus allowing to privilege the actions de- termined by strong relationships in achieving the final result of the framework. Moreover, the analysis of these pieces of information suggested some interesting impro- vements of the knowledge management inside the DGLs- CF. An example of application of the DGLs-CF is shown: the Redesign/ Reconfiguration Package - a list of actions to be performed on the product (model) and/or on the process to get the best compatibility between the product and the manufacturing technology - related to a headlight to be produced by SLA. In the future the same activities will be used for gath- ering data related to other technologies. In the meantime, this work suggests to evaluate all the parameters in the four tables of the technologies with respect to those in the four tables of the product features. In doing this, the affinity between some classes of technologies and some classes of products coming from experience could be confirmed or not. 7. Acknowledgments Authors would like to thank for her precious help Dr. Barbara Motyl, researcher at the DIEGM dept. of the University of Udine, Italy. 8. References [1] F. Alizon, K. Khadke, H. J. Thevenot, J. K. Gershenson, T. J. Marion, S. B. Shooter, and T. W. Simpson, “Frameworks for product family design and development,” Concurrent Engineering, Vol. 15, No. 2, pp. 187–199, 2007. [2] D. M. Andersen, “Design for manufacturability & con- current engineering,” Lafayette, CIM Press, CA, 2003. [3] E. K. Antonsson & J. Cagan, eds., “Formal engineering design synthesis,” Cambridge University Press, Cam- bridge, UK, 2001. [4] J. C. Borg, X. Yan, and N. P. Juster, “Exploring decisions’ influence on life-cycle performance to aid ‘design for Multi-X’,” Artificial Intelligence for Engineering Design, Analysis and Manufacturing, Vol. 14, pp. 91–113, 2000. [5] J. P. Clarkson & C. Eckert, (Eds.) “Design process im- provement - a review of current practice,” Springer, ISBN: 1-85233-701-X, 2005. [6] C. L. Dym and P. Little, “Engineering design: A pro- ject-based introduction,” Wiley and Sons, 2003. [7] J. S. Gero, (eds.) “Artificial intelligence in design’02,” Kluwer, Dordrecht, 2002. [8] K. Otto & K. Wood, Product Design, Prentice Hall. 2000. [9] G. Pahl & W. Beitz, “Engineering design: A systematic approach,” Springer, 1995. [10] D. Ullman, The Mechanical Design Process, Mac Graw Hill, 2002. [11] K. T. Ulrich & S. D. Eppinger, Product Design & Deve- lopment, Mac Graw Hill, 2000. [12] S. Filippi & I. Cristofolini, “The design guidelines (DGLs), a knowledge based system for industrial design developed accordingly to ISO-GPS (geometrical product specifications) concepts,” Research in Engineering De- sign, Vol. 18, No. 1, pp. 1–19, 2007. [13] R. M. Baecker, “Readings in groupware and computer- supported cooperative work,” San Francisco, CA, Mor- gan Kaufmann Publishers, Inc, 1993. [14] R. Crabtree, M. S. Fox, and N. Baid, “Case studies of coordination activities and problems in collaborative de- sign,” Research in Engineering Design, Vol. 9, No. 2, pp. 70–84, 1997. [15] A. H. B. Duffy, M. M. Andreasen, and F. J. O’Donnell, “Design co-ordination,” Proceedings of International Conference on Engineering Design (ICED'99), Vol. 1, pp. 113–118, 1999. [16] R. Houssin, A. Bernard, P. Martin, G. Ris, F. Cherrier, “In- formation system based on a working situation model for a new design approach in concurrent engineering,” Journal of Engineering Design, Vol. 17, No. 1, pp. 35–54. 2006. [17] H. Hung, H. Kao, and K. Ku, “Evaluation of design alter- natives in collaborative development and production of modular products,” the International Journal of Advanced Manufacturing Technology, Vol. 33, pp. 1065–1076, 2007. [18] Y . E. Nahm & H. Ishikawa, “Integrated product and process modeling for collaborative design environment,” Concurrent Engineering, Vol. 12, No. 1, pp. 5–23, 2004.  S. FILIPPI ET AL. 13 [19] P. Wilson, “Computer supported cooperative work: an introduction,” Kluwer Academic Publishers, 1991. [20] Z. Wu & A. Duffy, “Mutual knowledge evolution in team design,” Workshop on Learning and Creativity, 7th Inter- national Conference on Artificial Intelligence in Design (AID’02), Cambridge, UK, 2002. [21] C. Bandera, I. Cristofolini, and S. Filippi, “Customizing a knowledge-based system for design optimization in fused deposition modeling RP-technique,” AMST’05 Seventh International Conference on Advanced Manufacturing Systems and Technology, Springer Wien-New York, pp. 607–616, 2005. [22] I. Cristofolini, S. Filippi, and C. Bandera, “How rapid prototyping process parameters could affect the product design phase: a KBS approach,” Proceedings IDETC/CIE 2006 - ASME International Design Engineering Technical Conferences & Computers and Information In Engin- eering Conference DETC 2006, Philadelphia, PA, ISBN 0-7918-3784-X, 2006. [23] S. Filippi, C. Bandera, and G. Toneatto, “Generation and testing of guidelines for effective rapid prototyping ac- tivities,” Proceedings of “XII ADM International Con- ference on Design Tools and Methods in Industrial Engi- neering”, Italy, 2001. [24] “Draft federal information processing standards, FIPS PUB 183,” Standard for Integration Definition for Func- tion Modeling (IDEF0), National Institute of Standards and Technology, Gaithersburg, MD, USA, 1993. [25] P. F. Jacobs, “Stereolithography and other RP&M tech- nologies,” American Society of Mechanical Engineers, New York, 1996. [26] D. T. Pham and S. S. Dimov, “Rapid manufacturing,” Springer, Berlin Heidelberg, New York, 2001. [27] I. Raja, I. Vinesh, I. Fernandes and J. Kiran, Reverse en- gineering - An industrial perspective,” Spinger-Verlag London, 2008. [28] P. S. Banerjee, A. Sinha, and M. K. Banerjee, “A study on effect of variation of SLA process parameters over strength of built model,” Proceedings of the 2nd National Symposium on Rapid Prototyping & Rapid Tooling Tech- nologies, pp. 79–84, 2002. [29] H. S. Byun and K. H. Lee, “A decision support system for the selection of a rapid prototyping process using the modified TOPSIS method,” the International Journal of Advanced Manufacturing Technology, Vol. 26, pp. 1338– 1347, 2005. [30] W. Cheng, J. Y. H. Fuh, A.Y. C. Nee, Y. S. Wong, and T. Miyazawa, “Multi-objective optimization of part building orientation in stereolithography,” Rapid Prototyp Journal, Vol. 1, No. 4, pp. 12–23, 1995. [31] K. Chockalingam, N. Jawahar, K. N. Ramanathan, and P. S. Banerjee, “Optimization of stereolithography process parameters for part strength using design of experi- ments,” the International Journal of Advanced Manufac- turing Technology, DOI 10.1007/ s00170- 004-2307-0, 2005. [32] R. Harris, N. Hopkinso, H. Newlyn, R. Hague, and P. Dickens, “Layer thickness and draft angle selection for stereolithography injection mould tooling,” International Journal of Production Research, Vol. 40, No. 3, pp. 719– 729, 2002. [33] I. Horv´ath, J. J. Broek, Z. Rus´ak, G. Kuczogi, and J. S. M. Vergeest, “Morphological segmentation of objects for thick-layered manufacturing,” Proceedings of the 1999 ASME Conference on Design for Manufacturing,” Las Vegas, pp. 18–24, 1999. [34] S. H. Masood and A. Soo, “A rule based expert system for rapid prototyping system selection,” Robot Computer Integrated Manufacturing, Vol. 18, pp. 267–274, 2002. [35] X. Qian and D. Dutta, “Feature based fabrication in lay- ered manufacturing,” Transactions on ASME Journal Mechanism Design, Vol. 123, No. 3, pp. 337–345, 2001. [36] A. Rosochowski and A. Matuszak, “Rapid tooling: The state of the art,” Journal of Materials Processing Tech- nologies, Vol. 106, pp. 191–198, 2000. [37] Y. Tang, H. T. Loh, J. Y. H. Fuh, Y. S. Wong, and S. H. Lee, “An algorithm for disintegrating large and complex rapid prototyping objects in a CAD environment,” Inter- national Journal of Advanced Manufacturing Technology, Vol. 25, 895–901, 2005. [38] R. E. Williams, S. N. Komaragiri, V. L. Melton, R. R. Bishu, “Investigation of the effect of various build meth- ods on the performance of rapid prototyping (stereolitho- graphy),” Journal of Materials Processing Technology, Vol. 61, pp. 173–178. 1996. Copyright © 2010 SciRes IIM |