Materials Sciences and Applications

Vol.05 No.14(2014), Article ID:52816,4 pages

10.4236/msa.2014.514110

On the Temperature Dependent Excitation and Reflection Spectra of Ln3Al5O12:Ce3+ Ceramics (Ln = Y, Lu) for White LEDs

Thomas Jansen, Thomas Jüstel*

Department of Chemical Engineering, Münster University of Applied Sciences, Steinfurt, Germany

Email: *tj@fh-muenster.de

Copyright © 2014 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 4 October 2014; revised 28 October 2014; accepted 16 November 2014

ABSTRACT

Yttrium aluminum garnet (YAG) and Lutetium aluminum garnet (LuAG) doped with Ce3+ are widely applied phosphor powders or ceramics for the conversion of blue into green to yellow light in the rapidly expanding market of white light emitting high power LEDs. Surprisingly, the temperature dependent reflection and excitation spectra of these well-established materials have not been investigated until today. In this work, we report the temperature dependence of the reflection and excitation spectra of Ce3+ doped YAG and LuAG in the temperature range from 300 to 800 K.

Keywords:

Temperature-Dependent Reflection, Excitation Spectra, Garnet Phosphor Ceramics, Thermal Population

1. Introduction

Yttrium aluminum garnet (Y3Al5O12 or YAG) and Lutetium aluminum garnet (Lu3Al5O12) doped with Ce3+ are widely used luminescent materials with a rather long history. Already in 1967 Blasse and Bril reported on Ce3+ doped YAG as a new phosphor for flying spot cathode ray tubes (CRTs). Its unique properties like very high quantum efficiency, a short luminescence lifetime in the ns range, and an emission spectrum that matches well with the eye-sensitivity curve, brands the material as ideally suited for this application [1] . However, in the last 20 years light emitting diodes (LEDs) have attracted much attention due to their many benefits over other light sources like gas discharge and incandescent lamps. The main advantages of LED are a longer lifetime, a higher wall plug efficiency, and a better color rendering as observed for gas discharge lamps [2] -[4] . Since the publication of the first high brightness blue (In, Ga)N LED by Nakamura et al. in 1993, YAG:Ce and LuAG:Ce are the most common phosphors, which are applied to blue LED chips for white light application [5] . Due to these circumstances a lot of studies have been done in the past on this material and has not stopped until today [6] . Nevertheless, to the best of our knowledge, temperature dependent reflection and excitation spectra were not recorded for YAG and LuAG doped with Ce3+ so far.

2. Experimental Section

Precursors for the ceramic synthesis of (Lu0.99Ce0.01)3Al5O12(LuAG:Ce) and (Y0.99Ce0.01)3Al5O12 (YAG:Ce) were prepared by a sol-gel combustion method. The gels were prepared by using Lu2O3 (Treibacher 99.99%), Y2O3 (Treibacher 99.99%), (Al(NO3)3∙H2O (Aldrich 99.9%) and tris(hydroxymethyl)-aminoethane (tris) acting as a complexing agent and fuel at the same time. Starting materials were dissolved in diluted HNO3 and heated to 65˚C - 75˚C. Then, under continuous stirring, tris was added with a molar ratio 2:1 (to all metal ions). The solutions were stirred for additional 1 h at the same temperature. Next, after concentrating the mixtures by slow evaporation, sols turned into transparent, highly viscous gels. Afterwards, the temperature was raised to 250˚C to start the self-sustaining gel combustion process which was accompanied by the development of a large amount of gas. The resulting products were dried at 120˚C for several hours and ground to fine powders, which were heated for 4 h at 1000˚C in air to remove the organic residue after the combustion process. For the fabrication of the ceramics the precursor was first uniaxial pressed at 120 MPa into discs of 10 mm in diameter and 0.8 mm thickness. Secondly, to reduce pores, the obtained green bodies were isostatically pressed at 300 MPa. The powder compacts were sintered at 1700˚C at ambient pressure in air. Excitation and reflectance spectra were recorded in ranges 250 - 550 nm and 250 - 800 nm, respectively, on Edinburgh Instruments fluorescence spectrometer equipped with 450 W Xe arc lamp and cooled (−20˚C) single-photon photomultiplier (Hamamatsu R2658P). BaSO4 (99.999% Sigma-Aldrich) was used as reflectance standard. Temperature dependent measurements were carried out in a self-constructed heatable sample holder in the range from 300 to 800 K.

3. Results and Discussion

3.1. Diffuse Reflection Spectra

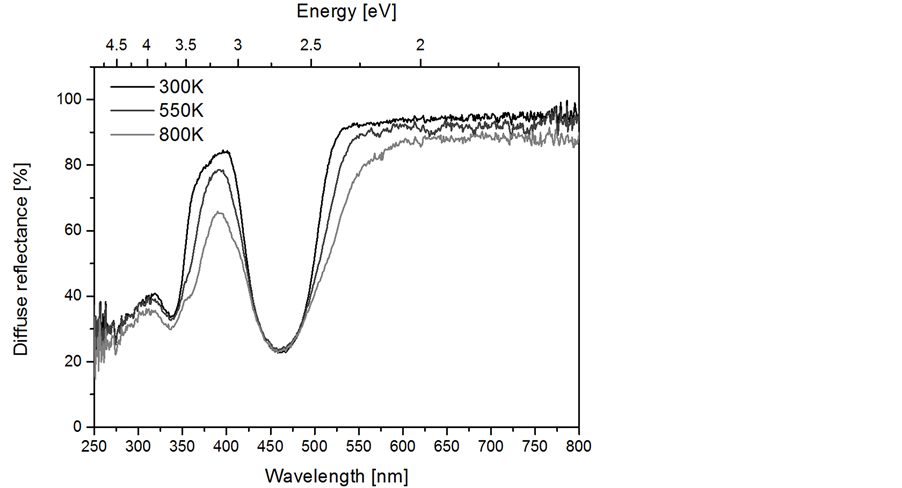

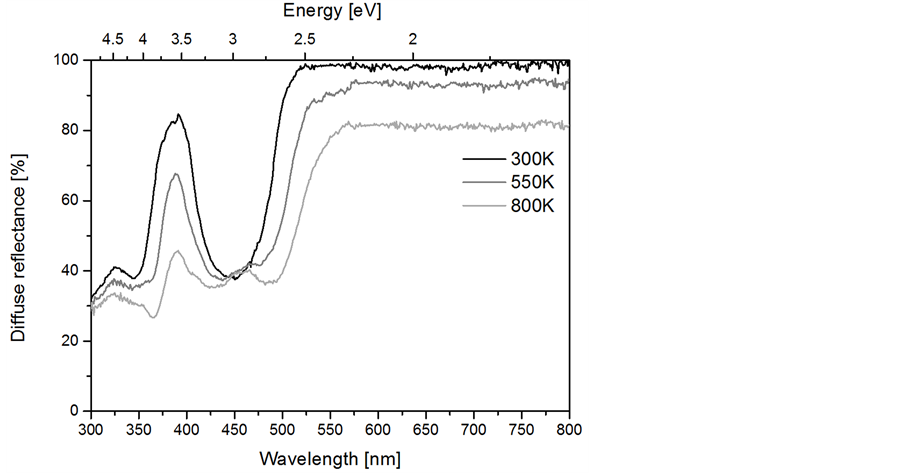

The diffuse reflection spectra relative to BaSO4 of the YAG:Ce and LuAG:Ce ceramics were recorded in the temperature range from 300 to 800 K (shown in Figure 1 & Figure 2). With increasing temperature two new

Figure 1. Diffuse reflection spectra of a Y3Al5O12:Ce3+ ceramic at 300, 550, and 800 K (at all temperatures BaSO4 was used as a white standard).

Figure 2. Diffuse reflection spectra of a Lu3Al5O12:Ce3+ ceramic at 300, 550, and 800 K (at all temperatures BaSO4 was used as a white standard).

significant absorption bands at around 375 nm and 550 nm can be observed for both ceramics. The two allowed absorption bands at 300 K originate from the lowest energy level 2F5/2 of the [Xe]4f1 configuration to the lowest crystal-field component 2DJ of the [Xe]5d1 of Ce3+ configuration. The second lowest energy level 2F7/2 of the [Xe]4f1 configuration which is separated by approximately 2300 cm−1 from the ground state 2F5/2 level is almost not thermally populated at room temperature [7] . Therefore, no visible absorption from 2F7/2 into the [Xe]5d1 configuration can be expected at room temperature. With increasing temperature the 2F7/2 level gets more and more thermally populated, which results for both garnet ceramics in a novel absorption band.

3.2. Excitation Spectra

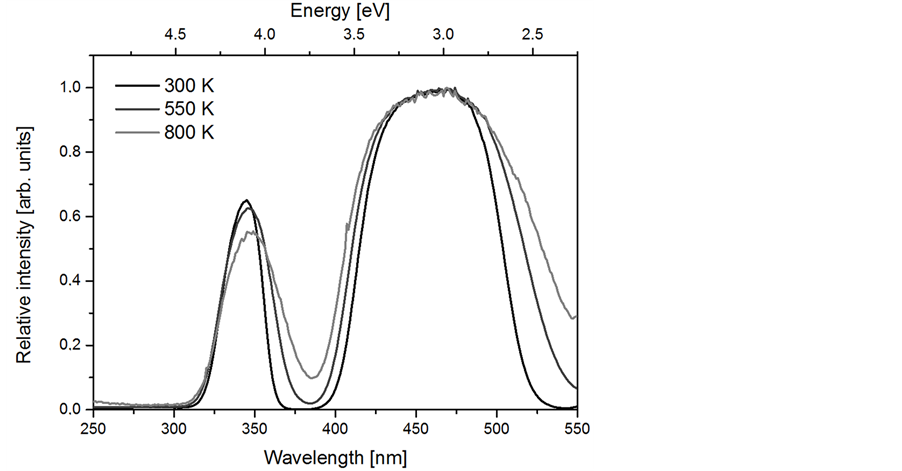

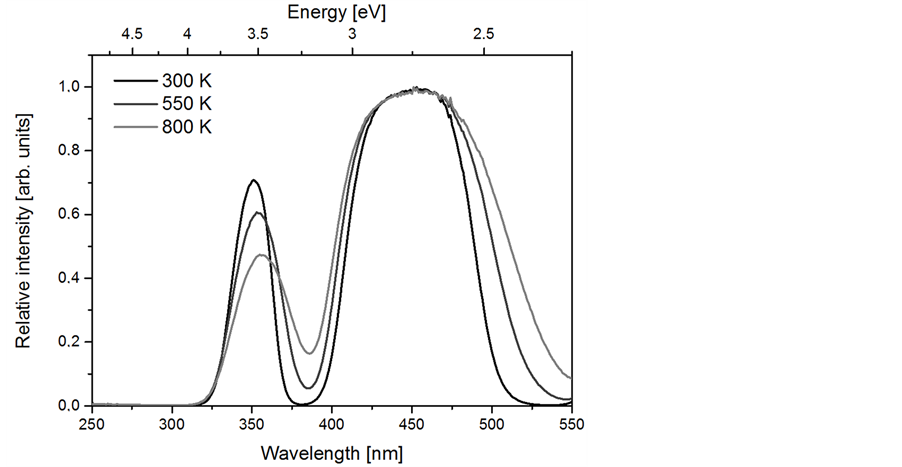

The normalized excitation spectra, as depicted in Figure 3 and Figure 4, of the YAG:Ce and LuAG:Ce ceramic were recorded in the same temperature range, viz. between 300 and 800 K, like the reflection spectra discussed above. The spectra show two excitation bands at 300 K which are as-signed to transitions to the two lowest energy levels of the five crystal field levels for a ligand field with D2 symmetry. The two bands, which are observed around 344 and 460 nm for YAG:Ce and about 350 and 450 nm for LuAG:Ce are assigned to the two lowest crystal-field components. These findings are in excellent agreement with the literature [7] . However, with increasing temperature up to 800 K two novel sidebands appear, which are attributed to the thermal population of the spin-orbit split sublevel 2F7/2. This population continuously increases with temperature as expected. This effect can be observed for YAG:Ce, but is much stronger for LuAG:Ce. We assume that this difference is caused by the larger spin-orbit coupling of the Ce3+ ground state level in LuAG in comparison to YAG.

4. Conclusions

A dedicated investigation on the temperature dependence of the reflection and excitation spectra of YAG:Ce and

LuAG:Ce ceramics was reported for the first time. Temperature dependent reflection spectra show two new ab- sorption bands occurring above 550 K for both ceramics, which is attributed to the thermal population of the 2F7/2 spin-orbit split level of the [Xe]4f1 configuration and the respective transition to the lowest crystal-field levels of the [Xe]5d1 configuration of Ce3+. In order to validate this striking effect, temperature-dependent excitation spectra were recorded as well.

The changes of the absorption spectrum of YAG:Ce and LuAG:Ce ceramics, will have a strong impact on the application of these ceramics in phosphor converted high power LEDs, if the chip temperature exceeds 200˚C or even higher [2] . In other words, the novel absorption bands will enhance the re-absorption in the LED package

Figure 3. Excitation spectra of Y3Al5O12:Ce3+ ceramic at 300 K, 550 K and 800 K. Emission monitored at 560 nm.

Figure 4. Excitation spectra of Lu3Al5O12:Ce3+ ceramic at 300 K, 550 K and 800 K. Emission monitored at 560 nm.

and will reduce the package gain once the quantum efficiency is not unity.

Acknowledgements

This work was financially supported by Merck KGaA, Darmstadt, Germany.

References

- Blasse, G. (1967) A New Phosphor for Flying-Spot Cathode-Ray Tubes for Color Television: Yellow-Emitting Y3Al5O12:Ce3+. Applied Physics Letters, 11, 53. http://dx.doi.org/10.1063/1.1755025

- Yan, B., You, J.-P., Tran, N.T. and Shi, F.G. (2013) Influence of Phosphor Configuration on Thermal Performance of High Power White LED Array. 2013 IEEE International Symposium on Advanced Packaging Materials, Irvine, 27 February 2013-1 March 2013, 274-289. http://dx.doi.org/10.1109/ISAPM.2013.6510411

- Feldmann, C., Jüstel, T., Ronda, C.R. and Schmidt, P.J. (2003) Inorganic Luminescent Materials: 100 Years of Research and Application. Advanced Functional Materials, 13, 511-516. http://dx.doi.org/10.1002/adfm.200301005

- Schubert, E.F. (2006) Light-Emitting Diodes. 2nd Edition, Cambridge University Press, Cambridge. http://dx.doi.org/10.1017/CBO9780511790546

- Nakamura, S., Pearton, S. and Fasol, G. (2000) The Blue Laser Diode. The Complete Story. 2nd Edition, Springer Berlin Heidelberg, Berlin. http://dx.doi.org/10.1007/978-3-662-04156-7

- Ivanovskikh, K.V., Ogieglo, J.M., Zych, A., Ronda, C.R. and Meijerink, A. (2012) Luminescence Temperature Quenching for Ce3+ and Pr3+d-f Emission in YAG and LuAG. ECS Journal of Solid State Science and Technology, 2, R3148-R3152. http://dx.doi.org/10.1149/2.011302jss

- Okada, F., Togawa, S., Ohta, K. and Koda, S. (1994) Solid-State Ultraviolet Tunable Laser: A Ce3+ Doped LiYF4 Crystal. Journal of Applied Physics, 75, 49. http://dx.doi.org/10.1063/1.355828

NOTES

*Corresponding author.