Materials Sciences and Applications

Vol.3 No.5(2012), Article ID:19207,6 pages DOI:10.4236/msa.2012.35048

Effect of Sintering Temperature on Structural and Magnetic Properties of Ni0.55Zn0.45Fe2O4 Ferrites

![]()

1The Department of Physics, Jahangirnagar University, Dhaka, Bangladesh; 2Materials Science Division, Atomic Energy Centre, Dhaka, Bangladesh; 3Department of Physics, Khulna University of Engineering & Technology, Khulna, Bangladesh.

Email: *robiulislam41@yahoo.com

Received December 23rd, 2011; revised February 17th, 2012; accepted March 18th, 2012

Keywords: Nanoparticle; sintering temperature; Curie temperature; microstructure; grain size

ABSTRACT

The effect of frequency and sintering temperature on initial permeability of Ni0.55Zn0.45Fe2O4 ferrites have been studied by using an impedance analyzer. The samples were prepared by conventional double sintering ceramic technique using oxide nanoparticles of grain size 30 - 50 nm. Single phase spinal structure has been confirmed for the prepared samples by X-ray diffraction. As the sintering temperatures increase from 1160˚C to 1300˚C, the permeability gradually increases. The increase of permeability is ascribed to the increase of density and grain size. Grain size is expected to grow with the increase of sintering temperature. Ferrites with large average grain size posses higher initial permeability. The Curie temperatures determined from temperature dependence of permeability of the samples sintered at different temperatures are found to be Tc = (321 ± 1)˚C and independent of sintering temperature. At Ts = 1300˚C, Tc is found to increase substantially which can be explained by the fact that Zn has evaporated from the surface layer.

1. Introduction

The Ni-Zn ferrites are one of the most versatile, reasonable cost magnetic materials for general use in both low and high frequency devices because of their high resistivity, low dielectric losses, high Curie temperature and chemical stability [1-4]. The magnetic properties of Ni-Zn ferrites are strongly dependent on their chemical composition, density, grain size, etc. [5-7]. The permeability increases with the substitution of Zn for Ni in Ni-Zn ferrites [8], but the Curie temperature slightly decreases at sufficiently high temperature due to Zn evaporation. It is observed that the permeability falls sharply at the ferri-paramagnetic phase transition i.e. the paramagnetic character. The sharp vertical drop of the permeability at Curie point indicates the degree of good homogeneity in the sample composition. Due to the remarkable behavior of magnetic and electric properties they are subjects of intense theoretical and experimental investigation for application purpose [9,10]. The X-ray diffracttion patterns for the composition at different sintering temperatures clearly indicate their single phase and formation of spinal crystal structure [11]. This papers focuses on the effect of sintering temperature on the initial and complex permeability of Ni-Zn ferrites. A possible correlation between sintering temperature, grain size and density is also discussed.

2. Experimental

The mixed ferrites of composition Ni0.55Zn0.45Fe2O4 was prepared by the double sintering ceramic method. The raw materials for the preparation of the studied composition were oxide nanoparticle of grain size 30 - 50 nm. The oxide powders were weighed precisely according to their molecular weight. Intimate mixing of the materials was carried out using agate mortar for 5 hours and then ball milled in a planetary ball mill in ethyl alcohol media for 4 hours with stainless steel balls of different sizes in diameter. The slurry was dried and the dried powder was pressed into disc shape. The samples were pre-sintered at 900˚C for holding time 4 hr. The pre-sintered materials were crushed and ball milled for another 4 hours in distilled water to reduce it to small crystallites of uniform size. The mixture was dried and a small amount of saturated solution polyvinyl alcohol were added as a binder. The resulting powders were pressed uni-axially under a pressure of 1.75 ton·cm−2 and 1.2 ton·cm−2 in a stainless steel die to make pellets and toroids respectively. The pressed pellets and toroid shaped samples were then finally sintered at 1160˚C, 1200˚C, 1250˚C and 1300˚C. Initial permeability were measured by an impedance analyzer at different sintering temperature 1160˚C, 1200˚C, 1250˚C and 1300˚C. The density was calculated by measuring the volume and weight of the cylindrical samples. X-ray diffraction (XRD) pattern of all the samples, recorded at room temperature with CuKa radiation of wavelength l = 1.54178 Å using Philips X’ Pert PRO X-ray diffractometer. X-ray patterns confirmed the spinal phase for the samples.

3. Results and Discussion

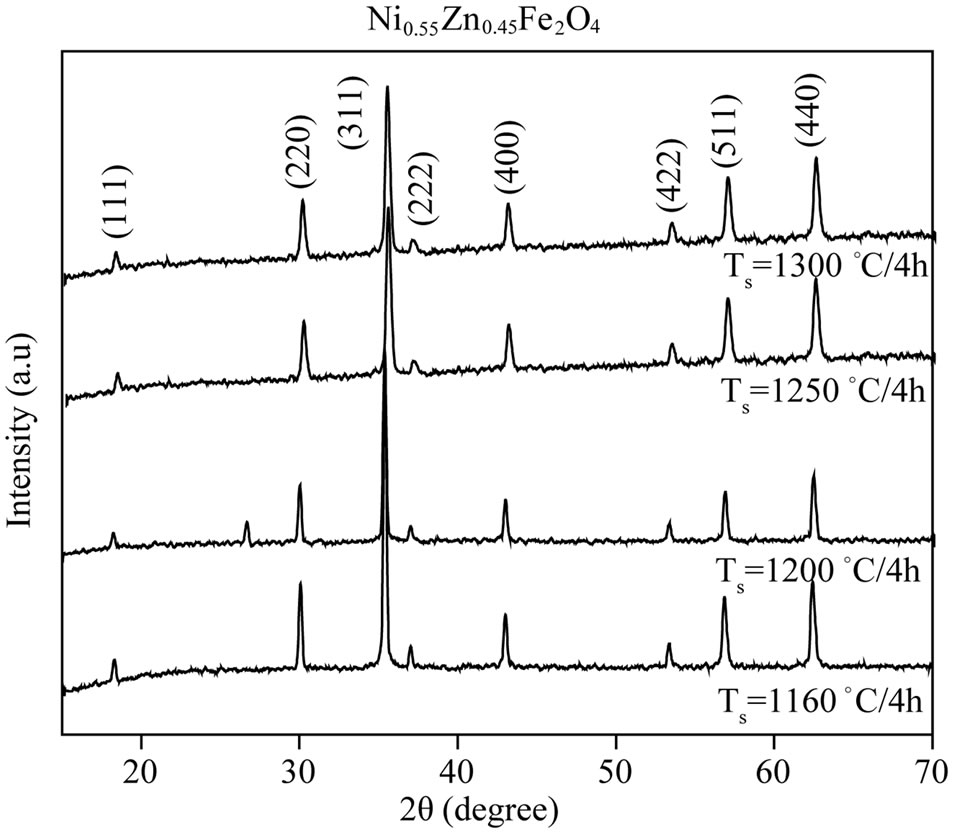

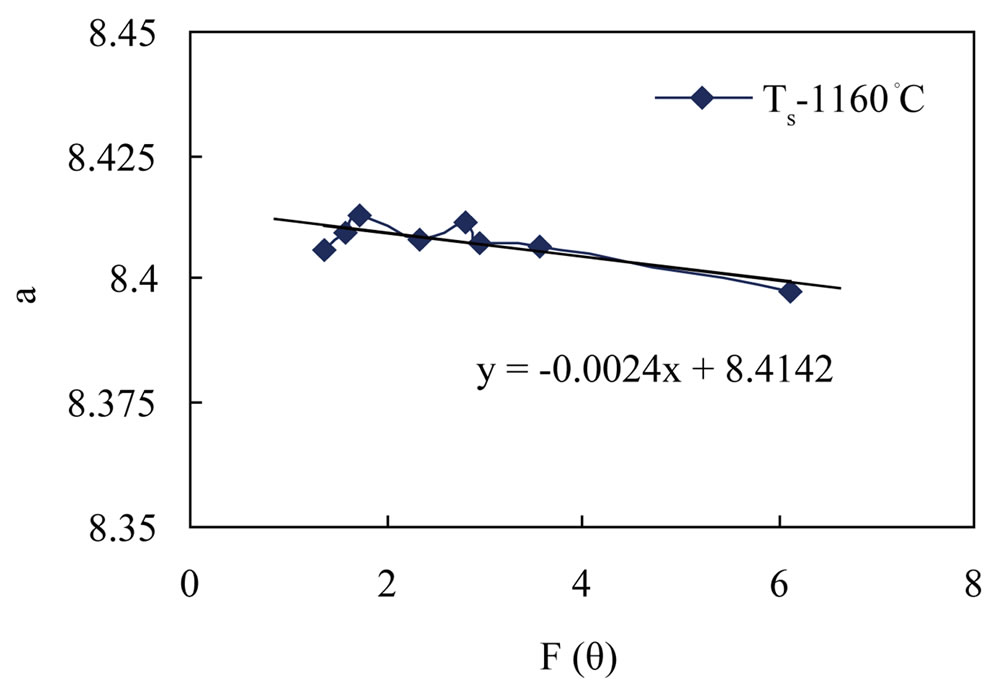

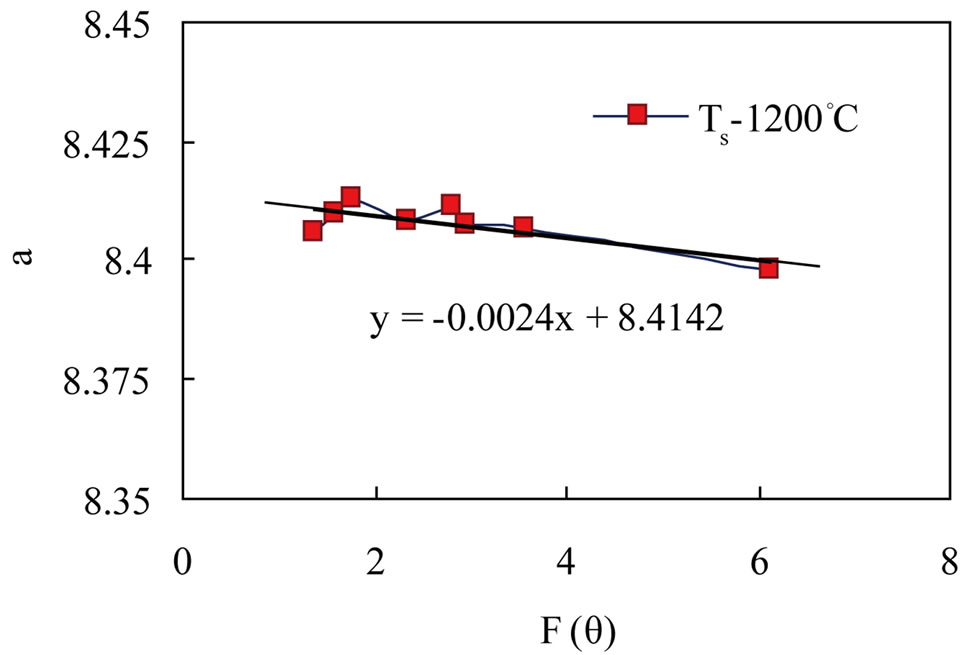

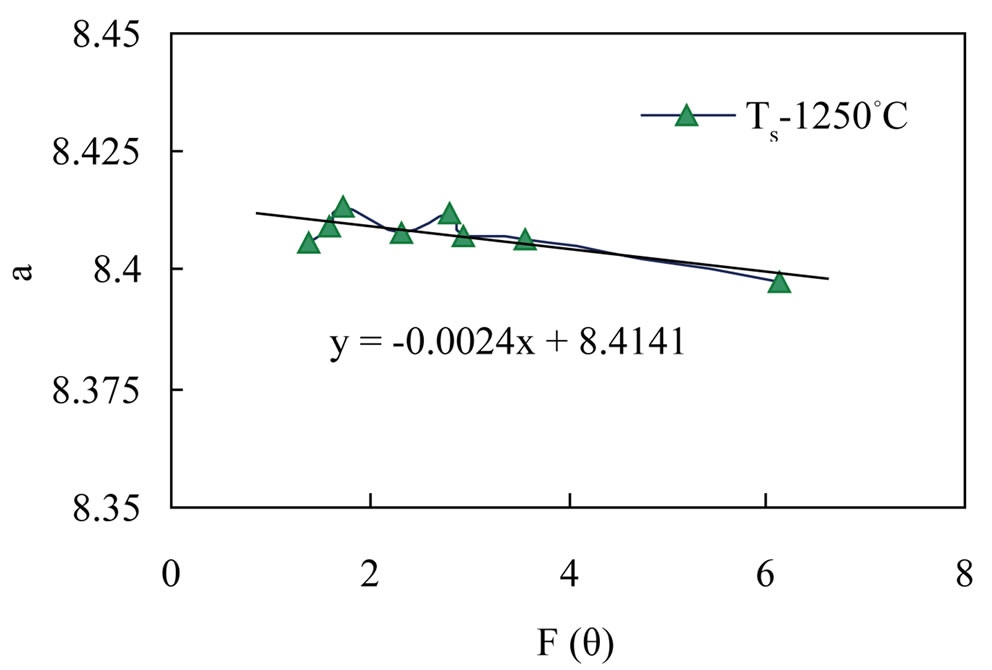

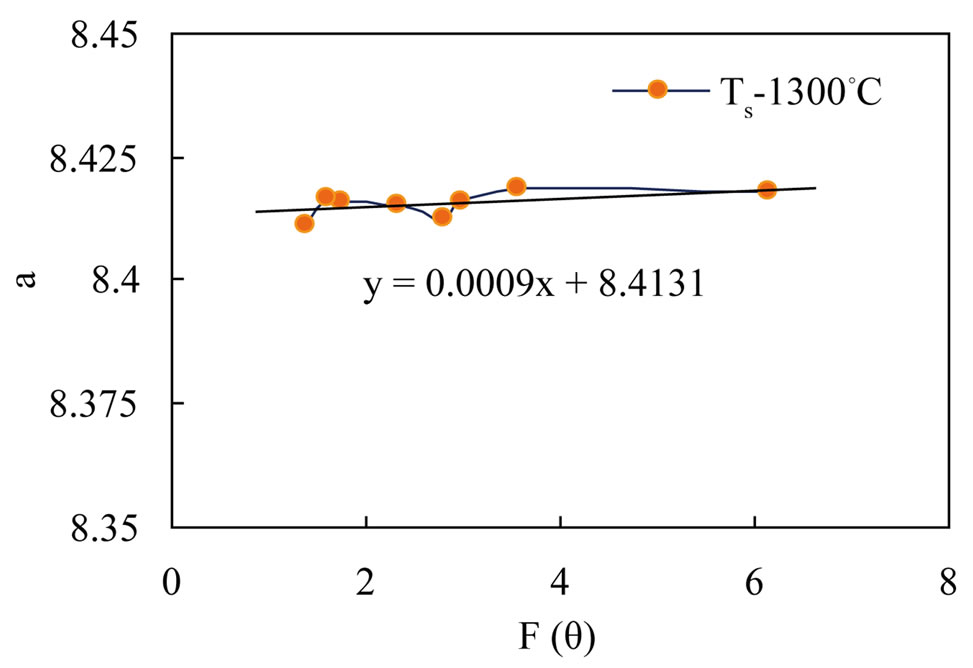

The XRD patterns of the sample Ni0.55Zn0.45Fe2O4 at different sintering temperatures are shown in figure 1. The main reflection were from plane (111), (220), (311), (222), (400), (422), (511) and (440) which are characteristic of spinel structure with a single phase [12]. The lattice parameter was determined by using the Nelson-Riley (N.R) extrapolation method. In this experiment we observed that, the lattice parameter remains constant with different sintering temperature [13], figure 2.

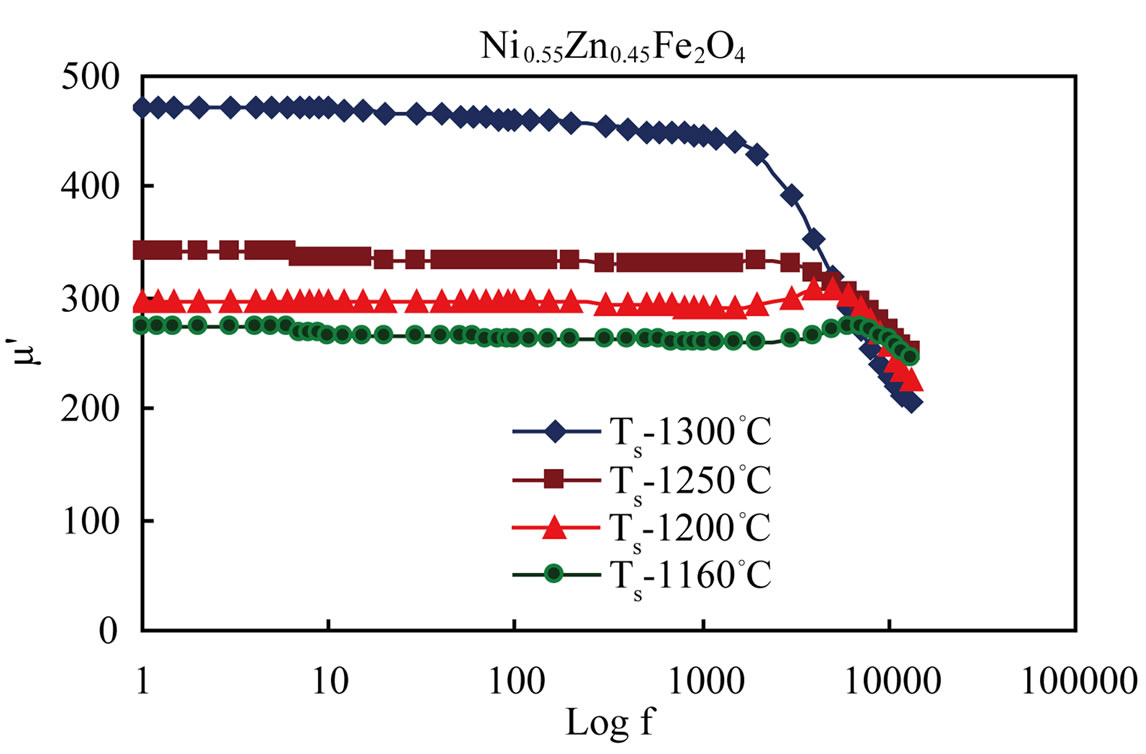

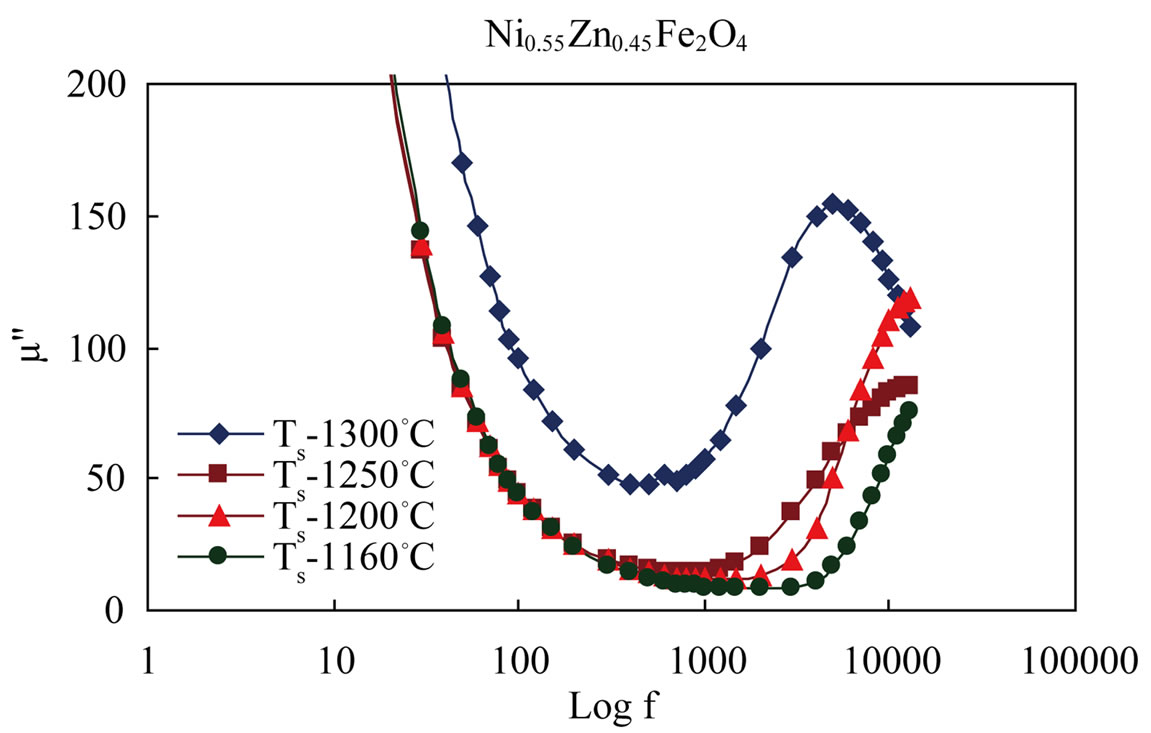

Initial permeability as dependent on frequency and temperature of a magnetic material is an important parameter. Figures 3 and 4 show the real part and imaginary part of permeability for different sintering temperature [14]. Here the real part of permeability µ' remains constant in a certain frequency range (1 KHz - 13 MHz), while at higher frequencies, after a small rise, it begins to drop due to resonance. We have found that the permeability increases with increasing sintering temperature. It is seen from table 1 that the grain size increases with increasing sintering temperature [15,16] because the density increases with increasing sintering temperature.

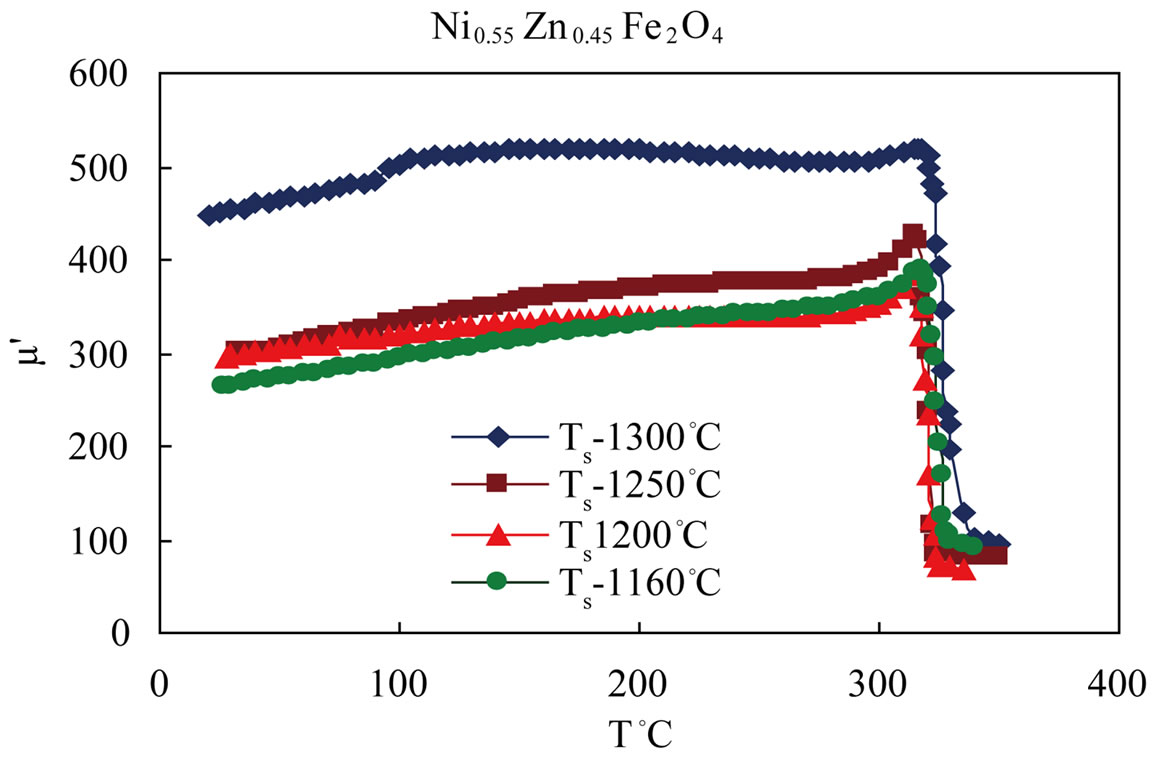

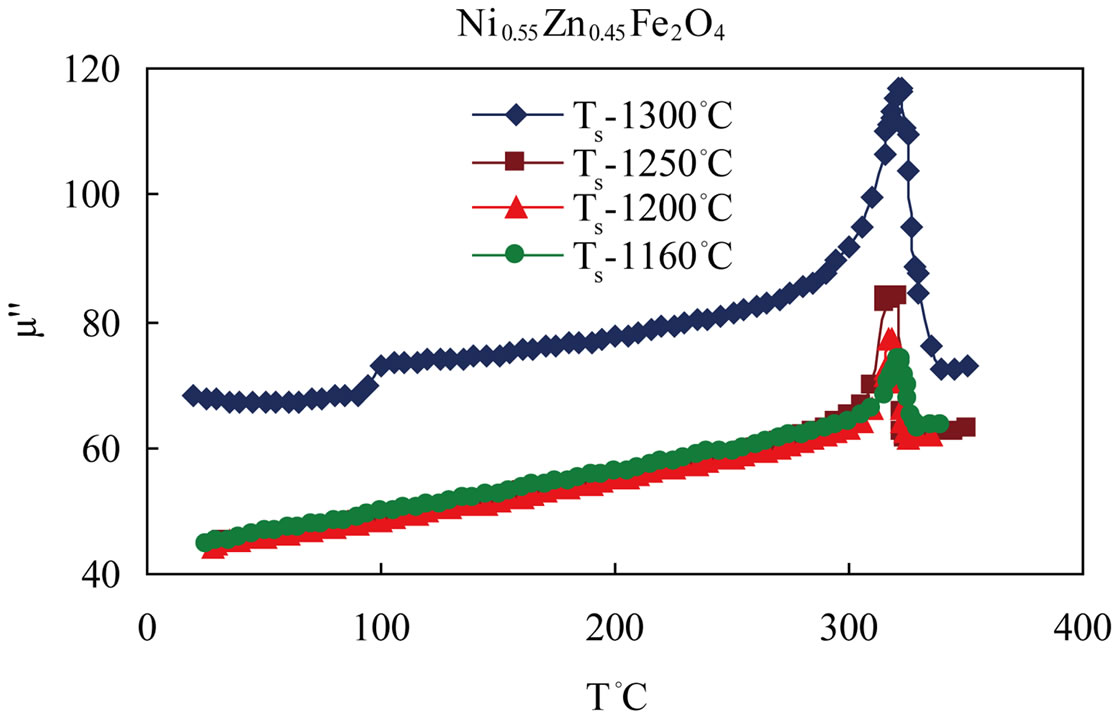

From figures 5 and 6 show the real and imaginary part of the complex permeability with variation of temperature [17]. It is observed that, µ' increases gradually with increase of temperature attaining a peak value just before Tc known as Hopkinson peak. The Curie temperature determined from temperature dependence of

Figure 1. XRD pattern of Ni-Zn ferrites at different sintering temperature.

Figure 2. The variation of lattice parameter “a” as a function of F(q).

Figure 3. Real part of permeability vs frequency at various Ts.

Figure 4. Imaginary part of permeability vs frequency at various Ts.

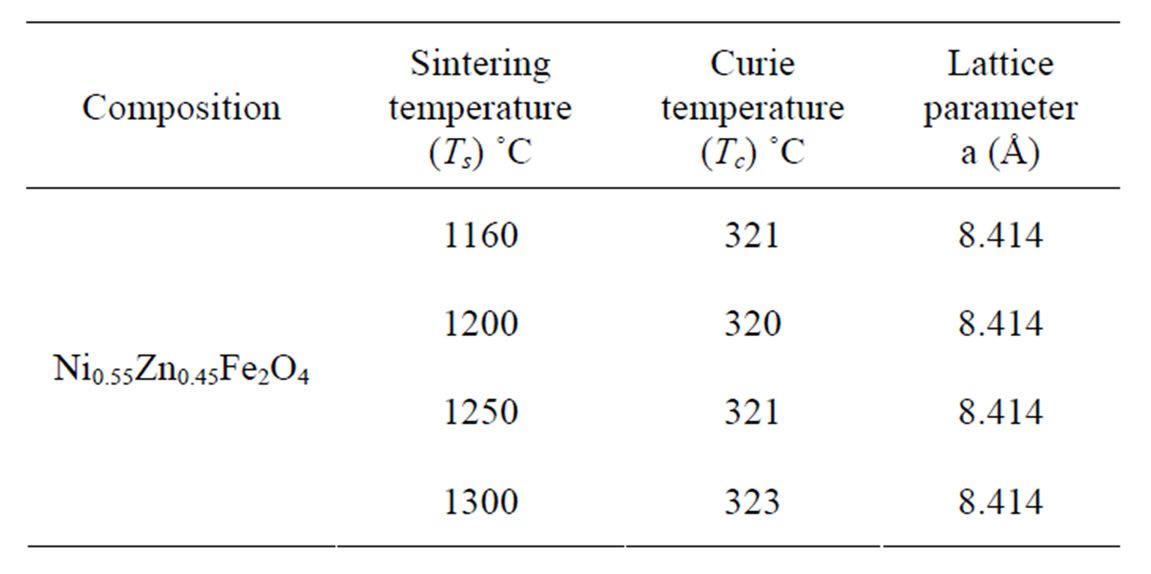

Table 1. Variation of curie temperature and Lattice parameter with different sintering temperature.

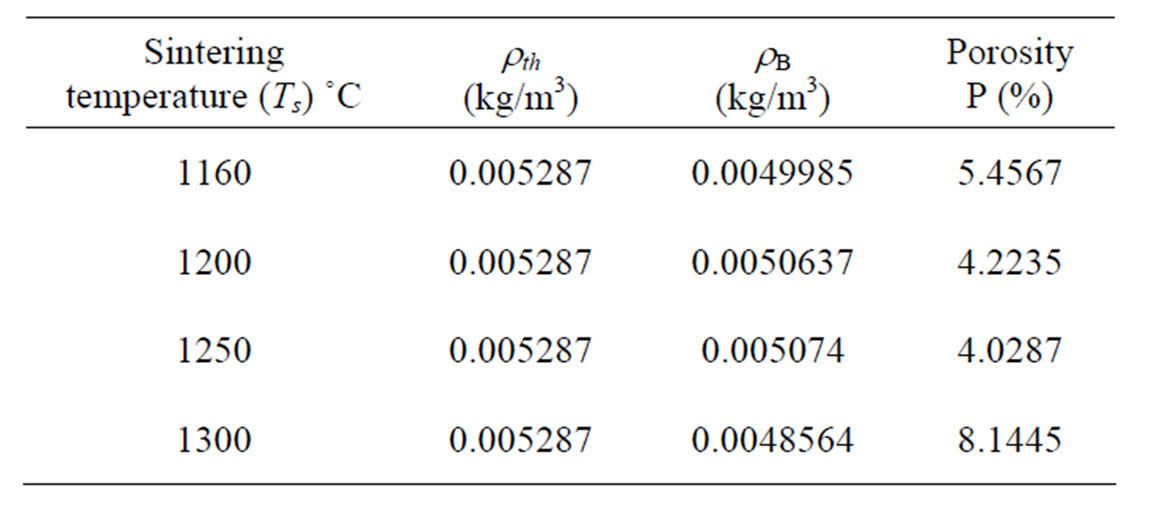

Table 2. Variation of density and porosity with sintering temperature.

Figure 5. Real part of permeability vs temperature at various Ts.

Figure 6. Imaginary part of permeability vs temperature at various Ts.

permeability of the samples sintered at different temperatures are found to be Tc = (321 ± 1)˚C. The Tc value is almost independent of Ts except for the sample sintered at 1300˚C where a substantial increase of Tc is found.

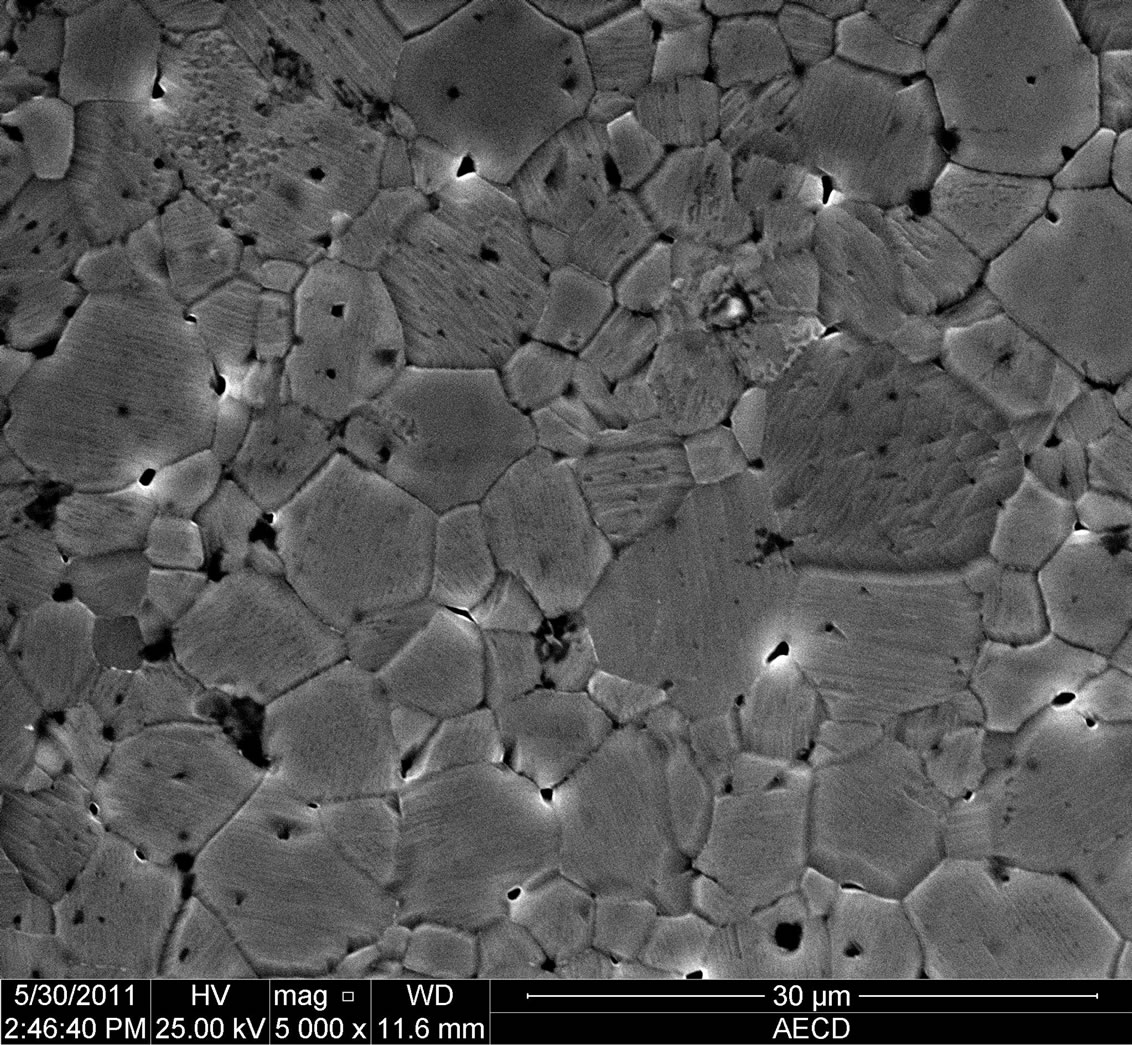

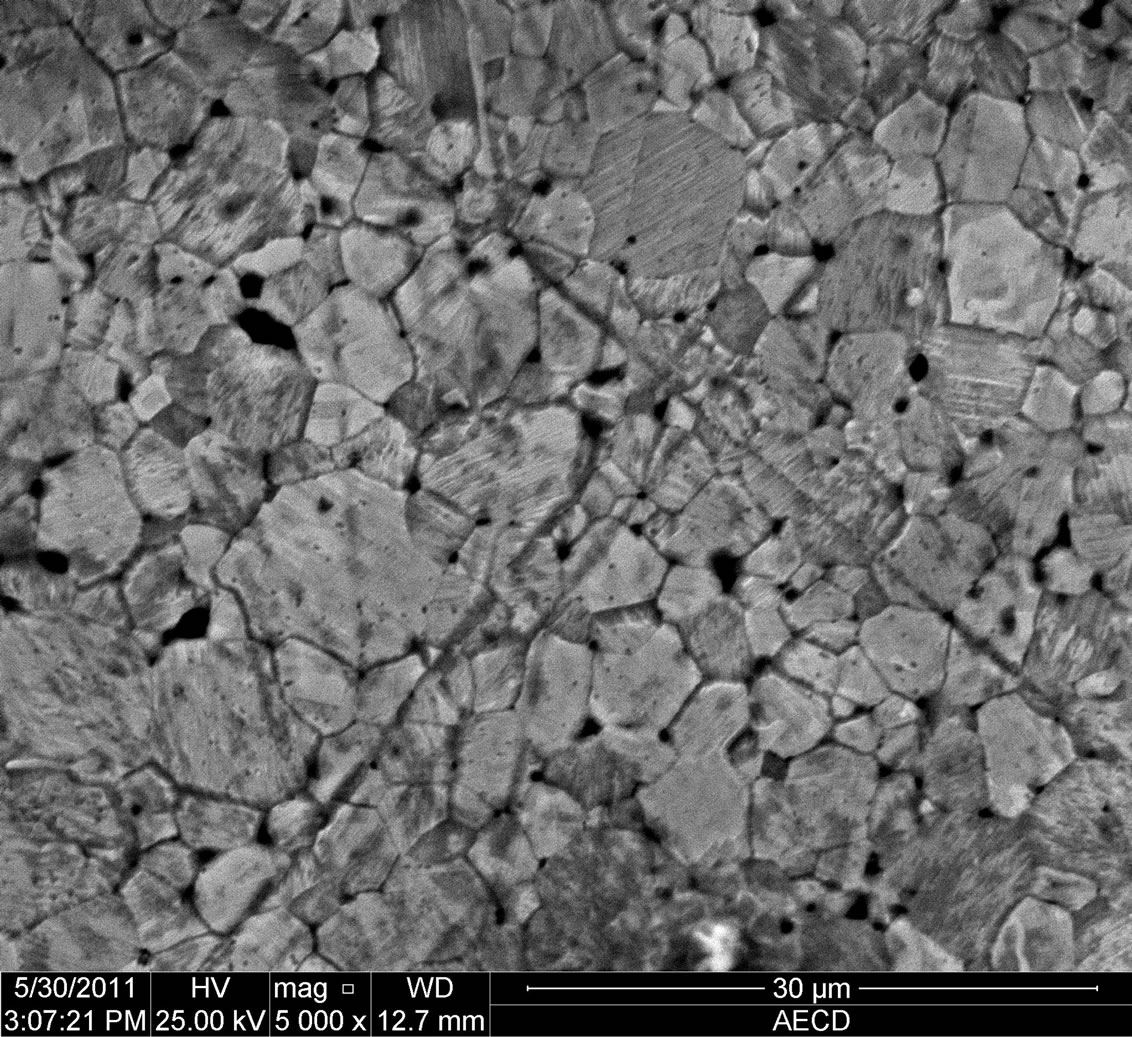

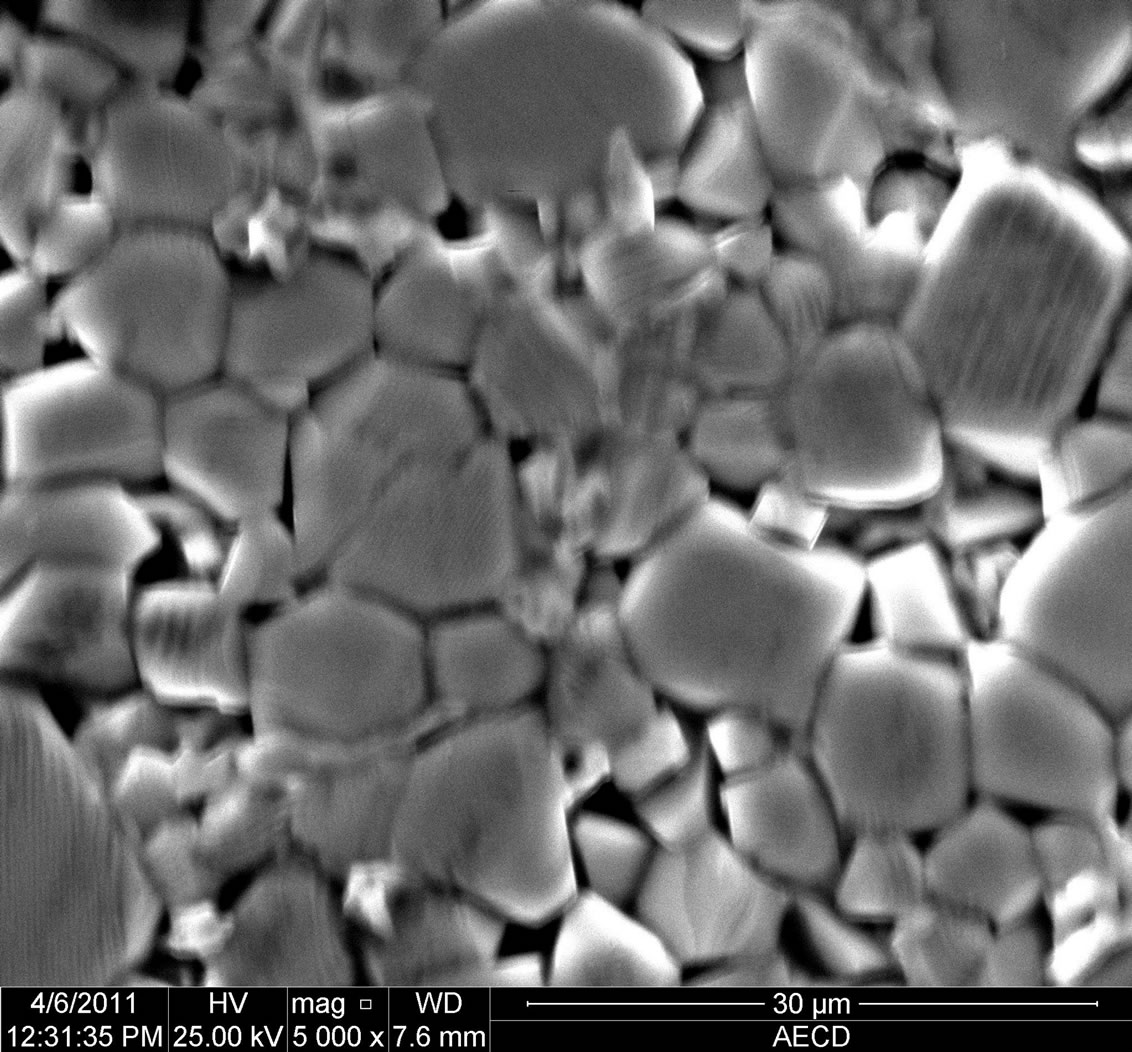

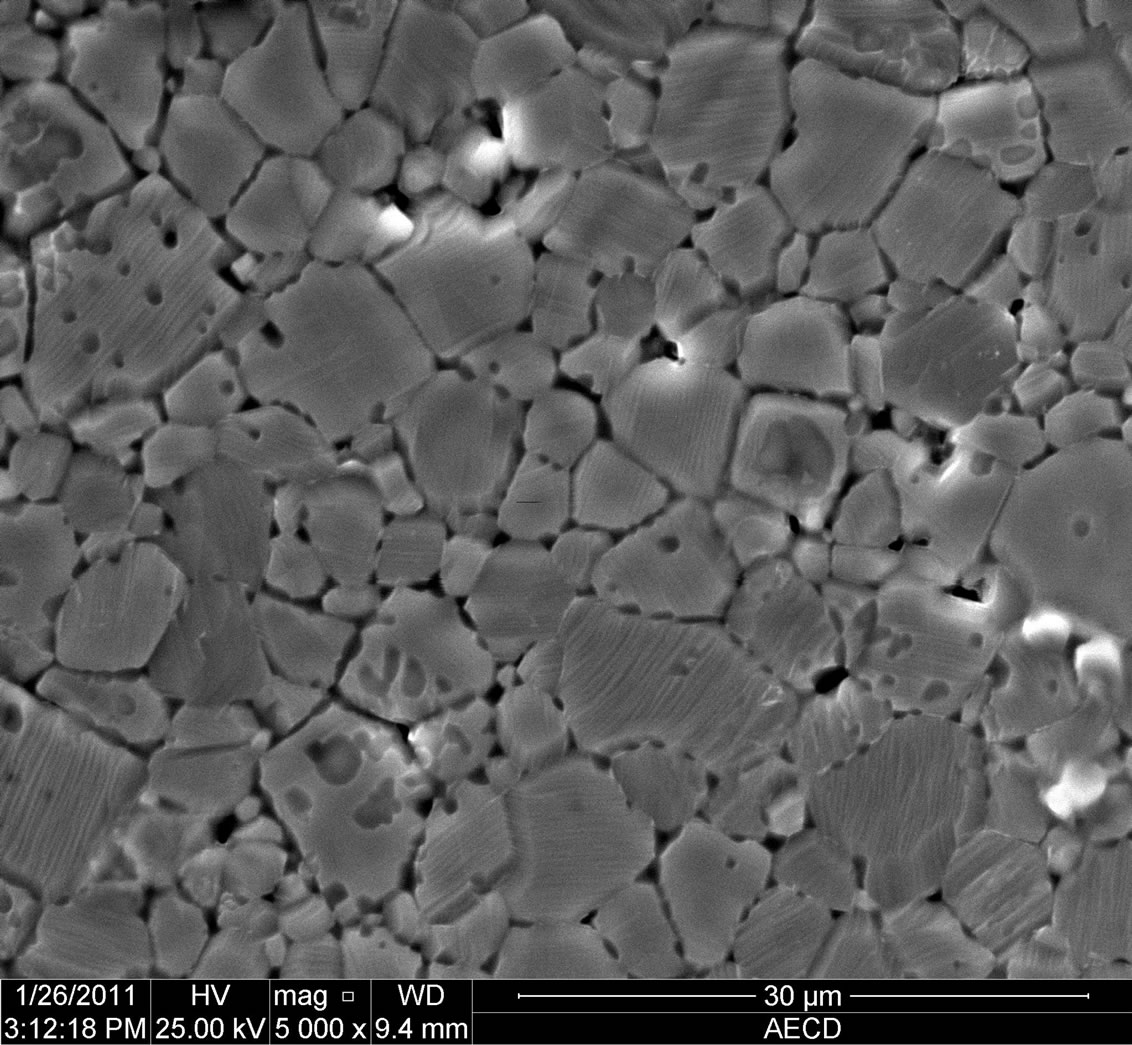

The Scanning Electron Microscope (SEM) of Ni0.55 Zn0.45Fe2O4 samples sintered at 1160˚C, 1200˚C, 1250˚C and 1300˚C are shows in Figures 7(a)-(d) respectively. The sintering temperature has a great influence on the microstructure. It was observed that the average grain size of the samples increased with increase sintering temperature [18].

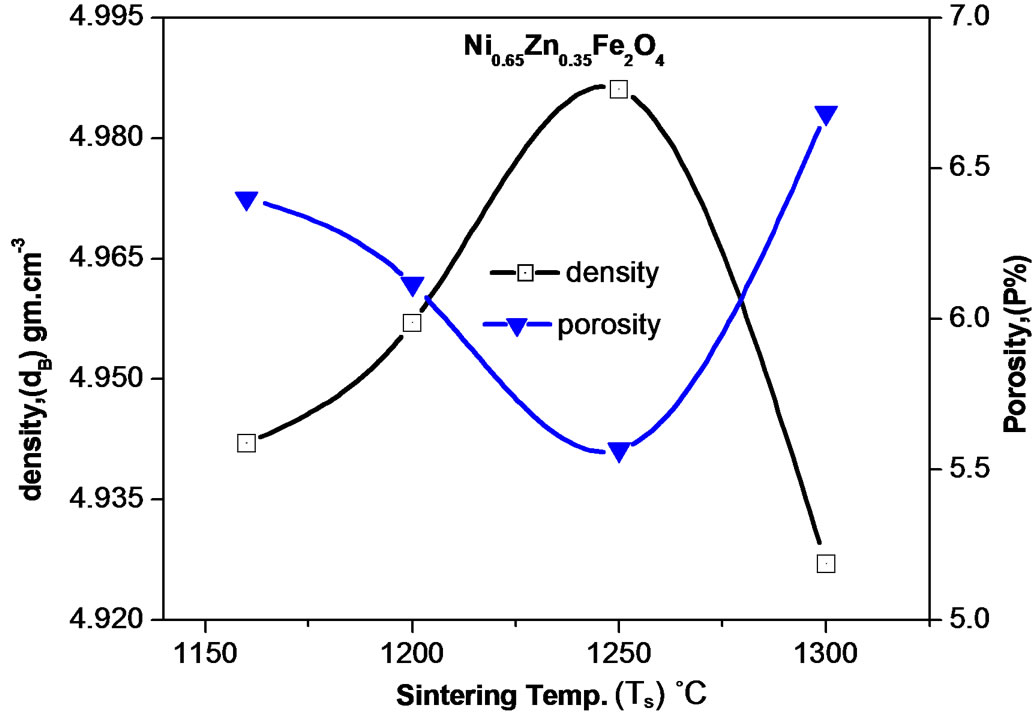

The density and porosity of the composition are changed with different sintering temperature [8]. The density of Ni0.55Zn0.45Fe2O4 samples increases from 1160˚C to 1250˚C and above 1250˚C the density begins to decrease as shown in Figure 8. On the other hand, porosity (P) of the samples decrease as increasing sintering temperature up to 1250˚C, and above 1250˚C the porosity increases which is also shown in table 2.

It is known that the porosity of the samples come from two sources, intragranular porosity and intergranular porosity. The intergranular porosity mainly depends on the grain size [18]. At higher sintering temperatures the den-

(a)

(a) (b)

(b) (c)

(c) (d)

(d)

Figure 7. Microstructure of the samples at different sintering temperature. (a) 1160˚C; (b) 1200˚C; (c) 1250˚C; (d) 1300˚C.

Figure 8. Variation of density and porosity with Ts for Ni0.55Zn0.45Fe2O4.

sity is decreased because the intragranular porosity is increased resulting from discontinuous grain growth.

According to sintering mechanism, we can explained the grain growth of the spinel ferrites. During the sintering process, a shrinkage of up to approximately 20% can occur and the samples produced an entirely dense material. But a product having a certain porosity. At higher sintering temperatures, the density is increased and the porosity is decreased (figure 8). But at Ts = 1300˚C, the porosity is increased slightly.

During the sintering process, the thermal energy generates a force that drives the grain boundaries to grow over pores, thereby the pore volume and hence the materials becomes denser. At higher sintering temperature, density is decreased because the intragranular porosity is increased. The crystal grain growth depends on grain boundaries migrating and larger crystal grains swallowing the small ones. During the growth the more different in size of crystal grains, the more beneficial for larger crystal grains to swallow smaller ones, so some pores inside the sintered ferrites are eliminated and the crystal growth improves.

When the grain growth rate is very high, pores may be left behind by rapidly moving boundaries. As a result in pores that are trapped inside the grains. This discontinuous grains growth rise with high temperature and the bulk density is reduced [10].

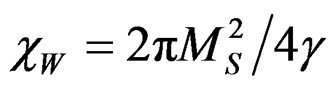

It is well known that the permeability of nanocrystalline ferrite is related to two different magnetizing mechanisms: spin rotation and domain wall motion, which can be described as, μi = 1 + χW + χSPIN, where χW is the domain wall susceptibility, χSPIN is intrinsic rotational susceptibility. We also written,  and

and  with Ms saturation magnetization, Ku is the total anisotropy, D the grain diameter and

with Ms saturation magnetization, Ku is the total anisotropy, D the grain diameter and  the domain wall energy. Thus, the domain wall motion is affected by the grain size and enhanced with the increase of grain size [19].

the domain wall energy. Thus, the domain wall motion is affected by the grain size and enhanced with the increase of grain size [19].

4. Conclusion

The X-ray diffraction confirmed the single phase cubic spinel structure of the samples. The initial permeability increases with increasing sintering temperature. Also the density is increased with increasing sintering temperatures. The Curie temperatures determined from temperature dependence of permeability of the samples sintered at different temperatures are found to be Tc = 321˚C ± 1˚C and independent of sintering temperature. But, at 1300˚C the Curie temperature is found to increase substantially which can be explained by the fact that Zn has evaporated from the surface layer. At higher sintering temperatures the density is decreased because the intragranular porosity is increased resulting from discontinueous grain growth. The lattice parameter is 8.414 Å and which is also independent of sintering temperatures.

5. Acknowledgements

The authors express gratefulness to the Chairman, Bangladesh Atomic Energy Commission and Director, Atomic Energy Centre, Dhaka for allowing me to use the laboratory facilities in the Materials Science Division, Atomic Energy Centre, Dhaka. The authors are also thankful to the chairman of the Department of Physics, Jahangirnagar University for their encouragement in this work. Financial support from International program in Physical Science (IPPS), Uppsala University, Sweden for this work is highly acknowledged.

REFERENCES

- Y. Li, J. P. Zhao and J. C. Han, “Self-propagation High Temperature Synthesis and Magnetic Properties of Ni0.35 Zn0.65Fe2O4 powder,” Bulletin of Materials Science, Vol. 25, No. 4, 2002, pp. 263-266. doi:10.1007/BF02704117

- J. Smith and H. P. J. Wijn, “Ferrites,” John Wiley and Sons, New York, 1995.

- B. D. Cullity and C. D. Graham, “Introduction to Magnetic Materials,” John Wiley and Sons, Hoboken, 2009.

- E. Olsen and J. Thonstad, “Nickel ferrites as inert anodes in Aluminium Electrolysis: Part I Material fabrication and Perliminary Testing,” Journal of Applied Electrochemistry, Vol. 29, No. 3, 1999, pp. 293-299. doi:10.1023/A:1003460220418

- M. M. Barakat, M. A. Henaish, S. A. Olofa and A.Tawfik, “Sintering behaviour of the Spinel Ferrites System Ni0.65 Zn0.35Fe2-xCuxO4,” Journal of Thermal Analysis and Calorimetry, Vol. 37, No. 2, 1991, pp. 241-248. doi:10.1007/BF02055926

- O. F. Caltun, L. Spinu and Al Staneu, “Structural and magnetic properties of Ni-Zn-Cu Ferrites Sintered at Different Temperatures,” Journal of Optoelectronics and Advanced Materials, Vol. 4, No. 2, 2002, pp. 337-340.

- A. M. Kumar, M. C. Verma, C. L. Dube, K. H. Rao and S. C. Kashyap, “Development of Ni-Zn Nano Ferrite Core Material with Improved Saturation Magnitizition and DC resistivity,” Journal of Magnetism and Magnetic Materials, Vol. 320, No. 14, 2008, pp. 1995-2000. doi:10.1016/j.jmmm.2008.02.129

- S. T. Mahmud, A. K. M. Akther Hossain, A. K. M. A. Hakim, M. Seki, T. Kawai and H. Tabata, “Influence of microstructure on the Complex Permeability of Spinel Type Ni-Zn ferrites,” Journal of Magnetism and Magnetic Materials, Vol. 305, No. 1, 2006, pp. 269-274. doi:10.1016/j.jmmm.2006.01.012

- G. F. Dionne and R. G. West, “Magnetic and dielectric properties of the Spinel Ferrite System Ni0.65Zn0.35Fe2-x MnxO4,” Journal of Applied Physics, Vol. 61, No. 8, 1987, pp. 3838-3910. doi:10.1063/1.338623

- A. K. M. A. Hossain, S. T. Mahmud, M. Seki, T. Kawai and H. Tabata, “Structural, Electric Transport and Magnetic Properties of Ni1-xZnxFe2O4,” Journal of Magnetism and Magnetic Materials, Vol. 312, No. 1, 2007, pp. 210- 219. doi:10.1016/j.jmmm.2006.09.030

- B. P. Rao, A. M. Kumar, K. H. Rao, Y. L. N. Murthy, O. F. Caltun, I. Dumitru and L. Spinu, “Synthesis and magnetic studies of Ni-Zn ferrite nanoparticles,” Journal of Optoelectronics and Advanced Materials, Vol. 8, No. 5, 2006, pp. 1703-1705.

- S. Zahi, “Synthesis, Permeability and Microstructure of the Optimal Nickel-Zinc Ferrites by Sol-Gel Route,” Journal of Electromagnetic Analysis and Applications, Vol. 2, No. 1, 2010, pp. 56-62. doi:10.4236/jemaa.2010.21009

- S. Akhter, D. P. Paul, Md. A. Hakim, D. K. Saha, Md. Al-Mamun and A. Parveen, “Synthesis, Structural and Physical Properties of Cu1-xZnxFe2O4 Ferrites,” Materials Science and Applications, Vol. 2, 2011, pp. 1675-1681. doi:10.4236/msa.2011.211223

- A. Verma, T. C. Goel and R. G. Mendiratta, “Frequency variation of Initial Permeability of Ni-Zn ferrites prepared by the Citrate Precursor Method,” Journal of Magnetism and Magnetic Materials, Vol. 210, No. 1-3, 2000, pp. 274-278.

- M. Sorescu, L. Diamandescu, R. Peelamedu, R. Roy and P. Yadoji, “Structural and magnetic properties of Ni-Zn ferrites prepared by Microwave Sintering,” Journal of Magnetism and Magnetic Materials, Vol. 279, No. 2-3, 2004, pp. 195-201. doi:10.1016/j.jmmm.2004.01.079

- S. R. Murthy, “A study of Ultrasonic Velocity and attenuation on polycrystalline Ni-Zn ferrites,” Bulletin of Materials Science, Vol. 24, No. 6, 2001, pp. 611-616. doi:10.1007/BF02704009

- J. L. Snoek, “Dispersion and absorption in magnetic ferrites at frequencies above one Mc/s,” Physica, Vol. 14, No. 4, 1948, pp. 207-217. doi:10.1016/0031-8914(48)90038-X

- Z.-h. Yang, Z.-q. Gong, H.-x. Li, Y.-t. Ma and Y.-F. Yang, “Synthesis of Ni-Zn ferrites and Its Microstructure and Magnetic Properties,” Journal of Central South University of Technology, Vol. 13, No. 6, 2006, pp. 618- 623. doi:10.1007/s11771-006-0004-x

- M. Jalaly, M. H. Enayati, P. Kameli and F. Karimzadeh, “Effect of composition on structural and magnetic properties of Nanocrystalline Ball Milled Ni1-xZnxFe2O4 ferrites,” Physica B: Condensed Matter, Vol. 405. No. 2, 2010, pp. 507-512. doi:10.1016/j.physb.2009.09.044

NOTES

*Corresponding author.