Journal of Environmental Protection

Vol. 4 No. 12 (2013) , Article ID: 40877 , 6 pages DOI:10.4236/jep.2013.412164

Removal of Alcyon II, CGR, MeV 60Co Teletherapy Head and Evaluation of Exposure Dose

![]()

Hot Laboratories and Waste Management Center, Atomic Energy Authority, Cairo, Egypt.

Email: yasser202000@yahoo.com

Copyright © 2013 Yasser Tawflk Selim et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. In accordance of the Creative Commons Attribution License all Copyrights © 2013 are reserved for SCIRP and the owner of the intellectual property Yasser Tawflk Selim et al. All Copyright © 2013 are guarded by law and by SCIRP as a guardian.

Received October 2nd, 2013; revised November 1st, 2013; accepted November 28th, 2013

Keywords: Alcyon; 60Co; Teletherapy; Head; Sealed Source

ABSTRACT

Teletherapy units containing 60Co source are used in Egypt and worldwide for treatment of cancer diseases. One of the widely used in Egypt is Alcyon CGR MeV. Different radiotherapy facilities need to unload this 60Co unit after being disused. The head containing the source was removed and put into approved package for transportation, after the source kept in safe position. This study describes the planning and removing process of the disused sources and, transports it into its head. The personal doses measured during the process. This work pre-estimates the doses received to workers during the removing process. The workers received doses of approximately 55 µSv during the whole process. This study shows that the original lead head can be used as the source container of this 60Co unit but not as a long term storage option. The 60Co machine was smoothly dismantled and transported by trained workers and driver, using planned and controlled radiation protection, followed by ALARA (as low as reasonably achievable) rule.

1. Introduction

Teletherapy 60Co unit has a specific energy and is easy to maintain. It was a useful tool for treating head and neck cancers and superficial tumors during several decades. However, the effectiveness of linear accelerators has greatly improved over recent years. Many old 60Co units are decommissioned because of weak activity as well as long treatment times required. The Alcyon CGR MeV teletherapy unit has been used in different radiation oncology institutes in Egypt for over 15 years. Recently it was decided to decommission those units and transfer them to the centralized waste facility at the Egyptian Atomic Energy Authority (Hot Labs & Waste Management Center, HLWMC). This paper describes the planning and dismantling steps of such type of 60Co units, and personal doses measured during the procedure.The safety development of nuclear energy and progressive increasing use of radioactive materials and sealed sources in industrial, medical and research applications increase the demand of establishing a procedure for removal and control of high spent radioactive sealed sources (SHARS) from its devices such as a head of teletherapy unit that contains more than 1000 Ci of 60Co. These activities have determined the necessity to formulate and apply an institutional strategy to assure harmless and ecologically rational management of spent sealed sources and radioactive waste conform national safety as well as security and in parallel with and international recommendations.

2. Material and Method

According to the law No.7/2010, Egyptian Atomic Energy Authority represented in the Hot Laboratories & Waste Management Center (centralized waste facility, HLWMC) has the responsibility of collecting, conditioning, storing and management of all types of radioactive waste from all Egyptian territory including spent radioactive sealed sources (SRSSs).

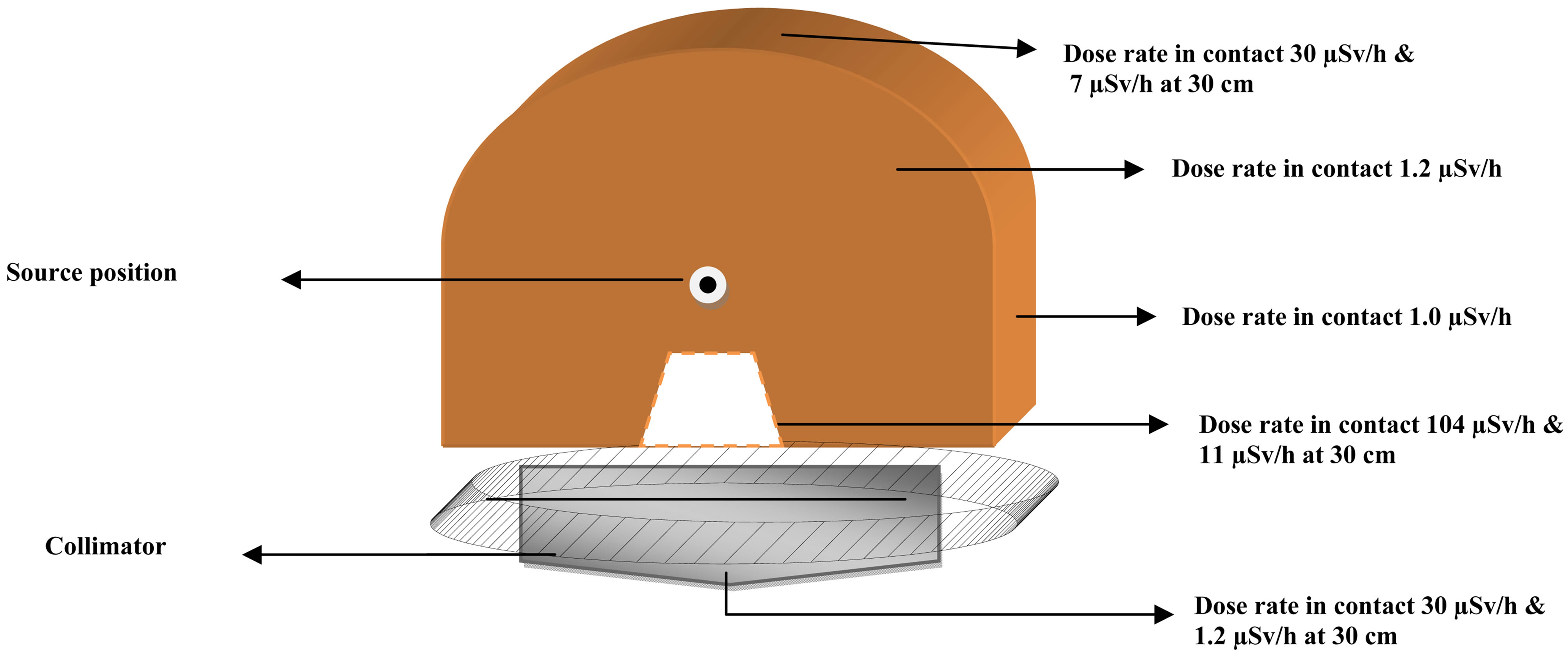

The removal process was performed including radiation dose measurement in contact and at 30 cm, and illustrated in Figure 1. The leak test was performed for possible contamination using a swap test and measured by Contamat (THERMO). The radiation dose also was performed for individuals who ranged from 50 to 60

Figure 1. Radiation dose measurements on contact and at 30 cm from the head.

µSv/hr.

The option, to reduce the risks for accidents or incident with spent radiation sources, is the conditioning of high risk sources including embedding in a matrix of cement mortar. This method is applicable for radiation sources with activities up to a few terabecqeurel (TBq), depending on the radionuclide and half life. The method has the advantage of using a simple and cheap technology, material and equipment that is available and it gives a waste package, the stability for a long time under interim storage for conditioning [1,2] and transfer to the storage facility area.

2.1. Planning

HLWMC received formal requests from different radiation oncology institutes to unload the 60Co teletherapy unit of type Alcyon CGR MeV (Figure 2) either to install a new fashion one or replaced with of linear accelerator unit. Figure 2 also describes the source head. The first step of the decommissioning was to calculate the current activity of the 60Co source according to the kinetic law of radioactivity. The initial radioactivity level was 222.64 TBq ≈ 6000 Ci. The current radioactivity on the removal procedure date was 21.1 TBq ≈ 600 Ci. The exposure rate was measured by a Thermo FH40G-L at 30 cm and in contact. The source was also identified using identifiFINDER Target insight, Germany. Figure 3 illustrateS the gamma ray spectrum results which revealed two gamma energy lines at 1332 & 1121 KeV.

2.2. 60Co Head Description and Installation

2.2.1. Radiation Head

1. lead shield;

2. wolfram shutter;

Figure 2. Head of 60Co source; metallic support and its accessories.

Figure 3. Gamma ray spectrum of 60Co.

3. depleted uranium sheets inside the head;

4. “beam off” position of the source;

5. primary collimator;

6. light fiber optical system;

7. quartz lamp;

8. mirror;

9. cast shell;

10. source information:

a. source number: 3897

b. radioactivity level: 222,621 TBq

c. date: 12 June 95

d. Radionuclide: 60Co.

2.2.2. Installtion

The installation/system teletherapy machine, Alcyon-II with cobalt 60Co source with initial activity Ai = 222,621 TBq in Oncological Department of the “ASSUIT” University Hospital Center has been in operation since 1996. This system contains four important panels as follow: 1) revolving head with 60Co source; 2) metallic support with its accessories; 3) electronic, electrical & surveillance instruments; 4) the ventilation installation.

The solid metallic frame was putted over the head of tele-therapy machine welding with a metallic dray with sizes: 800 × 800 mm and thickening 45 mm. The source’s window (collimator) was fixed by down head at the metallic plinth-sheet.

The Alycon II is both a teletherapy head and source shipping container, the head is placed in a protective shell made of steel frame, poly wood panels, ceramic wool, wood and belt. The shipping case is a single use item and includes an installation hoist which remains with customer or CGR district manager. CGR Baltimore will stock an installation hoist for emergency use. Source exchanges are not made in the field; rather, a decayed source head is replaced with a new, full-strength source head. The source capsule is contained in a source-holder barrel by means of bayonet type pins with locking clips. As a further precaution, CGR Baltimore, will have a part plug machined to fit the collimator part to ensure source containment within the head. There is an optional beam stop, 50 cm in diameter and 14 cm thick, made of lead with 4% antimony encased in steel, maximum transmission through the beam stop is 0.1% of the primary beam, 99.9% efficient. The gantry will rotate the source head through 0 to 3600 at a variable rote from 0.05 to 1 rpm the source head cannot be angled in relation to the gantry. The iso center is 80 cm ± 2 mm from the source and 120 cm above the floor with a maximum field size of 32 × 32 cm.

3. Result and Discussion

3.1. Report of Routine Swipe Test for Contamination [3]

Equipment containing radioactive sources shall be wipe tested for removable radioactive contamination at intervals not to exceed six months. Transport packages for radioactive material also shall be wipe tested for removable radioactive contamination on receipt and prior to shipment. Records of test results shall be kept in microcuries or S.I units and maintained for inspection by the appropriate Regulatory Authority. Sensitivity Factors [4] for 60Co:40 c/min = 0.005 µCi (185 Bq) and 238U:140 c/min = 0.005 µCi. If any wipe tests exceed than the background count per minute the calculation should be in microcuries. The wipe showed no contamination and the results was less than 0.005 µCi for 60Co and 238U.

3.2. Removal Procedures

1) Remove the rigid plastic cap cover from the head as well as the patient bed and performing the dose rate measurement, in this step the background was 80 nSv/hr;

2) Follow the safeguard guidelines. The dismantling steps are performed using the following;

a) Remove the cover of the collimator as illustrated in Figure 2.

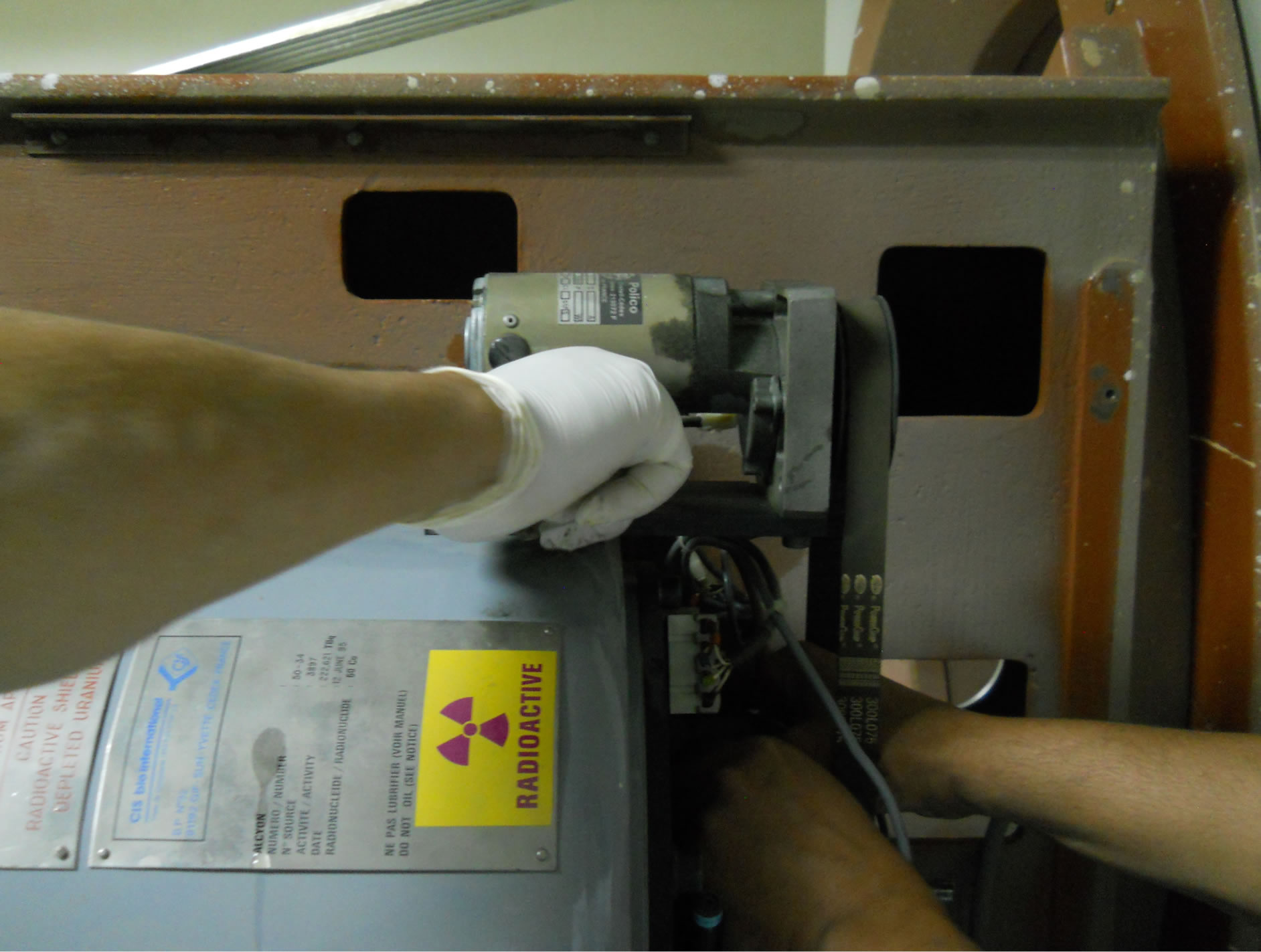

b) Rotate the machine manually or electrically clockwise with 180˚ angle, Figure 4.

c) Remove, and store the collimator in suitable package.

d) In each step the dose rate was recorded.

3) Fix the body of the machine to prevent unbalance change (when the head is removed) using stopper stick in the back which prevent the rotation of the machine due to the weight balance as shown in Figure 5.

Figure 4. Removing the collimator.

Figure 5. Fixation of machine stoppestick.

4) Rotates the head again anticlockwise 90˚ to start the removal of the head, Figure 2. This procedure was achieved using the following steps.

a) Disconnect and shut down the power source, Figure 6.

b) Start to safe the source to be in safe position by three different locks to prevent the rotation of the shutter. Figure 7. This was done using red metal fixed sheet in semi vertical position. The second step is to put the screw with angle 70˚ in contact perpendicular to the rotating disc. The final step is to put the last screw perpendicular to the rotating wheel.

c) Remove the four screws that being in contact with the head as in Figure 7, after being carried on the crane and safely transfer the head to the container, Figure 8.

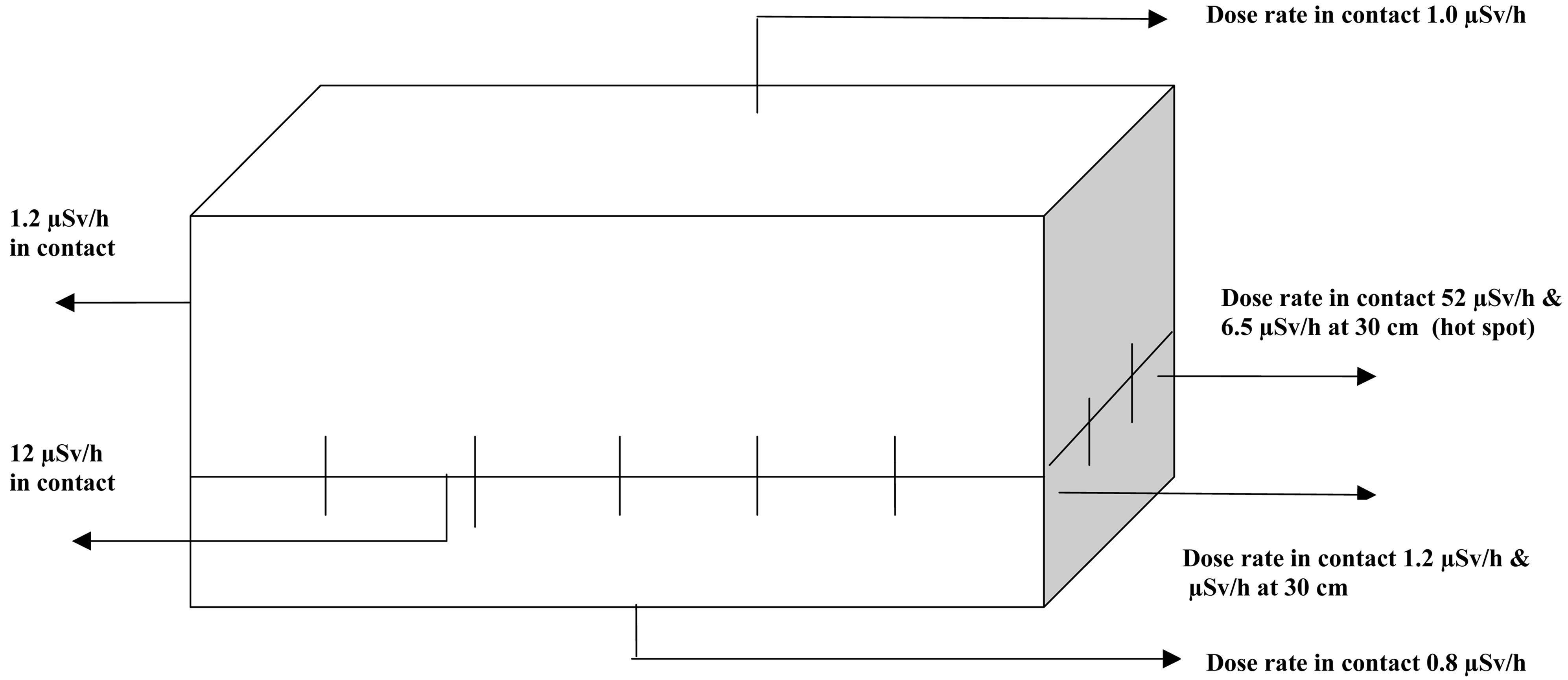

Figure 1 elucidates the skeleton of the head with the dose rate measurement from different positions, in each case before and after dismantling the collimator as well as dismantling the head, and the dose rate measurement on the final package Figure 9.

Figure 6. Disconnection of power source wire.

Figure 7. Insurance of safe position of radioactive source.

Figure 8. Loading the head in the package container.

3.3. Transport of Disused Sealed Sources to the Centralized Waste Facility in HLWMC [3] Transport and Safety Requirements

• All personnel performing the safeguard, loading, strapping, transport and unloading of the head shall be under the radiation protection program with direct reading pocket dosimeters.

• Transport package shall comply with the Transport regulations [5].

• Dose rate measurements at a distance of 2 m from the outer surface of the vehicle, were done and driver cabinet, shall not exceed 10 micro Sv/h.

• Loading and unloading of the package will be under supervision of the team leader [6].

• A maximum speed limit of 45 km/h in traffic areas and 80 km/h on highway and interstates road.

• No passenger other than a designated co-driver/assistance shall be allowed in the vehicle during the transport.

• The transport shall only commence once the prescribed the checklist, TS-VRM-003, (exhibit 1) all relevant measures taken and the documentation has been completed satisfactory and signed off by the specified persons.

Note 1: the checklist may be completed as the different tasks are performed or after all tasks have been completed, but before transport commences.

Note 2: if the answer to any of the questions is negative, transportation shall not commence.

It should be taken under considerations, which include the stability and security in Egypt, policy forces escorting the vehicle during the transportation.

• The vehicles shall follow the route as specified in the specified and declared plan.

• The escorting vehicle will be equipped with emergency equipments such as fire extinguishers, lead shield/warning tape.

All the transportations, of disused radioactive sources, are performed in accordance with the national and internationally transport regulations, which are based on recommendations of IAEA-s for the safety transport of

Figure 9. Skeleton of the container with the head and measurement of radiation dose.

radioactive materials.

3.4. The Recording of Database of Spent Radiation Sources

The most important aspects to be considered is the recordkeeping of all procedures and data collected from the whole operation and matched the RPO. There is some information must be known before planning for the operation, and this data include:

1) Radionuclide, activity, date and manufacture; 2) physical & chemical form of radionuclide and special form certificate; 3) source serial number and ID number; 4) user of the source including details of the source history; 5) measured dose rate in surface and 1 meter from the container and results of tests which have been done, in order to check the contamination in surfaces. The database of spent sealed sources are immediately transferred and recorded in PC using special inventory software.

3.5. Quality Control (QC) & Quality Assurance (QA)

All tools and devices should be checked before the operation especially the heavy duty crane and container. In our process the quality assurance system for spent or disused sealed sources contain two essential steps including: design control, assessment and inspection as well as conditioning process and documentation of conditioning, storage and disposal.

Conditioning process is the only way to ensure the stability of the final product and put in a shape not accessible to any intrusion scenario for safety and security purposes and the final product shall comply with requirements applying appropriate quality assurance measures to every steps of the program. Such measures include documented procedures as following:

1) Procurement and acceptance of raw material; 2) identification of unknown or orphan; 3) immobilization process; 4) waste packages identification marks and labels; 5) equipment maintenance and repair; 6) operational staff requirements; skills and training; 7) record keeping.

Documentation of Transportation it is the process of recording all information of the disued radioactive sealed sources such as radionuclide, activity, half life, serial number, manufacturer, status of the shield, surface dose rate and dose rate at 1 m and escorting requirements to ensure all safety measures for public, environment and workers. The information on record also includes the following:

1) Package identification mark and consign/consignee responsible persons; 2) activity and radionuclide contents; 3) recording of dose rate on surface and 1 meter distance from packages; 4) contamination level and the test control; 5) date and place of conditioning; 6) number of sources conditioned, accompanied by respective photos; 7) storage category (temporary, intermediate, long term or disposal after the conditioning process).

3.6. Storage of Radioactive Waste at Centralized Facility

The storage facility for radioactive waste and spent radiation source secures using the best equipment available. The old interim storage facility (5 m × 6 m × 3 m) which constructed in Egypt at Inshas site since 1982.

4. Conclusion

Dismantling process must be taken seriously to avoid any mistake or malfunctions of equipment. The personnel must be well trained and equipped. Radiation protection officer should be capable and well trained. All equipment and tools must be checked and well maintained. The drawer must be secured according to the manufacturer procedure. Special form certificate should be checked. Certified container should be checked and approved. The transport vehicle should be checked. Contamination must be checked and reported for approval.

REFERENCES

- International Atomic Energy Agency, “IAEA-TecDoc No. 806,” Vienna, 1995.

- Manual, “Handling and Processing of Rad Waste from Nuclear Applications,” INP, 2004

- T. El-Zakla, “Procedure for the Special Arrangement off Site Transport of 60Co Teletherapy Head from Owner to Waste Facility,” Journal of Radiation Research and Applied Sciences, Vol. 2, No. 5, 2009, pp. 1051-1065.

- HSE-INS-8170, “Off Site Transport of Radioactive Material and Contaminated Equipment,” 2005.

- RM-VSK-7160, “Transport of Dangerous Goods,” 2005.

- IAEA, TECDOC-1432, 2004.