Intelligent Information Management

Vol.4 No.1(2012), Article ID:16730,5 pages DOI:10.4236/iim.2012.41001

A Preliminary Study of Just-in-Time Methods for a Seamless Public Transportation Information Framework

Department of Business Administration, China University of Science and Technology, Taipei City, Chinese Taipei

Email: clhsu@cc.cust.edu.tw

Received August 28, 2011; revised October 21, 2011; accepted October 30, 2011

Keywords: Just-in-Time (JIT); Kanban Management; Mixed-Model Production; Public Transportation; Seamless Services

ABSTRACT

A seamless multimodal transit system has been a goal for transportation planners and users. Owing to the developments of advanced public transportation and telecom technologies such as automatic vehicle location (AVL) and real-time passenger information system, key just-in-time (JIT) concepts can now be realized in process design and coordinated scheduling to shape a seamless multimodal transit system. JIT refers to a production system that times both movements of goods during production and delivery from suppliers together. It meets the same logic for seamless multimodal services. Therefore, this study innovatively analyzes possible public transportation technologies for JIT uses; moreover, to layout the possible application frame-work of a transportation technology based JIT multimodal transit system for main station area in Taipei city. With this innovative framework, multimodal transit services can deliver to the right place at right time.

1. Introduction

Japanese motor maker Toyota originates JIT production concepts in 1973. During 1979-1980, after the Japanese industries had shown their high quality and efficiencies in production for years, many U.S. enterprise executives and university professors visited Japanese companies and found this critical idea-JIT [1]. After that, many famous U.S. companies switched their plants to the JIT system.

Mr. Ohno, vice-president for manufacturing of Toyota motor company, devised this new production system based on the reducing or elimination of waste from manufacturing, purchasing, manufacturing support, and distribution activities [2]. However, the meaning of “waste” is different for Japan and the U.S. The original Toyota definition of waste is “anything other than the least amount of equipment, materials, parts, and working time essential to production.” The U.S. defines it in a clearer way, as “anything that does not add value to the product” is the waste, and it also became the classic definition of waste from then on [3].

In a JIT system, just-in-time can eliminate waste, which means any items of production or service only move through the production system when needed [1]. More clearly, it refers to a production system that times movement of goods during production and delivery from suppliers together so that the batch arrives for processing nearly after completing the first batch. The JIT process results in no idle items, idle workers, and idle equipment wait to process.

The concept behind JIT is similar to a pull system [4]. Units of production or service pulled to just where just as needed. A pull system requests delivery and production from higher levels to satisfy the exact units necessary in lower levels. Moreover, with the pull system, inventory moves only as needed, and the ideal lot size is one piece. This method can cut excess inventory that hid production and quality problems. The hidden problems of production become clear and continuous improvement for quality then works.

In transportation industries, JIT can adopt for logistics and multimodal freight transportation for years [5,6]. Though, for the passenger transportation industries, the JIT is a brand new technique [7,8]. The delivery of goods is easier than transporting the people since the latter one is more dynamic and hard to predict. However, thanks to the mature public transportation and telecom technologies, now the key JIT concepts may realize in process design and coordinated scheduling to shape a seamless multimodal transit system [9-11]. On these grounds, the paper aims to point out some critical JIT concepts which are useful and applicable for multimodal transit services, and on the contrary, to select applicable existing public transportation technologies for JIT. Moreover, the paper tries to layout the possible application framework of a transportation technology based JIT multimodal transit system for main station area in Taipei city.

2. JIT Methods

JIT defines seven wastes in operations, which come from overproduction, waiting time, transportation, inventory waste, processing, motion/movement, and product defects. Therefore, the goal of a JIT system is to meet “Seven Zeros.” They are [1,2]:

• Zero Defects: to avoid delays due to defects

• Zero Lot Sizes: to avoid “waiting inventory” delays

• Zero Setups: to lower setup delay and produce small lot sizes

• Zero Breakdowns: to avoid stopping tightly coupled lines

• Zero Handling: to promote flow of parts

• Zero Lead Time: to make sure rapid replenishment of parts, and

• Zero Surging: to avoid unnecessary WIP (work-inprocess) buffers.

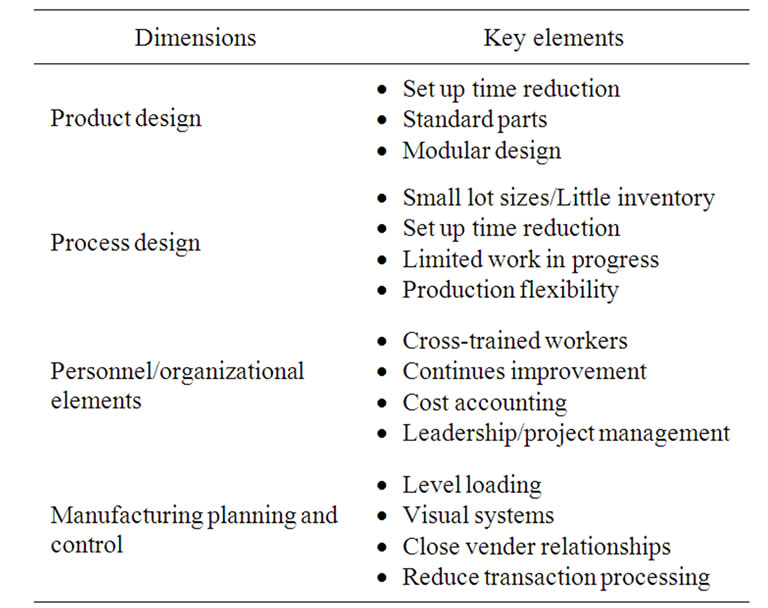

In details, some aspects of process design that are particularly important for just-in-time systems might include: small lot sizes, reduction of set up time, limited WIP, improving quality, production flexibility, and small quantity of inventory storage [2]. Key elements of JIT can catalog as product design, process design, personnel management, and production planning, as shown in Table 1.

Moreover, this study selects “Kanban Management System” and “Small Lot Mixed-Model Production” as the critical JIT techniques for multimodal transit uses. They can illustrate as follows.

2.1. Kanban Management System (Pull Method)

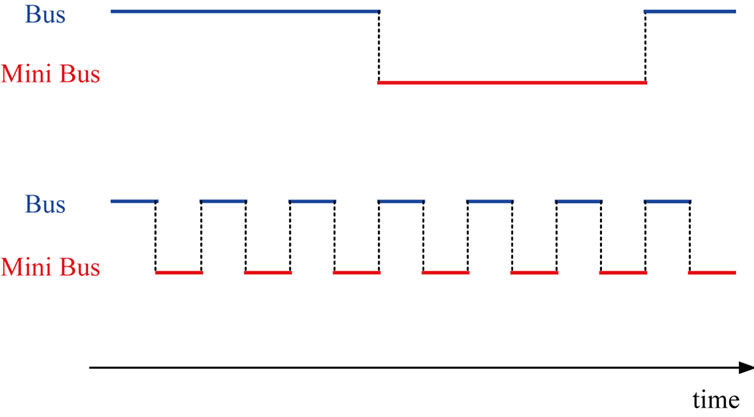

Figure 1 shows the theoretical concepts of Kanban management. There are m bus routes and n stops in this figure. The Movement of Kanban stands for signal/information feedback and capacity move stands for the exact capacity supply corresponding to the signal/information demand.

2.2. Small Lot Mixed-Model Production

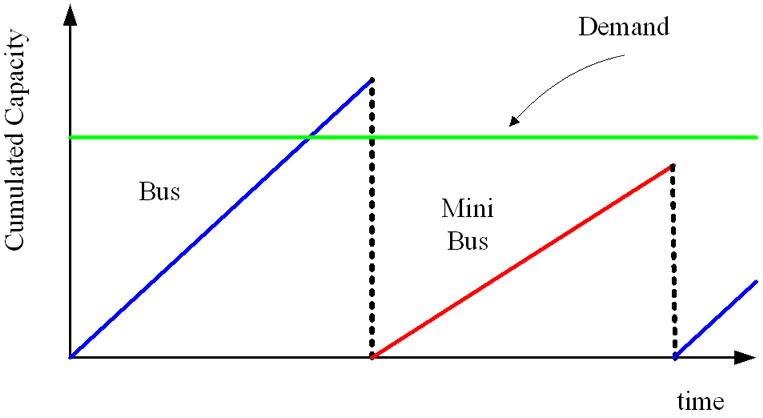

This method could produce more flexible and suitable capacity, neither too high nor too low [12]. Figure 2 shows the theoretical concepts; moreover, Figure 3 shows the benefits of small lot mixed-model production. For the current, bus size is always fixed in the same line and resulting the over, or insufficient supply capacities. By the means of mixed bus and mini bus service in a same route, supply capacity will be more flexible and correct to the passengers demand.

Except for the JIT concepts mentioned above, other characteristics such as “uniform workstation load (level production schedule),” “standardization of components and work methods: part commonality or modularity,” “flexible workforce,” cut unnecessary activities,” and “reorganize physical configuration” are also important ideas. However, they are tending left to further studies and not discussed in this study.

3. Results

Based on the selected JIT methods, this study proposes two preliminary results. The first part is a match of possible public transportation technologies with JIT. The second part is a JIT-based information framework for public transportation systems in Taipei City. They can illustrate as follows.

3.1. Applicable Public Transportation Technologies for JIT

For manufacturing industries, information technologies had enabled JIT in “production scheduling,” “material requirements planning (MRP),” and “manufacturing resource planning (MRP II).” For the production scheduleing, JIT system provides the forecast and detailed plans for producing all components of a final product [13]. For the MRP, JIT system takes the production schedule and determines which and when to require the raw materials or components; and for the MRP II, JIT can tie material requirements from MRP systems into other organizational systems.

Though, for the multimodal transit services, many

Table 1. Key elements of JIT.

Figure 1. Kanban pull system.

Figure 2. Mixed-model scheduling.

Figure 3. Mixed-model capacity.

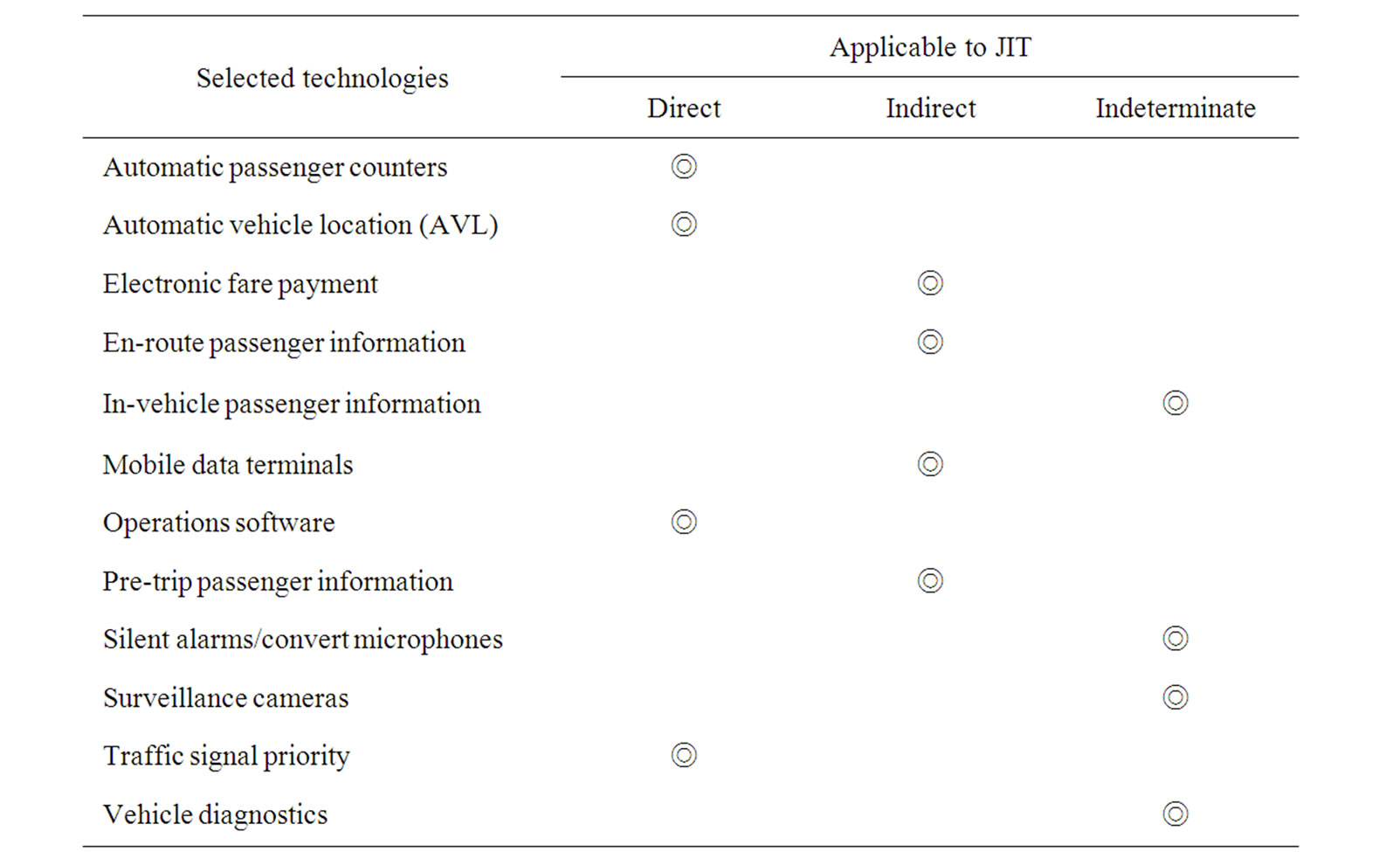

useful public transportation technologies such as information technologies can also help carry out the JIT concepts. Table 2 shows some available public transportation technologies. In Table 2, “Automatic passenger counter,” “Automatic vehicle location,” and “Traffic signal priority” are the most important public transportation technologies for implementation of a just-in-time multimodal transit system.

3.2. Scenario Framework for Taipei City

At present, there are two important information systems for public transit users in Taipei. One is the e-IOT (Information of Traffic and Transportation) system, launched by Institute of Transportation, Ministry of Transportation and Communication, Taiwan. There are three main functions in this system, as “a-traffic” to give national traffic information, “e-cti” to give specific city traffic information, and the most important one, “e-trans” to give intercity transportation information. For the e-trans, it provides passengers to have “e-Plan for route planning,” “e-Now for real-time information,” “e-Ticket for ticket information,” and “e-Transit for transfer information.”

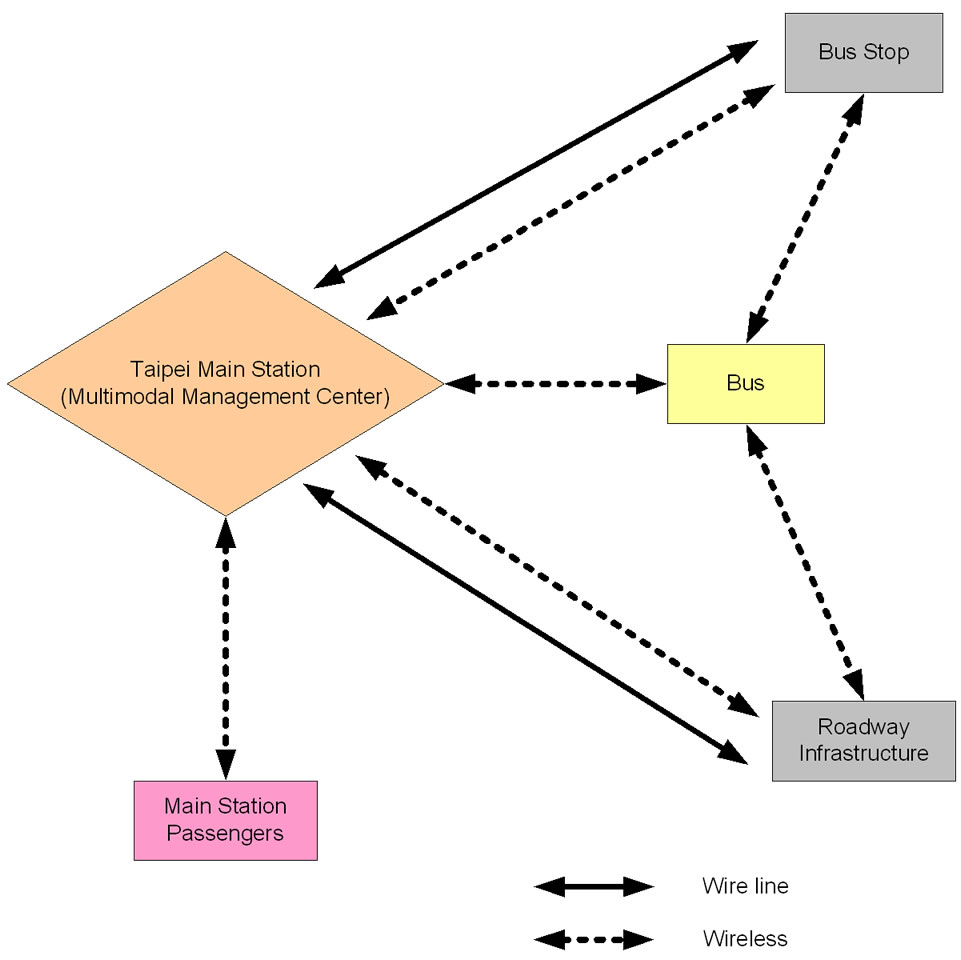

Except for the e-IOT system, the Taipei city department of transportation also develops a Taipei e-Bus system to provide users real-time bus information. However, the e-Transit function shows only static routes’ stops, and in the e-Bus system, it provides only information inquiry functions, not provides a real multimodal transit management platform. Therefore, they are not efficient for multimodal transit management. Therefore, this study try to frame a JIT based schematic communication architectture for Taipei city. Figure 4 shows the simplified communication flows.

Table 2. Analysis of public transportation technologies for JIT.

Figure 4. Schematic communication flows.

In the schematic flow, bus will report “location and routing” data, the roadway infrastructure report “traffic conditions,” the stop reports ”arrival time,” and the management center conducts dynamic bus schedule and delays. With this improved framework, city’s multimodal transit information will not only for passengers to use, but also be helpful for management units. In other words, it will provide not only passive information to users, but also provides active real-time dispatching and adjustment functions for operators. It will transform the present “information providing system” to a “multimodal transit management tool,” and to meet a just-in-time multimodal transit service.

4. Conclusions

Since the JIT management idea proposed in 1970s, the JIT techniques have been successfully deployed in manufacturing industries for decades, and in multimodal freight transportation industries. The logic of JIT refers to a production system that times both movements of goods or services during production and delivery from suppliers together, and it also meets the same logic for achieving seamless multimodal services. Therefore, multimodal transit systems should encourage deploying this important idea.

To date, as a result of the developments of public transportation and telecom technologies, such as AVL and real-time passenger information system, key JIT concepts can now be realized in process design and coordinated scheduling to shape a seamless multimodal transit system. Filtering in this study, it is found that “Automatic passenger counter,” “AVL,” and “Traffic signal priority” is the most important public transportation technologies for implementation of a JIT multimodal transit system, and interesting, this finding meets the present development trends for transit services around the world.

Meanwhile, for the critical JIT concepts that may applicable to form a seamless multimodal transit service are “Kanban management system” and “small lot mixedmodel production.” For the former, it is the key to meet a seamless service, and for the latter, it ensures that the supply capacity will appropriately meet the users demand, neither excess nor insufficient. Also, to improve the current passengers’ information system in Taipei city, this study proposed a draft framework of a JIT based schematic communication architecture for Taipei city. With this framework, multimodal transit services can deliver to the right place at right time.

Furthermore, it must emphasize that the JIT is not only a slogan, but something really important and needed to push ahead. Though, there are still many practical problems to solve to meet a really pulled JIT system for multimodal transit system, and they need more in-depth analysis in the further studies. In addition, statistical analysis and modeling may also help support the JIT idea in practical implementations.

REFERENCES

- T. J. Billesbach, “The Just-in-Time Philosophy: A Literature Review,” International Journal of Production Research, Vol. 29, 1991, pp. 657-676. doi:10.1080/00207549108930094

- O. K. Hobbs, “Managing JIT toward Maturity,” Production and Inventory Management Journal, Vol. 38, No. 1, 1997, pp. 8-13.

- D. Y. Golhar and C. L. Stam, “A Study of the Implementation of Just-in-Time in the United States,” Production and Inventory Management Journal, Vol. 36, No. 1, 1991, pp. 1-4.

- J. A. G. Krupp, “Some Thoughts on Implementing Pull Systems,” Production and Inventory Management Journal, Vol. 6, No. 2, 1999, pp. 35-39.

- J. F. Paniati and J. Wright, “National Intelligent Transportation Systems Program Plan: A Ten Year Vision,” Intelligent Transportation Systems Society of America, 2002.

- R. E. White and J. N. Pearson, “JIT System Integration and Customer Service,” International Journal of Physical Distribution and Logistics Management, Vol. 31, 2001, pp. 313-333. doi:10.1108/EUM0000000005515

- R. M. Healy, “The Changing Face of Transit: A Worldwide Survey of Transportation Agency Practices,” New York City Transit, New York, 2001.

- M. Guttenplan, “Model Regulations and Plan Amendments for Multimodal Transportation Districts,” Department of Transportation, Florida, 2004.

- M. Hwang, J. Kemp, E. Lerner-Lam, N. Neuerburg and P. Okunieff, “Advanced Public Transportation Systems: State of the Art Update 2006,” Department of Transportation, Federal Transit Administration, Washington D.C., 2006.

- D. G. Janelle and A. Gillespie, “Space-Time Constructs for Linking Information and Communication Technologies with Issues in Sustainable Transportation,” Transport Reviews, Vol. 24, No. 6, 2004, pp. 665-677. doi:10.1080/0144164042000292452

- J. J. Schiavone, “Understanding and Applying Advanced On-Board Bus Electronics,” Transportation Research Board, National Research Council, Washington D.C., 1999.

- L. K. Duclos, S. M. Siha and R. R. Lummus, “JIT in Services: A Review of Current Practices and Future Directions for Research,” International Journal of Service Industry Management, Vol. 6, 1995, pp. 36-52. doi:10.1108/09564239510101518

- C. Hsu W. A. Wallace, “An Industrial Network Flow Information Integration Model for Supply Chain Management and Intelligent Transportation,” Enterprise Information Systems, Vol. 1, No. 3, 2007, pp. 327-351. doi:10.1080/17517570701504633