Advances in Aerospace Science and Technology

Vol.02 No.01(2017), Article ID:75179,16 pages

10.4236/aast.2017.21001

The Study on the Electrorocket Engine for the Future

Alexander Rubinraut

Technische University, München, Germany

Copyright © 2017 by author and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

Received: December 27, 2016; Accepted: March 28, 2017; Published: March 31, 2017

ABSTRACT

A project of electrical rocket engine of the future, which operates on principle of a magnetoplasmadynamic engine, is being considered. New concept of the superconducting magnetic system, stipulating installation of external field winding, in which the current is directed parallel to longitudinal axis of the engine, makes it possible to increase the magnitude of the transversal magnetic field in working chamber, to decrease the rated current and to raise the engine efficiency. On the basis of equations that describe the process of converting electrical energy into mechanical energy, a mathematical model has been composed with whose help the characteristics of magnetoplasma engine having conventional design and the characteristics of the engine being developed in the project have been determined. Conducted research has shown that new design increases engine efficiency from 50% up to 91%. The project also contains a consideration of the new engine design with movable cathode and with cathode having forced cooling which helps to reduce carryover of cathode mass and to increase lifetime by several times. In conclusion, the results of calculations and constructive development of electrorocket engine for flight towards planet Jupiter, which creates tractive force of 250 N at 2500 kW power, are given.

Keywords:

Magnetoplasma Electrorocket Engine, Superconducting Magnet System, Plasma Electroconductivity, Cryostat, Movable Cathode, Cooled Cathode

1. Introduction

Cosmonautics development is closely connected with means for providing necessary traction of spaceships. In the 20th century with the help of chemical rocket engines the problem of large masses launching onto circumferential orbit has been solved. But due to the small magnitude of the specific impulse the chemical rocket engines are not capable to implement interorbital flights.

For this purpose the electrical rocket engines are intended, which are being developed by scientists and engineers in many countries of the world.

At present, as the work, in which the overall results of researches in this area are summed up, one can consider the article of Professor Princeton University Edgar Y. Choueiri. “Das Zeitalter der elektrischen Raketen” (“The era of electrical rockets”) [1] .

In this work the description of three different types of the electrorocket engines is given: ionic electrorocket engine (ERE), providing the traction up to 0.25 N, the ERE, operating while using Hall effect and providing the traction up to 0.6 N and magnetoplasmadynamic (MPD) electrorocket engine, providing the traction up to 25 N.

The electrorocket engine of MPD type provides the substantial traction consumes megawatts of power and is capable to move the spacecrafts of large mass between orbits of solar system planets.

The purpose of this research work is to develop a conception for creation of the most advanced engine of this type.

2. The Mathematical Model for Calculation of Main Characteristics of a Magnetoplasmadynamic Engine (MPDE)

In the work [1] the design of the MPDE and its characteristics (which are also being reproduced on Figure 1) are given.

To Figure 1

A Status:

Tested in flight, but not yet employed

Power consumption: from 100 kW to 1 MW

Rate of working substance outflow: from 15 to 60 km/s

Tractive force: from 2.5 to 25 N

Efficiency: 40% to 60%

Purpose of the development: main drive for heavy unmanned and manned spaceships

1) Heated gaseous lithium flows through the central hollow cathode

2) When gaseous lithium enters into the working chamber, lithum atoms are ionized owing to discharge between cathode and cylindrical anode and plasma is formed

3) It is the radial component of an electric current induces the magnetic field, which circulates around

4) The radial component of the current and the magnetic field which they induce, create the Lorentz force, which ejects plasma from the working chamber

5) Current consumption

6) Lorentz force

7) Working chamber

8) Magnetic field

8a) Cylindrical anode

Figure 1. Design and the main characteristics of the MPDE.

9) Hollow cathode

9a) The radial component of the current (discharge)

10) Plasma

As one can see on Figure 1, MPDE has an internal axial electrode-cathode, which has the form of hollow cylinder. In the internal cavity the working substance-gaseous lithium is fed.

Working chamber of the engine is located in the ending part on the exit of cathode. The outer electrode-anode has geometrically shaped conical form. It is necessary in order to the current between the electrodes had elongated field lines, as it is shown in Figure 1.

Due to such a configuration of the current between the electrodes in working chamber an axial component appears in addition to a radial component. And it is just the component, which creates in the working chamber the tangentially directed magnetic field.

After voltage application, the electric current, which ionizes the gaseous working substance, begin to flow between the electrodes.

Due to interaction of a tangential component of the magnetic field and radial component of the current, a force arises, which is directed along axis of the engine.

Under the influence of this force, the current-conducting plasma is being thrown out from the working chamber, creating a reactive traction.

While the plasma movement in the magnetic field an EMF is induced between the electrodes. In the MPD engine, which is shown at Figure 1 and which sometimes is called “end engine” we observe a process of direct conversion of electrical energy in mechanical energy, as it takes place in the usual DC engine.

From MPDE characteristics, which are shown at Figure 1 (A Status), one can see, that efficiency of MPDE is substantially lower as compared with ordinary electrical machines, as the MPDE efficiency does not exceed 60%. Let us analyze the reason of this substantial disadvantage of MPDE, which results in increasing almost twice of the power of on-board energy source and consequently in increasing of the flight weight.

For the analysis we will use some well-known dependence of electro mechanics, which are determine the main characteristics of MPDE.

Voltage between electrodes being supplied by the on-board source of electric energy

(1)

(1)

where:

E―EMF, being induced between electrodes,

I―total current,

R―electrical resistance of electroconducting plasma.

The EMF is determined from Faraday law

(2)

(2)

where

―tangential component of magnetic field induction in working chamber of the engine,

―tangential component of magnetic field induction in working chamber of the engine,

l―distance between electrodes,

v―velocity of plasma expiration.

The electrical resistance of the plasma is determined from Ohm law

(3)

(3)

where

―plasma electroconductivity,

―plasma electroconductivity,

―the area of cathode working surface.

―the area of cathode working surface.

Current density of the cathode surface:

(4)

(4)

Tractive force is determined by using Amper law:

(5)

(5)

where

―radial component of current.

―radial component of current.

Value of  is determined in accordance with Biot-Savart-Laplace law

is determined in accordance with Biot-Savart-Laplace law

(6)

(6)

where:

―axial component of current between the electrodes.

―axial component of current between the electrodes.

―a coefficient, which depends on the current configuration between the electrodes, and is determined by way of solving of the problem of magnetic field distribution in working chamber.

―a coefficient, which depends on the current configuration between the electrodes, and is determined by way of solving of the problem of magnetic field distribution in working chamber.

The energy losses while the current flows through electroconducting plasma are being determined under Joule law

where (7)

where (7)

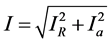

Current value

(8)

(8)

The indicator of overall efficiency  of the engine operation is being determined from the relation

of the engine operation is being determined from the relation

(9)

(9)

where:

P―the power, which is applied to the engine from energy source.

The calculations, which have been carried out making use a mathematical model in which base the Equations (1)-(10) were laid, have shown that for providing the necessary traction force F the corresponding magnitude of tangential component of magnetic field

As it can be seen from (7), (8) and (9), decreasing of current I and its density increases the effectiveness. But according to (6) it results in decreasing of the magnetic field induction

Thus, if to think up a such design of engine, in which magnetic field is arisen independently from the current between electrodes, it would help to solve the problem of MPDE effectiveness increase.

A version of such constructive solution had been proposed by the author in year 2006. In year 2013 the German patent had been given out on the new design of magneto plasma dynamic rocket engine [2] .

3. The Constructive Conception of MPDE

Longitudinal section of the MPDE with independent excitation of magnetic field is shown at Figure 2.

Figure 2. Longitudinal section of the MPDE with independent excitation of magnetic field.

The engine has cathode 1, which is located along its axis, and external cylindrical anode 2. The cathode 1 is fastened on the anode 2 with the help of intermediate bushing 3. The electrodes are separated one from another with the help of an insulator 4, which has form of cylinder. At the bushing 3, the channels 5 are made for filing of the working substance in gaseous state into the working chamber 6. The field winding 7 of the MPDE is located outside the anode 2 in a closed cylindrical Dewar vessel 8. The field winding is manufactured out of superconducting high temperature wire. It is installed on a cylindrical base 10, which is hung up with the help of disks 11, which are performed the role of thermal bridges.

The flat disks 11 are being connected with the external cylinder 12, The Dewar vessel 8 serves as a cryostat, which internal cavity is filled with liquid hydrogen. The case of the cryostat 8 has an external envelope 13, which is fastened inside of a cylindrical tumbler 17.

On Figure 3(a) and Figure 3(b) the picture of currents and magnetic field in longitudinal and transversal section of MPDE is shown.

The external winding 2 creates magnetic field directed transversely direction of the current between electrodes, therefore the current in it shall be directed along engine axis. For the sake of this the winding consists of four separate coils of rectangular form. Before laying the coils are being shaped and they acquire cylindrical form. The laying of the coils is performed in such way that only a part of the coil 2 with half-turns coiled in forward direction is placed on the outer surface of the cylinder 1. Another part of the coil 3 with half-turns coiled in the opposite direction is moved off the cylinder surface and is turned down in radius direction. The turned down part of the coil 3 is being fastened mechanically with

Figure 3. (а) Longitudinal section of MPDE; (b) Transversal section of MPDE. 1―cylinder, 2―one part of external winding, 3―another part of external winding, 4―rib.

the help of ribs 4.

As it can be seen on Figure 3(a), ionized plasma of the working body when leaving the working chamber is subjected to impact of the radial magnetic field

In the radial magnetic field the plasma stream under impact of Lorenz force is being compressed and its volume is decreased, as it is shown at Figure 3(a).

In order to implement an independent control of the plasma process compression a solenoid 14 (magnetic nozzle) is installed in the ending part of the magnetic system (Figure 2), inside cryostat 8, on the cylinder 10 surface. The winding of the solenoid 14 is being manufactured from high temperature superconductor and during operation is being immersed in liquid hydrogen. Mechanical strength of the superconducting windings 7 and 14 of the engine magnetic system is achieved with the help of mechanical belts 15 and 16.

Stabilization of the electric arc during flow of the current between the electrodes 1 and 2 is provided by way of its uniform rotation. To this purpose on the outside of the belt 15 a cylindrical superconducting winding 19 is wound up, which creates magnetic field along longitudinal axis of the engine.

4. The Study on the MPDE

Reverting to the problem of the MPDE efficiency increase, it should be taken in account some special features of the physical processes while electric current flowing through plasma. The major parameter, which defines the energy losses, is electrical conductivity of the plasma. In the ordinary electrical machines with solid conductors the conductivity does not depends on magnetic field magnitude. When the conductor consists of a mass of ionized gas, conductivity depends on magnetic field magnitude. Under influence of Lorenz force electrons create an additional electric current (which is called “Hall current”) around force lines of magnetic field, changing electrical resistance of plasma.

It shall be reminded, that theoretical as well experimental investigations of plasma electroconductivity in magnetic field had been conducted by scientists still 50 years ago while creation of magneto hydrodynamic generators (MHDG) [3] . Particularly, a mechanism of plasma electroconductivity in a crossed magnetic and electric field is considered in details in [4] . In this work it has been shown that plasma electroconductivity depends on physical features of working substance and its physical state in working chamber of MHD generator.

It can be represented as

where:

p―gas pressure in work in chamber in kg/sm2,

А―Hall coefficient, depending on gas chemical properties and temperature.

For hydrogen at temperature 2000 ˚K A = 1.8 at p = 1 kg/sm2.

With the help of dependence 11 the change of hydrogen plasma electrocon- ductivity depending on tangential component

This dependence is given at Figure 4.

In this work a consideration of dependence of plasma coefficient electrocon- ductivity σ on magnetic field magnitude was performed, which had shown that it depends not only on axial component

The distribution pattern of the magnetic field components

As the calculations had shown, due to action of the current, flowing in direction, which is perpendicular to longitudinal axis, the magnitude of radial component of magnetic field

Figure 4. Dependence of plasma electro- conductivity on tangential component Bτ.

Figure 5. The distribution pattern of the magnetic field inductions Bτ and BR.

Direction of component

Under the influence of Lorentz force, electrons create an additional current around force lines of magnetic field component

And under the influence of Hall e.m.f., an electrical field arises, which is directed perpendicularly to magnetic field

The Hall e.m.f. is defined as:

where:

l―distance between electrodes;

Task solution of plasma electroconductivity definition was carried out in two stages.

At the first stage with the help of a program for three-dimensional magnetic field calculation the average values of

The calculation results are given at Figure 6, where the electroconductivity coefficient

The total coefficient of electroconductivity is defined as:

The performed calculations show that the developed electrorocket engine (Figure 2) has an important useful feature: under the influence radial component of magnetic field being created by the external superconducting field coil, the increase of plasma electroconductivity and the corresponding increase of the engine effectiveness takes place.

The calculation procedure makes it possible to compare the main characteristics of both different designs of the MPDE which are shown at Figure 1 and Figure 2.

The comparison was carried out while maintaining traction force and such geometrics of MPDE as diameter and length of the working chamber. The comparative calculations have been carried out at the following values of output characteristics:

Tractive force―14 N

Movement speed of working substance (hydrogen)―60 km/s

Distance between electrodes―6 cm

Temperature of working substance between electrodes―2000˚K

Gas pressure―1 kg/cm2

The results of these investigations are give in Table 1 and are shown at Figure 7.

Table 1 shows, that in MPDE of end type (Figure 1) the magnitude of magnetic induction in working chamber is

The constructive conception of MPDE being illustrated by Figure 2, makes it possible by means of changing of the excitation current in the superconducting winding 7 (Figure 2) to increase value of induction

Figure 6. Dependence of plasma electro-conduc- tivity on radial component BR.

Table 1. The main characteristics of the MPDEs, which are shown at Figure 1 and Figure 2.

Figure 7. Dependences of main MPDE characteristics on Bτ.

To preserve the traction force, geometric dimensions and outflow speed of the working substance unchanged, the magnitude of magnetic induction is increased up to

A mass (M) of onboard power supply for energy supply of racket engine depending on magnetic induction

In conclusion it shall be noticed still one important special feature of MPDE designs. Both designs (Figure 1 and Figure 2) have electrodes and therefore they can be classified as MPDE of constructional type. The application of electrodes results in necessity to solve the problem of life time extension of the engine.

Limitation of engine resource is conditioned by the fact that during current flowing between the electrodes the cathode surface is being bombarded by ions of very high energy. Cathode mass is gradually decreased. The erosion (carry-over of mass) speed of cathode is defined by density of the ion current. From the comparison of two version of MPDE one can see, that current density of the engine shown at Figure 2 three times less than in the engine shown at Figure 1. Therefore its resource will be in three times larger.

In order to cardinally solve the problem of MPDE lifetime increase in year 2008 the author has suggested new design of the engine, which is shown at Figure 8.

Figure 8. MPDE design with movable cathode.

The engine has the same sizes and characteristics as the engine shown at Figure 2. The special feature of this MPDE design (Figure 8) is, that cathode 1 is done movable along horizontal axis.

After cathode erosion as a result of prolonged engine operation in space flight, the cathode 1 is moved relative to working chamber 6 (along engine axis) in a new position and is fastened. Now the part 20 of the cathode, which formerly was not in the working chamber 6 and was not subjected to erosion, begins to work. For the cathode displacement a mechanism is developed, which operates automatically with the help of magnetic interaction force [5] .

The movable cathode 20 of cylindrical form, which is manufactured out of tungsten, is displaced along axis in the metallic bushing 21. The bushing 21 is fastened inside isolator 4. The end of cathode 20 is rigidly fastened along axis in the center of crosspiece 22, which is displaced along horizontal axis together with vertical spokes 24. The displacement of the spokes 24 is made with the help of runners 25 and 26, which is moved along the internal surface of the external cylinder 17. The cylinder 17 serves not only as the external casing of the engine but also as a bearer of the construction for the cathode displacement.

The cathode 20 displacement is made with the help of usage of magnetic interaction force. To this purpose, the electromagnets 27 and 28 are installed on the vertical spokes 24. The electromagnets 27 and 28 of cylindrical form have a core 29 made out of electrotechnical steel and a DC winding 30. During the engine operation the electromagnets 27 and 28 are in constant magnetic field, which is generated by the superconducting field winding 7, located in cryostat 8.

The force, which arises as a result of this process, is directed along axis of the engine. The electromagnets are refrained from a movement under influence of this force with the help of latches 31 and 32, which are installed on the internal surface of the cylinder 17.

The device for the movement of the cathode 20 begins to operate only when the maximum permissible value of cathode erosion is achieved, as a result of its long-term operation.

With the help of the automatic indicator, detecting the thickness of cathode surface layer, the command is given to activate the electromagnets 27 and 28. The latches 31 and 32 on the surface of cylinder 17 are become released and the current is supplied in winding of the electromagnets 30.

At increase of the current in the winding 30, the magnetic induction and interaction force between the engine field winding 7 and the electromagnets 27 and 28, are increased too. Under the influence of this force the movement of the crosspiece 22 together with the cathode 20 takes place. The skids 25 and 26 are moved along the internal surface of the cylinder 17 up to stop 33 and are locked. The electromagnets 27 and 28 are switched off. As a result of this device operation into the working chamber of the engine will shift a fresh, not subjected to erosion cathode 20.

The developed device of the shifting cathode permits to increase lifetime of the engine in twice.

A more detailed consideration of the lifetime increase problem has shown that solution of this problem can be achieved not only by application of the shifting cathode but also by the decreasing of mass carryover during the thermal evaporation of the cathode.

As it is known, thermo emission current substantially depends on temperature in the active zone of cathode.

This dependence is defined by Richardson-Dashmen equation

where:

А―a constant, which is equal:

Researches have shown that decreasing of cathode temperature T makes it possible to decrease mass carryover and to increase its trouble-free time of operation.

An engine design, shown at Figure 9, was developed, in which intensive cooling of cathode is used.

The elements of construction indicated by numbers 1 - 19 at Figure 2 are kept without changes. Only the cathode 1 is subjected to a change: it is increased in the length. An axial bushing 21 is put tightly onto the cathode 1 from the side, which is opposite to working chamber. With the help of the axial bushing 21 on the cathode metal disk 20 is installed. The disk 20 is rigidly connected with external cylinder 17 of the cryostat 8. It serves as “a thermal bridge”, along which thermal flow from the hot cathode 1 is fed to the cold surface of the external cylinder 17.

Figure 9. MPDE design with intensive cooling of cathode.

The thermal bridge 20, which is described in patent [2] , has high thermal resistance, which is provided by means of notches decreasing flow area of the disk. The thermal flow sets in such a way that amount of liquid hydrogen, which is evaporated in the cryostat, corresponds to nominal gas consumption in the working chamber of the engine.

The gas, which has been evaporated in cryostat 8, is fed along gas pipeline 18 and then along the channel 5 into interelectrode space. During this process the cathode 1 cooling occurs.

For more intensive cooling of the cathode 1 the design, which is shown at Figure 8, provides for also heat delivery by means of radiation into space. To this purpose an axial bushing on which external surface the radiator 24 is installed, is fixed on the cathode 1. The radiator 24 has a well-developed heat transmitting surface, which is being created by cylindrical metallic plates 22.

It should be noted, that in accordance with Stefan-Boltzmann law the heat transmission by way of radiation is proportional to the fourth degree of the absolute temperature. Therefore the application of radiator at temperature about 2500˚К will be very effective.

The calculations, which have been carried out, prove that the constructive solution, shown at Figure 9, makes it possible to decrease the cathode temperature from 3000˚К up to 2500˚К, while the thermal emission current is decreased by an order. Owing to it, the cathode mass loss will be decreased, resulting in increase of engine resource.

Application on space aircrafts the electrorocket engines of new design makes it possible to solve many problems associated with flights towards planets of the solar system.

A typical application example of the MPDE, which design is shown at Figure 8, was the project of expedition towards planet Jupiter [6] .

A space train electro movement system of 10 MW power is developed, consisting of the jointly working MHD AC generator and the cryoturbogenerator,

Table 2. The main characteristics of the electrorocket engine for flight towards Jupiter.

using the MPDE with external superconducting field winding were installed. At the projecting an optimization of all the characteristics of these electro movement system components: generators and electric motor, was conducted.

The main optimization criterion was the achievement of minimal duration of the flight towards Jupiter.

The calculation results of the main characteristics of the electro rocket engine for flight towards Jupiter are given in Table 2.

5. Conclusions

A new design of magnetoplasmadynamic engine with external superconducting field winding, in which the current is directed along the axis of the engine, is proposed. Based on the equations of electrodynamics, a mathematical model for calculation of the main parameters of the engine is developed.

The calculation research has proved the number of the advantages of the developed electro rocket engine:

1) High efficiency (about 90%);

2) The possibility of obtaining large traction force;

3) Simplicity of design and high reliability in operation;

4) Increased lifetime.

Cite this paper

Rubinraut, A. (2017) The Study on the Electrorocket Engine for the Future. Advances in Aerospace Science and Technology, 2, 1-16. https://doi.org/10.4236/aast.2017.21001

References

- 1. Choueiri, E.Y. (2009) Das Zeitalter der elektrischen Raketen. Spektrum der Wissenschaft.

- 2. Rubinraut, A. (2013) Elektrischer Düsenantrieb für den Flug zum Mars DPMA München. Patent DE 102006022559B4.

- 3. Coomber A. (1964) Magneto-Hydrodynamic Generation of Electrical Power. Chapman and Hall, London.

- 4. УрусовИ.Д. МГД – генераторы <Наука> Москва 1966.(In Russian)

- 5. Rubinraut, A. (2016) Elektrisches Raketentriebwerk für Dauerweltraumflüge. DPMA München. Patent DE 102013008832A1.

- 6. Rubinraut, A. (2016) The Expedition to Jupiter. International Journal of Emerging Technology and Advanced Engineering, 6, S.283-S.293.