Journal of Textile Science and Technology

Vol.03 No.01(2017), Article ID:78766,16 pages

10.4236/jtst.2017.31001

Consecutive Impact Loading and Preloading Effect on Stiffness of Woven Synthetic-Fiber Rope

Vannei Sry1*, Yoshihiro Mizutani2, Gen Endo2, Yoshiro Suzuki2, Akira Todoroki2

1Department of Mechanical Sciences and Engineering, Graduate School of Tokyo Institute of Technology, Tokyo, Japan

2Department of Engineering, Tokyo Institute of Technology, Tokyo, Japan

Copyright © 2017 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

Received: February 3, 2017; Accepted: February 25, 2017; Published: February 28, 2017

ABSTRACT

We studied consecutive impact loading on woven high-modulus polyethylene rope, which is used in robotics fields. An impact tester was developed to conduct the experiments. Five consecutive impact loads (five drops) were applied to the rope and the stiffness of the loading part that corresponds to each drop was evaluated. The stiffness of the woven ropes was affected strongly by consecutive impact loading. The change in stiffness is undesirable in some applications such as in robotic fields. Therefore, we have proposed a method that can optimize changes in stiffness by applying a preload before impact testing (preload treatment). The experimental results show that preload is an efficient way to reduce changing rope stiffness. We have also proposed an empirical equation that can estimate the rope stiffness after arbitrary preload treatment, and this equation is a function of the number of drops and the static preload level. The equation can be used to determine the preload treatment conditions to stabilize the stiffness of the woven ropes before they are used in engineering fields.

Keywords:

Consecutive Impact Loading, Woven Synthetic-Fiber Rope, Stiffness, Preload Treatment, Empirical Equation, Number of Drops

1. Introduction

Woven synthetic-fiber ropes such as high-modulus polyethylene (HMPE), polyester, polyamide and aramid were developed decades ago and they have emerged as potential materials to replace steel-wire ropes because they offer advantages of light weight, high strength, a high flexibility and a low friction coefficient. They have been used in many applications, such as in offshore mooring systems, climbing mountaineering ropes, and recently, in robotics fields in artificial muscles [1] , tendon-driven robots [2] [3] [4] and active endoscopes [5] .

Although synthetic-fiber ropes have been used in many applications, their mechanical behavior is complicated, mainly because of the polymeric nature of the fibers that are used in their manufacture and the construction geometry of the ropes (either in twisting or braiding) [6] [7] . The mechanical behavior of polymer fibers under shear and tension loading was studied by Northolt and his colleagues [8] [9] [10] . They found that a rearrangement of rope molecules was the main factor that changed the mechanical behavior of the rope. An increase in tension stress caused the fibers to stiffen because of the decreasing angles of the fibers with respect to the rope axis [9] . Nikonov et al. [11] conducted consecutive impact loading on polyamide climbing rope by changing the moisture conditions to assess the influence of moisture on the mechanical properties. Two main parameters to consider before using synthetic-fiber ropes in real applications include the minimum break load (MBL) and the stiffness. In general, an inconsistence in stiffness occurs in synthetic-fiber ropes because of the visco- elastic properties of the ropes [12] . Davies et al. [13] conducted experiments to determine the dynamic stiffness of HMPE and aramid ropes under dry and wet conditions. Casey and Banfield [14] used large-diameter polyester rope that is applied in mooring lines to determine the dynamic stiffness of the rope. They proposed an empirical expression of stiffness in the function of the mean load and strain amplitude. Liu et al. [15] studied the stiffness evolution of polyester, HMPE and aramid under cyclic loading. They also proposed an empirical expression for stiffness by taking the mean load, strain amplitude and number of loading cycles into account. The quasi-static and dynamic stiffness of the polyester rope was studied by Kwan et al. [12] in which they considered the effect of mean load, loading period, loading history and preload level. They found that the loading history and preload level affected the quasi-stiffness value, for example, a reduction in preload level from 40% to 30% of the MBL of the rope caused an approximate 10% reduction in quasi-static stiffness.

Flory et al. [16] [17] [18] proposed visco-elastic models that consist of a spring-dashpot-ratchet. These models can be used to determine the stiffness of synthetic-fiber ropes that are subjected to dynamic and static loading. However, these models are unsuitable for constant loading because the ratchet in the model locks and prevents rope elongation when the loading is equal to or less than the previous loading.

Therefore, the stiffness of the synthetic-fiber ropes that are used in offshore mooring lines has been studied extensively, particularly for large-diameter ropes under cyclic loading. However, no specific research has investigated the stiffness of synthetic-fiber rope because of the constant consecutive loading of large- or small-diameter ropes. Small-diameter synthetic-fiber rope is used in the robotic fields [1] [2] [3] [4] [5] . In this field, the main concern is the increasing rope stiffness and maximum cycle life [3] . However, it is difficult to obtain a high stiffness from new synthetic-fiber ropes because of the inconsistent stiffness of the visco-elastic material. No research has studied how to stabilize the stiffness of synthetic-fiber rope, although Kwan et al. [12] mention that a reduction in preload level yielded a decrease in quasi-stiffness. No detailed studies exist on this topic and quasi-static stiffness is infeasible in the robotic fields. From a robotics perspective, the impulse response has been studied extensively [19] [20] [21] because when the impulse response of a system is determined, then the characteristics of the system are described fully. Theoretically, the impulse response is derived from impulse as the input, which can be replaced by impact loading in practice. Therefore, it is necessary to investigate the stiffness of synthetic-fiber rope when it is subjected to impact loading. Because inconsistencies in stiffness exist in synthetic-fiber rope, more than one impact loading, i.e., consecutive impact loadings were required to study the evolution of rope stiffness.

In summary, because of the lack of research that deals with consecutive impact loading and methods to optimize stiffness changes of synthetic-fiber rope, the main purpose of this research has been to study the effect of consecutive impact loading and to optimize changes in the rope stiffness. Consecutive impact loading is represented in terms of the number of drops. A preload method was used to determine its effect on the stiffness of a fiber rope. We proposed an empirical equation for stiffness by considering the number of drops and the preload level based on experimental data, and we discuss the pre-treatment of rope before using it in a robotics application.

2. Material and Experimental System

HMPE, which is normally used in robotic fields, was used in this study. This rope has an MBL of 1765 N under a static loading, a linear density of 1760 dtex, and 8 strands in braided construction. Tex is a unit that is used commonly in textile engineering to measure the linear mass density of fibers and yarns, and it equates to the mass in grams per kilometer (1 tex = 10 dtex). A photograph and the properties of this rope are shown in Figure 1 and Table 1, respectively.

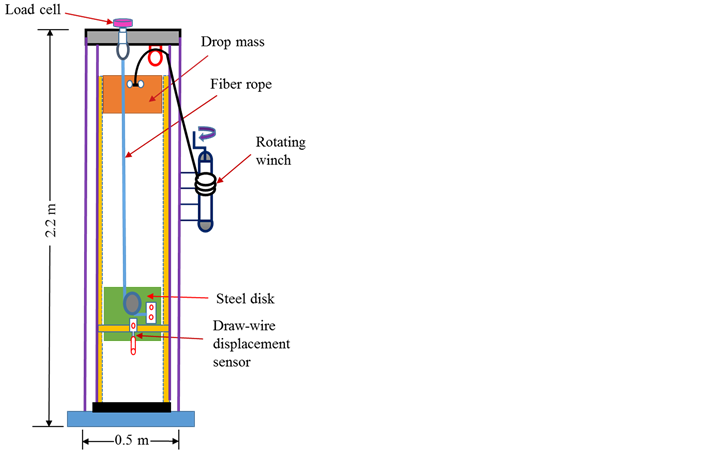

An impact tester as shown in Figure 2 was developed to conduct impact testing and preload treating of the ropes. This apparatus contains five main com-

Table 1. Material properties of the rope.

Figure 1. Woven HMPE rope.

Figure 2. Impact tester.

ponents with the first being the drop mass that is used to generate an impact load. The mass moves along linear guides that are mounted on side poles of the tester. The second part that is located on the side of the drop mass is the steel disk that is used to fix the fiber rope at the bottom end. The disk is used to reduce the stress concentration of the ropes at a fixed point. The third component is the rotating winch on the right of the tester that is used to lift and release the drop mass by connecting it with a rope. The fourth component is a load cell (Kyowa, LUK-A-10 KN) that is used to measure the impact load by mounting on top of the tester. The fiber rope is fixed to this load cell directly. The fifth component is the draw-wire displacement sensor (Tokyo Sokki Kenkyujo, DP-500E) that is used to measure the rope elongation.

3. Experimental Procedure

Impact testing was performed by releasing a 5.1-kg drop mass from 1.2 m. Impact testing was carried out under two conditions, with the first being for virgin rope and the other being for rope after preload treating. Ropes were cut to 1.8 m and were subjected to five consecutive impact loads. Impact load simulates most severe load that will apply to the robots. Preload treatment was performed by applying a deadweight on the rope for 1 h and the preload levels used in the experiment are presented in Table 2. The preload levels were chosen in such a way that they were well below MBL in order to maintain the strength of the rope. We express the preload level as a ratio between the preload force and the MBL.

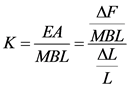

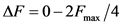

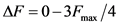

A normalized stiffness of the ropes that were subjected to consecutive impact loading was calculated by using Equation (1), which was proposed by Francois and Davis [22]

(1)

(1)

where K is the non-dimensional stiffness of the rope from impact loading, E is the longitudinal elastic modulus of the rope (MPa), A is cross-sectional area of the virgin rope ,

,  is the variation in load,

is the variation in load,  is the minimum break load of the rope,

is the minimum break load of the rope,  is the elongation of the rope with

is the elongation of the rope with

is the rope length.

is the rope length.

4. Results and Discussion

4.1. Results of Impact Testing for Virgin Rope

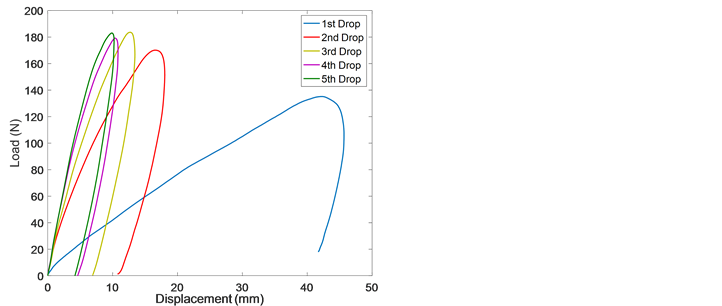

The obtained parameters were the load and displacement with respect to time for each impact test. We investigated the relationship between load and displacement. Figure 3 shows a plot of load vs. displacement from the first to the fifth consecutive impact load. Based on this result, the maximum displacement at the first drop was largest. The maximum displacements decreased with the number of drops. The maximum load was smallest at the first drop and it increased in the second and third drops. However, it tended to be constant from the third drop. The stiffness of the loading part of the ropes for each drop was calculated from Equation (1). Because the load?displacement relationship shows a non-linear behavior, the stiffness is determined by changing the section of the fitting area as follows; case 1: , case 2:

, case 2:  and case 3:

and case 3: , where

, where  is the maximum load in each drop. The rope stiffness for five consecutive impact loads for each difference case is given in Table 3. The difference in stiffness in each case results from the nonlinear curve of the load vs. displacement of the rope. This paper focuses on the effect of

is the maximum load in each drop. The rope stiffness for five consecutive impact loads for each difference case is given in Table 3. The difference in stiffness in each case results from the nonlinear curve of the load vs. displacement of the rope. This paper focuses on the effect of

Table 2. Preload level applied to rope.

Table 3. Stiffness of virgin rope from five impact loadings.

Figure 3. Load-displacement curve of virgin rope from five consecutive impact loadings.

consecutive impact loading and preload treatment on stiffness, so we take the average of the stiffness for the three cases as a representative rope stiffness. The stiffness results indicate that consecutive impact loading affects the HMPE rope significantly by changing the stiffness with respect to the number of drops. These phenomena occurred because of the nature of the viscoelastic ropes and their construction geometry. Northolt et al. [10] indicated that an increase in a tension load caused a change in the angles of fibers in some areas of the ropes. The angle and the area increase with load until they are saturated. A similar situation results for consecutive impact loading; when rope is subjected to the first loading, all fibers in each zone in the rope move toward to rope axis and thus the ropes stiffen in the next loading. However, the stiffness tends to a constant value as the number of drops increases, because the same loading levels are applied, and then the fibers in the rope do not move further.

4.2. Results of Impact Testing after Preload Treatment

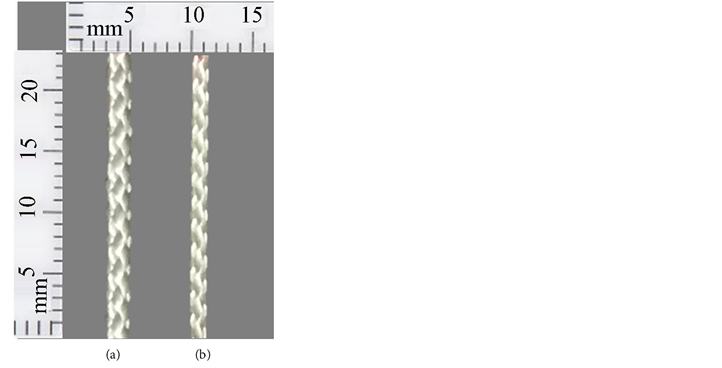

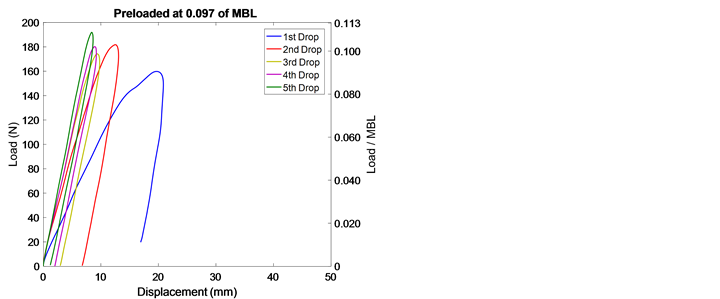

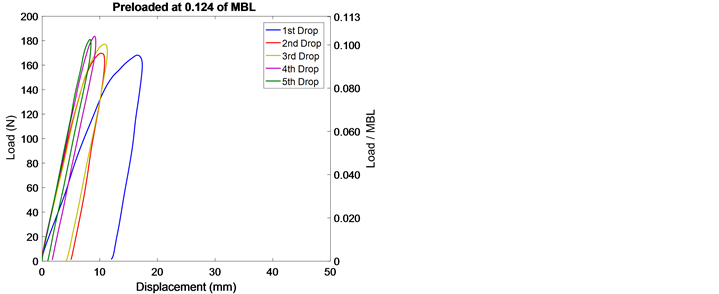

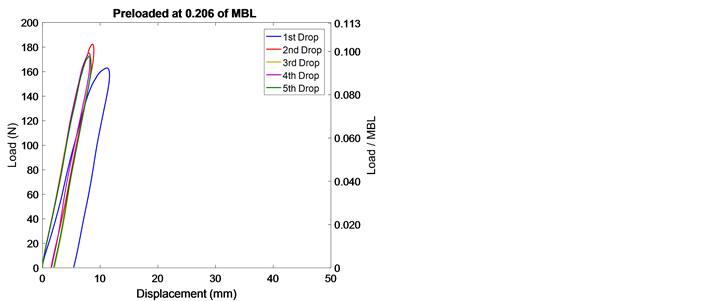

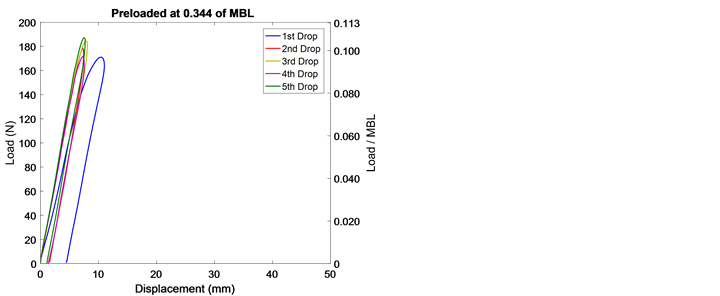

According to the results of virgin rope that was subjected to consecutive impact loading, the rope stiffness was changed by the number of drops. The stiffness changed significantly after the first drop (second to fifth drops). This inconsistence of stiffness causes a number of problems in practical applications, for example, in robotic fields, because the transfer function of the robot system is changed by this inconsistence. Based on this problem, we propose a so-called preload treating method to minimize the change in rope stiffness. Preload treatment was applied at 0.097, 0.124, 0.206 and 0.344 of the rope MBL for 1 h prior to conducting impact testing. When the rope was subjected to preloading, its construction geometry changed notably when the preload value was high because of a rearrangement of fibers and strands that move toward to rope axis as depicted in Figure 4. The rope became compact because of the preload effect by changing the rope diameter from 2 mm to ~1.3 mm after preloading at 0.344 of the MBL. Impact test results for preloaded ropes at 0.097, 0.124, 0.206 and 0.344 of the MBL are presented in Figures 5-8 in which x-axis is the displacement, left

Figure 4. Picture of fiber rope (a) before preloading; (b) after preloading at 0.344 of the MBL.

Figure 5. Load-displacement curve of preloaded rope at 0.097 of the MBL from five consecutive impact loadings.

Figure 6. Load-displacement curve of preloaded rope at 0.124 of the MBL from five consecutive impact loadings.

Figure 7. Load-displacement curve of preloaded rope at 0.206 of the MBL from five consecutive impact loadings.

Figure 8. Load-displacement curve of preloaded rope at 0.344 of the MBL from five consecutive impact loadings.

Table 4. Stiffness of preloaded rope from five impact loadings.

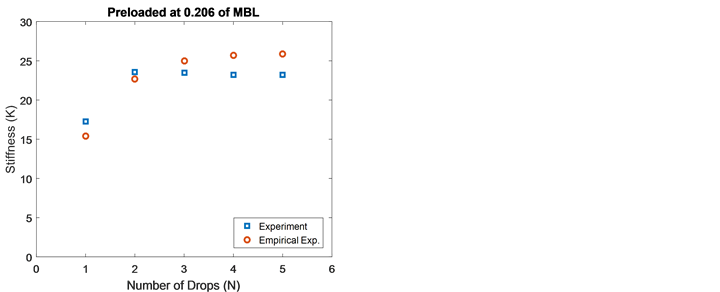

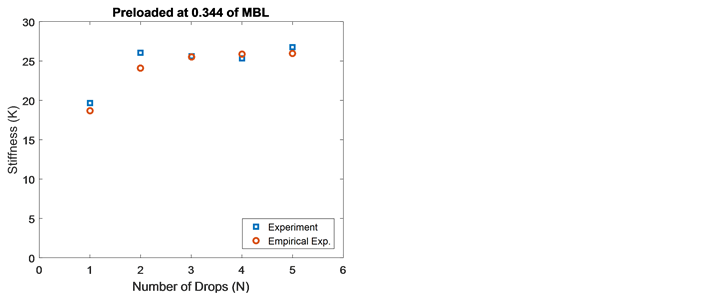

y-axis is impact load and right y-axis is the ratio of impact load to MBL. Figure 5 and Figure 6 show that a large area of hysteresis still occurred in the first drop because a small preload levels was applied before impact testing, and the area of hysteresis decreased significantly from the next drops (second to fifth drops). Figure 7 and Figure 8 show a small area of hysteresis, even at the first drop as a higher preload level was applied prior to impact testing. The stiffness values from five consecutive impact loadings of the preloaded ropes are presented in Table 4. The preload levels are the only factor that influences the stiffness of the rope at the first drop. The stiffness of the first drop is high if the preload level is high and vice versa. At high preload levels, the stiffness becomes stable from the second drop onward, for example, for preload levels of 0.206 and 0.344. At low preload levels, the stiffness becomes stable from the third drop onward, such as occurs for a preload level of 0.097. The stiffness of the fiber rope still changes significantly whenever a low preload level is implemented and it changes less for a high preload. At high preload level

4.3. Empirical Equation for Stiffness

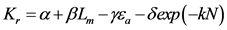

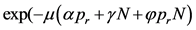

An empirical equation is usually needed to compare results from experimental data, discuss trends in results and estimate results at the outer range of the experimental data. Many proposed empirical equations exist for the stiffness for woven synthetic-fiber ropes based on experimental parameters and researchers’ concepts. Recently, Liu et al. [15] proposed an empirical equation of the dynamic stiffness of synthetic-fiber ropes as a function of mean load, strain amplitude and the number of loading cycles as expressed in Equation (2):

where

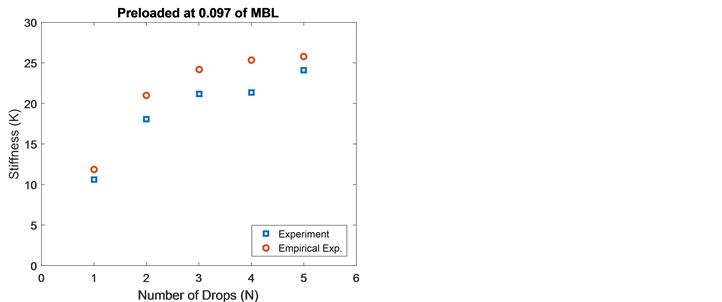

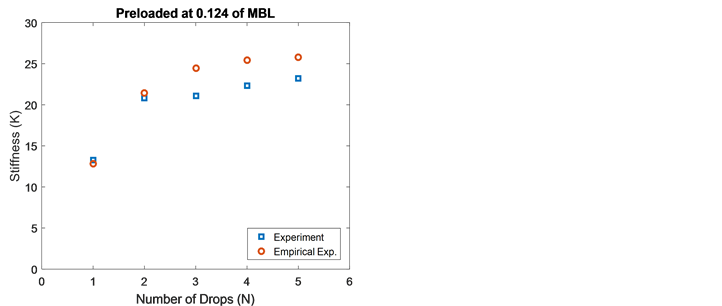

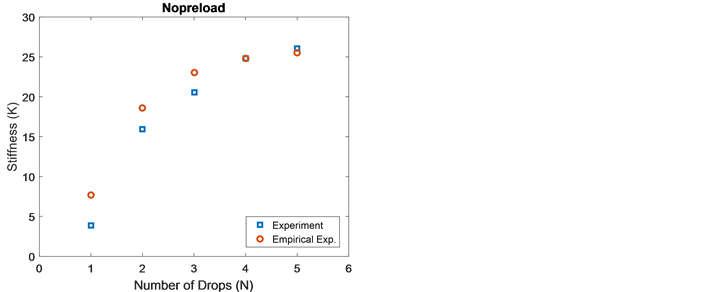

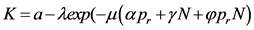

Inspired by Equation (2) and based on the experimental data from our research, we found that the stiffness of the synthetic-fiber rope depends on two main parameters, namely, the number of drops and the preload level. The stiffness increases as the preload level and/or the number of drops increases and it becomes stable as the preload level and the number of drops becomes large. An empirical equation of the stiffness in this research is proposed as follows:

where

In Equation (3), the stiffness is dimensionless because the preload level

Table 5. Value of coefficients in empirical Equation (3).

Table 6. Estimated stiffness from empirical Equation (3).

Figure 9. Comparison between experimental data and empirical expression for rope with preload level of 0.097 of the MBL.

Figure 10. Comparison between experimental data and empi- rical expression for rope with preload level of 0.124 of the MBL.

Figure 11. Comparison between experimental data and empirical expression for rope with preload level of 0.206 of the MBL.

Figure 12. Comparison between experimental data and empirical expression for rope with preload level of 0.344 of the MBL.

Figure 13. Comparison between experimental data and empirical expression for rope with no preload.

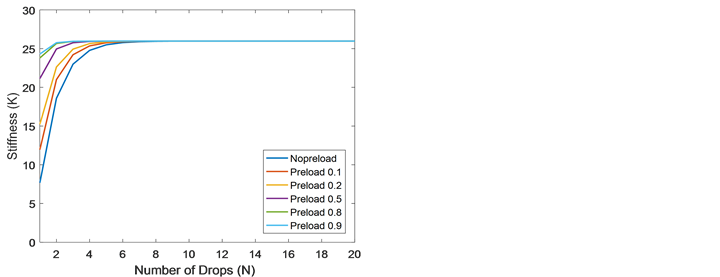

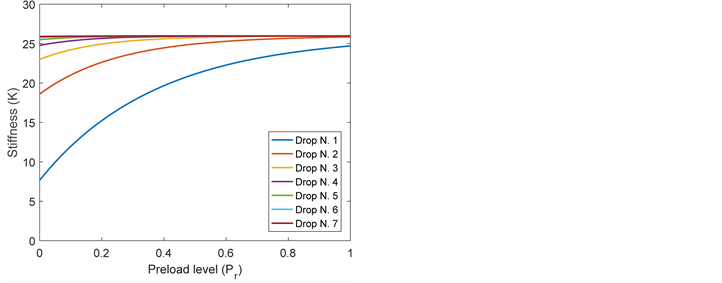

To discuss the detail of the effect of consecutive impact loading in terms of the number of drops on the stiffness of the HMPE rope, the relationship between stiffness and number of drops with a variation in preload levels at 0, 0.1, 0.2, 0.5, 0.8 and 0.9 of the MBL was calculated by using Equation (3) with the parameters in Table 5. The results are presented in Figure 14. The stiffness increases as preload level and the number of drops increases. However; when the preload level is high, there is a slight change in stiffness with respect to the number of drops. For no preload, the stiffness depends strongly on the number of drops such that at the first drop, the stiffness is very small and it increases substantially in the next drops. Overall, the stiffness becomes constant from the sixth drop onward. To examine the influence of preload levels on the rope stiffness, a plot of stiffness vs. preload level with a variation in the number of drops (

Equation (3) is the empirical expression for stiffness in which only the preload and number of drops is considered. This empirical expression provides the basis for understanding the effect of preload and number of drops on the HMPE rope and it will be useful for future research by taking additional parameters into account, such as density, diameter and braiding angle of the rope. There is a possi- bility that a suitable procedure exists (level of preload and number of drops) for preload treatment to stabilize the rope stiffness.

Figure 14. Stiffness versus number of drops obtained from empirical equation.

Figure 15. Stiffness versus preload level (Pr) obtained from empirical equation.

5. Conclusions

We investigated changes in the stiffness of HMPE rope subjected to consecutive impact loading and studied the effect of preload treatment on the rope stiffness. Based on these research results, we could derive useful conclusions:

² Consecutive impact loading affects the properties of virgin HMPE rope by changing the stiffness from the first to the next drops because of a rearrangement of rope structure such that all fibers or strands move towards to the rope axis.

² The construction geometry of the rope is changed by preload treatment.

² It was found that the rope stiffness becomes stable and hardened by preload treatment when the maximum of impact loading is around 1/3 of preload level (0.344 of MBL). This treatment is useful to stabilize response of woven synthetic-fiber rope in robotic.

² An empirical expression for stiffness is proposed by considering the number of drops and preload level. Results from experimental data and empirical equation agree reasonably well. Suitable preload-treatment can be estimated by using this equation.

² The stiffness of virgin rope becomes stabilize when the rope experiences six consecutive impact loadings (six drops) as depicted in Figure 14. The preloaded rope at 0.5 of MBL required only three drops to obtain hardened and stable stiffness as presented in Figure 15. Therefore, preload and/or consecutive impact loading should be implemented on woven synthetic-fiber ropes if a high stiffness is required in a practical application such as in robotic fields. When the rope has stable and hardened stiffness, a stable robot response can be obtained.

Acknowledgments

This paper is based on results from a project commissioned by the New Energy and Industrial Technology Development Organization (NEDO).

Cite this paper

Sry, V., Mizutani, Y., Endo, G., Suzuki, Y. and Todoroki, A. (2017) Consecutive Impact Loading and Preloading Effect on Stiffness of Woven Synthetic-Fiber Rope. Journal of Textile Science and Technology, 3, 1-16. https://doi.org/10.4236/jtst.2017.31001

References

- 1. Mori, M., Suzumori, K., Seita, S., Takahashi, M., Hosoya, T. and Kusumoto, K. (2009) Development of Very High Force Hydraulic McKibben Artificial Muscle and Its Application to Shape-Adaptable Power Hand. Proceedings of the 2009 IEEE International Conference on Robotics and Biomimetics, Guilin, 19-23 December 2009, 1457-1462. https://doi.org/10.1109/ROBIO.2009.5420382

- 2. Kitano, S., Hirose, S., Endo, G. and Fukushima, E.F. (2013) Development of Light Weight Sprawling-Type Quadruped Robot TITAN-XIII and Its Dynamic Walking. Proceedings of IEEE International Conference on Intelligent Robots Systems, Tokyo, 3-7 November 2013, 6025-6030.

- 3. Mazumdar, A., Spencer, S.J., Hobart, C., Dabling, J., Blada, T., Dullea, K., Kuehl, M. and Buerger, S.P. (2017) Synthetic Fiber Capstan Drives for Highly Efficient, Torque Controlled, Robotic Applications. IEEE Robotic and Automation Letters, 2, 554-561. https://doi.org/10.1109/LRA.2016.2646259

- 4. Horigome, A., Yamada, H., Endo, G., Sen, S., Hirose, S. and Fukushima, E.F. (2014) Development of a Coupled Tendon-Driven 3D Multi-Joint Manipulator. Proceedings of IEEE International Conference on Robotics & Automation, Hong Kong, May 31-June 7 2014, 5915-5920. https://doi.org/10.1109/ICRA.2014.6907730

- 5. Wakimoto, S., Kumagai, I. and Suzumori, K. (2009) Development of Large Intestine Endoscope Changing Its Stiffness. Proceedings of the 2009 IEEE International Conference on Robotics and Biomimetics, Guillin, 19-23 December 2009, 2320-2325. https://doi.org/10.1109/ROBIO.2009.5420727

- 6. Chailleux, E. and Davies, P. (2003) Modelling the Non-Linear Viscoelastic and Viscoplastic Behaviour of Aramid Fiber Yarns. Mechanics of Time-Dependent Materials, 7, 291-303. https://doi.org/10.1023/B:MTDM.0000007199.01142.f8

- 7. Chailleux, E. and Davies, P. (2005) A Non-Linear Viscoelastic and Viscoplastic Model for the Behavior of Polyester Fibers. Mechanics Time-Dependent Materials, 9, 147-160. https://doi.org/10.1007/s11043-005-1082-0

- 8. Baltussen, J.J.M. and Northolt, M.G. (1999) The Stress and Sonic Modulus versus Strain Curve of Polymer Fibers with Yield. Polymer, 40, 6113-6124. https://doi.org/10.1016/S0032-3861(99)00194-9

- 9. Northolt, M.G. (1980) Tensile Deformation of Poly (P-Phenylene Terephalamide) Fbers, an Experimental and Theoretical Analysis. Polymer, 21, 1199-1204. https://doi.org/10.1016/0032-3861(80)90088-9

- 10. Northolt, M.G., Baltussen, J.J.M. and Schaffers-Korff, B. (1995) Yielding and Hysteresis of Polymer Fibers. Polymer, 36, 3485-3492. https://doi.org/10.1016/0032-3861(95)92020-F

- 11. Nikonov, A., Saprunov, I., Zupancic, B. and Emri, I. (2011) Influence of Moisture on Functional Properties of Climbing Ropes. Journal of Impact Engineering, 38, 900-909. https://doi.org/10.1016/j.ijimpeng.2011.06.003

- 12. Kwan, C.T., Marine, J.D., Devlin, P., Tan, P.L. and Huang, K. (2012) Stiffness Modelling, Testing, and Global Analysis for Polyester Mooring. Proceedings of the ASME 2012 31st International Conference on Ocean Offshore Arctic Engineering, Rio de Janeiro, 1-6 July 2012, 777-785. https://doi.org/10.1115/OMAE2012-84159

- 13. Davies, P., Reaud, Y., Dussud, L. and Woerther, P. (2011) Mechanical Behavior of HMPE and Aramid Fiber Ropes for Deep Sea Handling Operations. Journal of Ocean Engineering, 38, 2208-2214. https://doi.org/10.1016/j.oceaneng.2011.10.010

- 14. Casey, N.F. and Banfield, S.J. (2002) Full-Scale Fiber Deepwater Mooring Ropes: Advancing the Knowledge of Spliced Systems. Proceedings of Offshore Technology Conference, Houston, 6-9 May 2002, 2189-2201. https://doi.org/10.4043/14243-MS

- 15. Liu, H., Huang, W., Lian, Y. and Li, L. (2014) An Experimental Investigation on Nonlinear Behaviors of Synthetic Fiber Ropes for Deepwater Moorings under Cyclic Loading. Journal of Applied Ocean Research, 45, 22-32. https://doi.org/10.1016/j.apor.2013.12.003

- 16. Flory, J.F., Ahjem, V. and Banfield, S.J. (2007) A New Method of Testing for Change-in-Length Properties of Large Fiber Rope Deepwater Mooring Lines. Proceedings of Offshore Technology Conference, Houston, 30 April-3 May 2007, 1087-1096. https://doi.org/10.4043/18770-MS

- 17. Flory, J.F. and Ahjem, V. (2013) Testing Polyester Fiber Rope for Six Change-in-Length Properties (6CILP). Proceedings of IEEE Conference, Bergen, 10-14 June 2013, 1-10.

- 18. Flory, J.F., Banfield, S.P. and Petruska, D.J. (2004) Defining, Measuring, and Calculating the Properties of Fiber Rope Deepwater Mooring Lines. Proceedings of Offshore Technology Conference, Houston, 3-6 May 2004, 151-164. https://doi.org/10.4043/16151-MS

- 19. Ramasamy, M. and Sundaramoorthy, S. (2008) PID Controller Tuning for Desired Closed-Loop Responses for SISO Systems Using Impulse Response. Journal of Computer and Chemical Engineering, 32, 1773-1788. https://doi.org/10.1016/j.compchemeng.2007.08.019

- 20. Suzuki, T., Otsuka, H., Akahori, W., Bando, Y. and Okuno, H.G. (2017) Influence of Different Impulse Response Measurement Signals on Music-Based Sound Source Localization. Journal of Robotics and Mechatronics, 29, 72-82. https://doi.org/10.20965/jrm.2017.p0072

- 21. Hidayat, E. and Medvedev, A. (2012) Laguerre Domain Identification of Continuous Linear Time-Delay Systems from Impulse Response Data. Journal of Automatica, 48, 2902-2907. https://doi.org/10.1016/j.automatica.2012.06.077

- 22. Francois, M. and Davies, P. (2000) Fiber Rope Deepwater Mooring: A Practical Model for the Analysis of Polyester Mooring Systems. Proceedings of Oil Gas Conference, Rio de Janeiro, 16 October 2000.